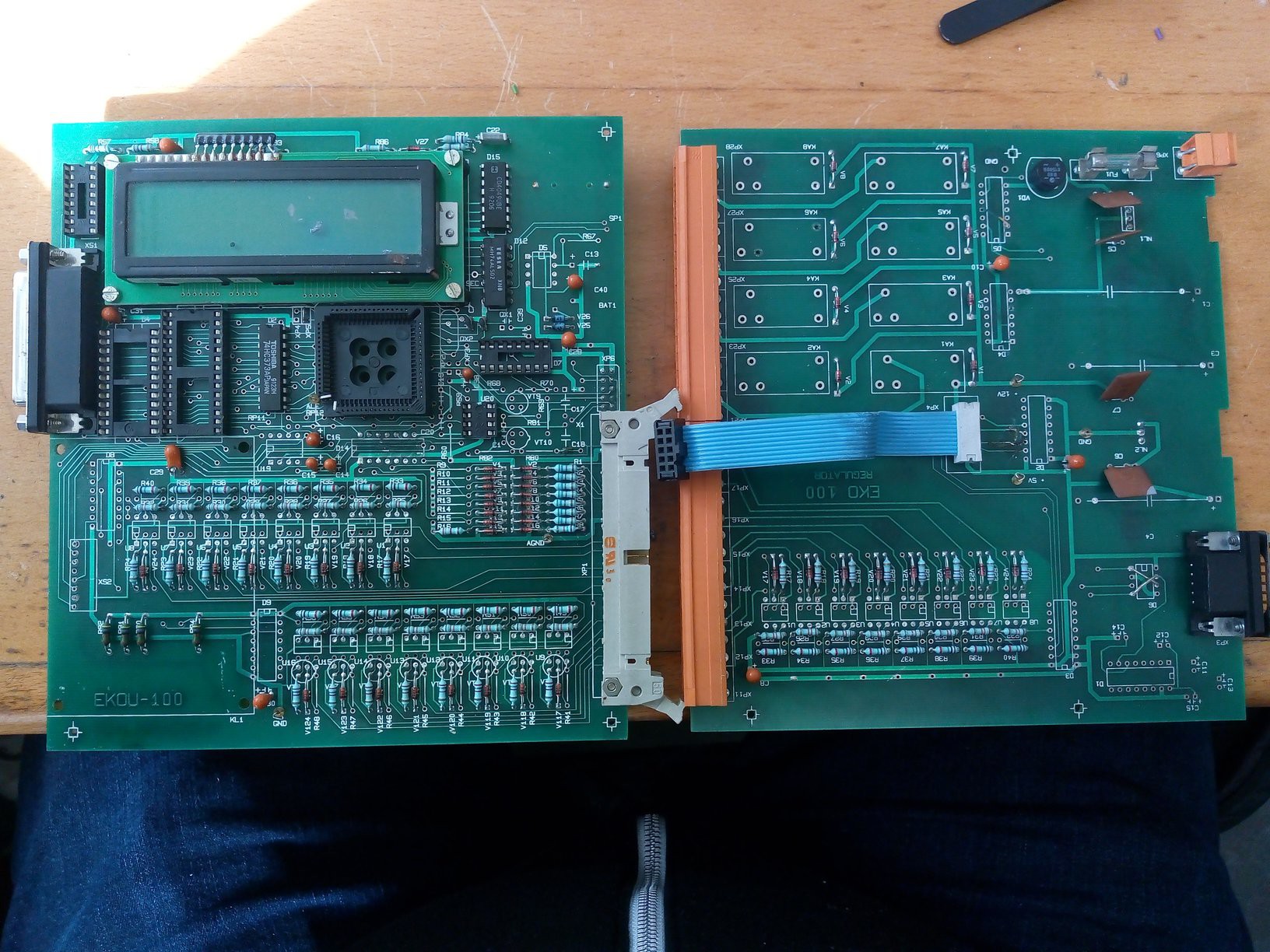

I designed 6-digit multimeter, capable of measuring voltage (1, 10 and 100V ranges), current (10mA and 100uA ranges, with separate 1A range) and resistance (1, 10, 100 and 1000kOhm). Project logs:

