Deadbolt lock levers are another door feature that require hands to operate. This project log discusses a 3D printed hack that allows the user to turn the deadbolt lever with their forearm. The video below demonstrates the right handed and left handed forearm motion required to unlock and lock the deadbolt with this device.

The greatest challenge of this hack was accommodating the large variation in deadbolt geometries. Deadbolt levers have different widths, heights, and lengths. Some are located in the middle of the deadbolt cover plate while others are offset. Because of all the geometry variations I wasn't able to develop a universal forearm deadbolt turn design. Instead, the dimensional parameters may have to be tailored to each deadbolt design.

Perhaps the most difficult geometry to design around is the taper on the sides of the levers. The tapered sides makes it very difficult to make a mechanical connection to the lever without gluing something to it. To get around a permanent glued connection, the design makes a connection to the door using adhesive strips and is raised off the door just enough to mechanically engage the deadbolt lever.

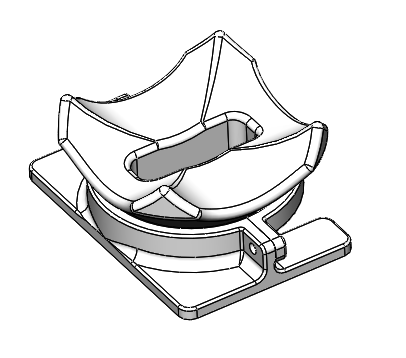

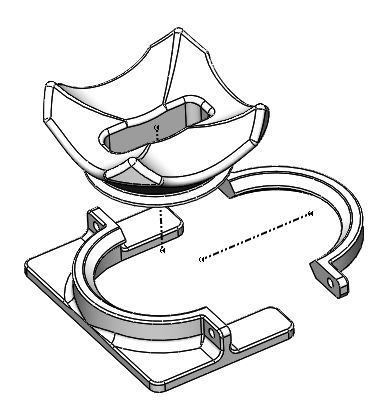

Three parts are required for the assembly - the rotating disk and two ring halves. There are two cylindrical cutouts at 90 degrees from each other on the face of the rotating disk to fit the user's forearm for right handed and left handed motions. M4 bolts are used to capture the rotating disk and connect the two ring halves. The deadbolt lever is made visible through the assembly so the user can see it's orientation and determine if the door is locked.

It took five and a half hours to 3D print all three parts at 30% infill and 0.6mm wall thickness. I used drawer slide lubricant on the rotating contact surfaces. My landlord probably doesn't want me to drill holes in the door so I used adhesive picture frame strips to secure the assembly to the door.

I would consider this a successful build. The only things I might change on the next revision are removing the sharp corners on the face of the rotating disk and raising the front face of the rotating disk a little farther from the door face (at the current offset, the user's hand may occasionally hit the door frame).

At this point, I am starting to run out of door features to hack for hands-free operation.

John Opsahl

John Opsahl

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.