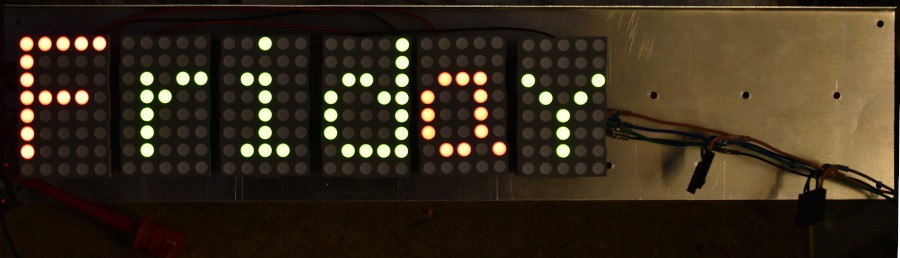

The rev 1.1 PC Boards are back from OSH Park. I built up all three of them. They are much quicker to assemble since all of the components are on the top side of the board except the sockets for the LED Matrix.

I made sure to keep the bolt pattern and it's relationship to the LED Matrix the same as the rev 1.0 boards so they will both live on a mounting plate and be interchangable with the rev 1.0 boards. I also added resistors to support translating the low nibble of the I2C address that were lacking on the rev 1.0 boards.

I now have 6 of these boards built and operating, and I want 3 more. Those will be ordered this weekend.

The cost on these modules is higher than I am happy with. Separate driver chips (IS32FL3738) are used, one for red and one for green. There are only 4 options for I2C address selection on these driver chips, so I added an I2C address translator to each board to allow running more than 2 boards on an I2C bus. The PCB is a 4 layer board. I chose to use a 4 layer board to get low impedance ground and power distribution to both display drivers and the address translator. Also, the driver chips have a heat spreader pad under them and I wanted to be able to use a ground plane for heat sinking the drivers.

Poking around in the projects on Hackaday, I found a project that is very similar to this one: #PIXIE - Chainable, Dual 5*7 Micro-LED Displays! The display driver chip (IS31FL3730) used on that project is capable of driving both the red and green matrices in the display, so I laid out a board to use that chip. These chips also support 4 choices for the I2C address, but only one chip is needed per board, allowing up to 4 displays on an I2C bus segment. I removed the I2C address translator and added jumpers to select the address and enable/disable the I2C terminators. My concerns about heatsinking the driver chip did not seem warranted with the rev 1.0 boards, the drivers only run a few degrees above ambient temperature. With a single driver chip to supply power and ground to, a 2 layer board makes more sense. With the changes listed above, the parts count is less than half of what the current boards are using, and it will go on a 2 layer board. To get the same functionality as the previous boards, either bus multiplexing or address translators are going to have to go into a system somewhere. A prototype board for the new driver is ready to send out to OSH Park.

The new driver chip handles the two matrices in kind of a strange way. One matrix connects to the driver pins labelled row[8:1} and column[8:1] matching the LED pin designations. This is a common cathode matrix. The second matrix looks to be a common anode matrix, but since both matrices in the LED block are common cathode, I rotated the second matrix, connecting driver rows to LED columns and driver columns to LED rows. It is not clear from the documentation whether the hardware corrects for this in the registers for the second matrix or not. I am just going to have to build one and mess with it. If the hardware does not correct for this, it will be necesary to do the pixel rotation in software.

It is not clear what the maximum LED current is for the new driver. The electrical specs in the data sheet say that the maximum is 40mA, but in the register set description, there is an option for 75mA. Running 40mA per LED may be enough, but that is another thing to test when the boards get back.

The IS31FL3730 uses my least favorite package for assembly at home, the QFN leadless package. None the less, it is worth trying. It is not like there is a deadline or anything.

Bharbour

Bharbour

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.