FAQ - answering typical questions

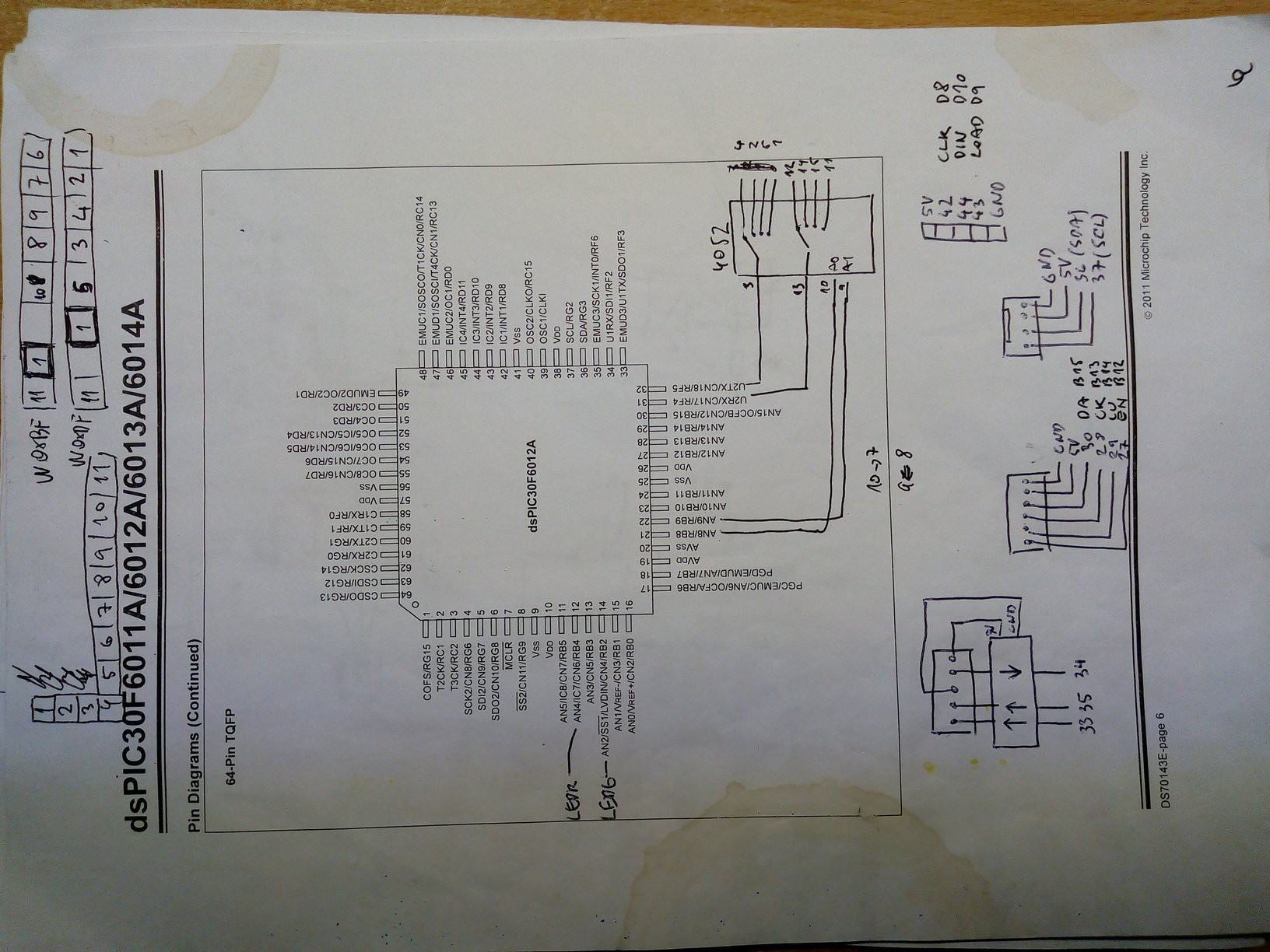

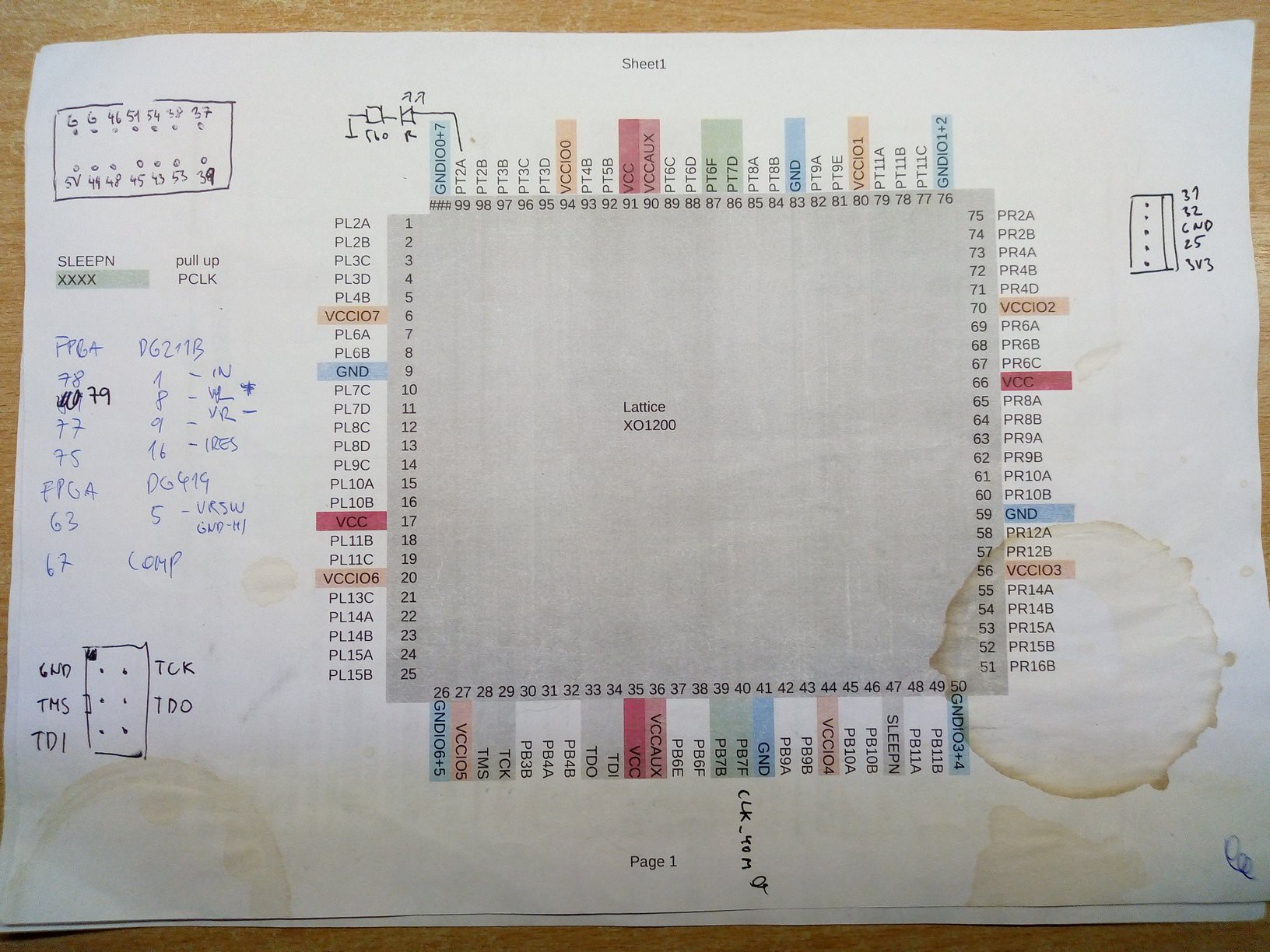

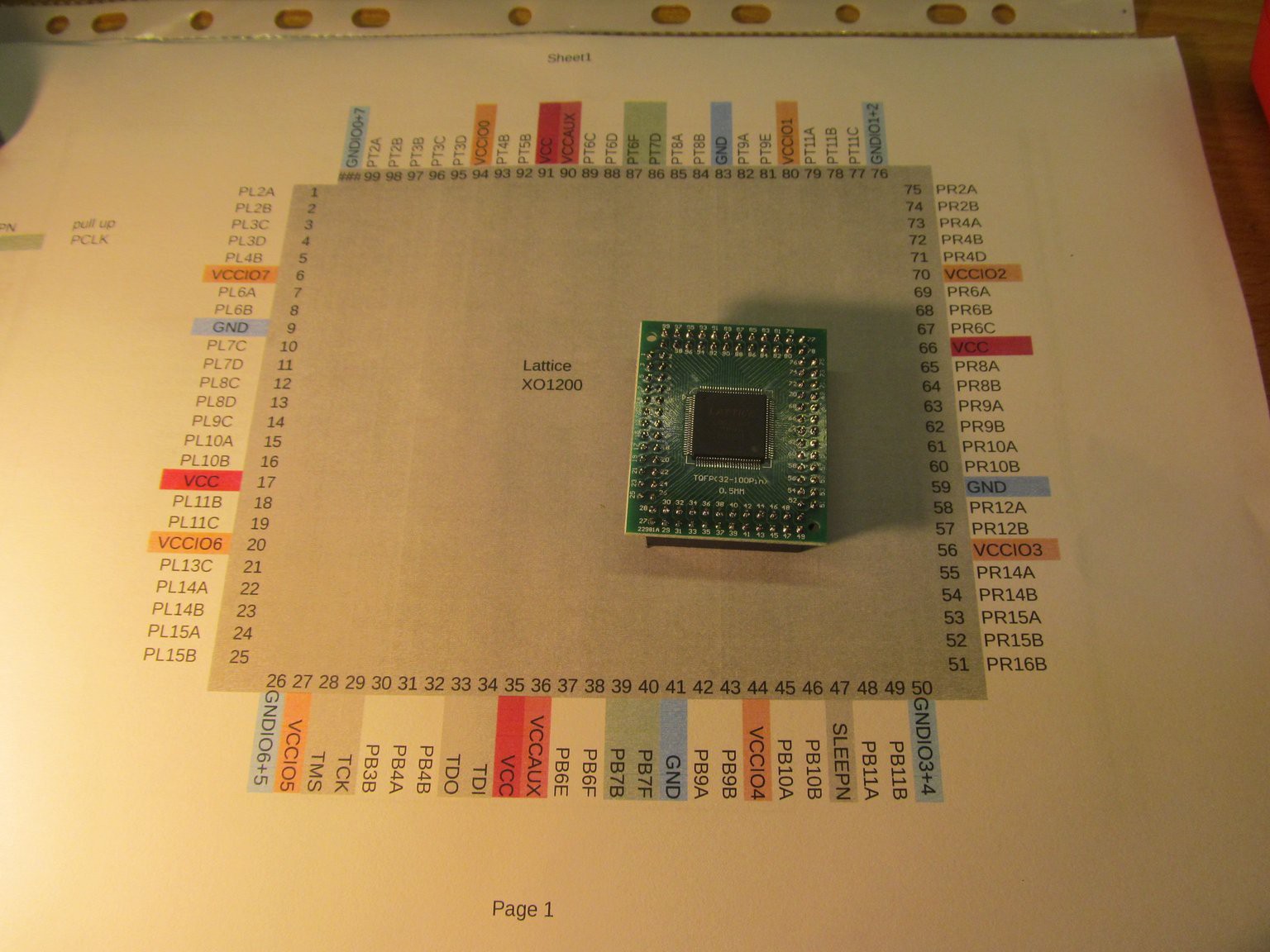

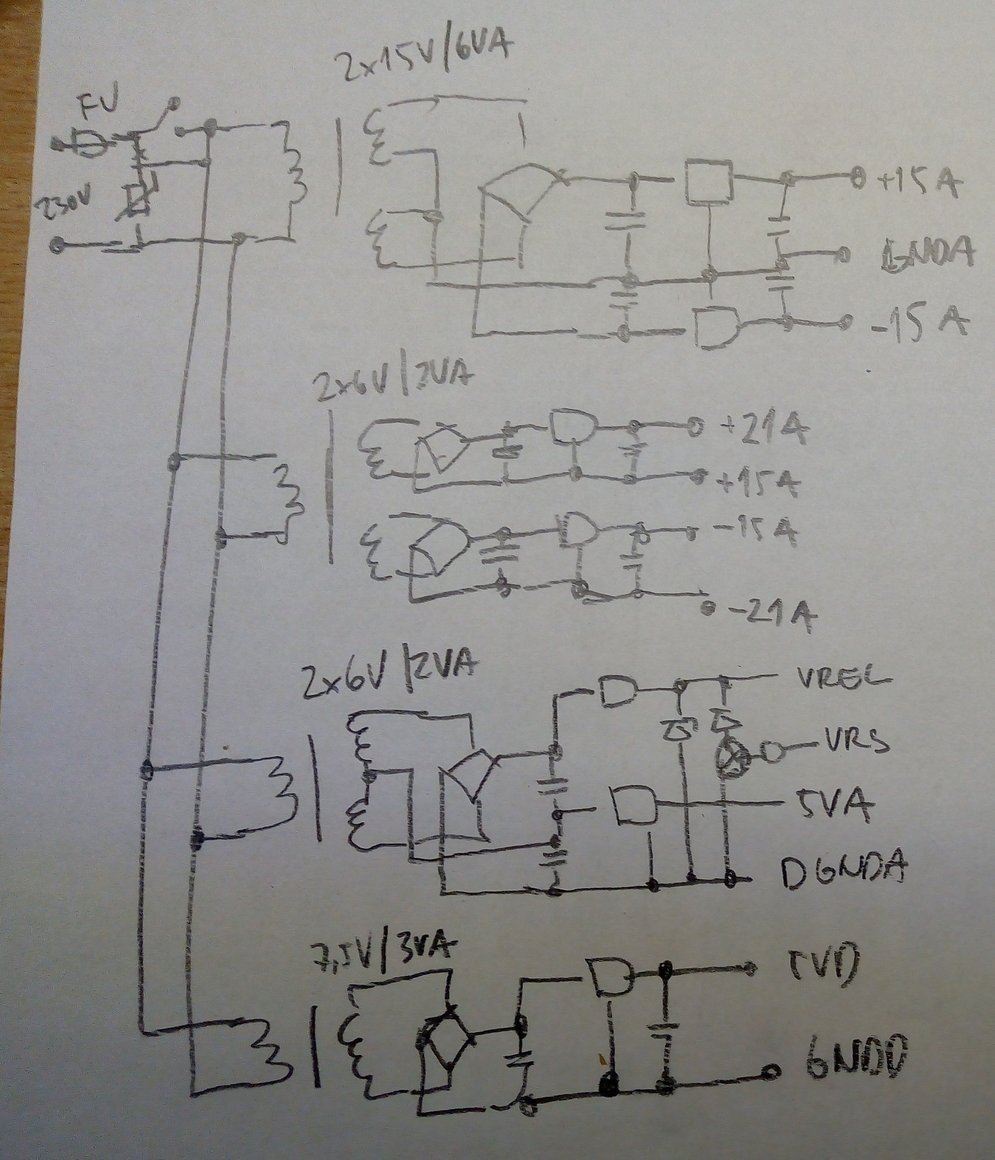

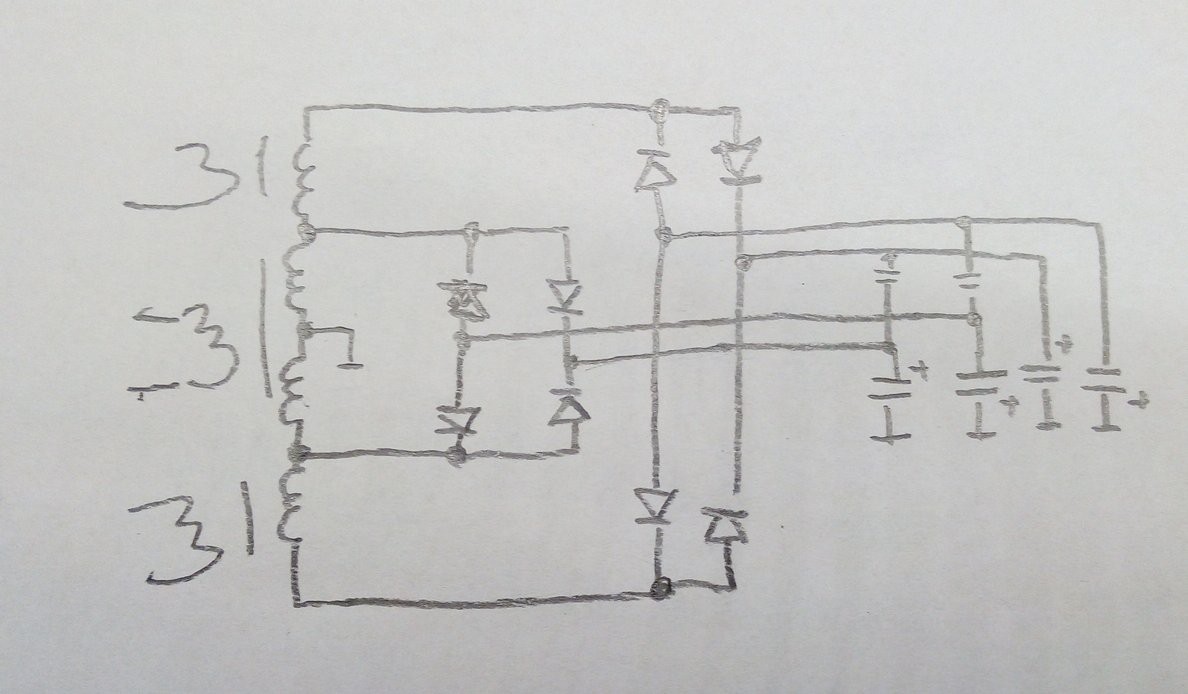

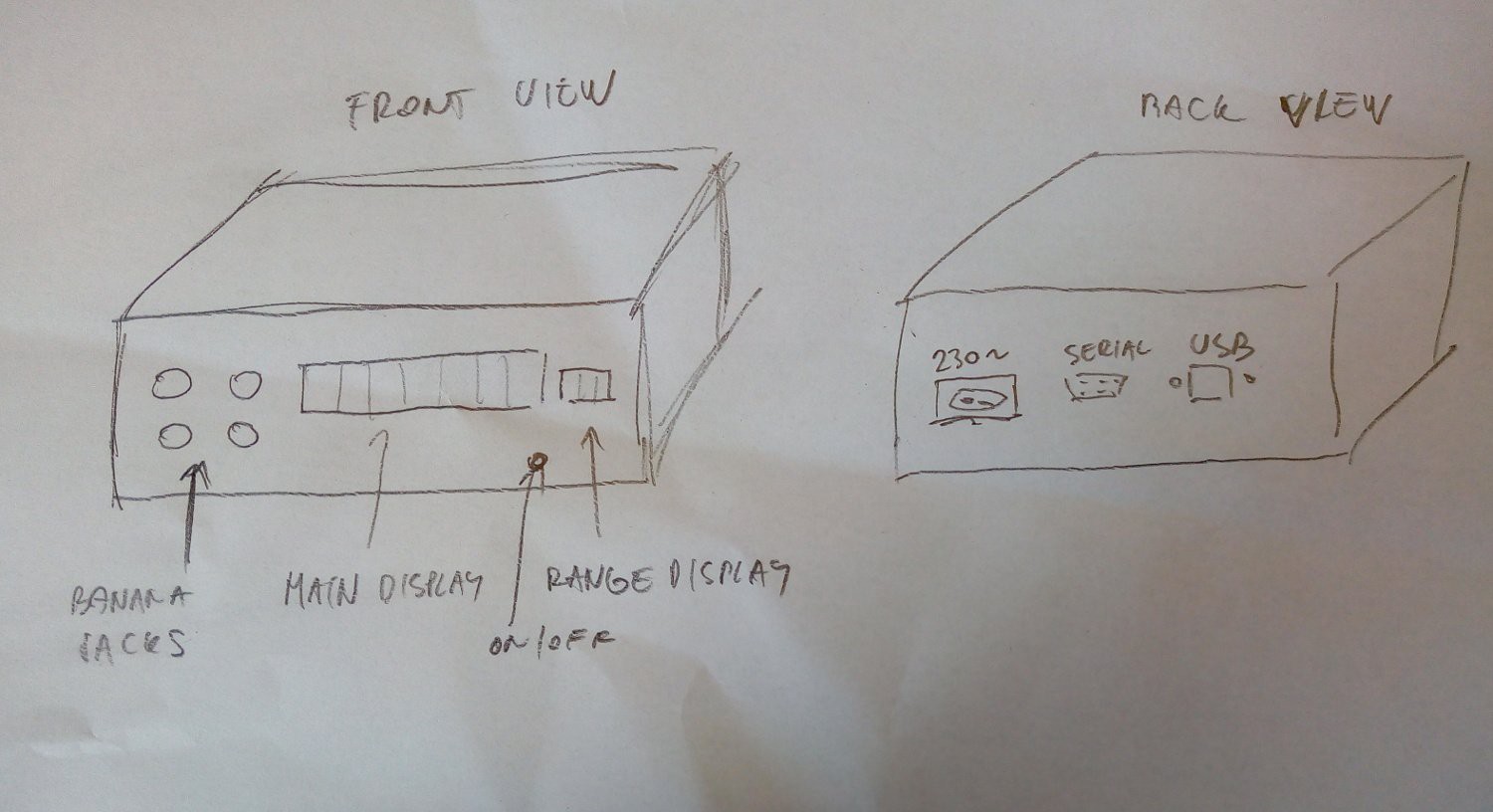

