All of the parts are on their way or have been shipped now.

Both Ender 5 printers were shipped out, the TH3D EZBoard Lite V1.2 boards became in stock and were purchased with a filament sensor. Still not able to get the Raspberry Pi Model 3B's, but adding octoprint to these is not something that is needed for initial operation and modification.

https://www.th3dstudio.com/product/ezboard-lite/

https://www.th3dstudio.com/product/ezout-v2-filament-sensor-only-replacement-spare/

I have decided against moving any of the endstop limit switches to keep these as stock as possible. This also means that for the moment I will not be using the second rear right Y axis cover, as it requires another bracket for moving the Y axis limit switch.

A little tangent, probably belongs more in my Ender 3 Pro build and mods page that I am making, however it was my backup plan in case the original boards I had decided on did not arrive or could not be ordered.

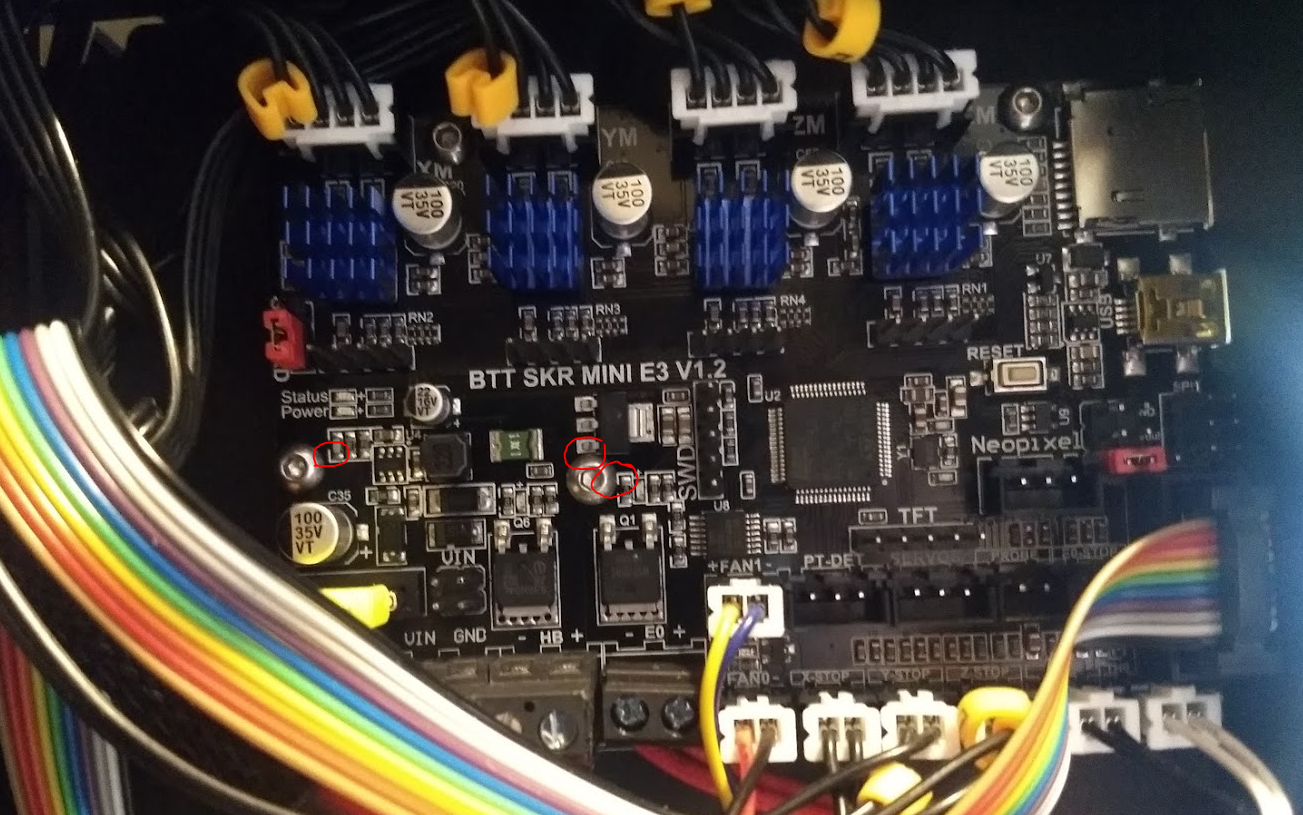

Since I got my Big Tree Tech SKR Mini E3 V1.2 boards in and had some time to configure and mess with them I have determined there are certainly oversights in the engineering that stop these from being used on my hackerspace's printers.

Some of the screws are REALLY CLOSE to components and it would not be farfetched that if these boards were ever removed that if the utmost care was not taken in putting it back into place that one or more of these components could be shorted to the chassis or eachother. I had to angle my own board to avoid any kind of contact of components against screws, and I would say if you are using stock mounting hardware on Ender 3 or Ender 5 printers and have this board, you should check your own installation to make sure nothing shorts out. I have not consulted the schematic or board layouts to confirm exactly what would happen though. I have been told that they have increased clearances in the SKR Mini E3 V2 board that they will be offering soon.

