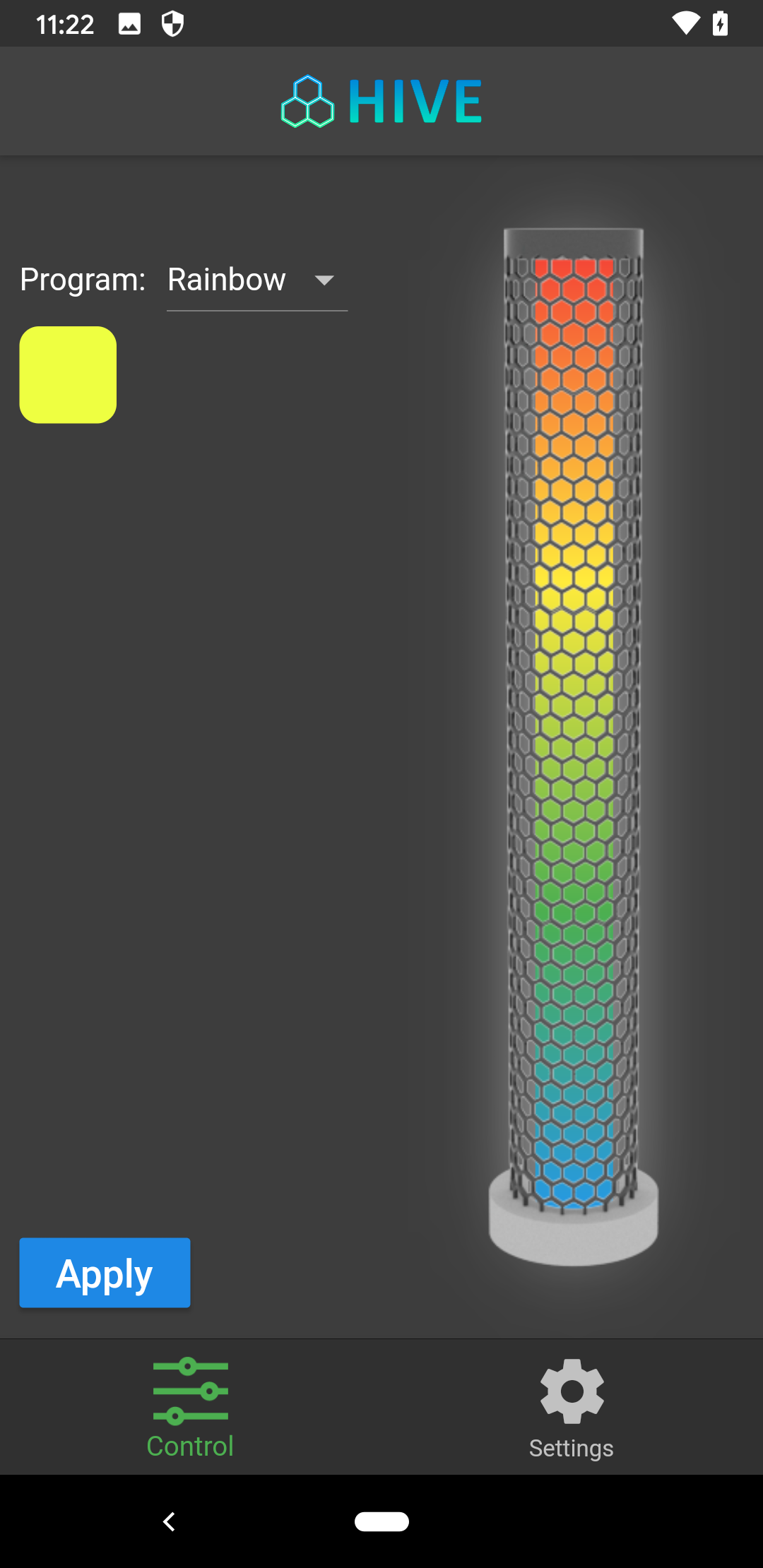

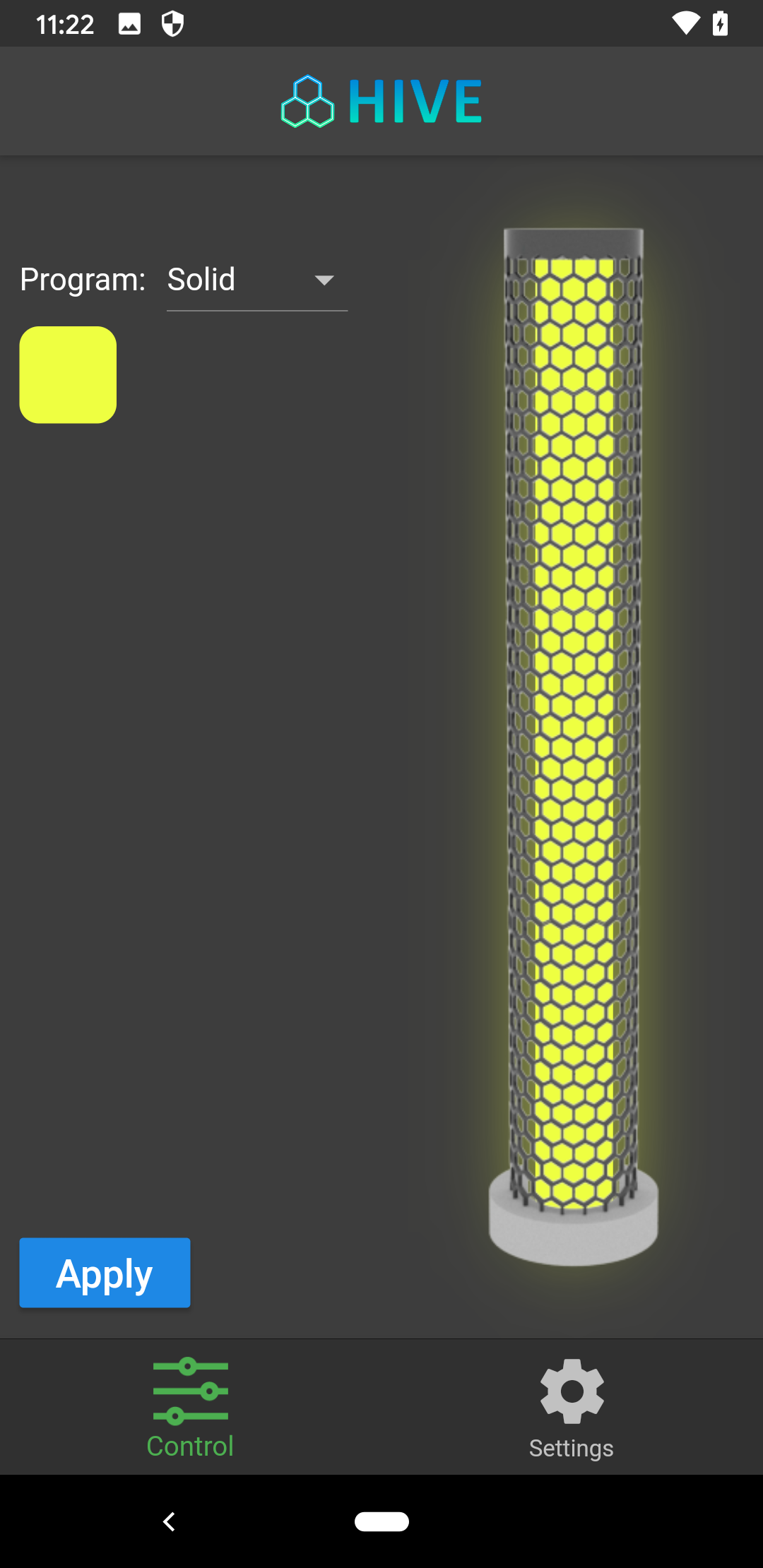

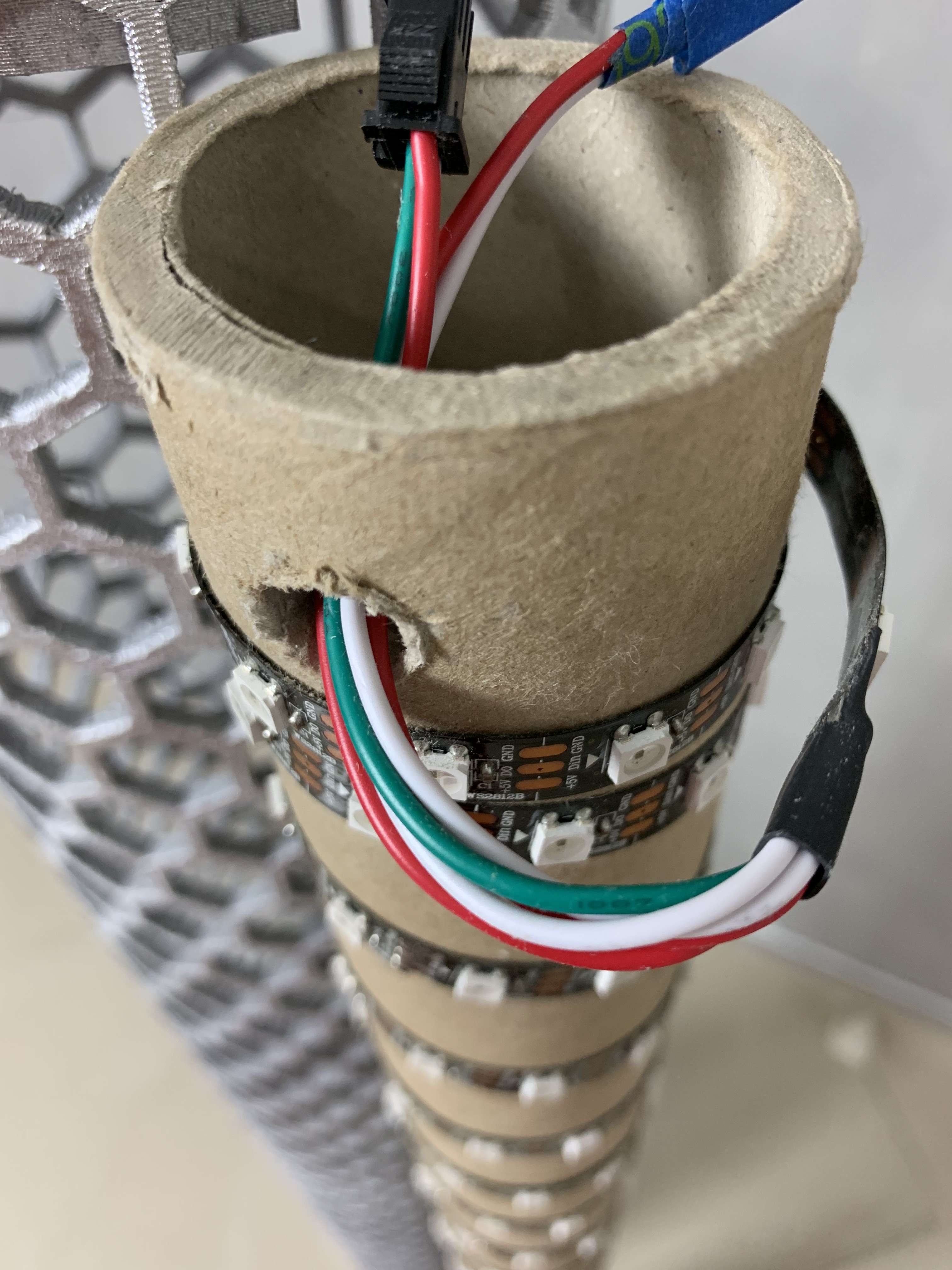

Hive is based on ESP32 for Wi-Fi connectivity and Bluetooth for fast pairing process with mobile device. The ESP controls 5 meter ws2812b LED strip (300 LEDs) so at max power it can draw 5v@18A.

To avoid that power consumption when I what it to glow in white I'm going to replace the LED strip with RGBW strip for pure white color.

Hive has a concrete base to make it stable.

It took me two tries to make it work. In the first one I was impatient and I've tried to demold it after 2 days and it cracked and broke.

For the second try I've waited week and a half and it came out perfect.

You can find the source code for this project in my GitHub repository that linked to the project.

Tovi Levis

Tovi Levis

Neil Mundt

Neil Mundt

ZaidPirwani

ZaidPirwani

igorfonseca83

igorfonseca83