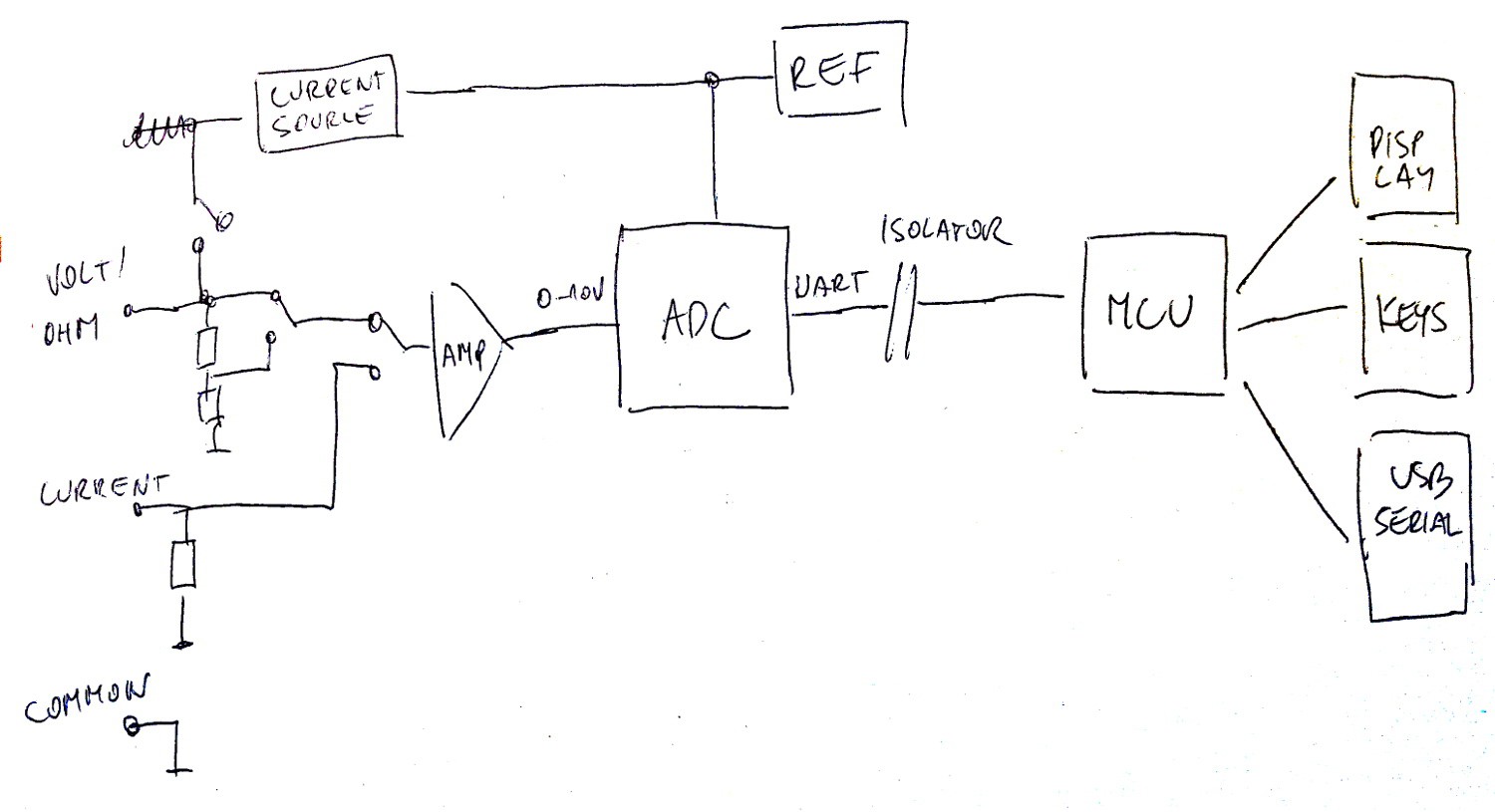

Basics - design sketches

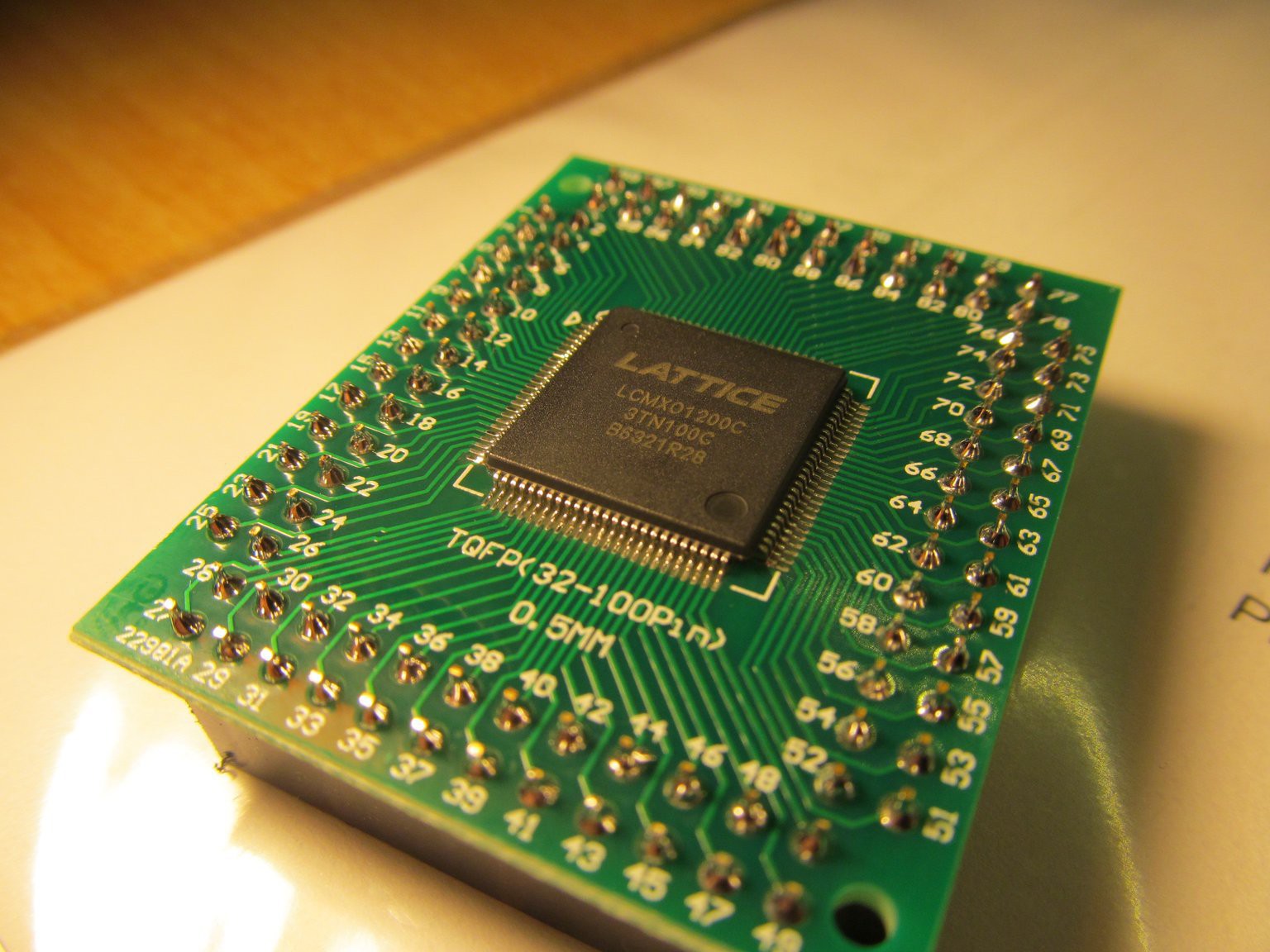

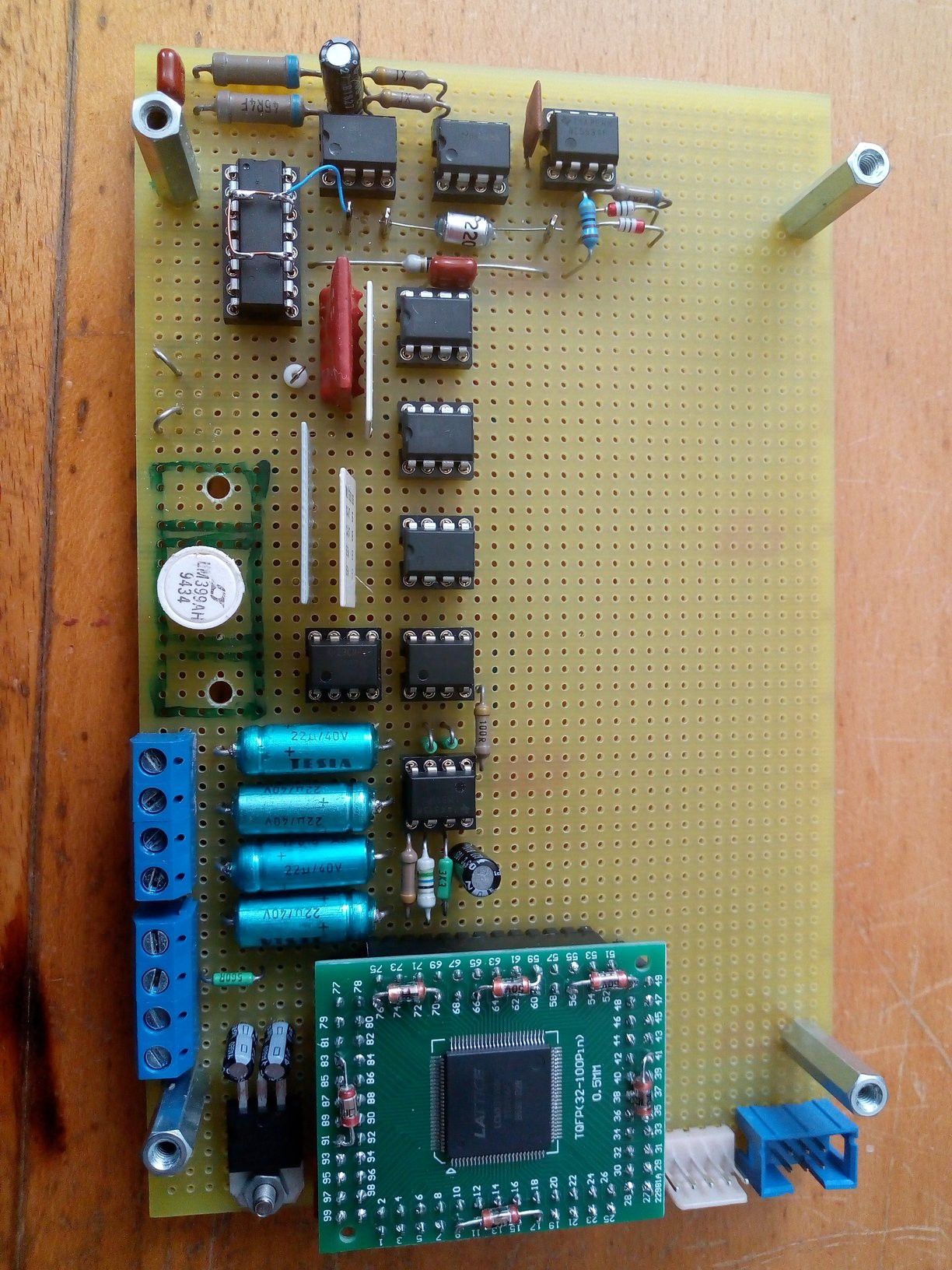

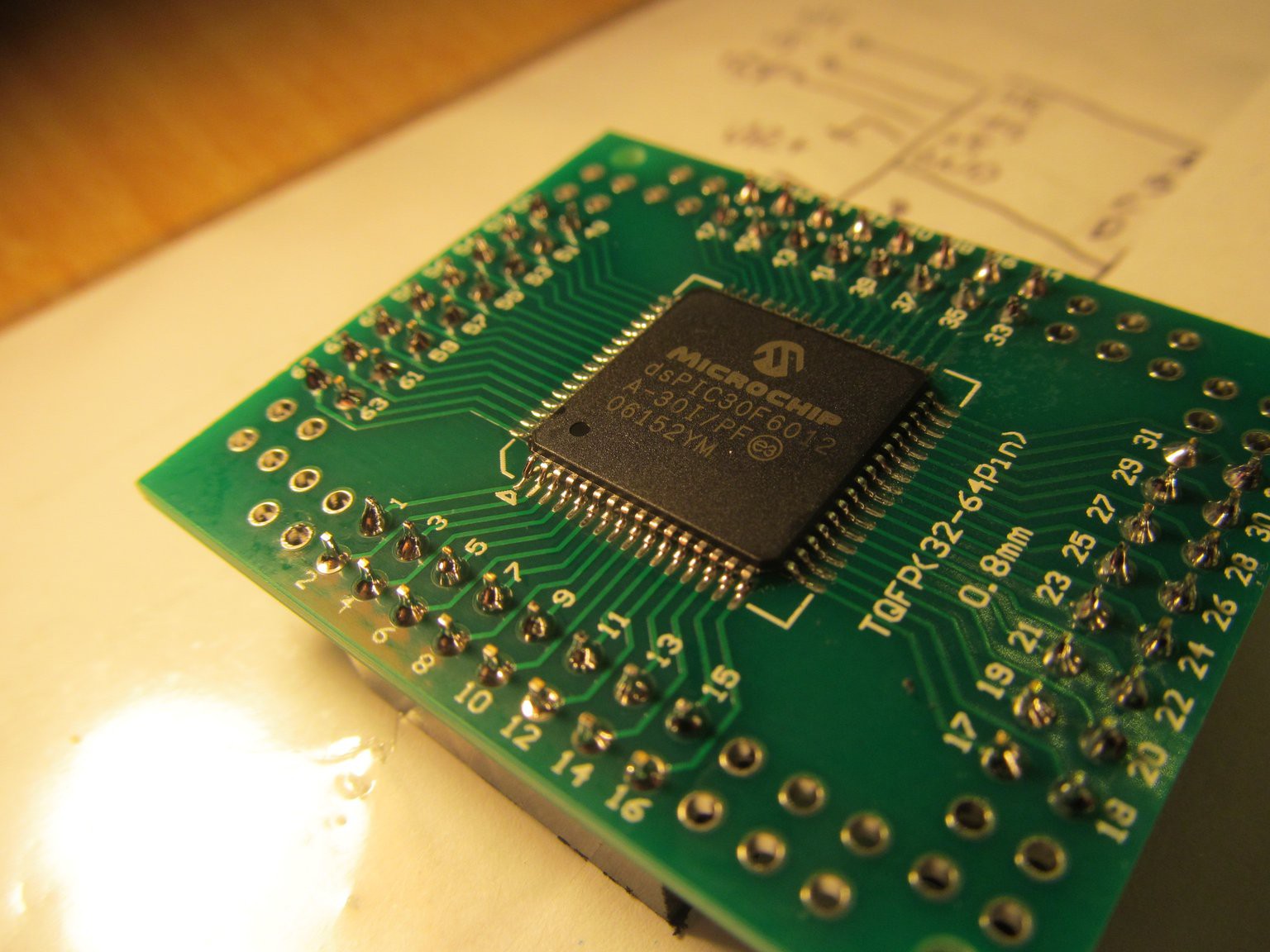

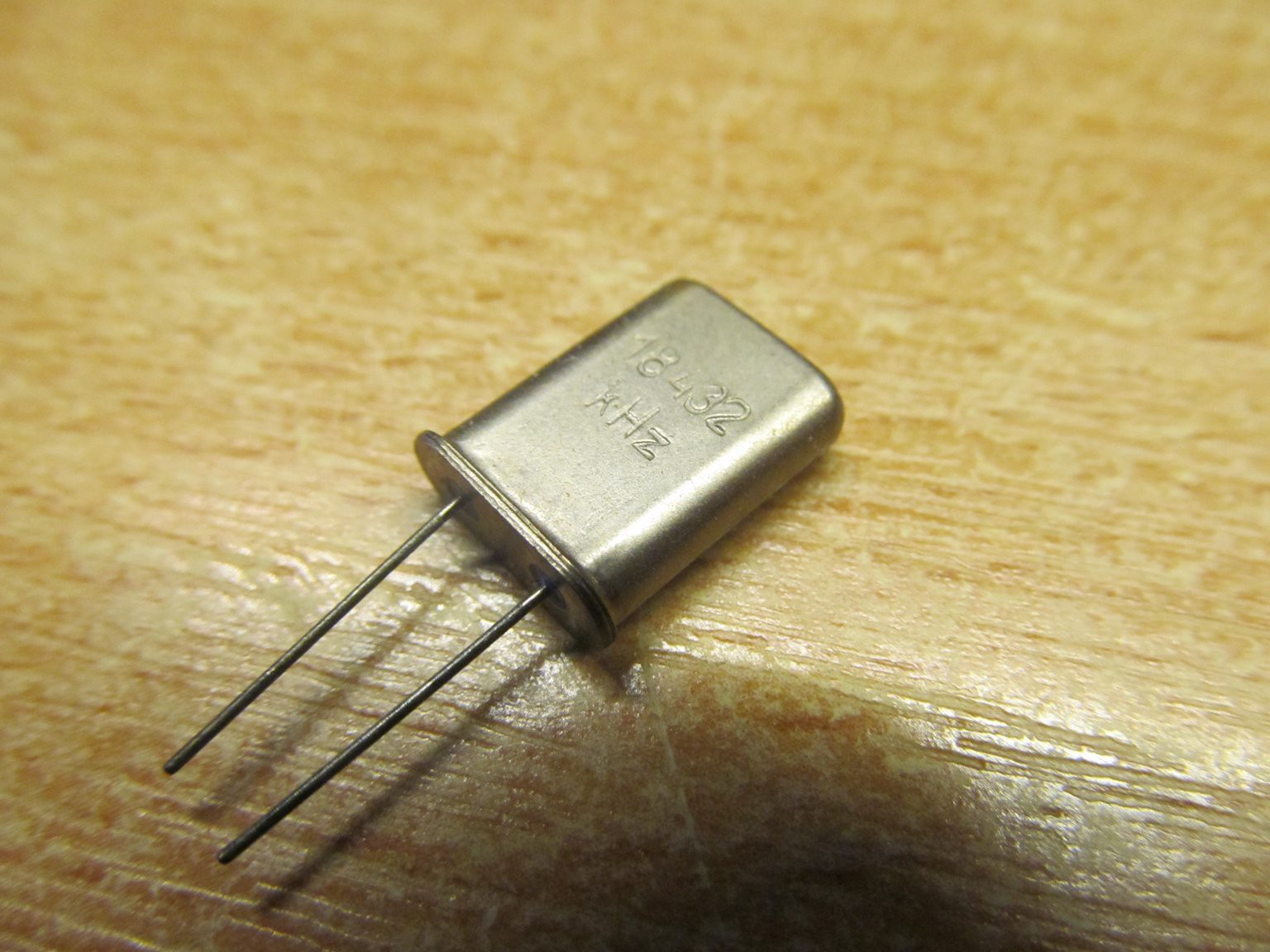

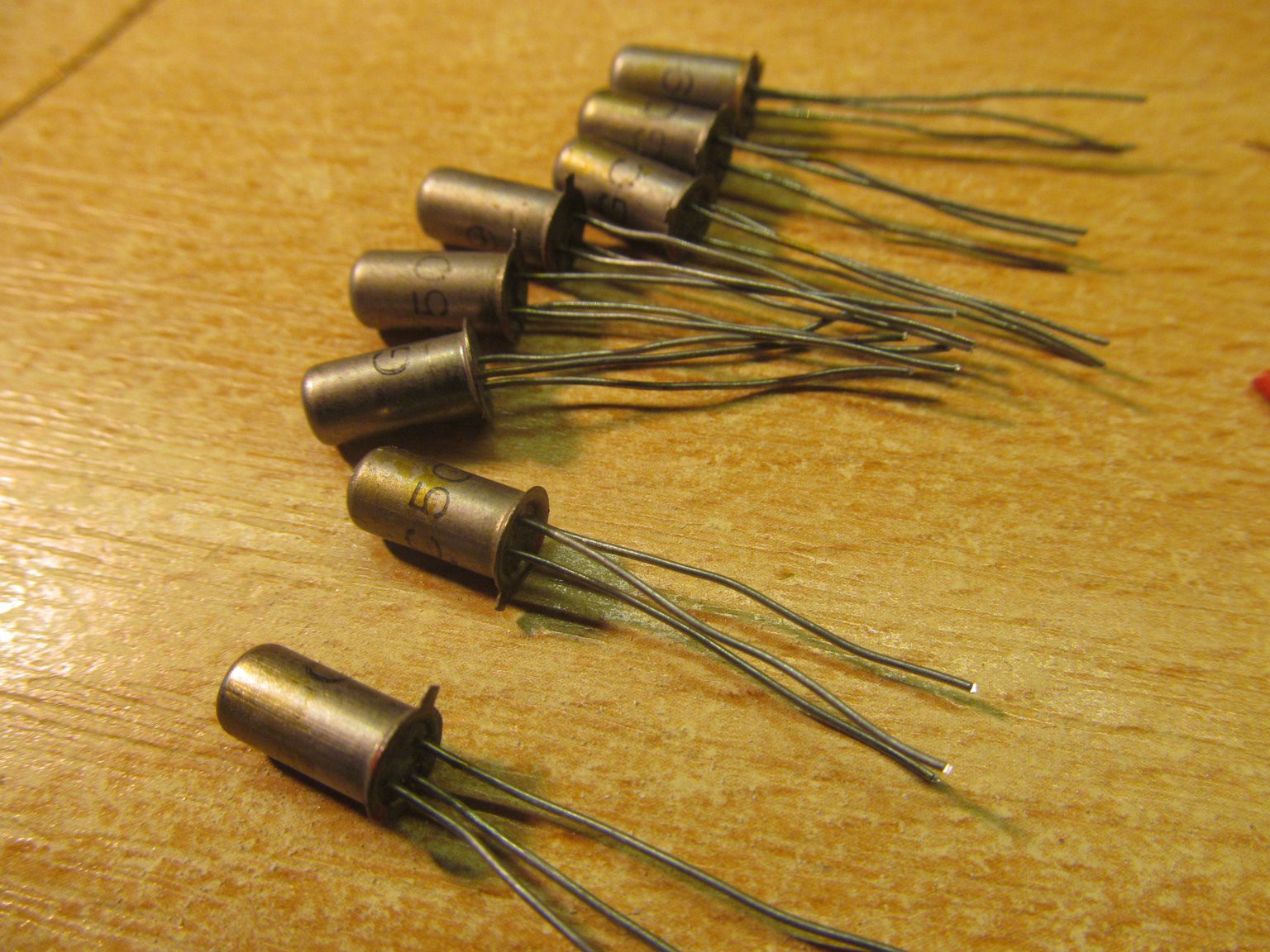

