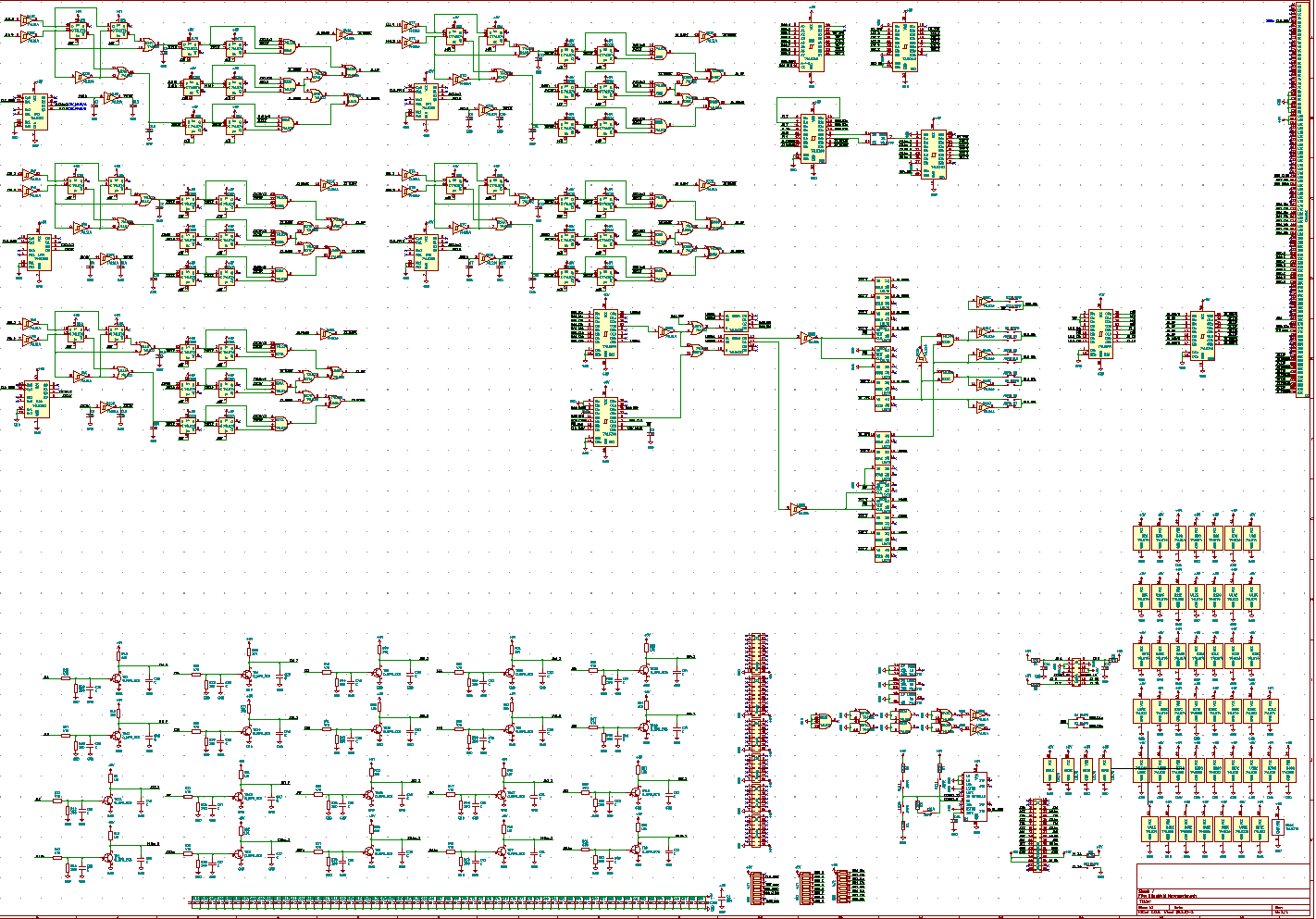

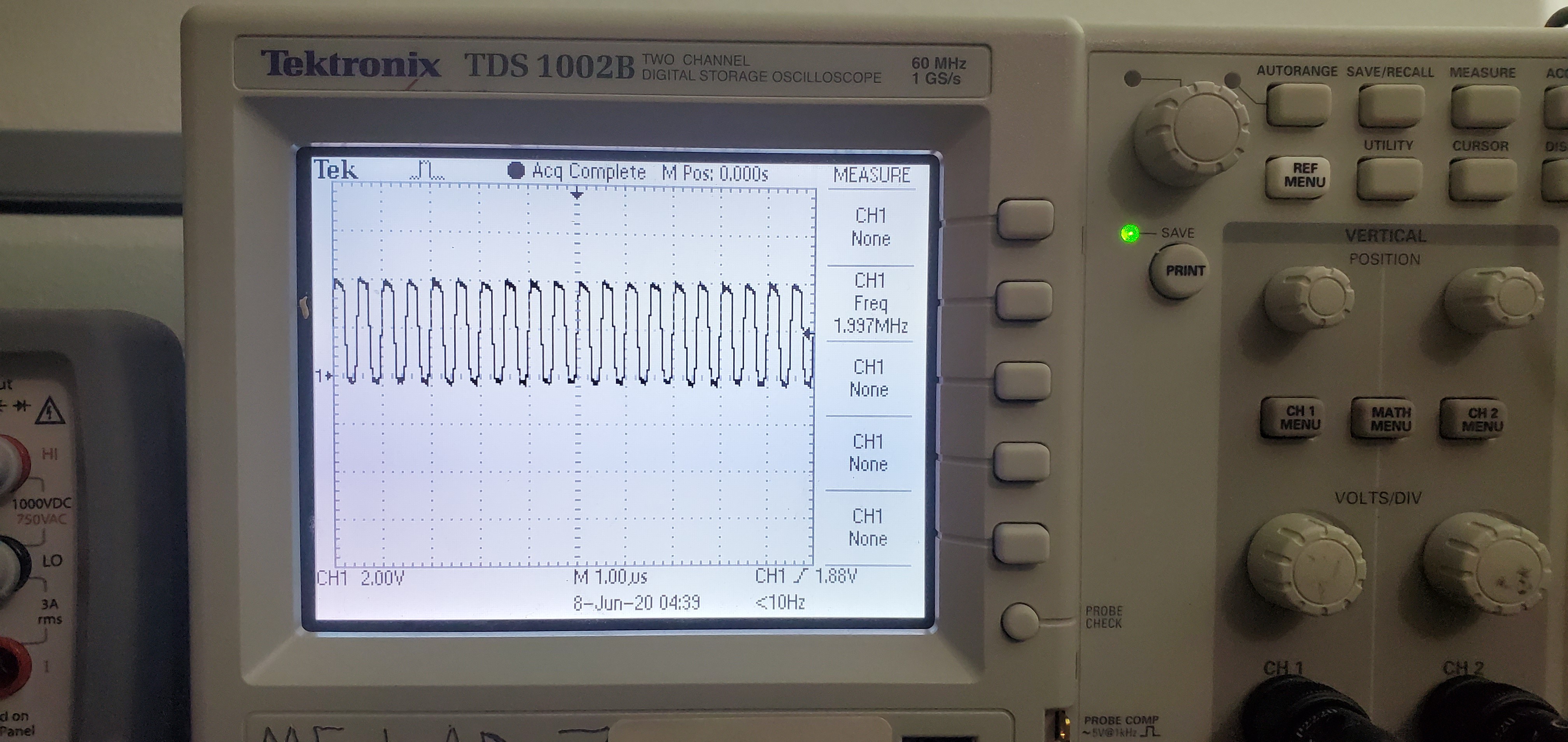

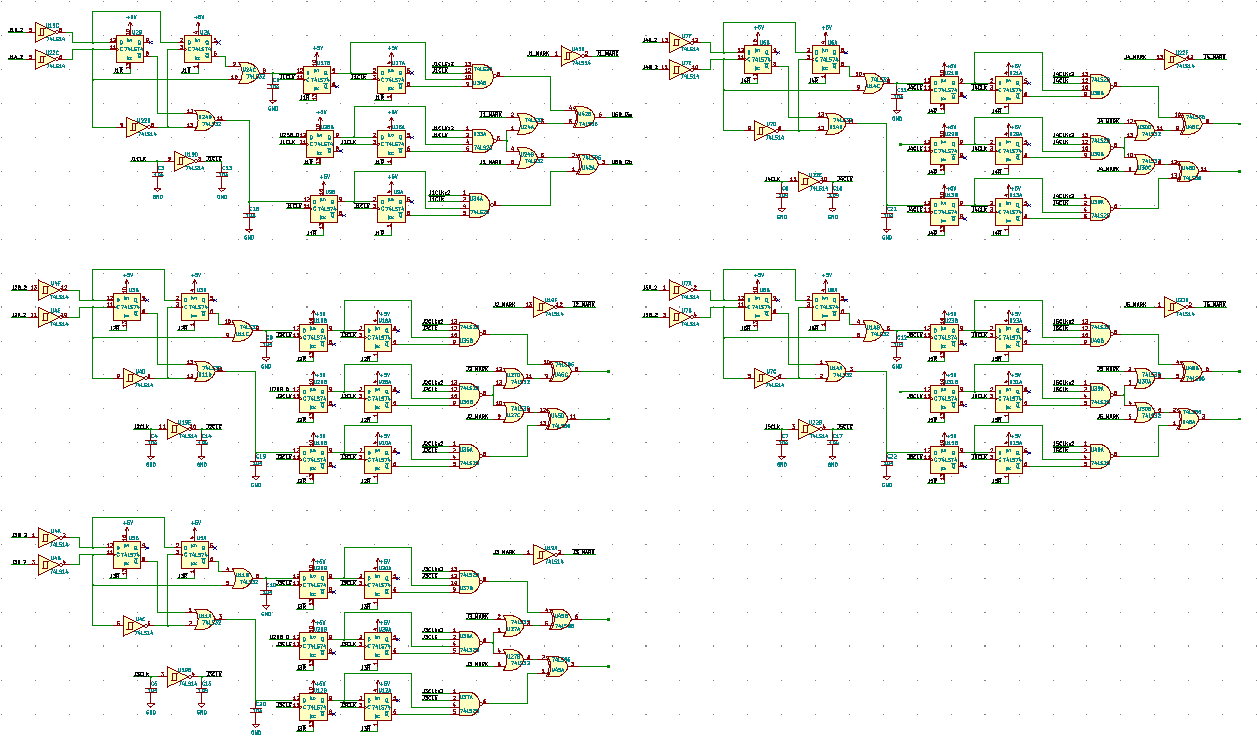

