I'd like to keep my filament for as long as possible, even the partial rolls.

Up to this point I would store them in a large zip-lock bag with a desiccant pack.

A few complaints about the zip-lock bags:

* Sometimes they develop holes that are not obvious.

* Filament becomes brittle quite fast.

* Zip lock bags are an eyesore piled up in a corner.

* You need a bag... can't find one.

* The status of the desiccant pack is unclear. Might be saturated.

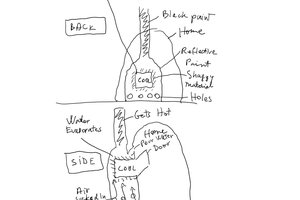

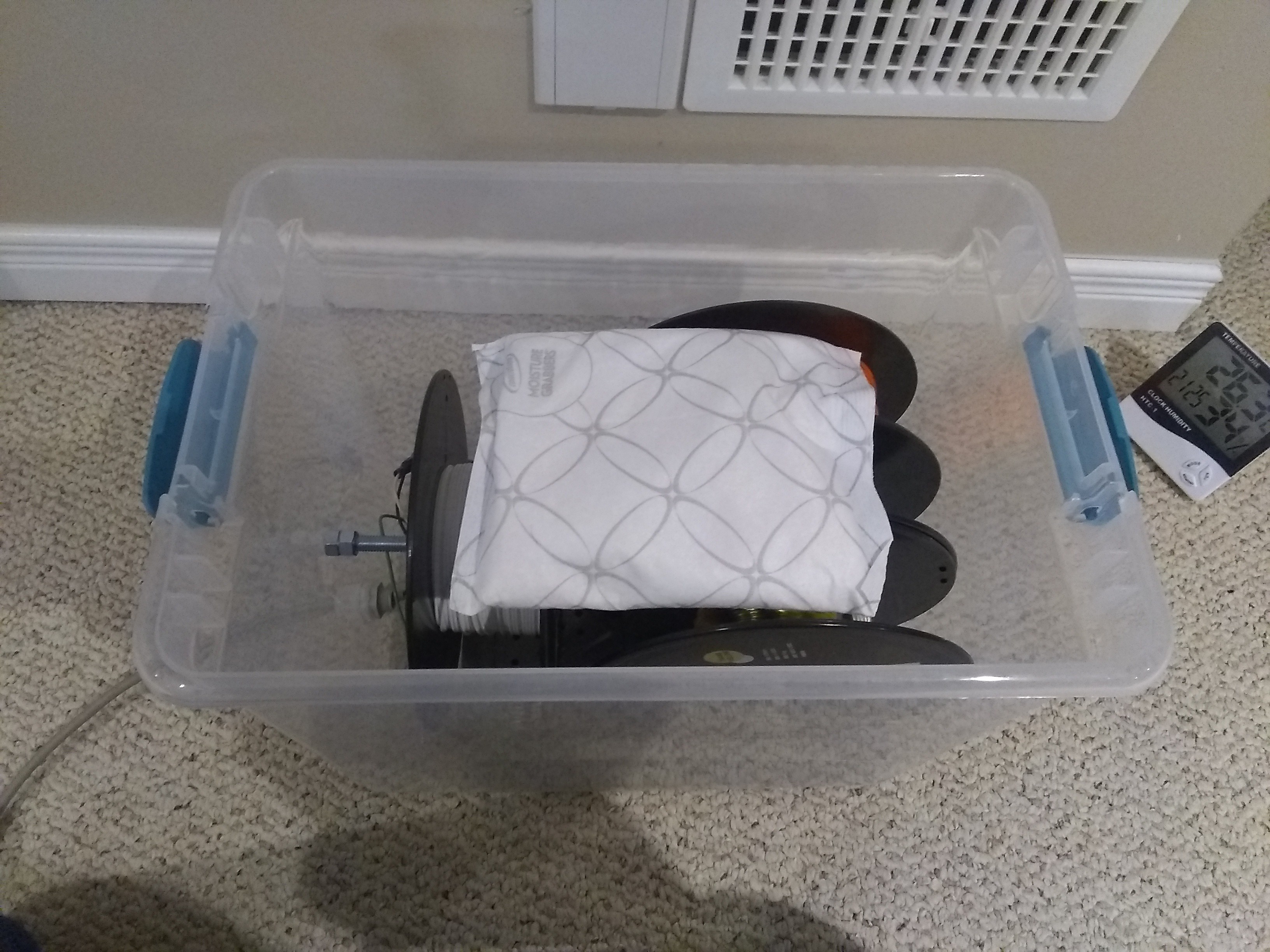