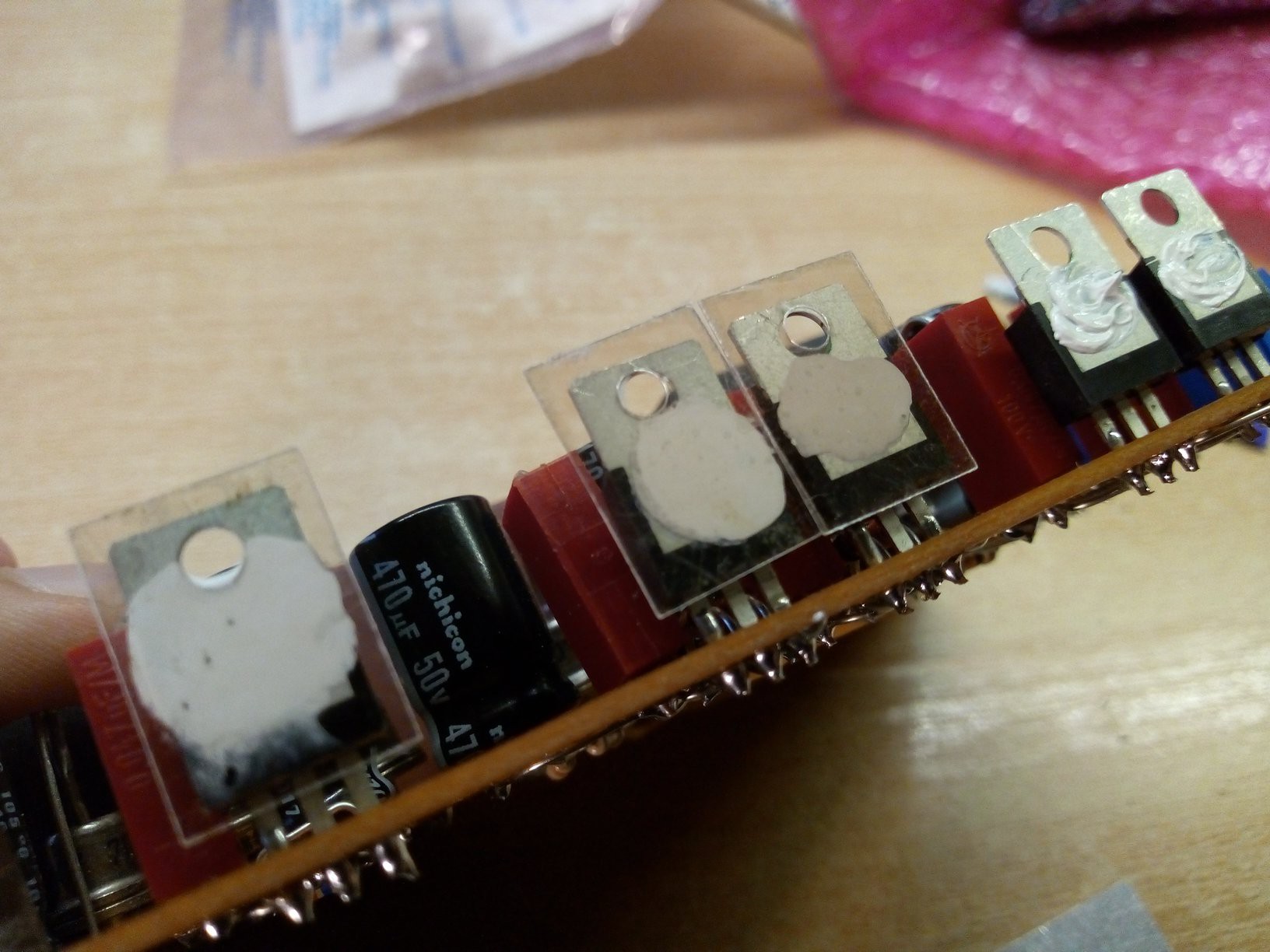

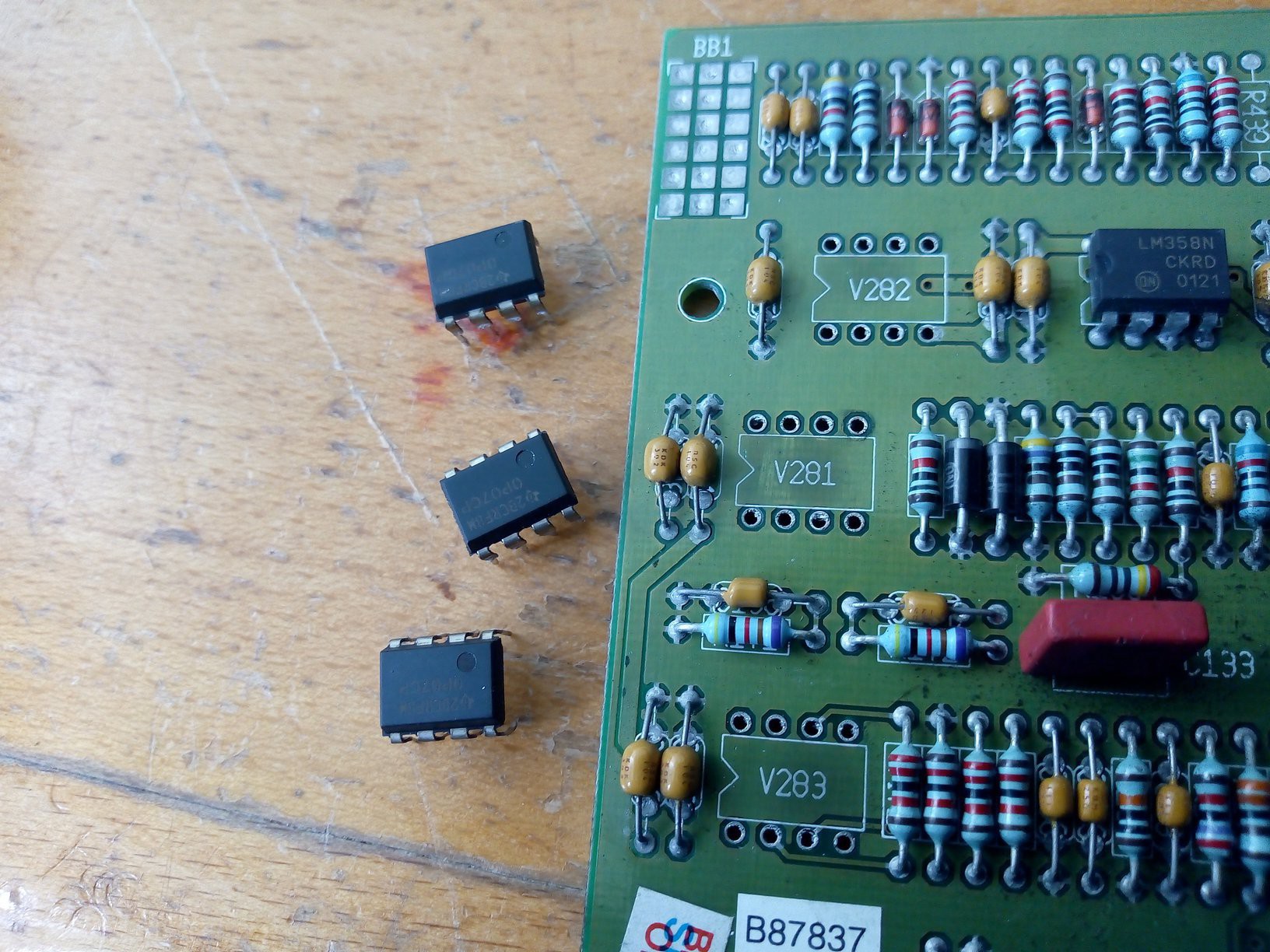

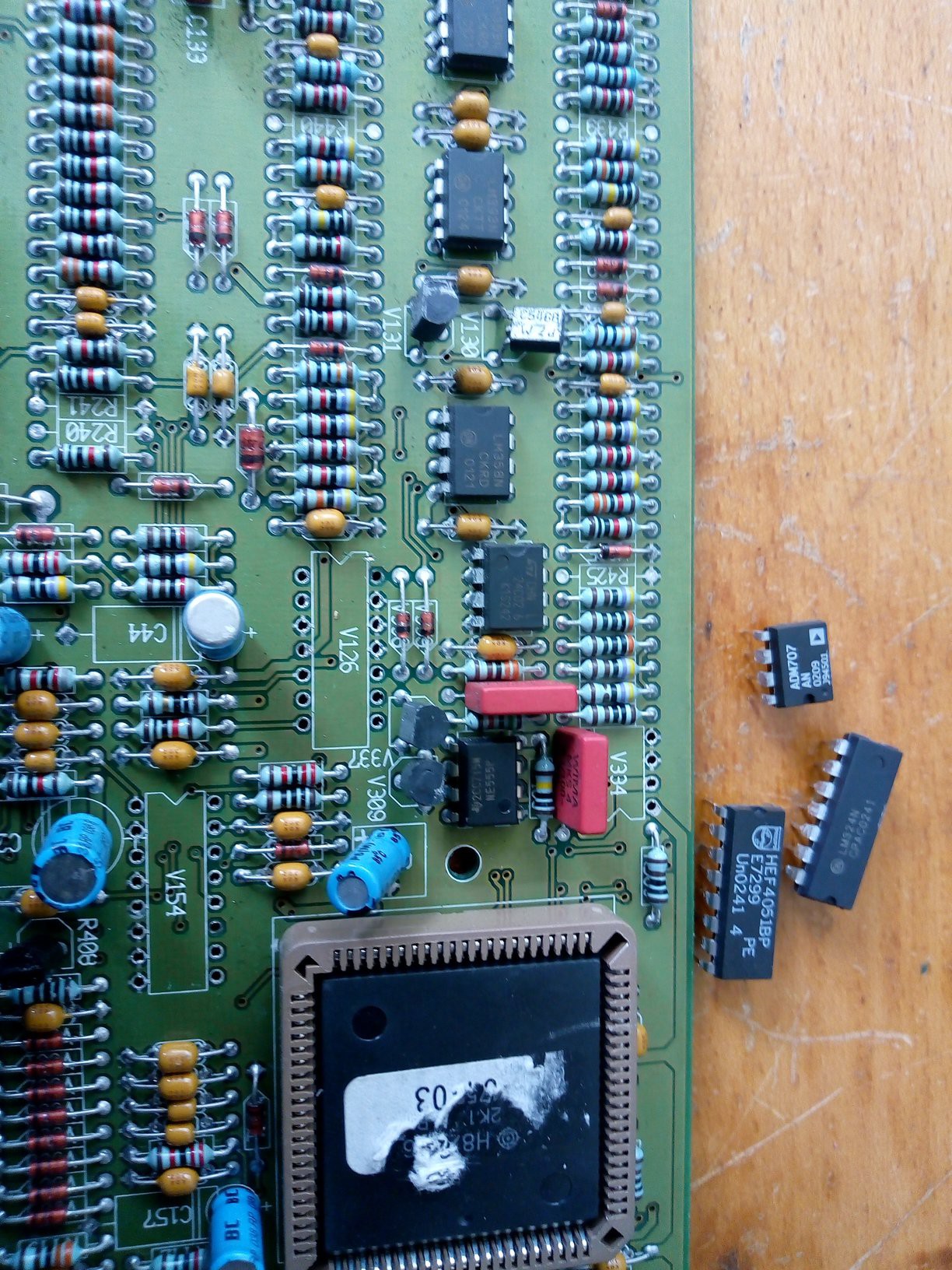

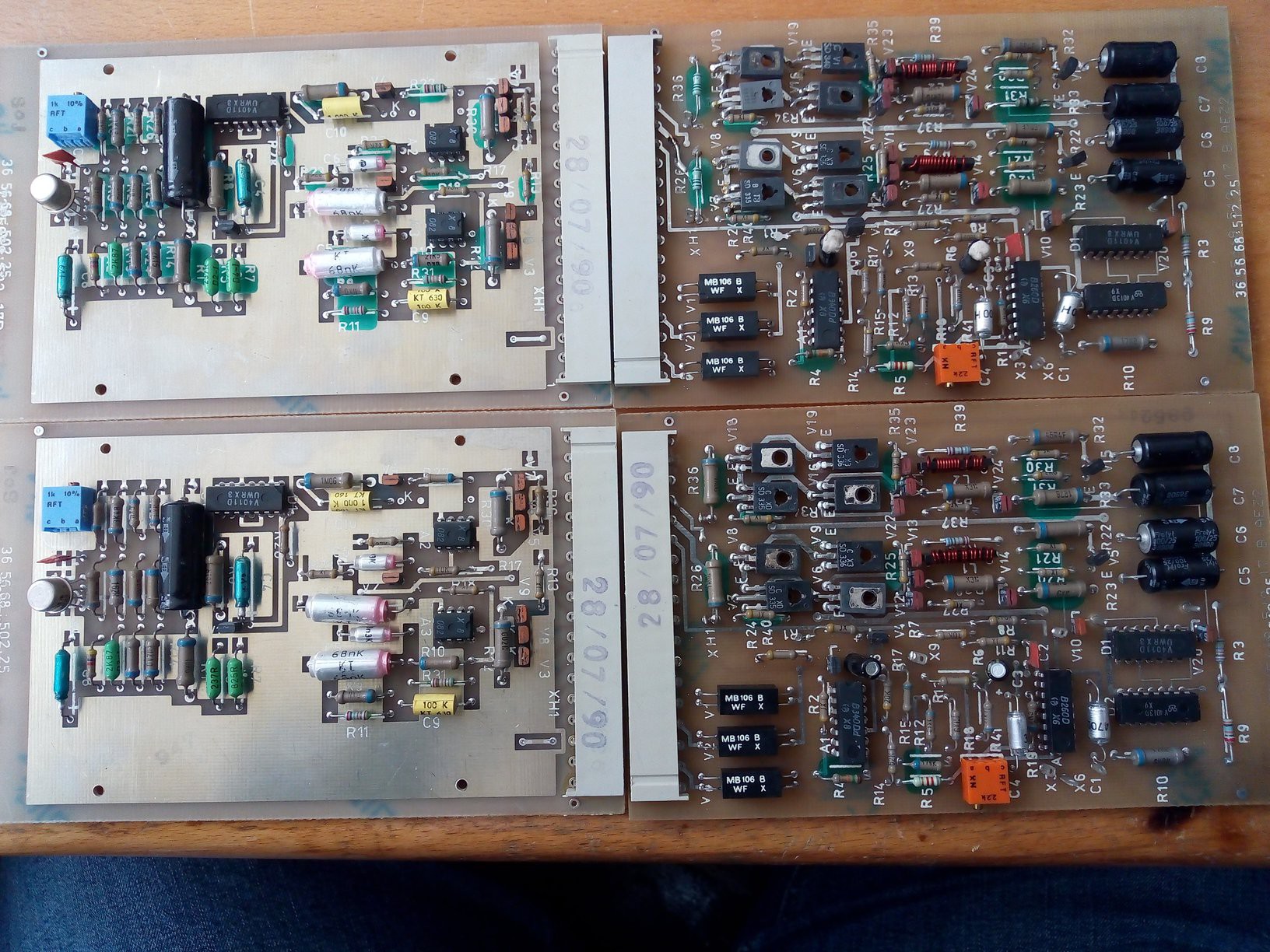

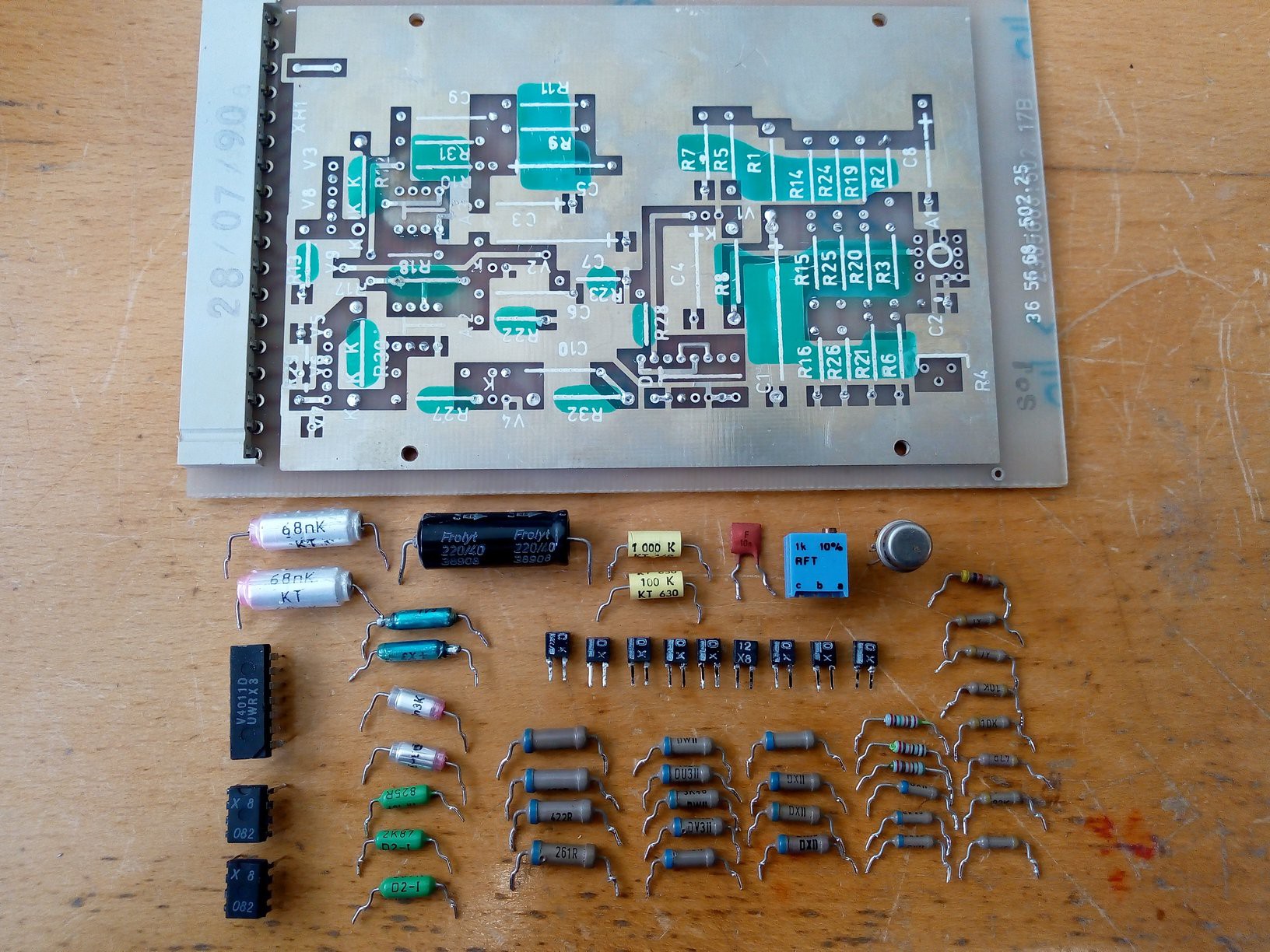

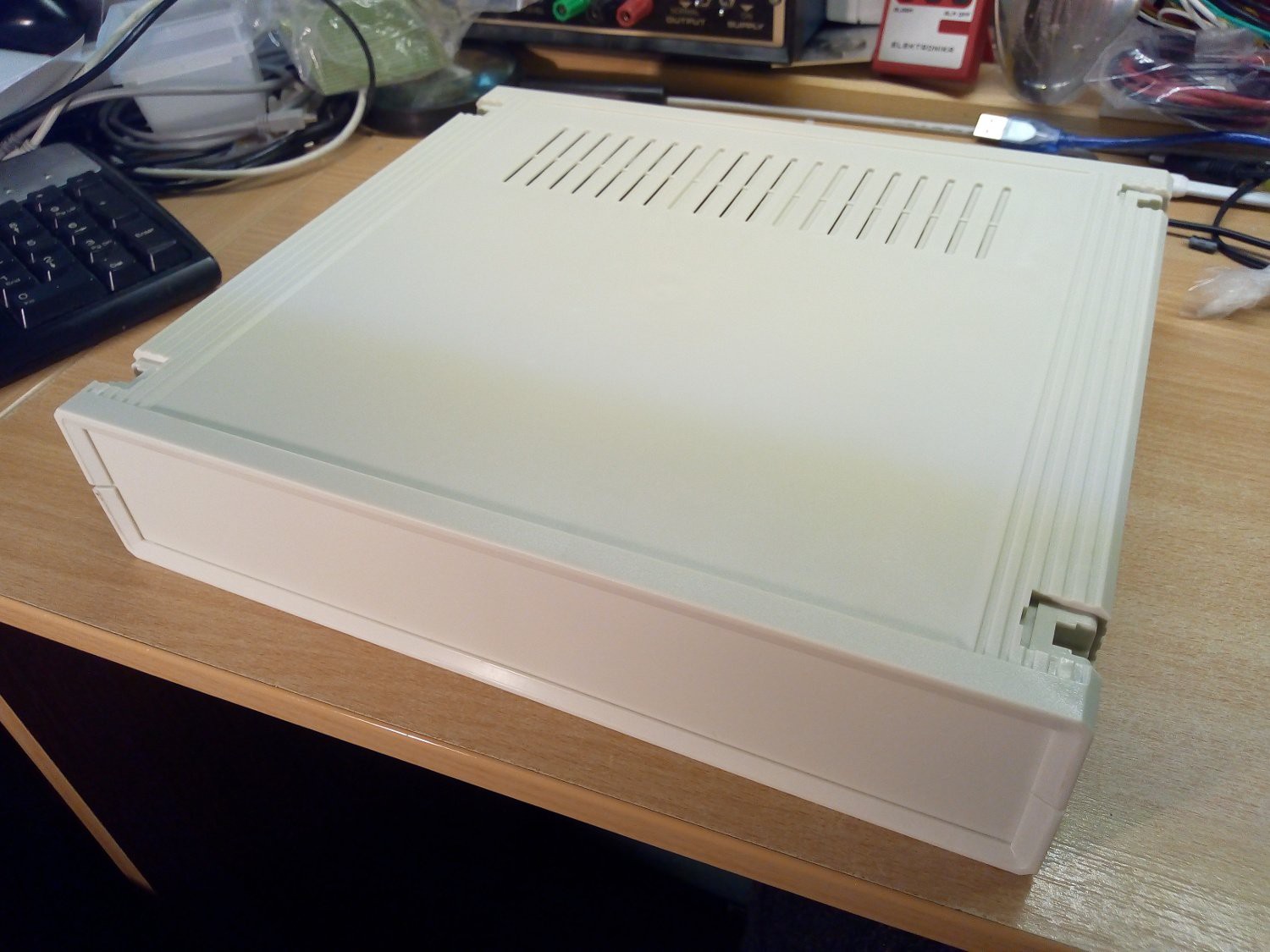

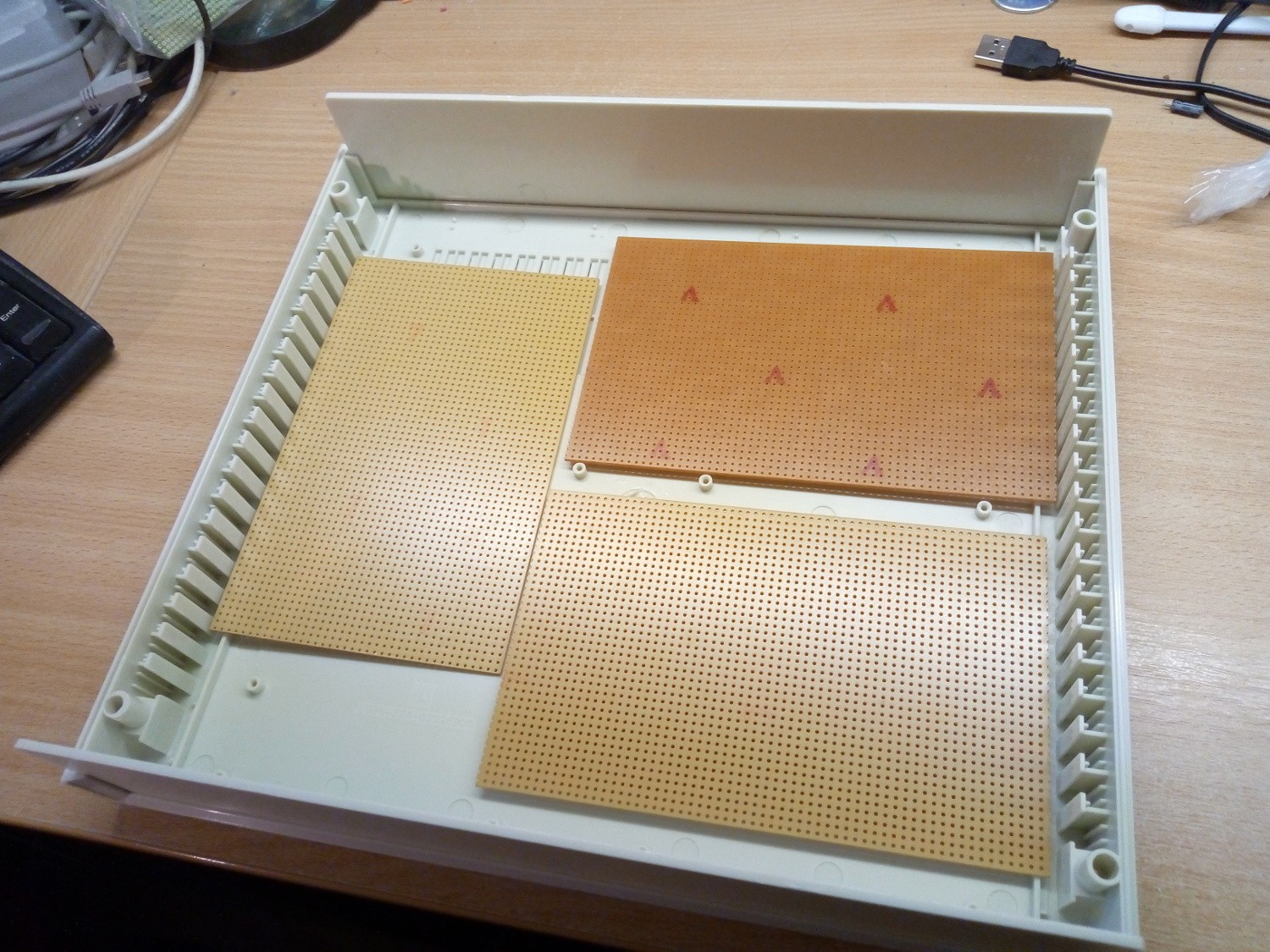

