Change the Planet with PSoC® IoT Design submission questions:

1. What planet-changing IoT project do you want to build?

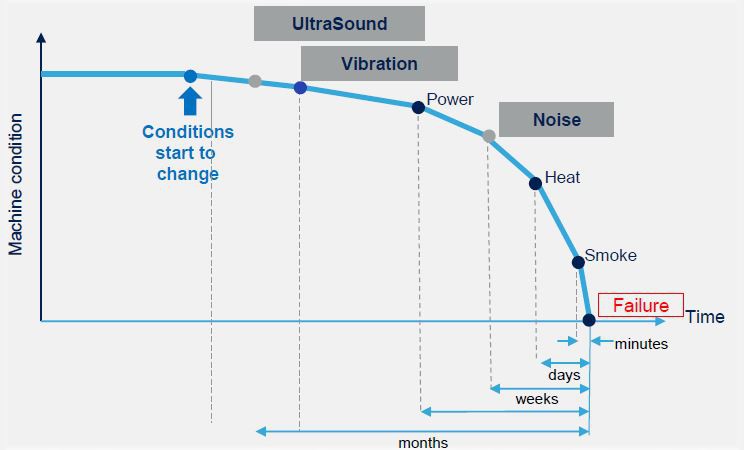

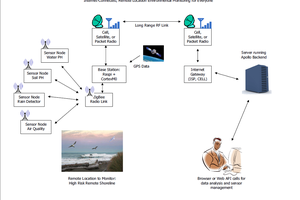

The aim of the project is to build a predictive maintenance system for any general Industrial Equipment by analyzing the time series data of temperature , Vibration and Acoustic signals and predicting the failure before hand using ML models on the cloud servers.

Prime candidates for Predictive Maintenance include machines that:-

• Run 24 hours a day

• Perform functions that are crucial to the production process

• Have high failure consequences

• Are expensive to maintain

• Could pose a risk to personnel safety or the environment.

Examples include machines used in continuous processes, e.g. plastic production, where a service interruption could ruin an entire production run. Those with high failure consequences include turbine generators and equipment located in hazardous environments. Also consider machines that experience frequent failures because of a tough operating environment — common in mines, cement plants, and fertilizer plants.

Initial signs of wear mechanical typically create high-frequency noise with could be detected using accelero-meters and microphone which are placed over the motor, data is collected and processed on the microcontroller itself using Fast Fourier Transform (FFT). Direct sending all collected data from the sensor node would put strain on the existing network bandwidth and also will lead to more power consumption. Hence the only FFT data is then sent to gateway. Looking at the steady-state vibrations, at the time of installation, thresholds were set.

The data is then used to build a ML model , train it so that later on it could predict anomalous behavior of the equipment. Then, connect the anomaly to the appropriate work task to minimize production loss, quality issues, or other collateral damage.

Our system resorts energy harvesting to power the sensor nodes, with neither cabling for power supply (unadvisable in hazardous areas) nor batteries (which require regular maintenance). The thermal dissipation around the motor is used to generate a voltage through a thermoelectric generator. The voltage generated when fed into low voltage boost converter can give regulated voltage output to charge a supercapacitor. This in turn powers up the whole system in regular interval of time.

Examples:

• Compressed Fluid Leaks

• Vacuum leaks

• Steam trap failures

• Bearing condition monitoring

• Electrical arcing/tracking

• Fan and motor unbalance

The overall energy savings and minimum waste due this is invaluable towards developing sustainable environment on planet.

