I thought about what can be improved on the machine to make it more reliable and to give it more features. So I'm currently testing some optical modifications.

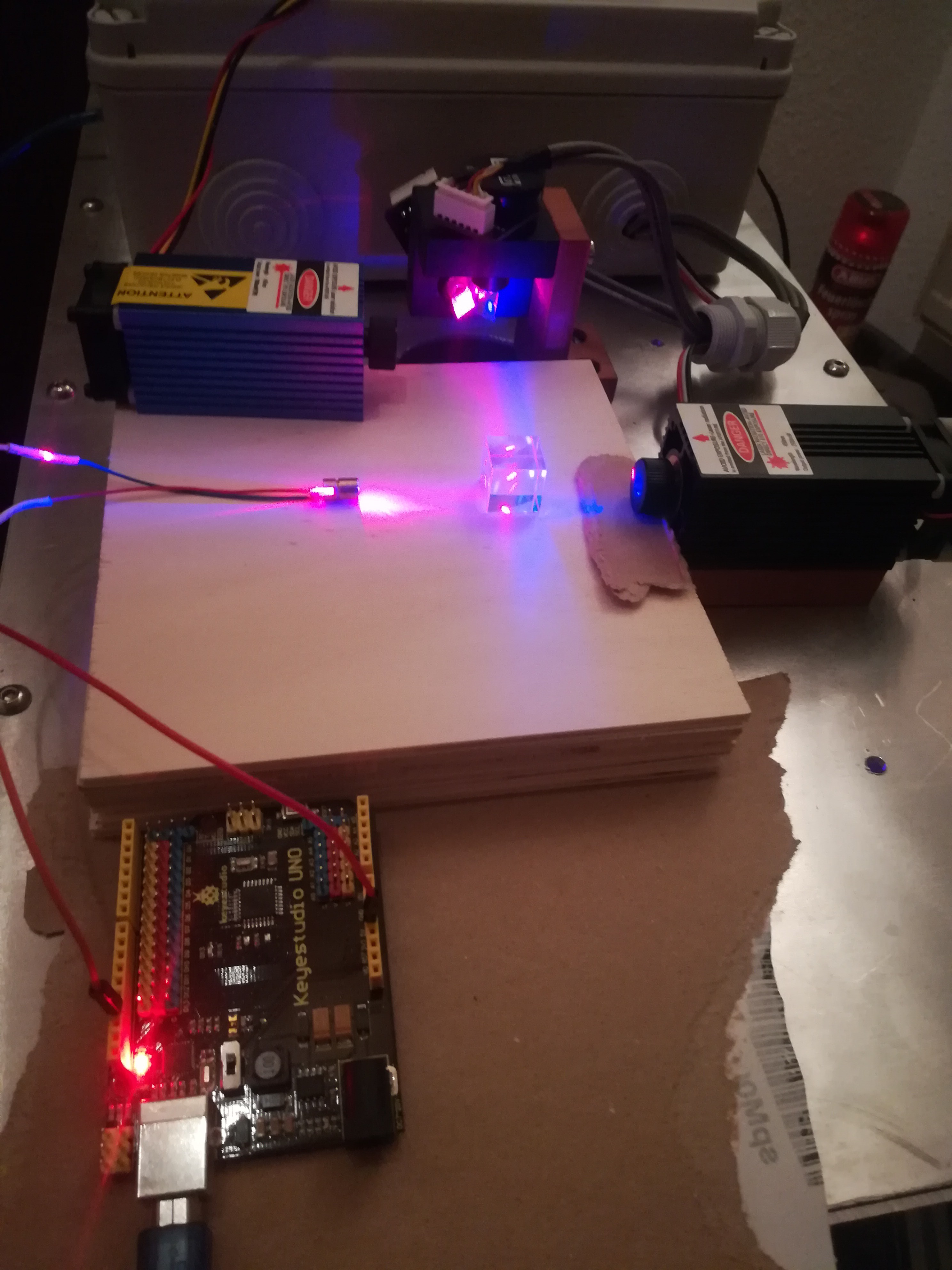

One thing could be adding a red dot laser to show the laser position and the work area on a dry run like on other galvo laser machines.

I used to do it with the blue laser on lowest power, but through the safety glasses that I use the laser dot is barely visable at lowest power and using higher power would burn the material. So I think a red dot would be better.

