I will explain this project step by step in the project updates. The roadmap is fairly simple:

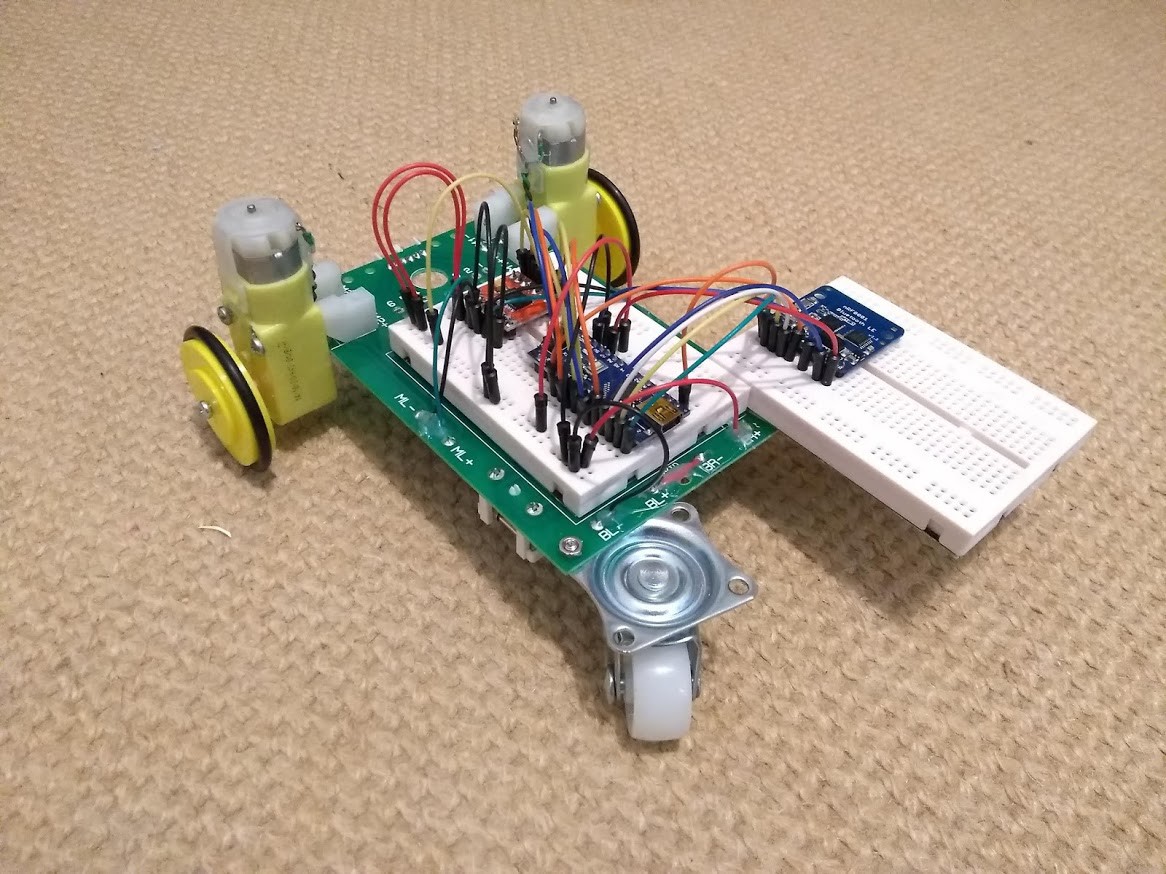

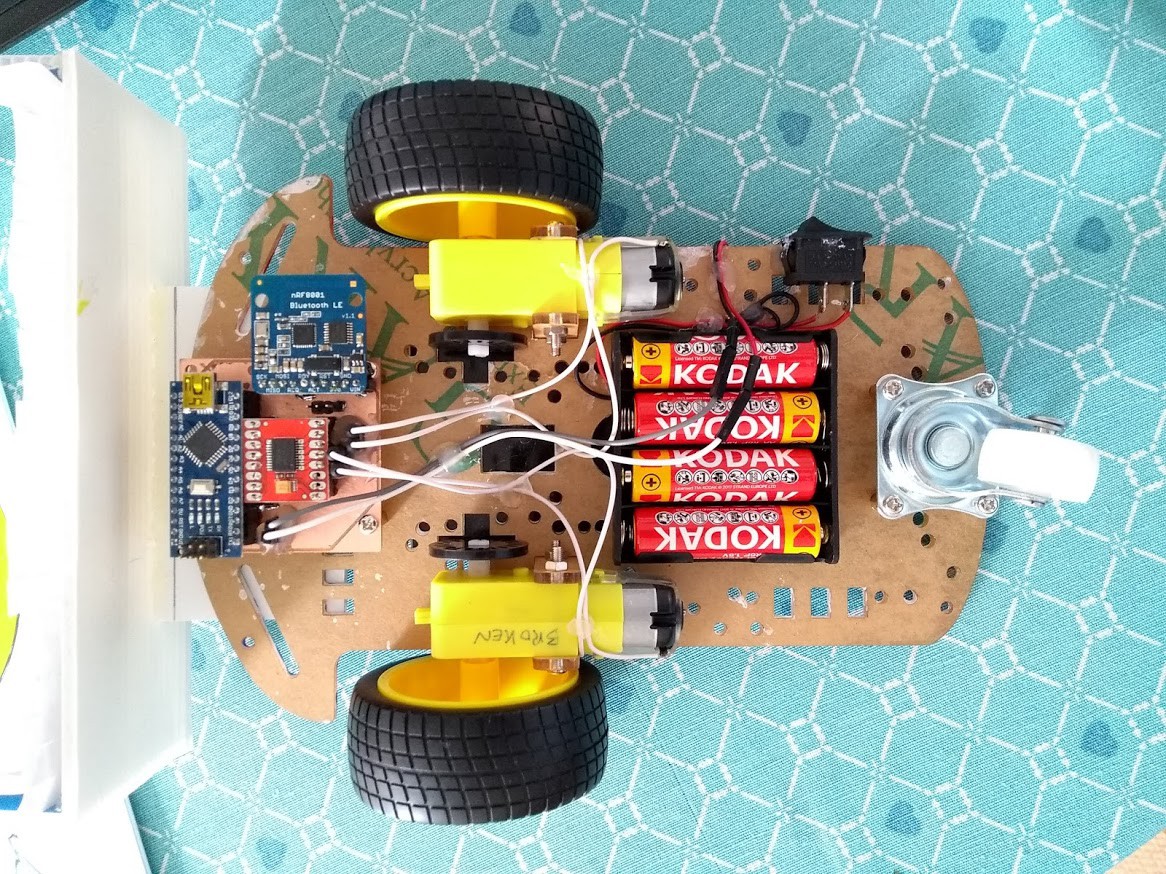

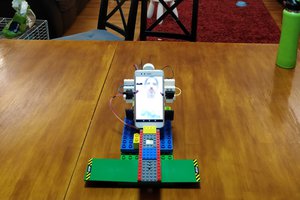

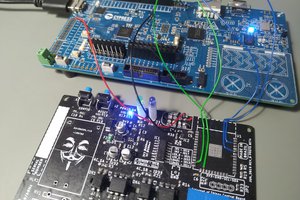

- Build a small Arduino-controlled autonomous turtle bot / robot car

- Implement BLE communications to be able to control the car from a phone/laptop/Raspberry Pi.