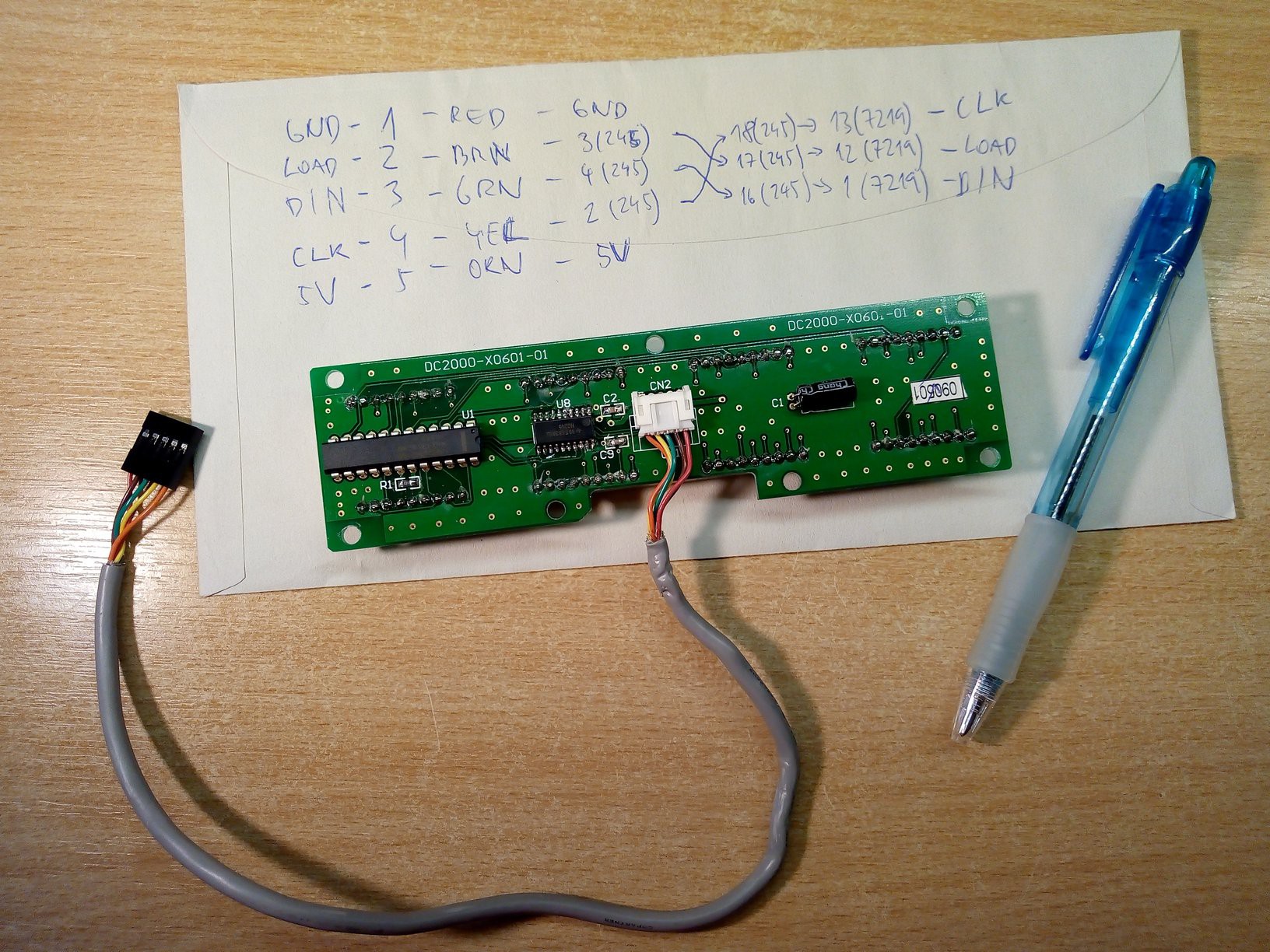

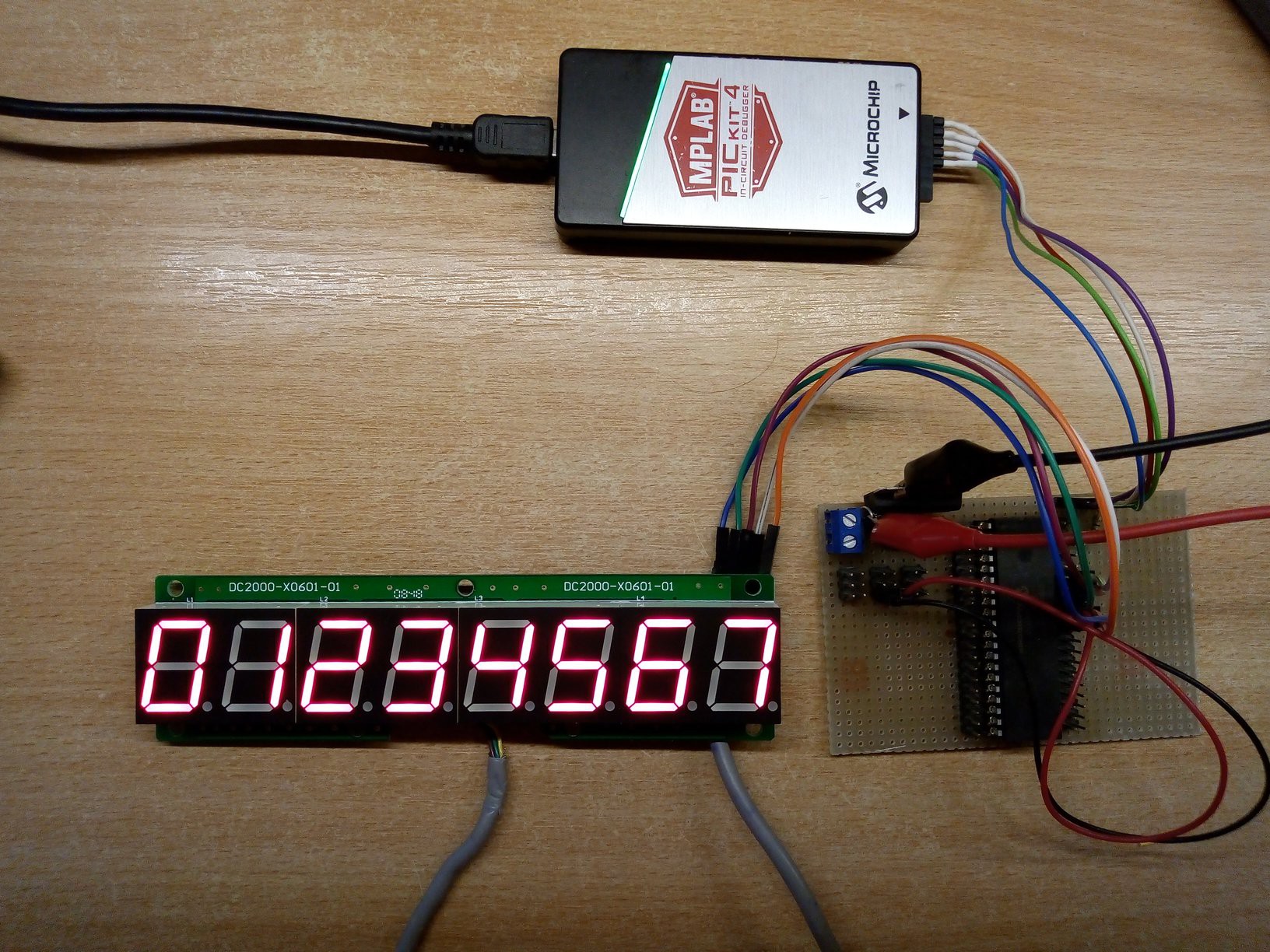

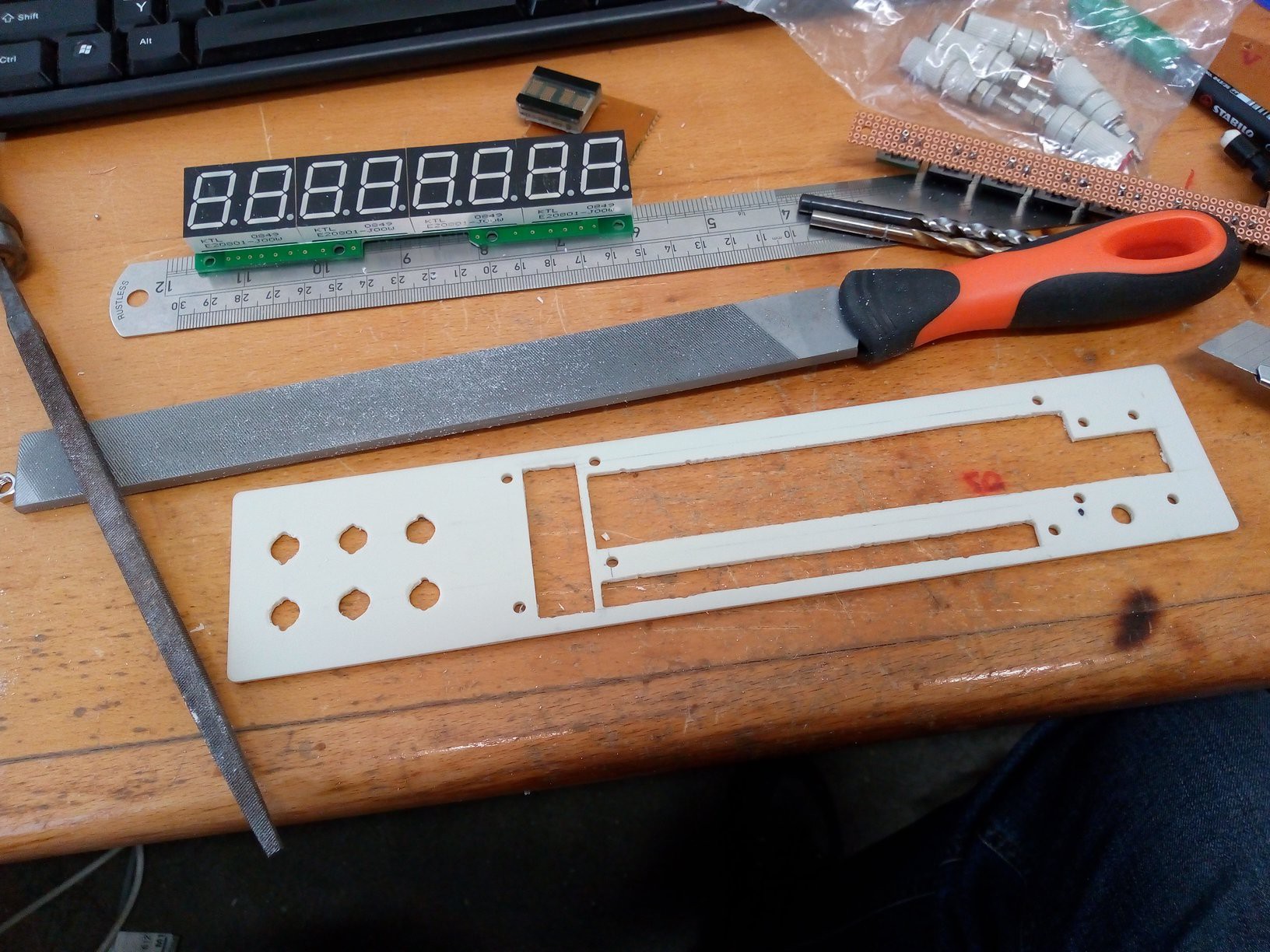

Design, part 1 - sourcing basic parts

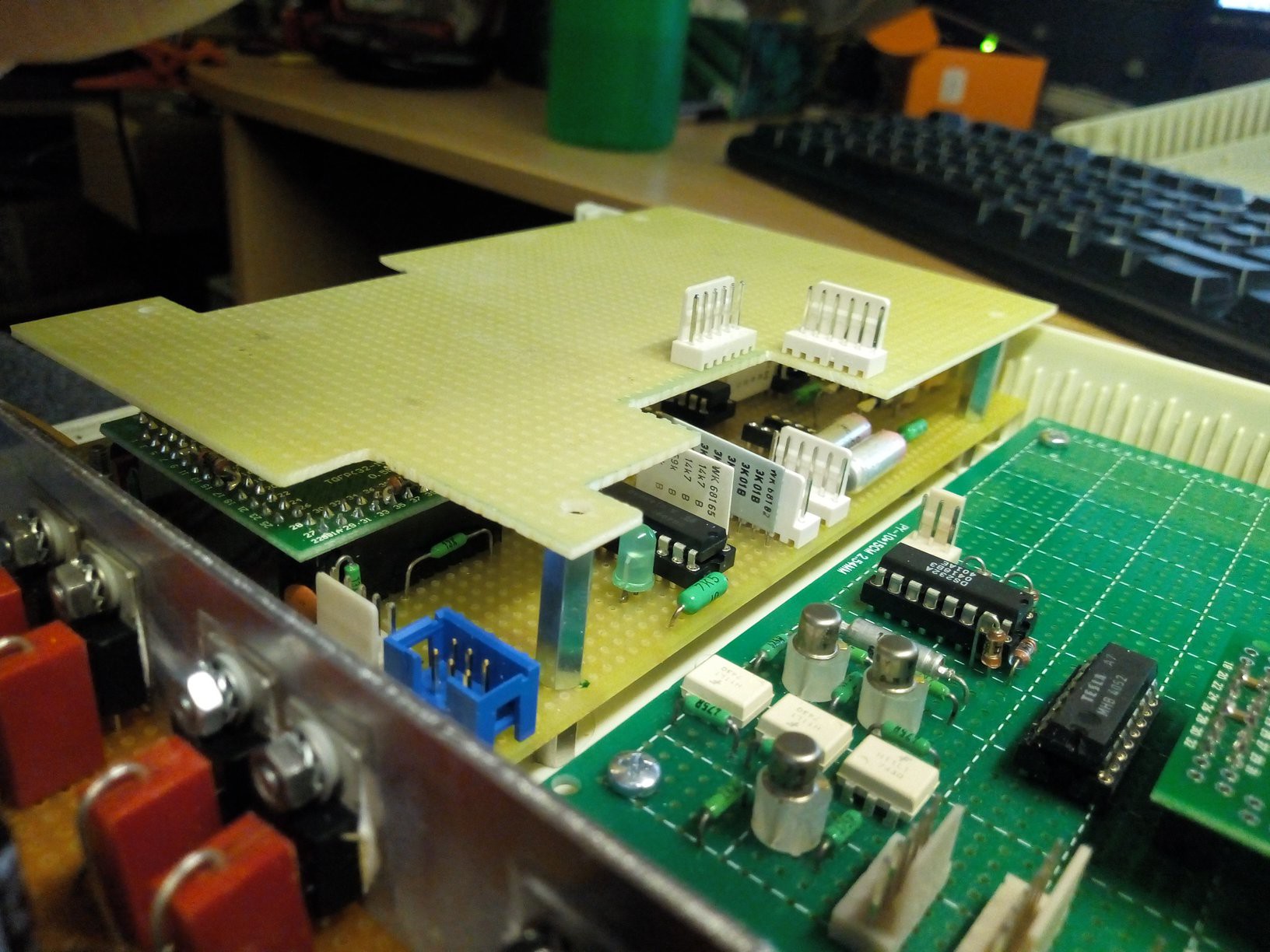

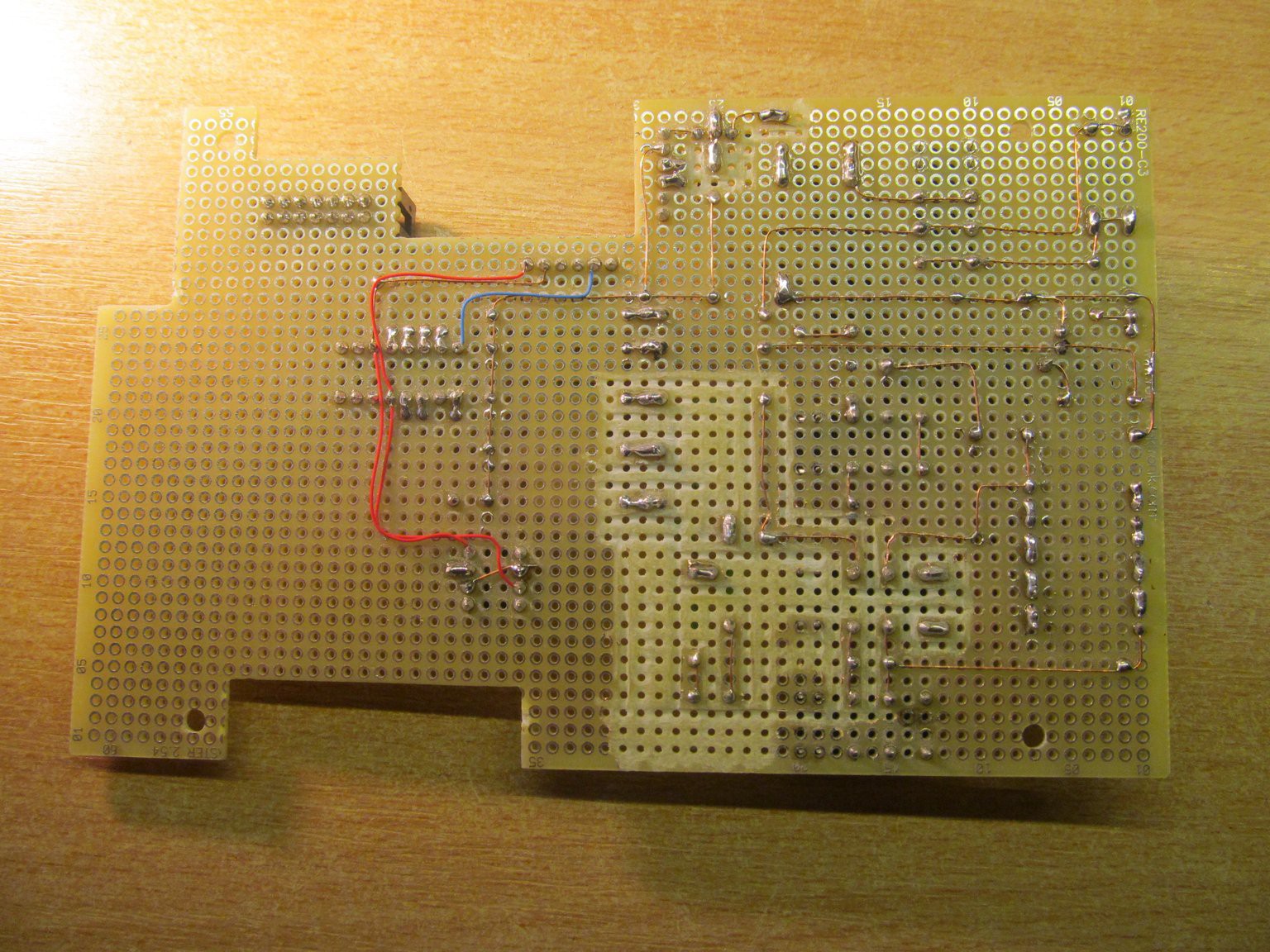

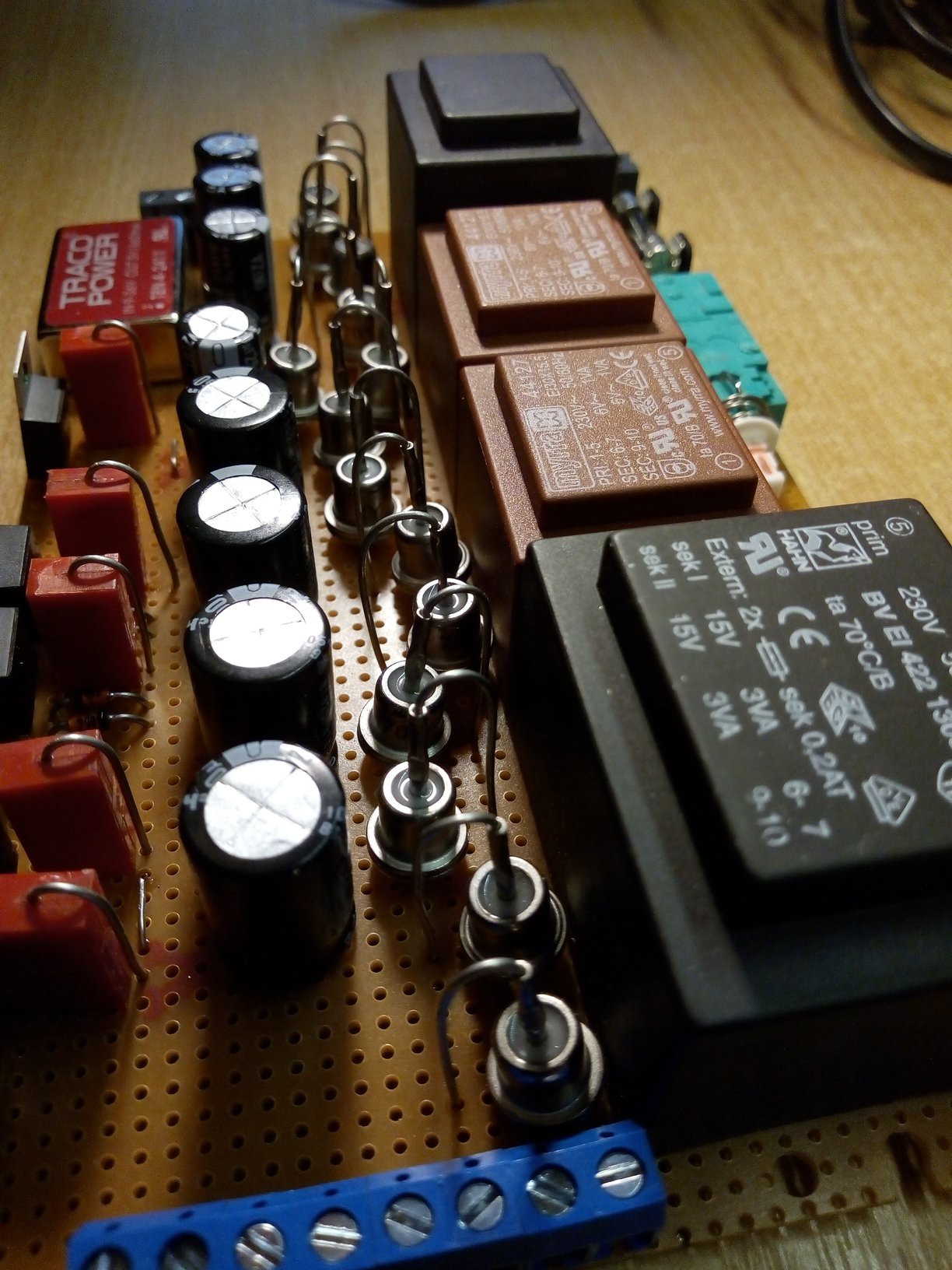