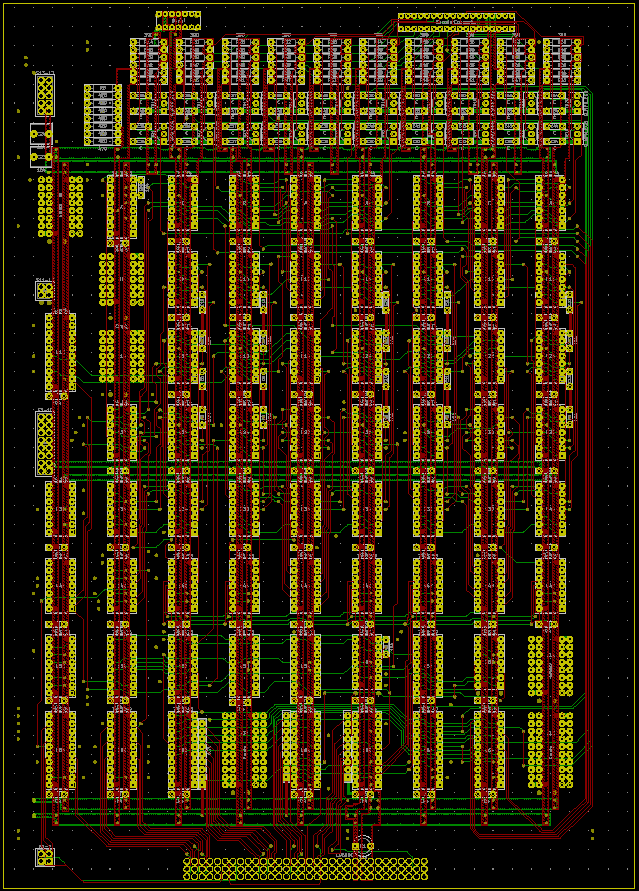

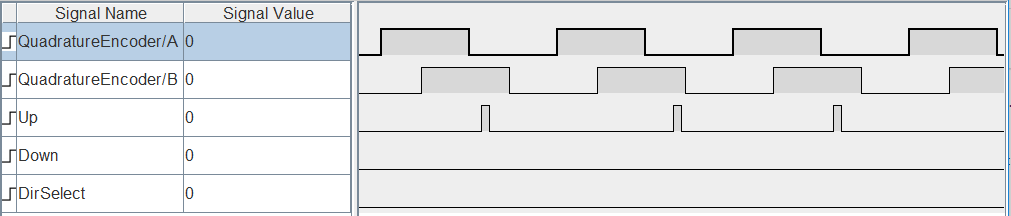

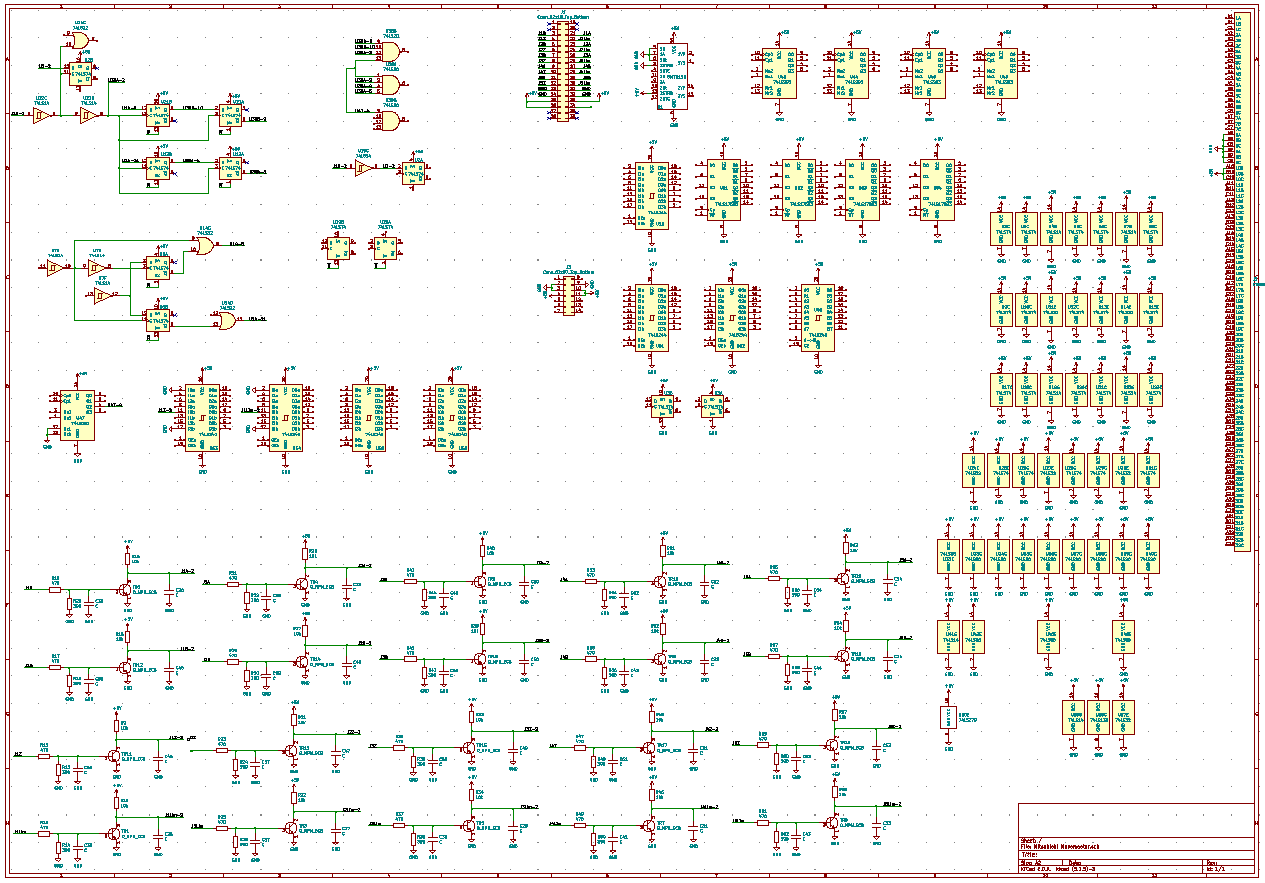