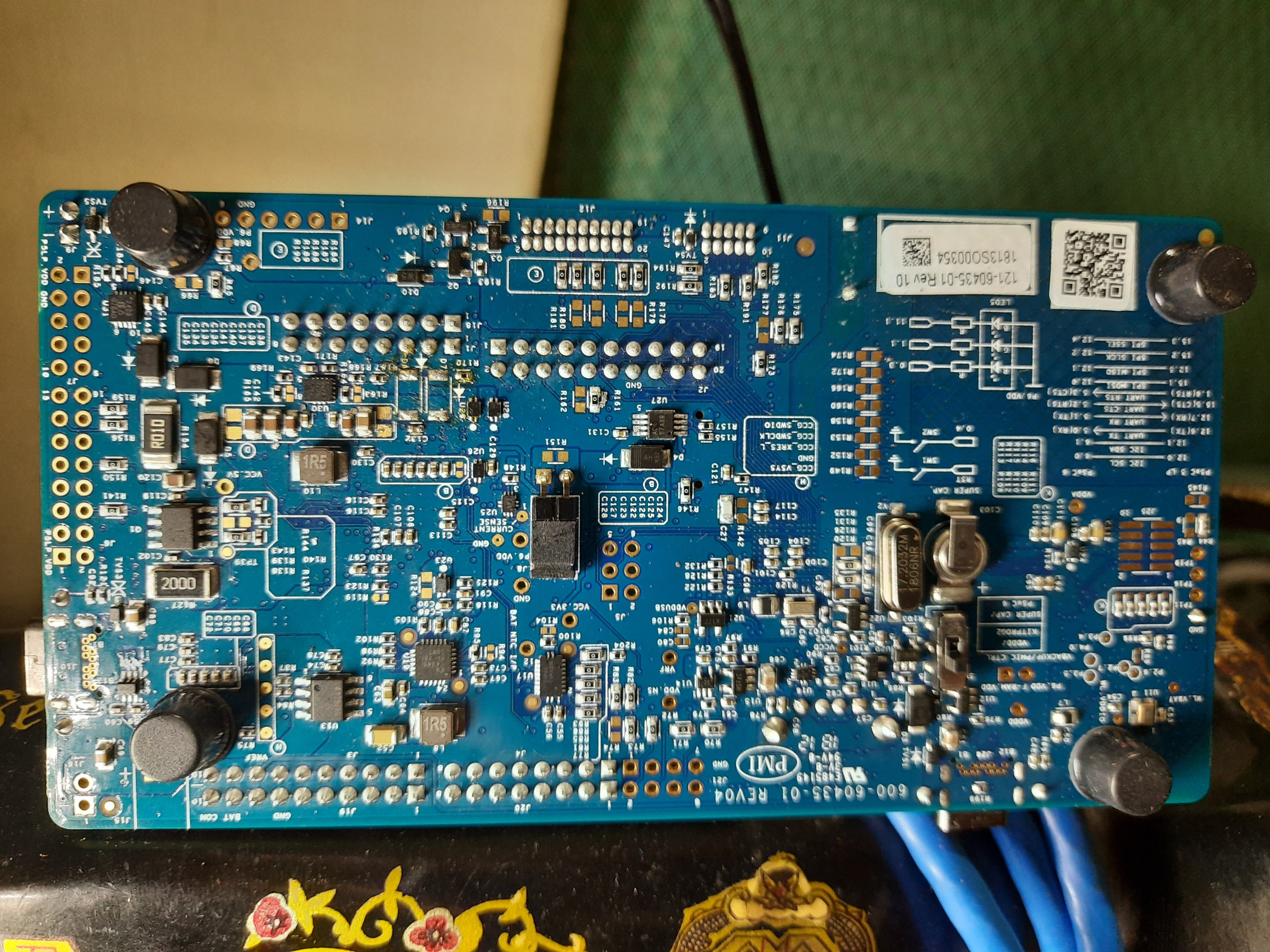

I would like to use PSoC® 6 WiFi-BT Pioneer Kit (CY8CKIT-062-WIFI-BT) for this project as this the TFT display shield board include in the kit has 6-axis motion sensor, and a digital microphone which essential for monitoring the machine conditions. The Industry-leading CapSense would facilitate the Technicians to interact with the device even in harshest factory environment example wearing gloves . The display on the screen could be used alert the the coworkers nearby. The data from the sensor is used transmitted via Bluetooth 4.1 to the gateway node and also the prediction results are being received from cloud to be displayed on the screen.

3. How will you use AWS IoT or other cloud services in your project?

I would like use AWS IoT service for the below mentioned tasks:

- The collection of data to build and train a model.

- The deployment of models back to the factory sensor nodes.

- The evaluation of data to perform local inference.

First we collect data from the machines or equipment that you want to...

Read more » Pratyush-Mallick

Pratyush-Mallick

x3n0x

x3n0x

Alex

Alex

Fabio Balzano

Fabio Balzano