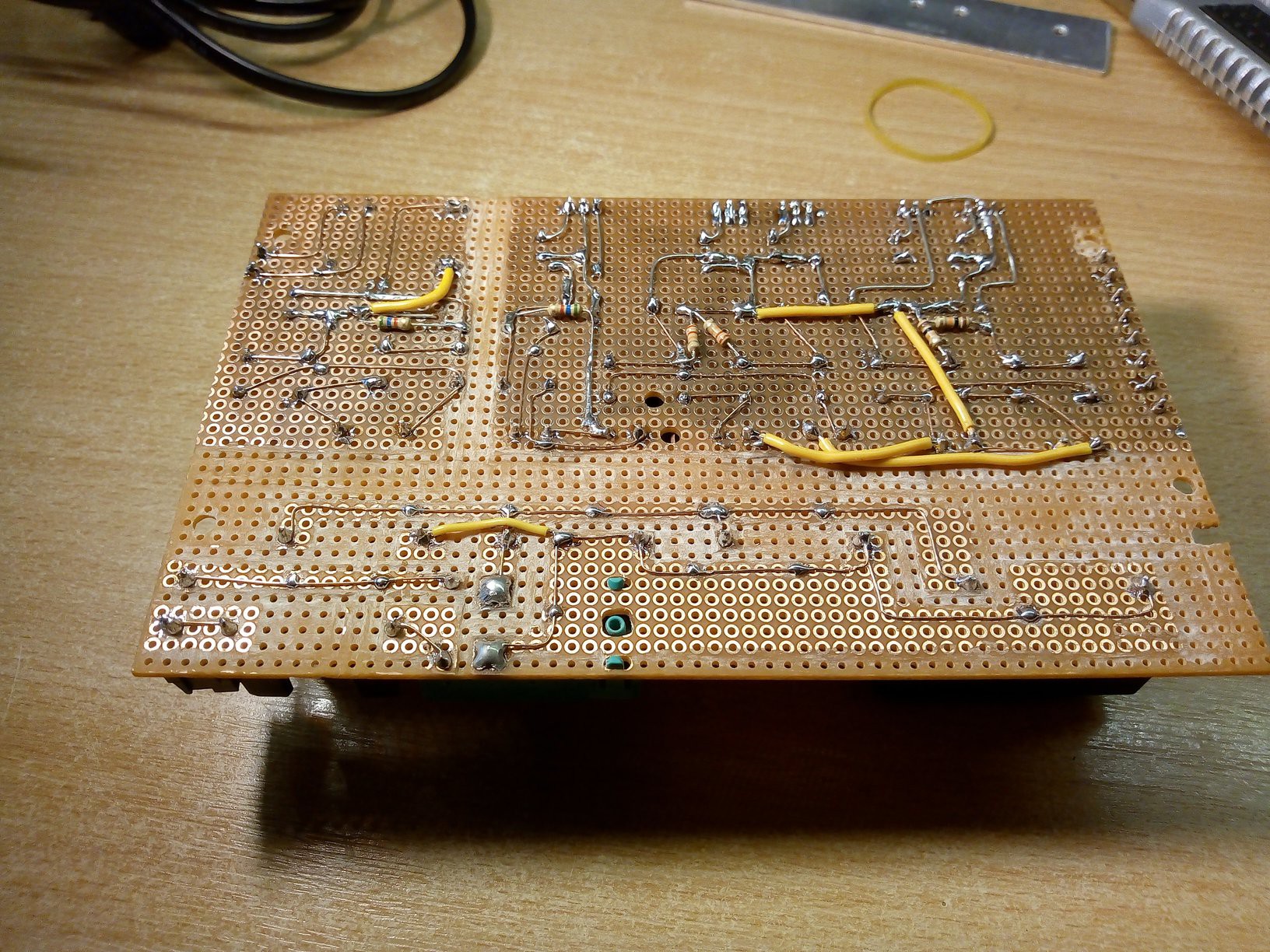

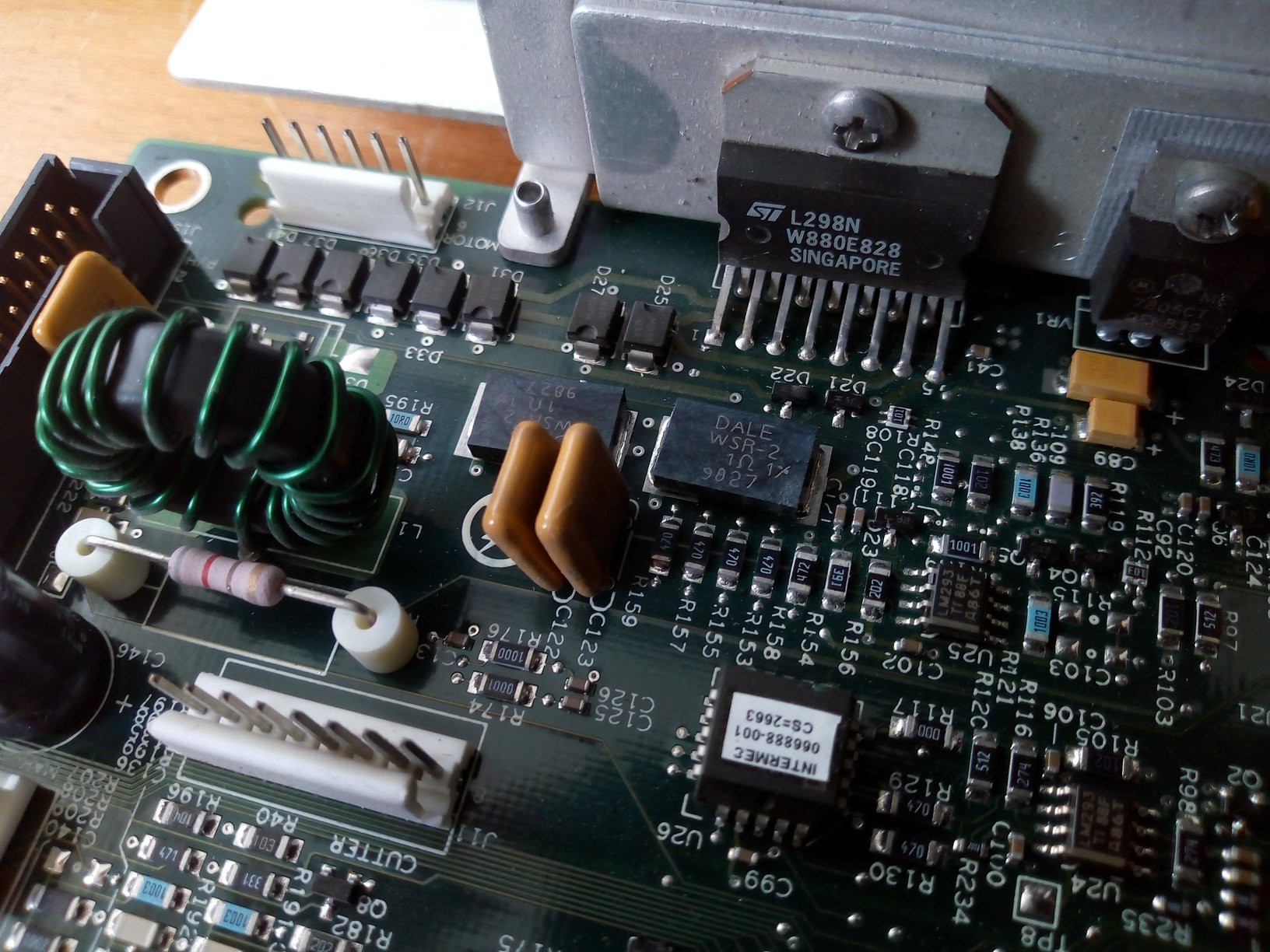

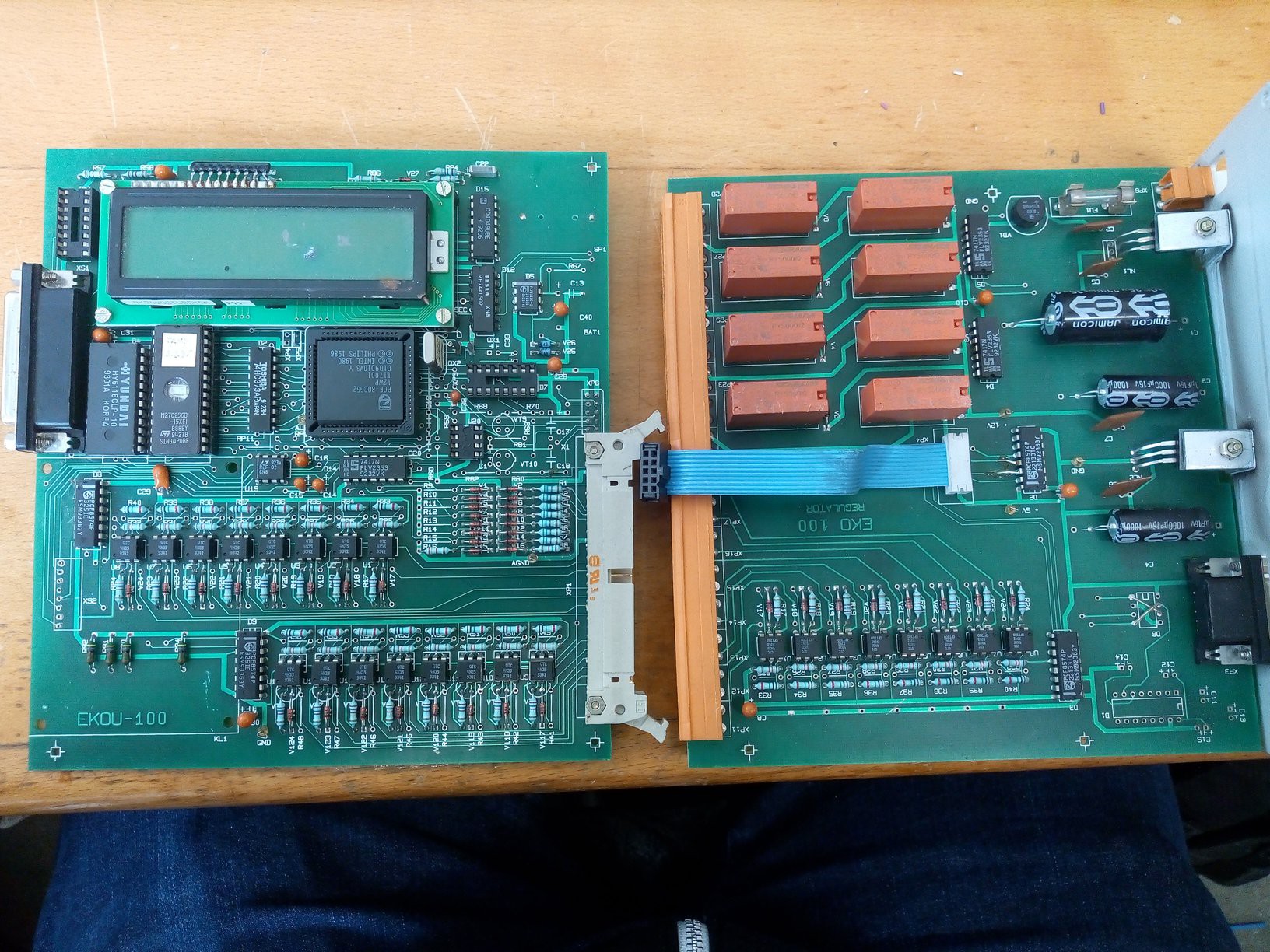

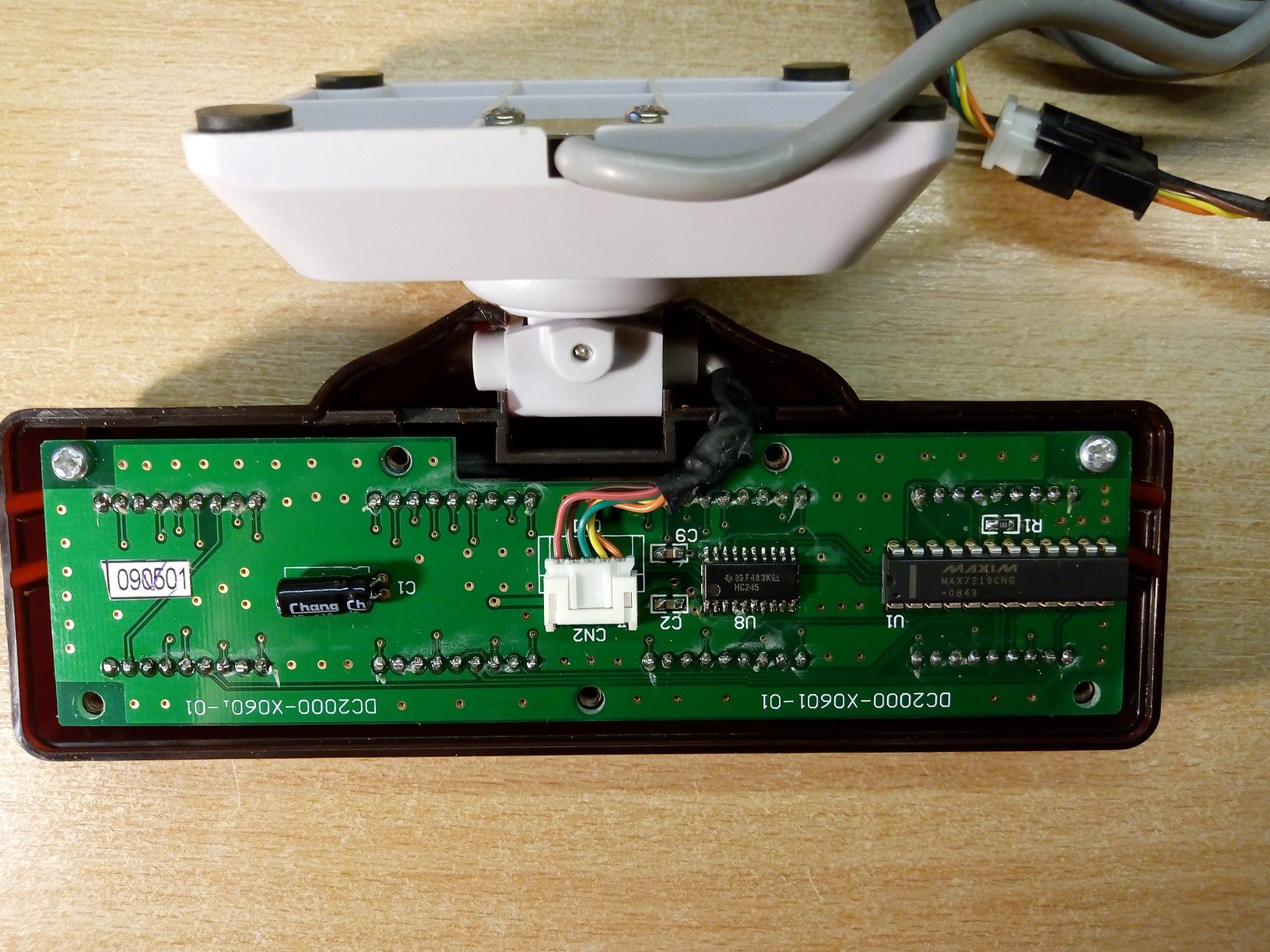

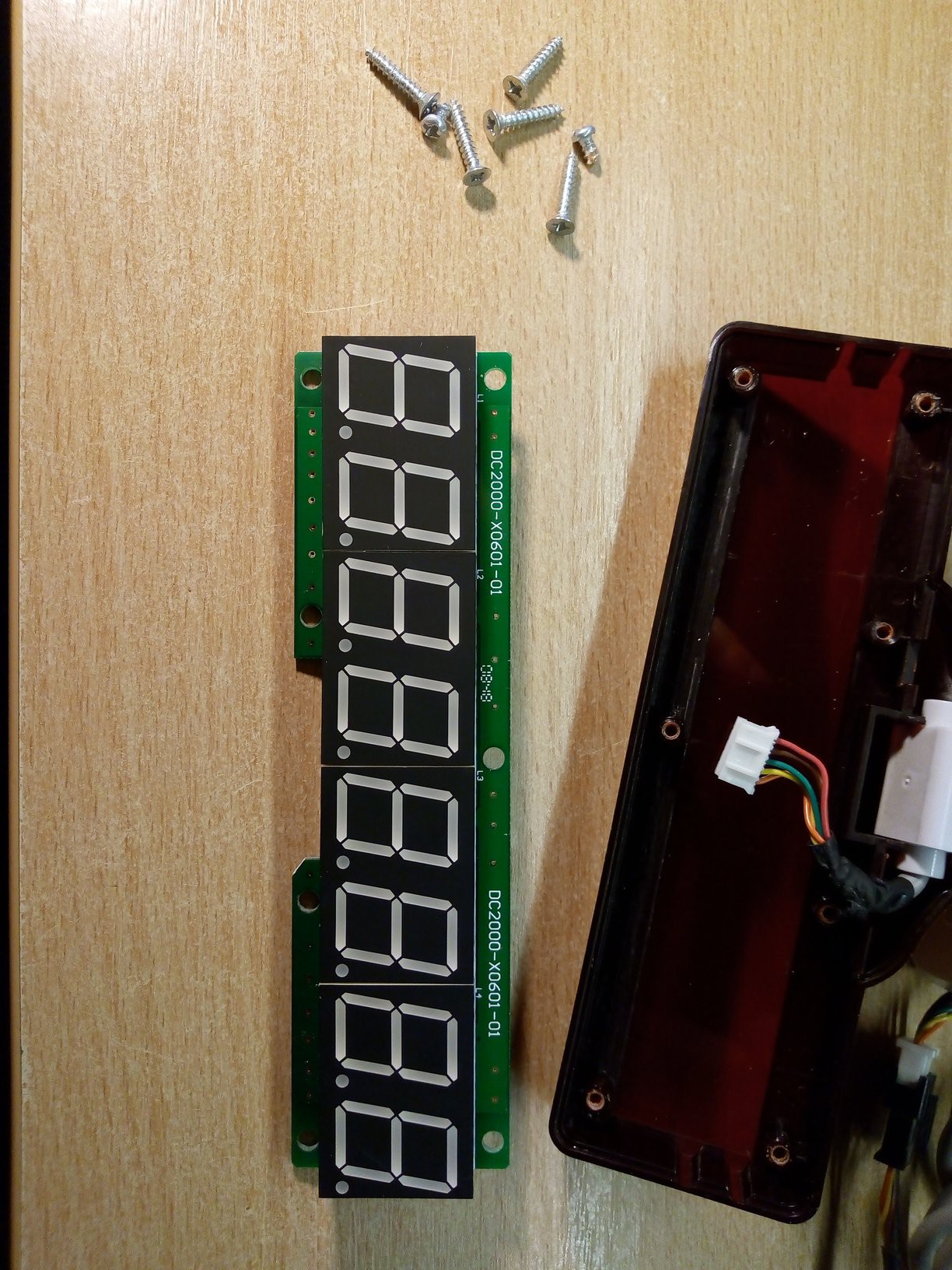

Design, part 2 - power supply, parts scavenging

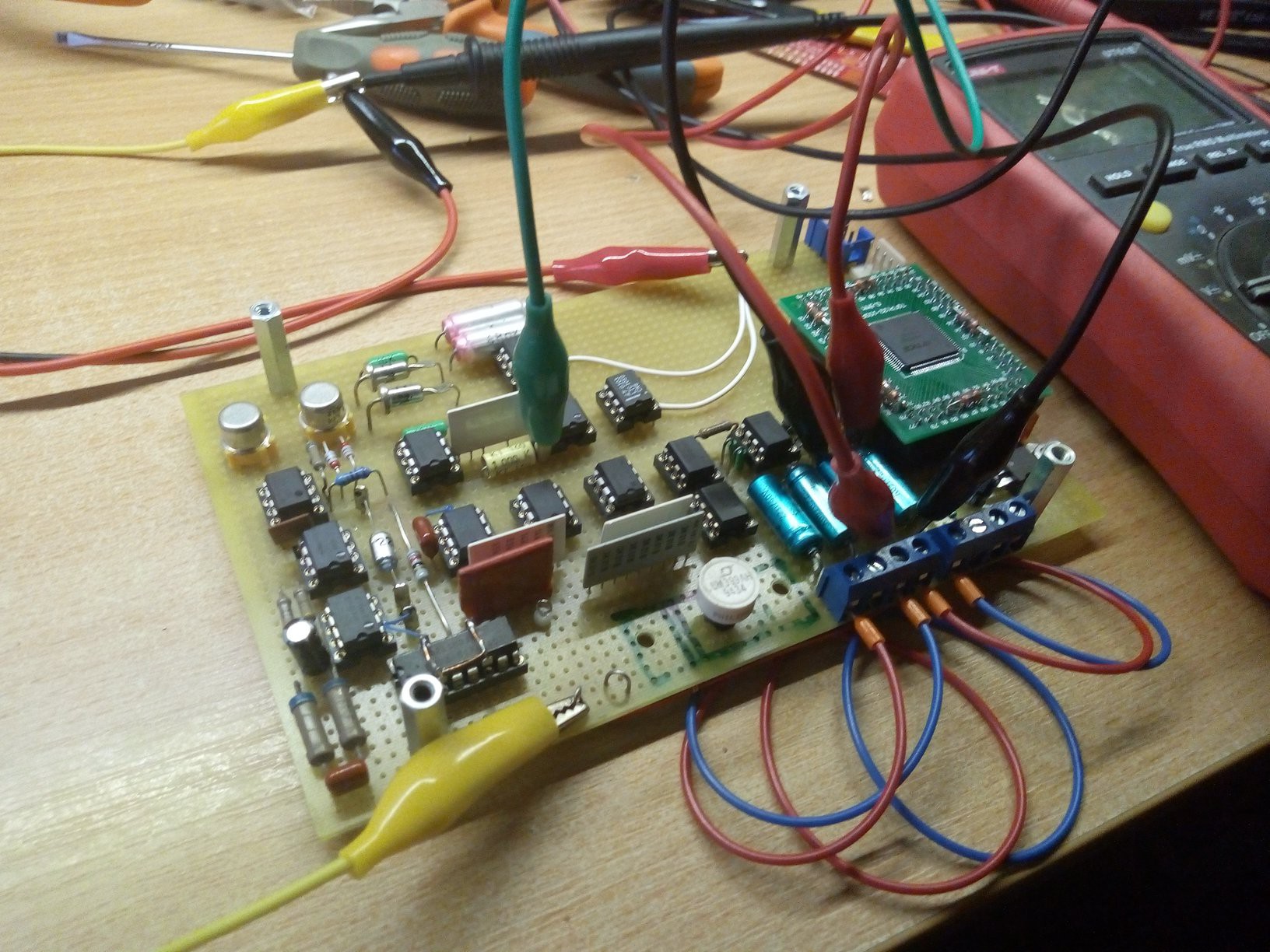