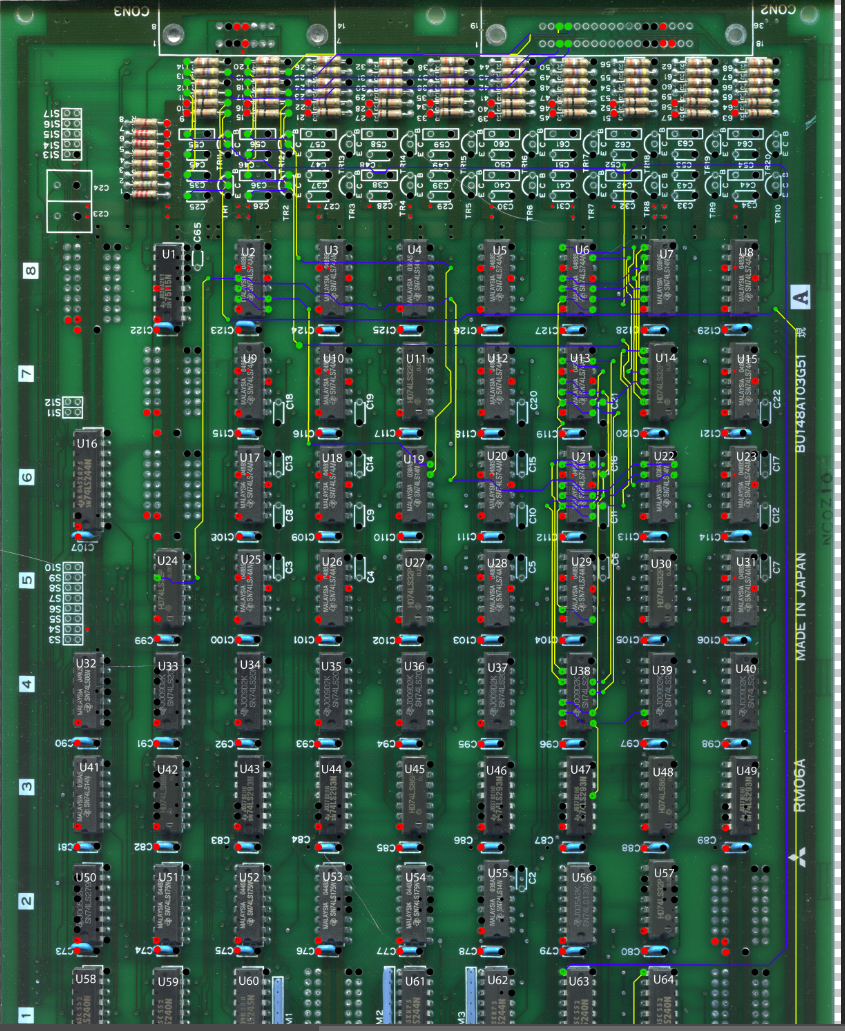

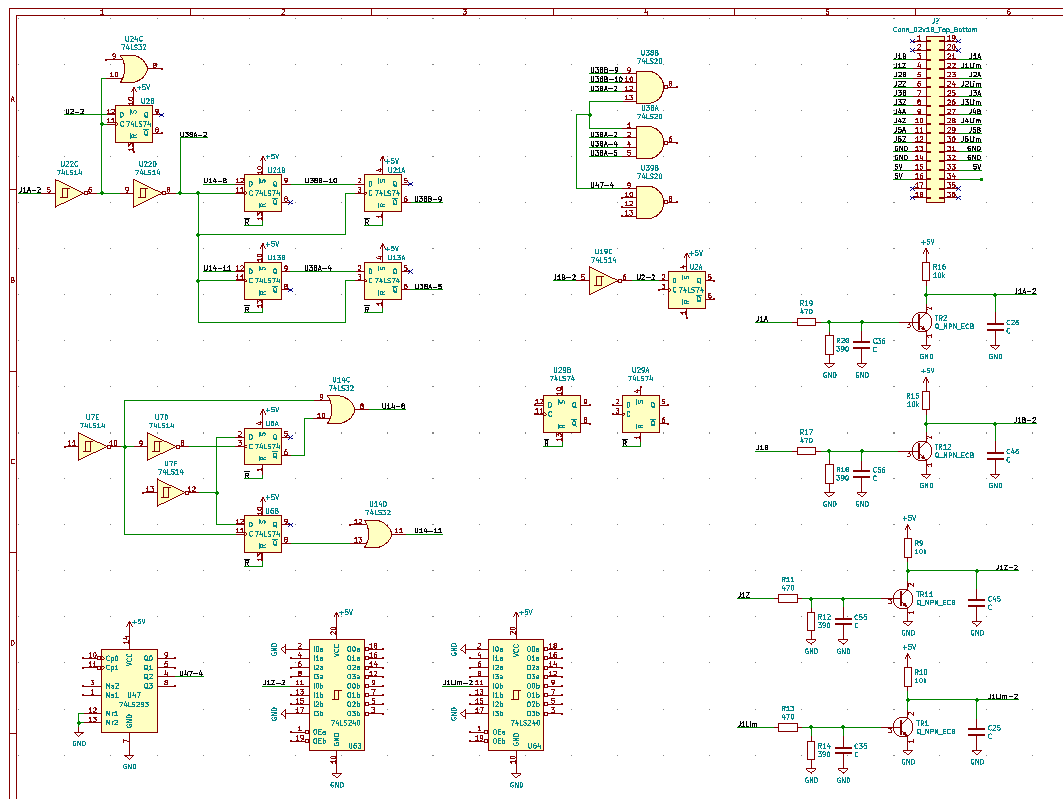