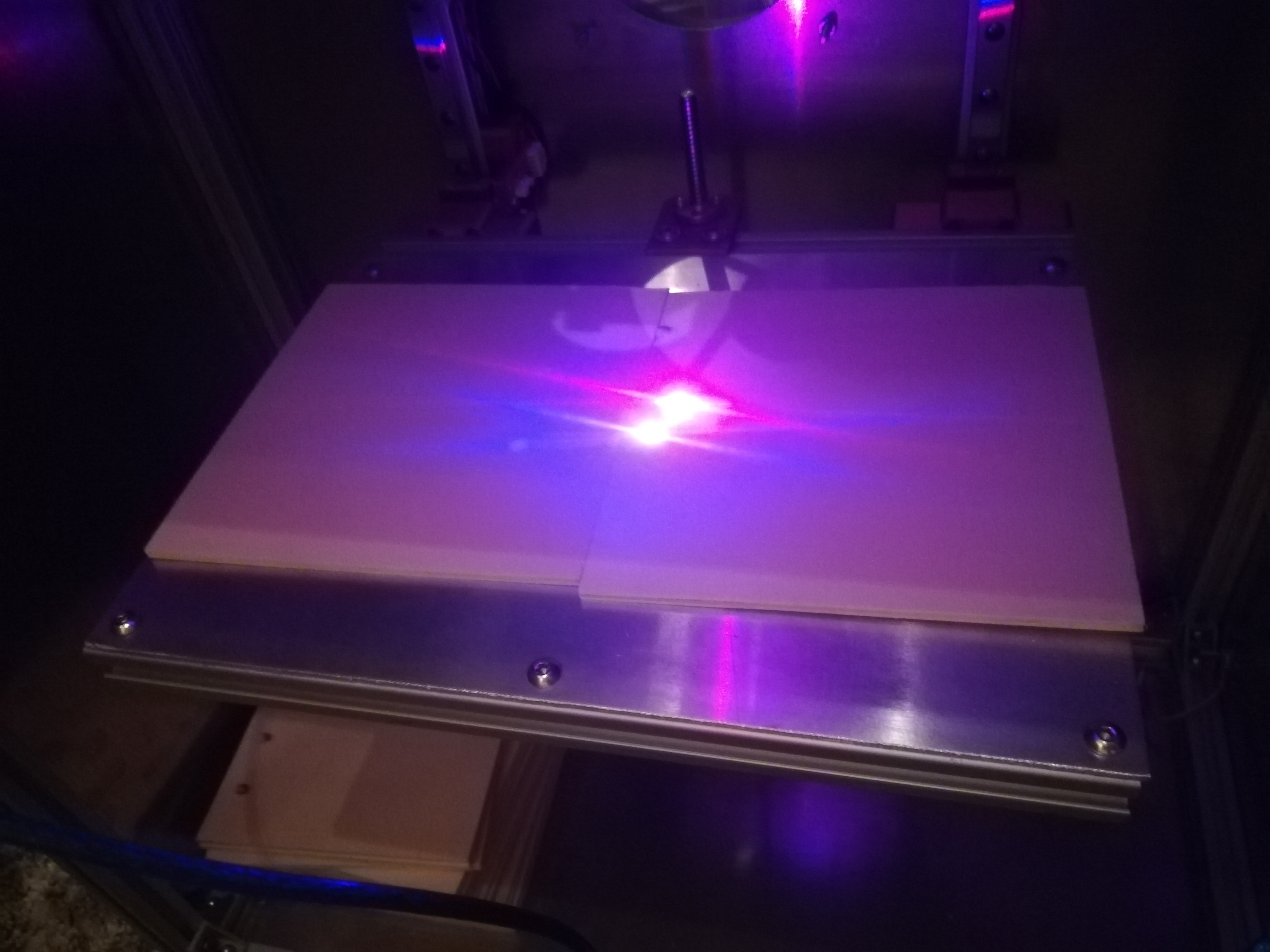

I did some testing with one of this projector prism cubes from Amazon and it worked to direct both laser beams to the galvo mirrors and to the work area.

The downside of the cube is that the lasers not only got reflected 90° to one side, but got also weaker reflected to the other 3 sides. So I think using a dichroic mirror (If I can find a cheap one) would be better.

What would be better than a Red Dot for the Galvo Laser? I think a Red Dot + Beam Distance Measurement can top it.

I tested out the cheapest laser distance meter I could find and got ... some results.

The meter I used couldn't give useful readings of the beam length over the prism the two galvo mirrors down to the workpeace, but its reading reacted to changes in the beam path like increasing or decreasing the distance between the workpiece and the galvo mirror.

So I think in general the hardware could give the right readings, but the software is not supposed to do so - what makes sense because the distance meter should show the distance to the next object it hits with the laser.

I will try to find a way to use the bare hardware and add something like a min distance after which the first measurement starts. I've seen something like this for the vl53l0x distance sensor (to use it behind a glass) and I think it could maybe be possible to add it to the distance meter software.

Update:

After reading some articles about it and testing some stuff I think it will likely make things worse to measure the beam distance, because of false readings and too low resolution.

So instead of that it want to try sending the DAC Value of each Converter board to another board which controls a fast lightweight focus axis which should be able to keep up with the galvo speed and I also want to add the red dot laser + dichroic mirror.

Just realized that the printer is already able to automatically set the right Z height.

Just place the workpiece under the endstop before homing and you get the right Z height for every workpiece thickness.

What's left is the red dot and the galvo focus correction.

Dominik Meffert

Dominik Meffert

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.