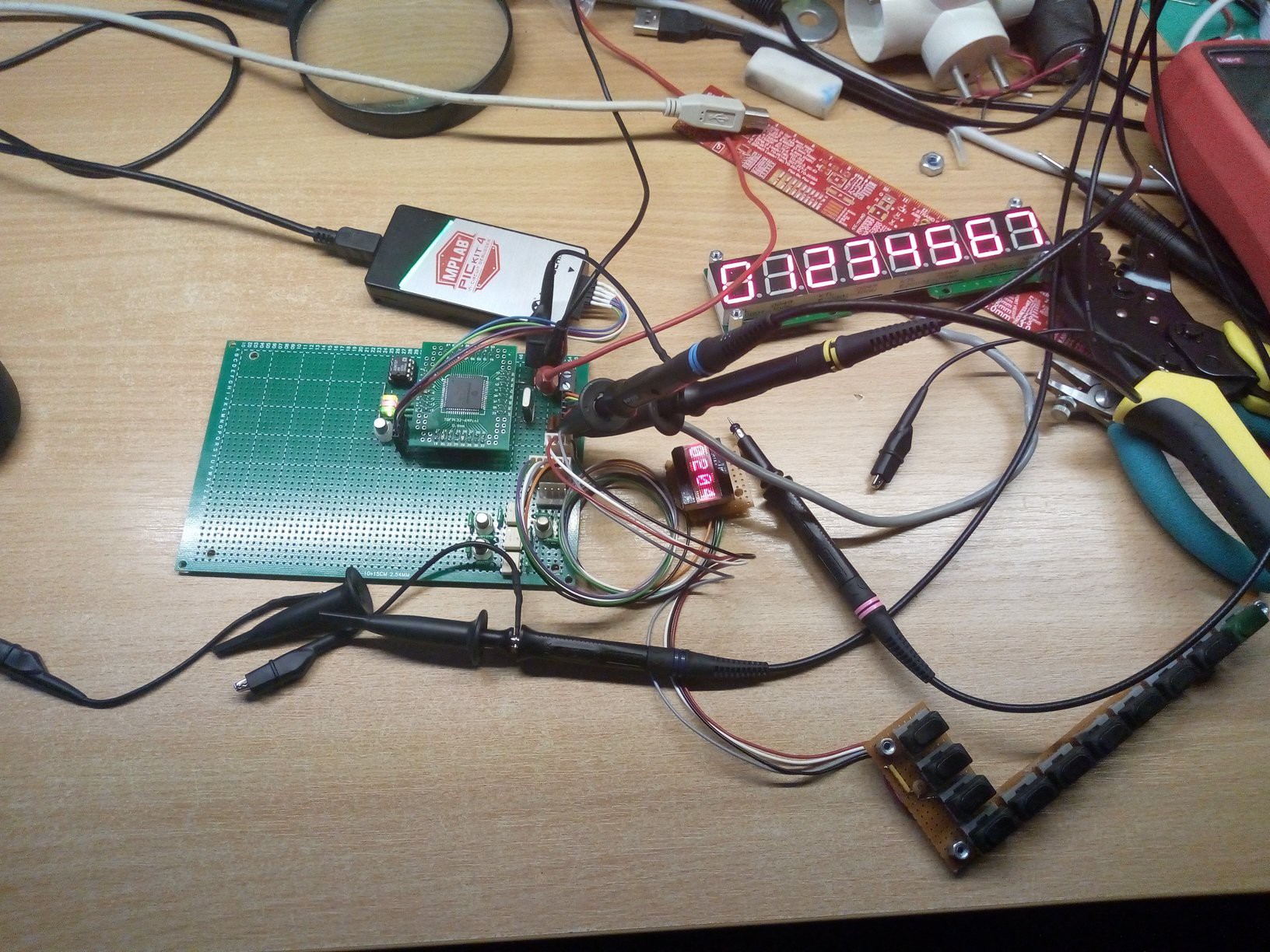

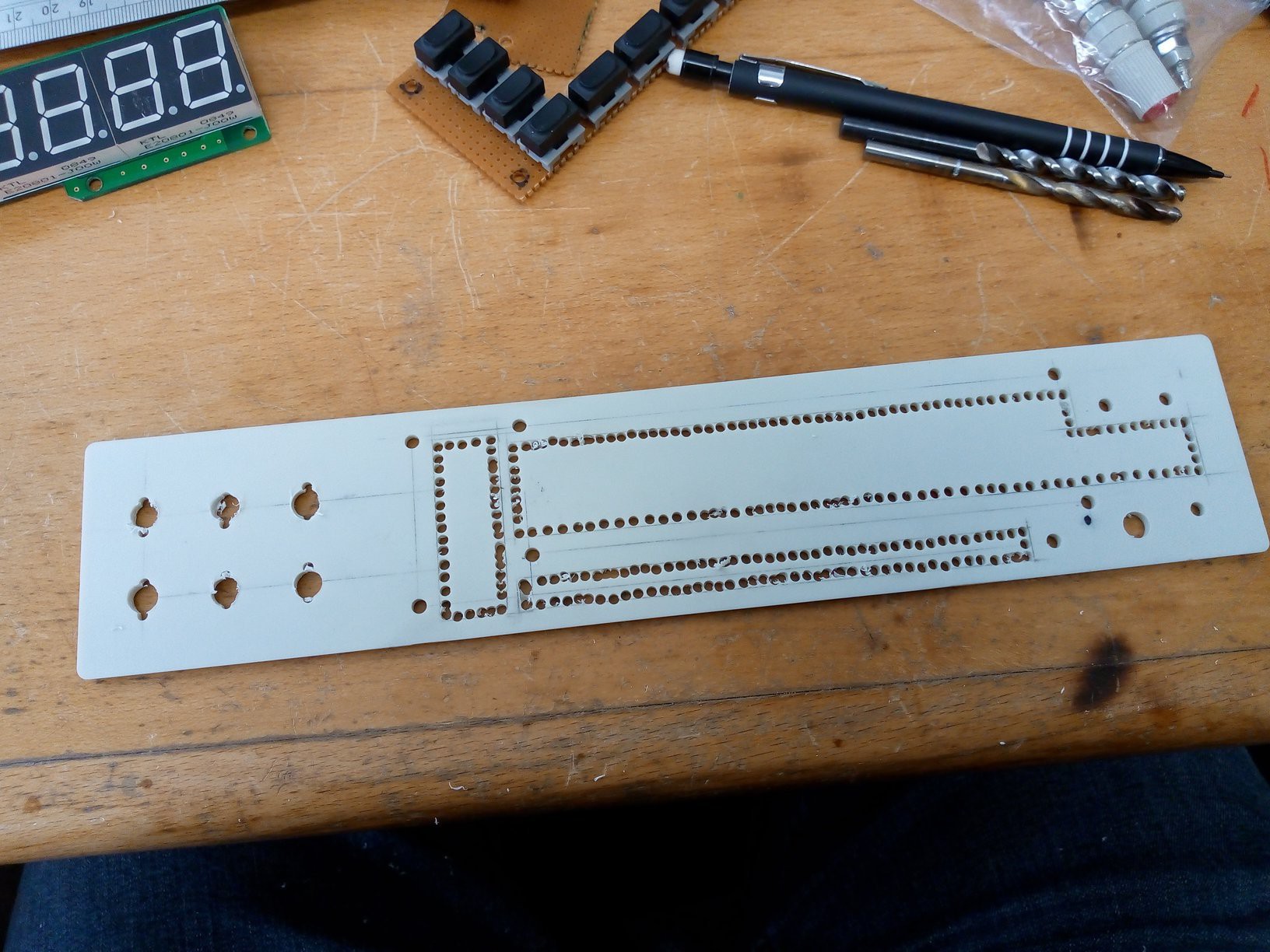

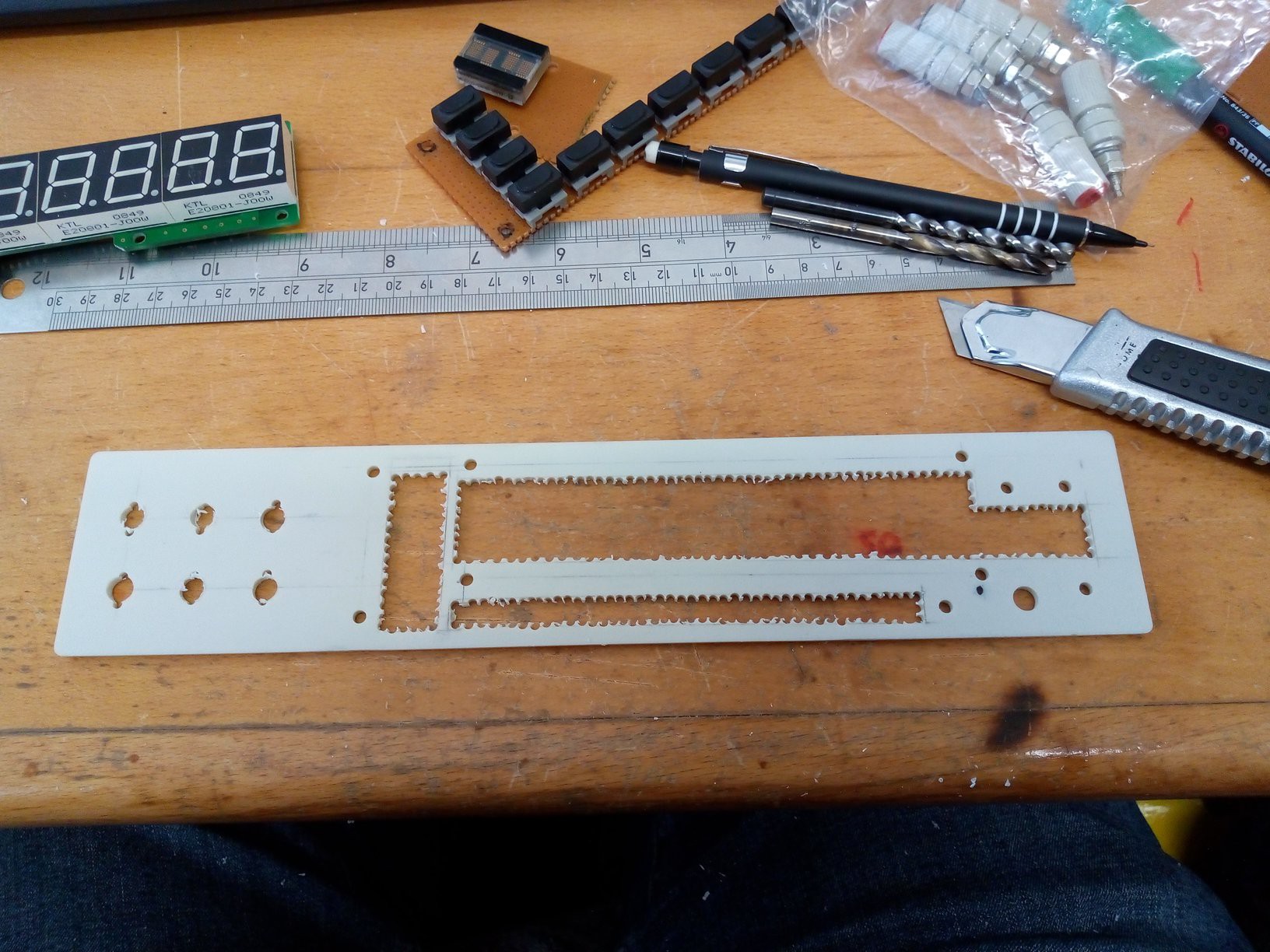

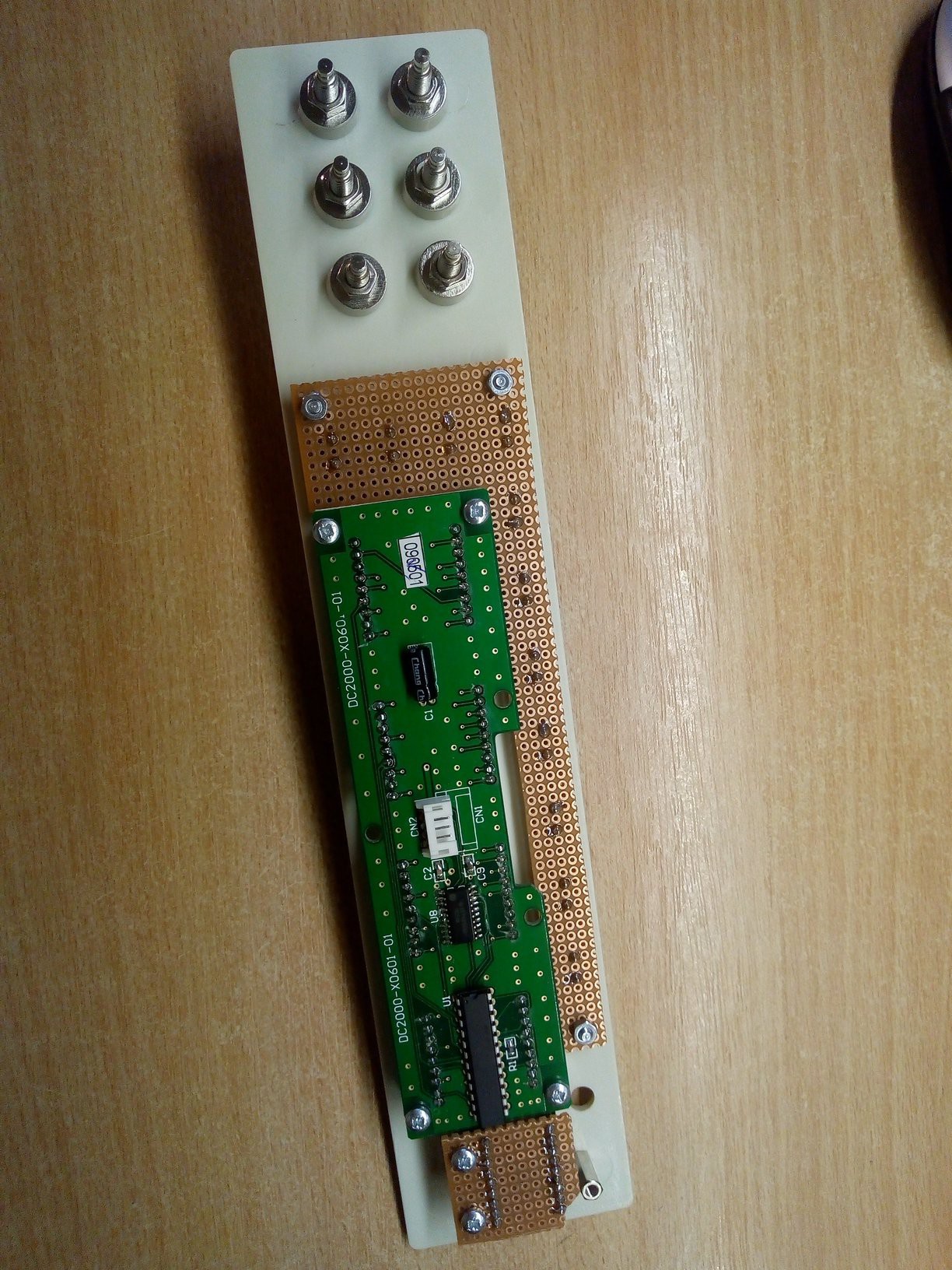

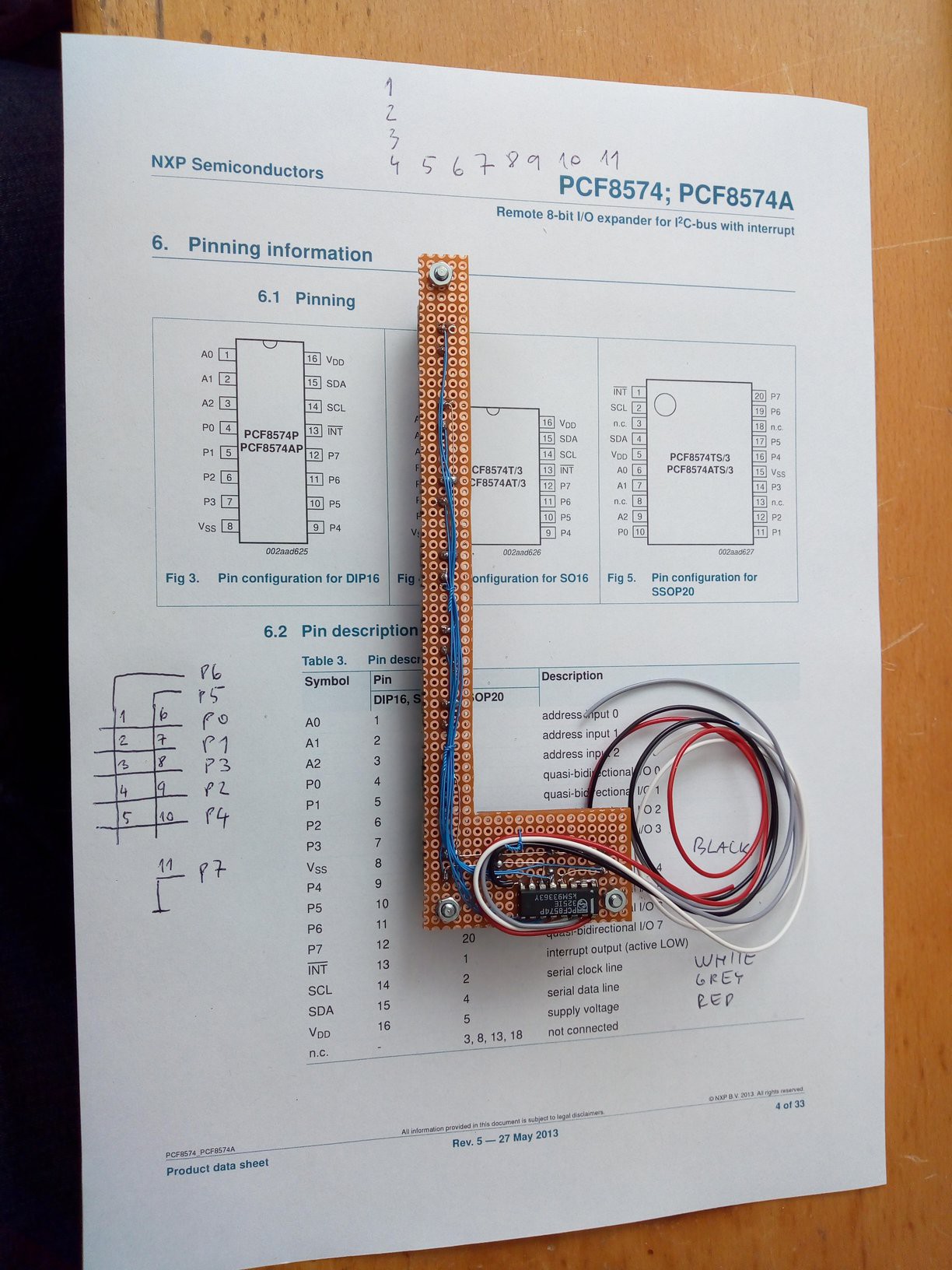

Design, part 3 - the real deal

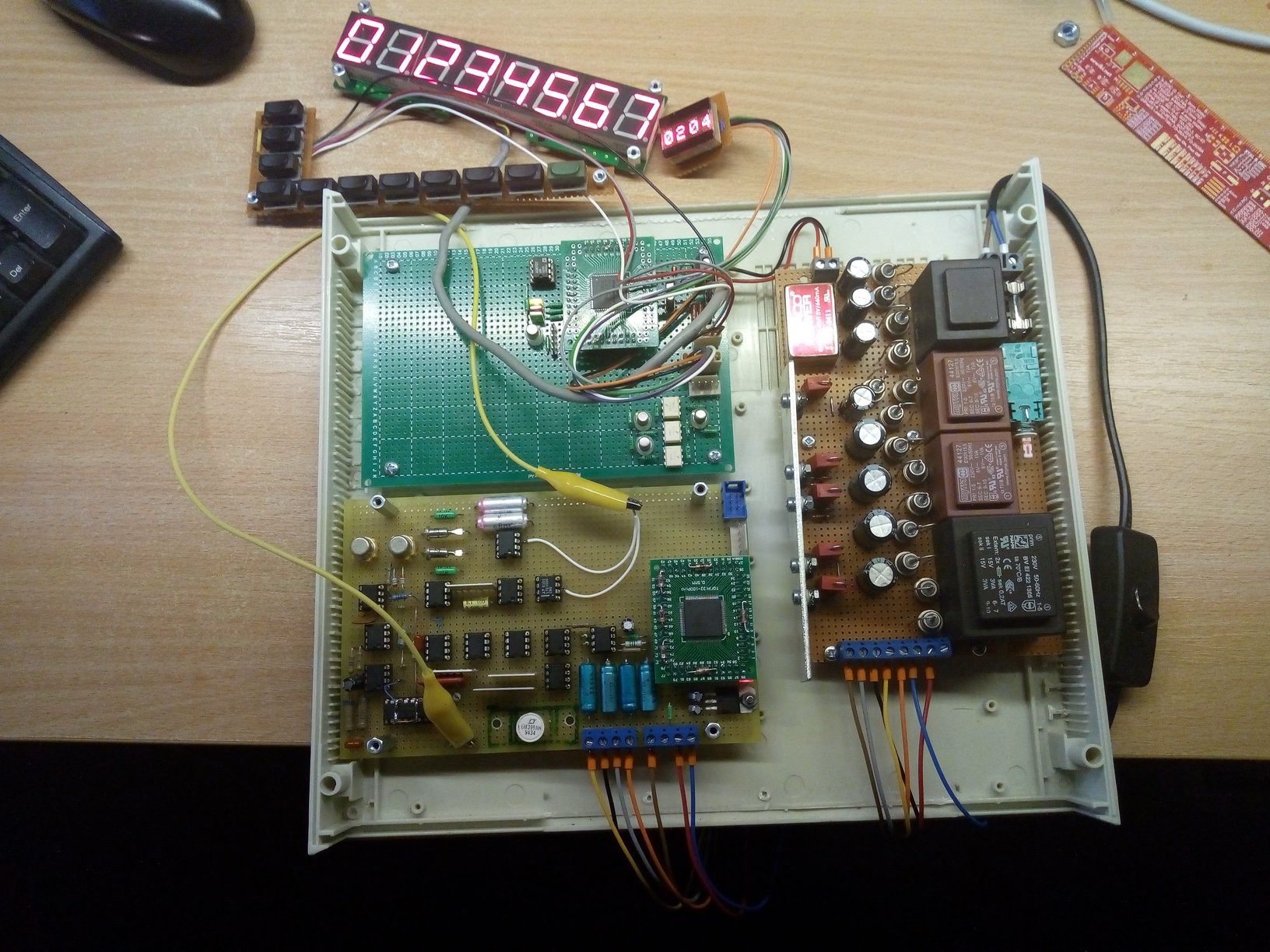