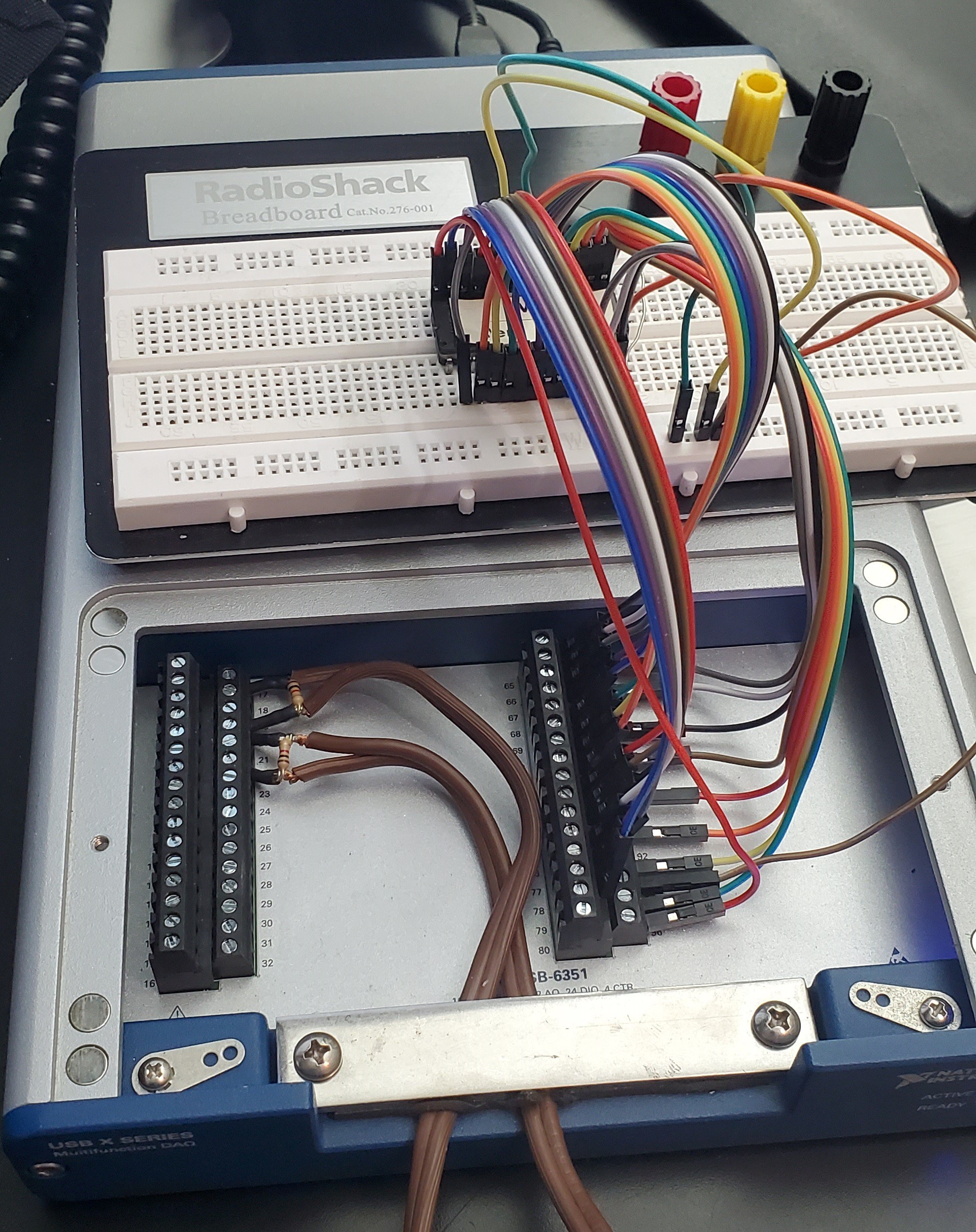

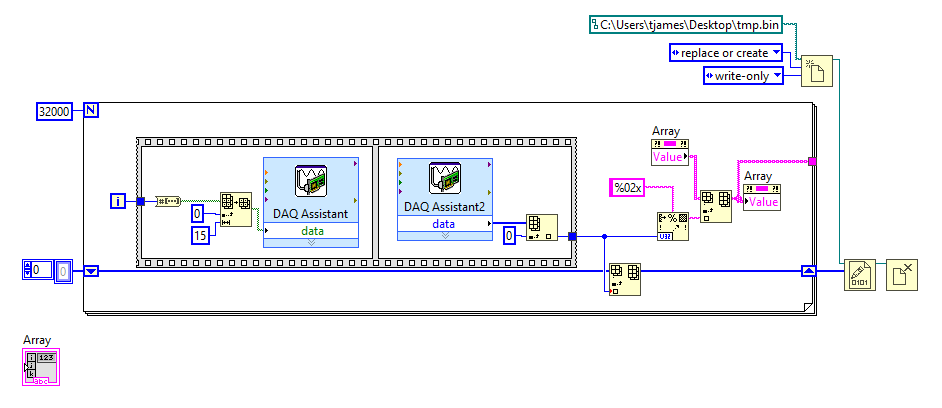

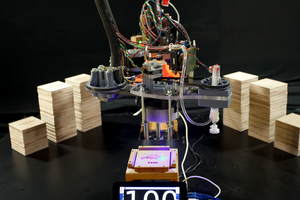

This will be a two part project. First, I'm going to do some reverse engineering of the drive unit because I'm curious how they implemented some aspects of the kinematics. Second, I'm going to make a controller to replace the drive unit.