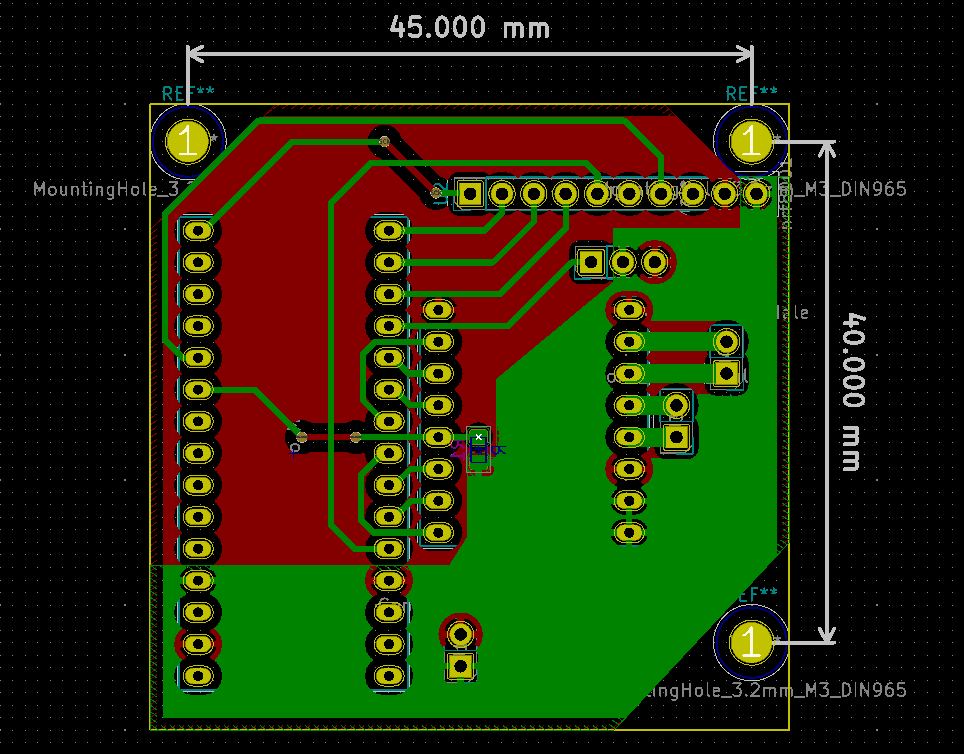

- Build a more sturdy prototype.

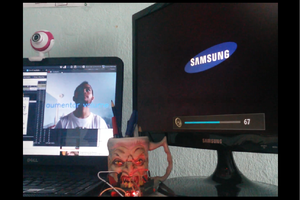

- Add a Raspberry Pi handling the bluetooth communications and providing a video feed for FPV.

- (potentially: use OpenCV to implement some basic autonomous driving)

adria.junyent-ferre

adria.junyent-ferre

Cassio Batista

Cassio Batista

Artur Majtczak

Artur Majtczak

Pedro Minatel

Pedro Minatel