Anyway, while it's fine for my own machine, I will not be babysitting the ones at the hackerspace, or doing the bulk of the maintenance over their lifetime.

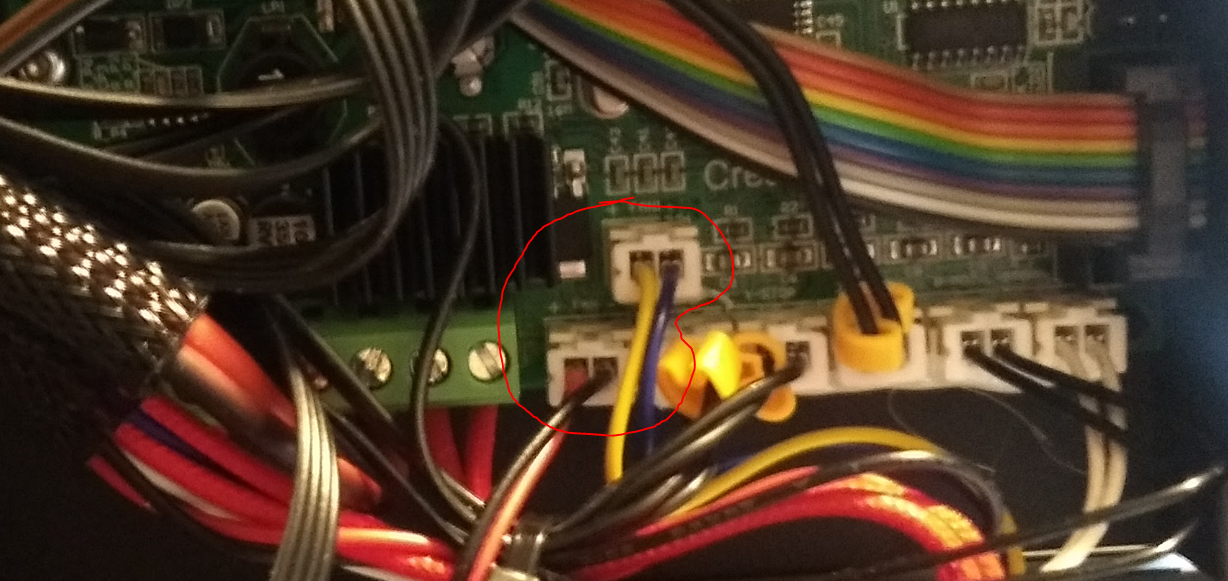

Also interesting is that the "FAN0" and "FAN1" options on the SKR Mini E3 V1.2 are swapped around compared to the stock Creality v1.1.4 board.

So it is not a 1 to 1 install (Very close though!)

Miss this fact, and the fan% speed of your parts cooler will instead be controlling the fan that cools your control board, and your parts fan will be running 100%

^ So do this, not the other thing! Trap for young players!

I have also decided to start working on the format for the google document that will be printed for physical documentation, and kind of deciding how I want that to look.

https://docs.google.com/document/d/16c49D2hAlmgXGwfXPbLPVt4-z9uCsGNumb_vEArCTAw/edit?usp=sharing

I would like there to be physical documentation, likely in a 2" 3 'slanted D ring' binder in page protectors, a google doc, a PDF hosted on our wiki, the documentation of the build here hosted on hackaday.io as well as details on our Google Groups page, that way we have redundancy. I am literally making this up as I go along, and I think it will start getting more cohesive as I actually get all the parts together and build the printers up and get to the point of operating them.

I will be updating the stock creality v1.1.4 boards with stock marlin software (likely the same v1.1.9 firmware I am using on my own Ender 5) to use as backup units in case the fancy boards have some sort of failure. This will include burning a bootloader on them, pushing custom firmware to them (to ensure important things like thermal runaway protection are indeed enabled), and making sure that they function as intended.

I want each printer to have a tacklebox of parts, and some kind of modification/repair log. Since we're replacing the control boards and the power supplies on each printer,

each machine will have available as spares:

1 stock power supply (original generic unit, likely a Landy brand, I might actually tag it "TEMPORARY USE ONLY!")

1 stock Creality V1.1.4 board loaded with custom Marlin firmware

1 extra complete hotend (from the teflon tube all the way down to the nozzle) just in case anything happens

1 T-nut kit

1 plastic spring loaded feeder assembly

Other than that, I have not yet decided what I am going to do about the fans and blowers that are used in this printer, but I do want to make them serviceable, and I do want to switch them to parts less likely to fail.

There are 2 24volt 40mmx10mm fans (one cooling the control board, and one cooling the heatbreak), and a 24 volt 40mm blower assembly that is used for parts cooling. All of these fans are relatively loud, and are sleeve bearing. Upgrading these to maglev or ball bearing would likely help out with service life and noise, and installing some form of removable connector on both the fan and the blower on the hotend would allow for easy swap outs if filament gets stuck in them, or the fans fail.

cprossu

cprossu

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.