Reviving and Reverse Engineering an Old Robot Arm

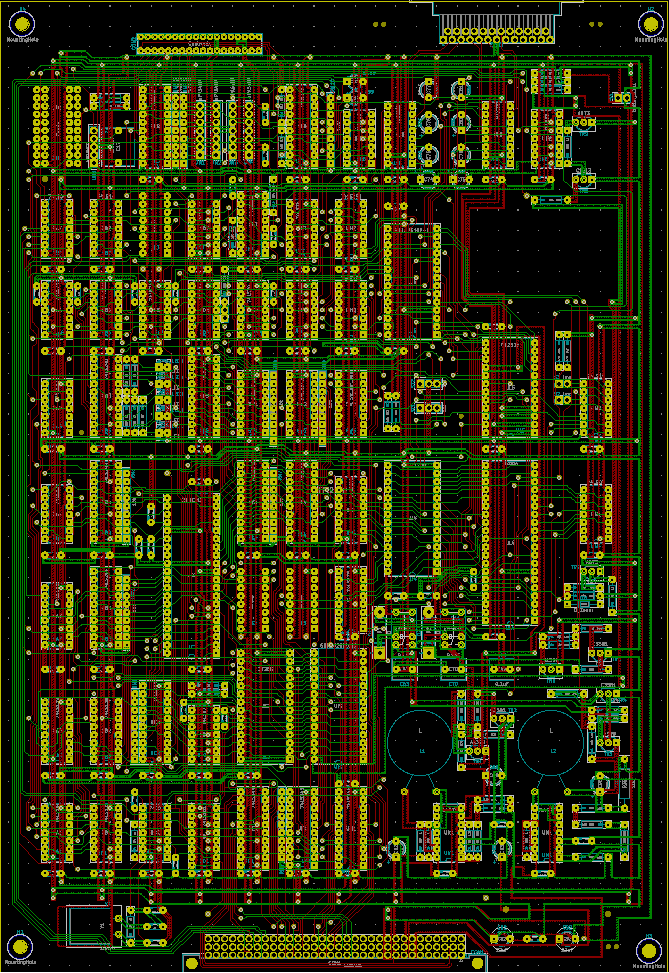

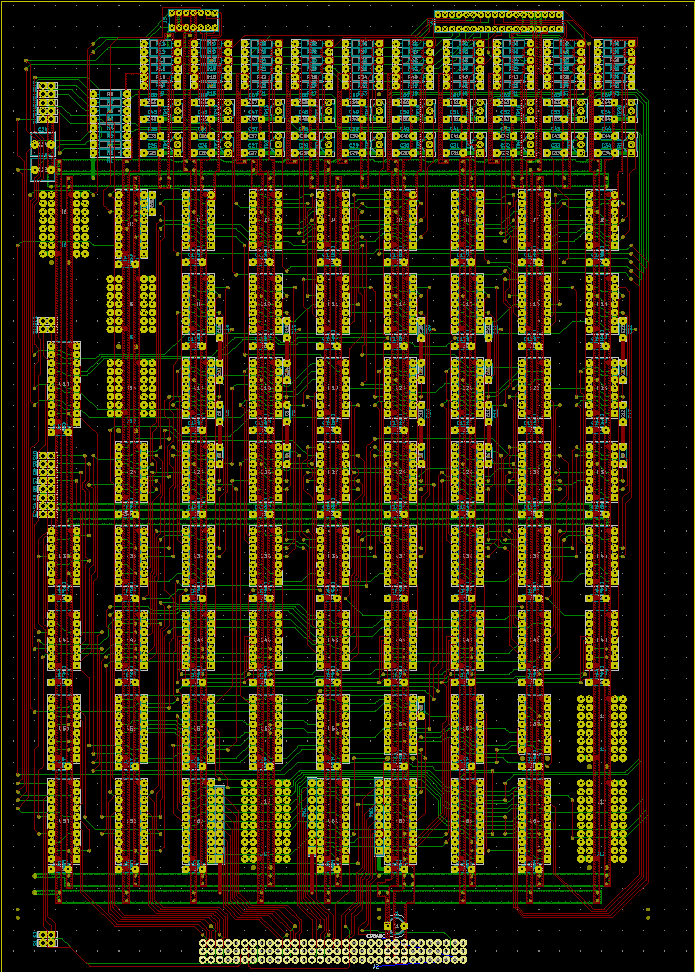

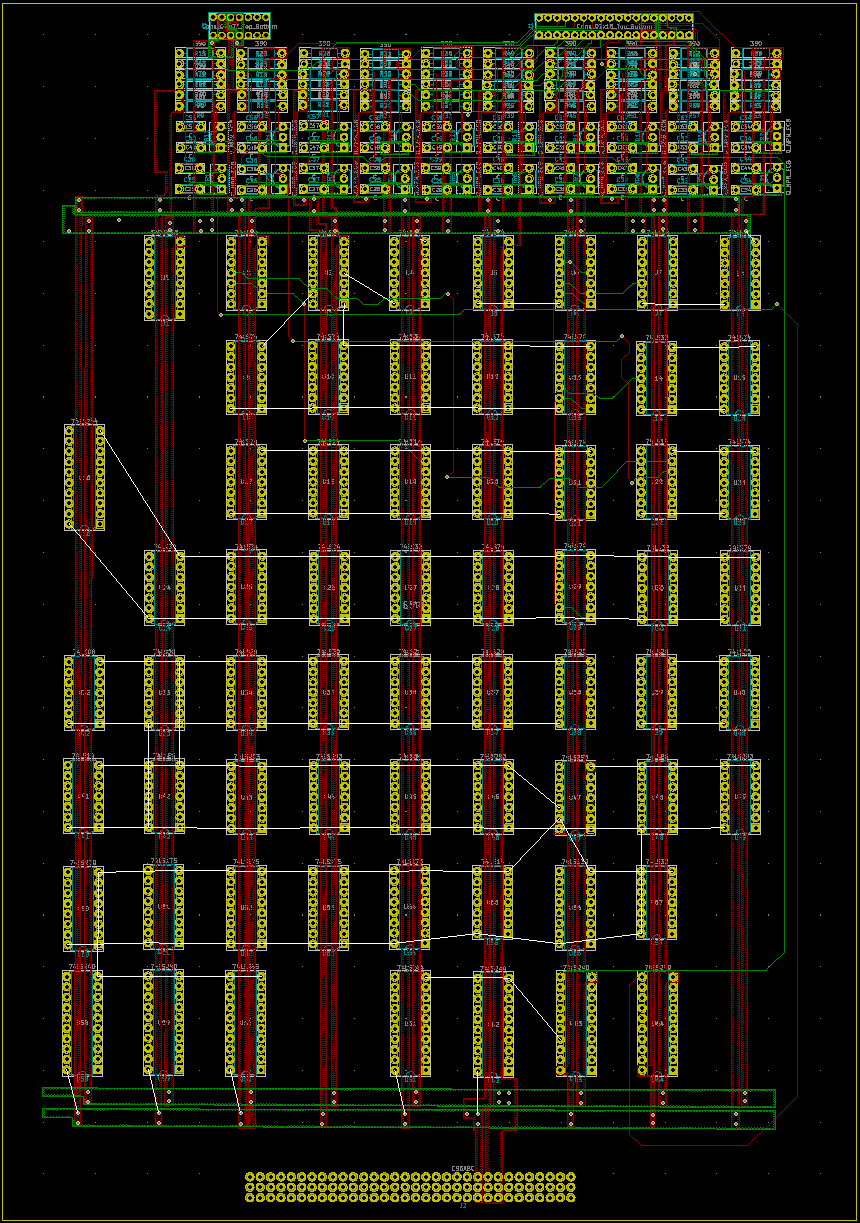

A full reverse engineering and rebuild of a Mitsubishi Movemaster robotic arm

Taylor Schweizer

Taylor Schweizer

anfroholic

anfroholic

Torbjörn Lindholm

Torbjörn Lindholm