Design, the end - final remarks

Short demonstration video

jaromir.sukuba

jaromir.sukuba

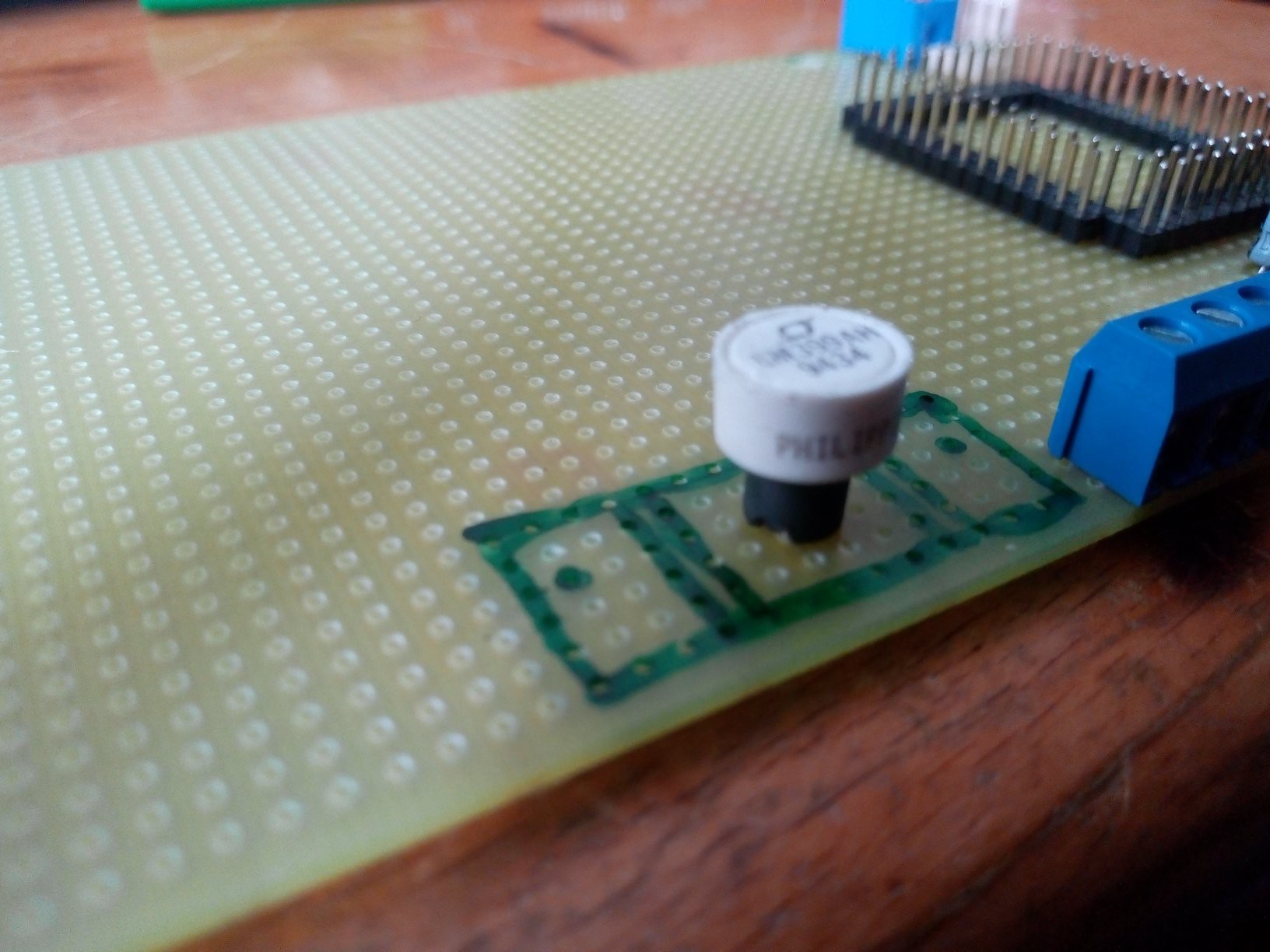

Row of diodes

Row of diodes

2bluesc

2bluesc

Mastro Gippo

Mastro Gippo

Hello,

I really like your project and I think I can help you to make it.

Thankful