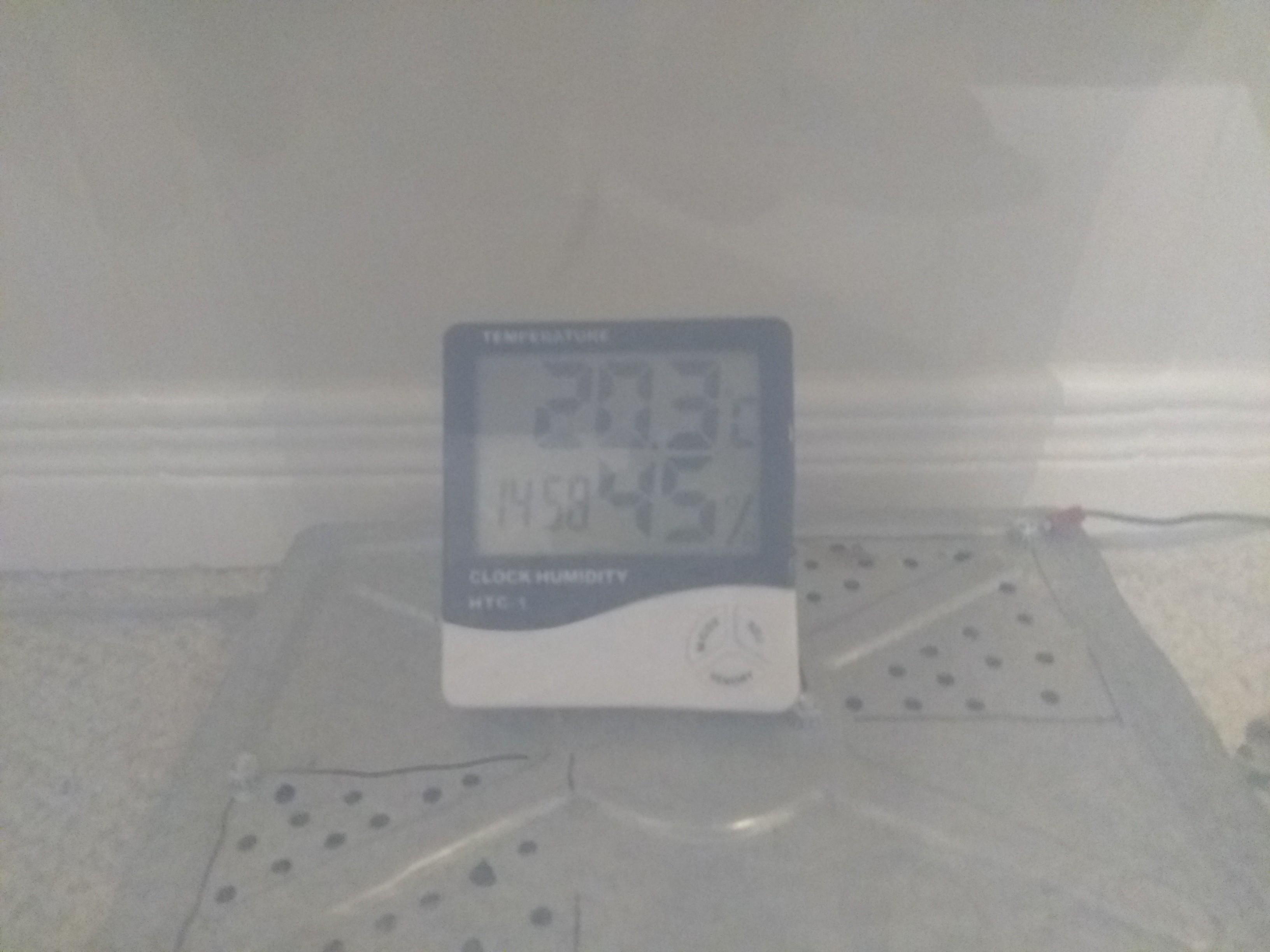

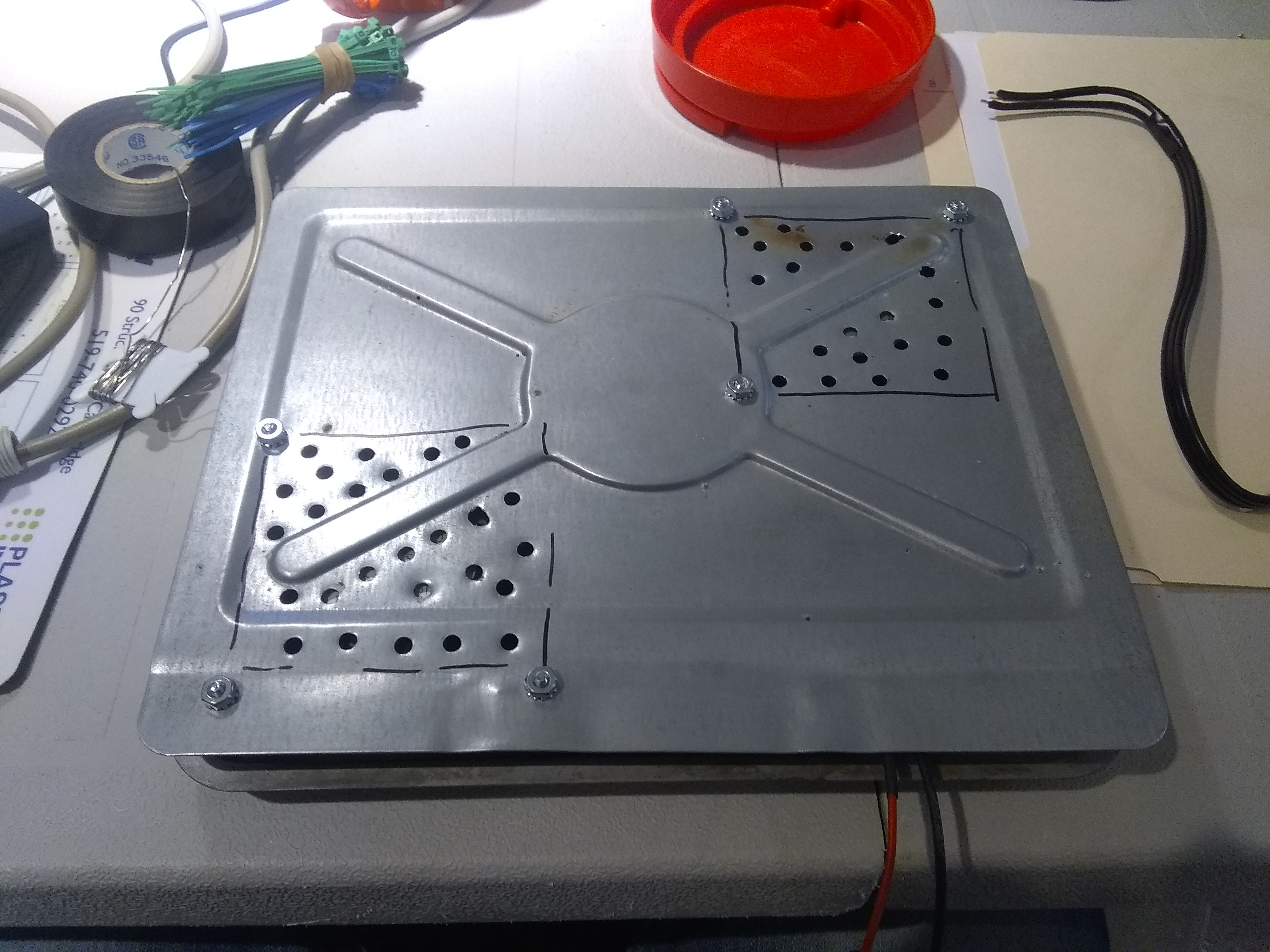

This is my first attempt at the simplest storage solution I could muster up with stuff that I already had.

TheGrim

TheGrim

Michael Perrone

Michael Perrone

Andrew Shevchuk

Andrew Shevchuk