Hi there - Tom here! So - who am I? Well, my first degree was in Electronic and Information Engineer, but I’ve just finished two years studying Innovation Design Engineering in London, expanding my technical base to include all sorts of design know-how!

But enough about me - what have we been up to? I’ve been working with Meesha and Antonio for a week now, and I couldn’t have asked for better teammates. Their tireless dedication to this project has been fantastic, and having such a range of backgrounds really means the ideas, inspiration and approaches to the project have been limitless. Meesha has brought understanding from her software background - from helping us think about information flows, to getting dug in with research, and Antonio has knowledge about the human-centred design process that he’s bringing to help us master our project flow. This, for me, has been key - because there’s no point pushing forwards and making something if you don’t know what the client actually needs.

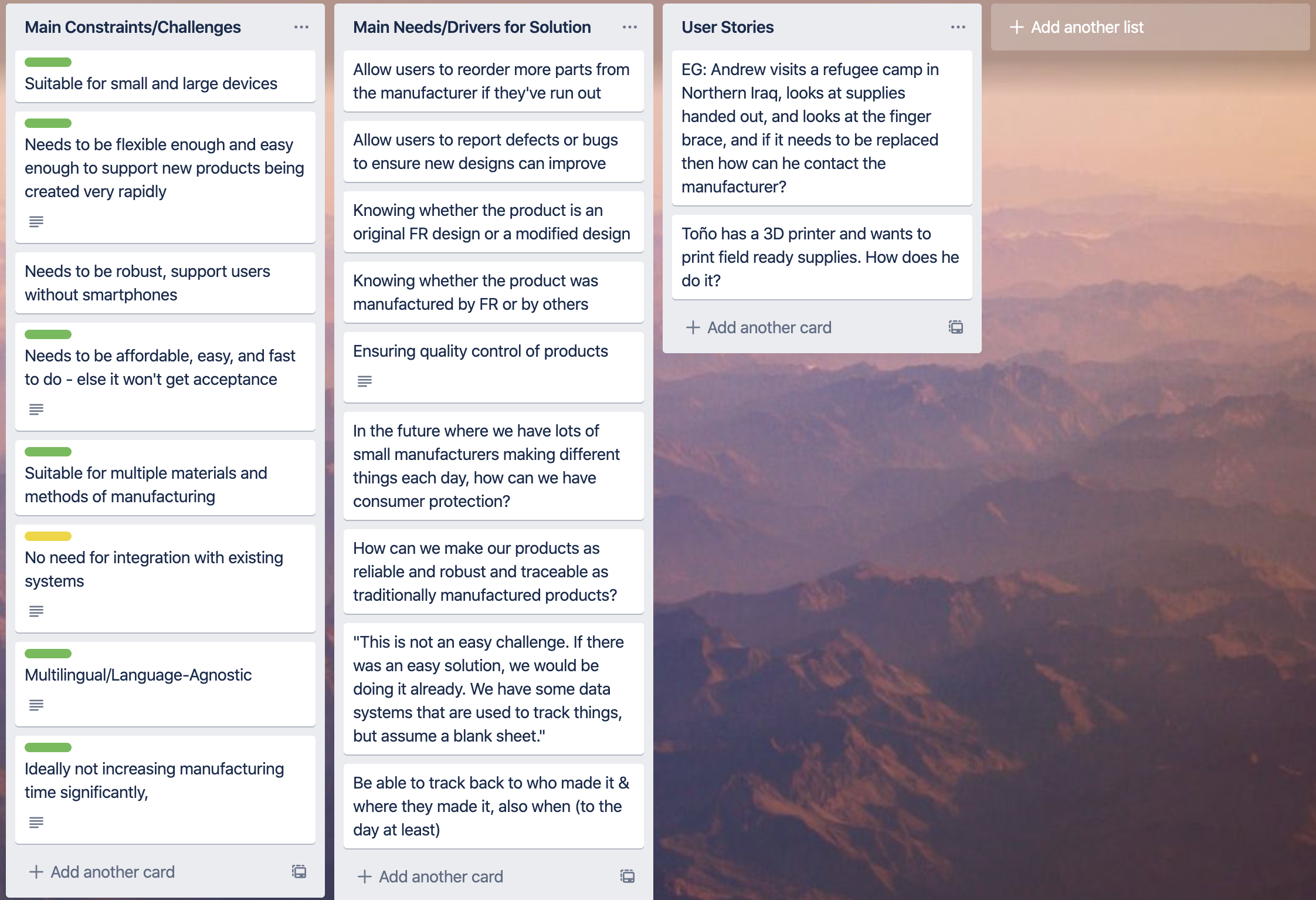

So, what *does* our client actually need? Field Ready, the NGO we’re supporting, have been fantastic and provided us with a wealth of information. We started with this fantastic interview , scoured their website for knowledge, and then built up a set of questions to ask them. We had a talk with them midweek, and managed to build up our understanding of the organisation and the challenges they’re facing even further. We took all the information we’d gathered, and condensed it into two key categories:

- What are the drivers and issues experienced that have pushed Field Ready to invite us to work on this problem?

- What are the constraints on our solution?

Using Trello, we were able to capture this information and run it past Field Ready to ensure that our assumptions were valid. After some minor alterations, we were happy that we had understood the core of the challenge.

As you can see, it’s not plain sailing by any means - with 10 weeks to create a working prototype for Field Ready, we’re all recognising the need to work efficiently and smartly. But beyond just the (slightly daunting) nature of many of the requirements, a closer look shows another pattern too: the problem we’re solving is clearly not just a technical one. It’s a human one. We’ve been invited to redesign and reengineer entire supply chains, design new services and fundamentally change how manufacturing works. As Andrew Lamb of Field Ready put it during our call with him: "To have distributed manufacturing, we have to have distributed quality control.” What does that look like? I’m hugely excited to find out.

P.S. Thank you for reading till the end! If you have a moment, I'd be thrilled to hear what you think about our approach. Are we missing anything? What interesting QC projects have you seen? Drop us a message or comment, we'd love to hear!

Tom Hartley

Tom Hartley

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.