Log catch-up campaign: closing in on caught up so I can get back to work getting ahead of logs again.

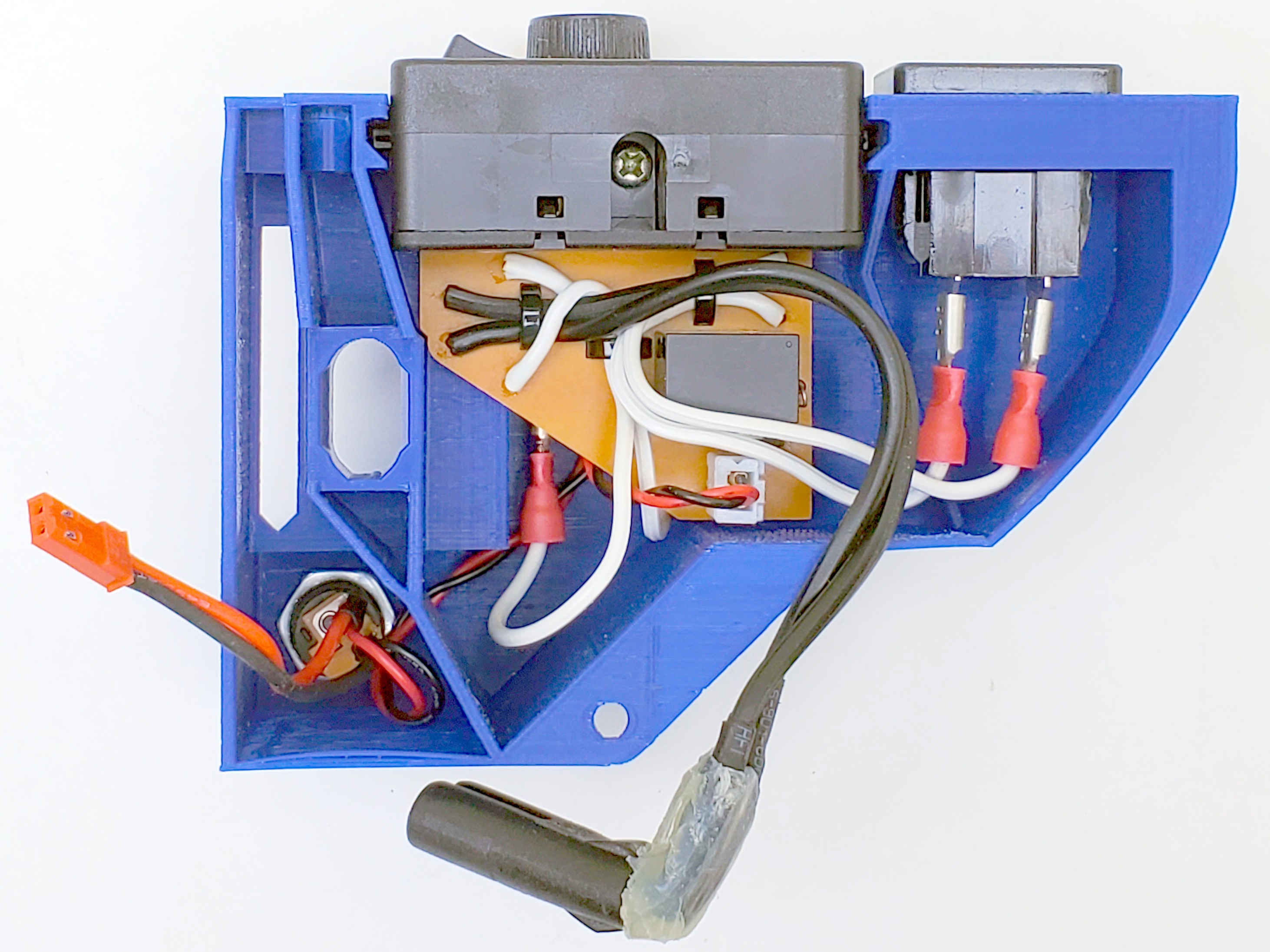

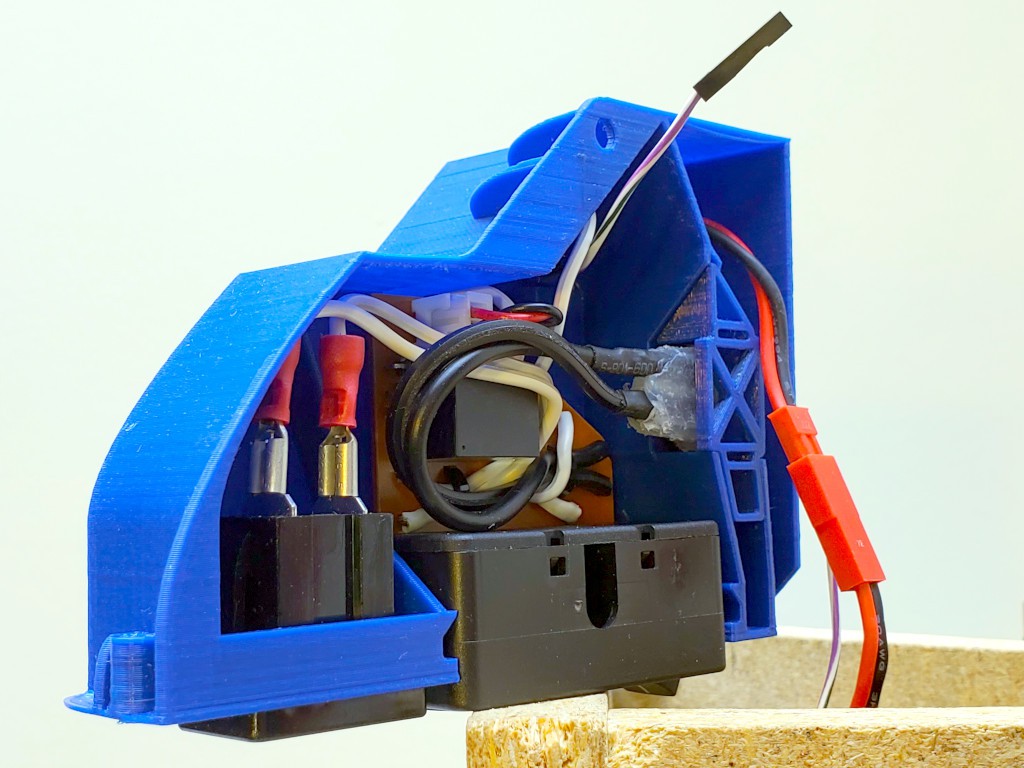

So I've got this box with a few compartments and a plan to keep all the AC power wiring in the top compartment in order to separate "high" voltage from low voltage DC.

This iteration of the AC stuff seems to be at least ok. For me; for now.

I've made this harder for myself by chasing conflicting ̶r̶e̶q̶u̶i̶r̶e̶m̶e̶n̶t̶s̶ aspirations.

And I don't know jack about "best practices" for making stuff with line voltage AC in it. If I may quote myself from elsewhere:

Dear reader: this is random Internet "content" by an unqualified author for entertainment only. Misuse of [mains AC] can kill you and burn your house, which may entail killing other people. How to do anything with [AC] other than what the label says without burning stuff or killing people is beyond the scope of this writeup. Consider this first-person account as a pre-staged footnote for my eventual Darwin Award and not as instructions for anything you should do.

For AC stuff, I wanted

- onboard DC supply

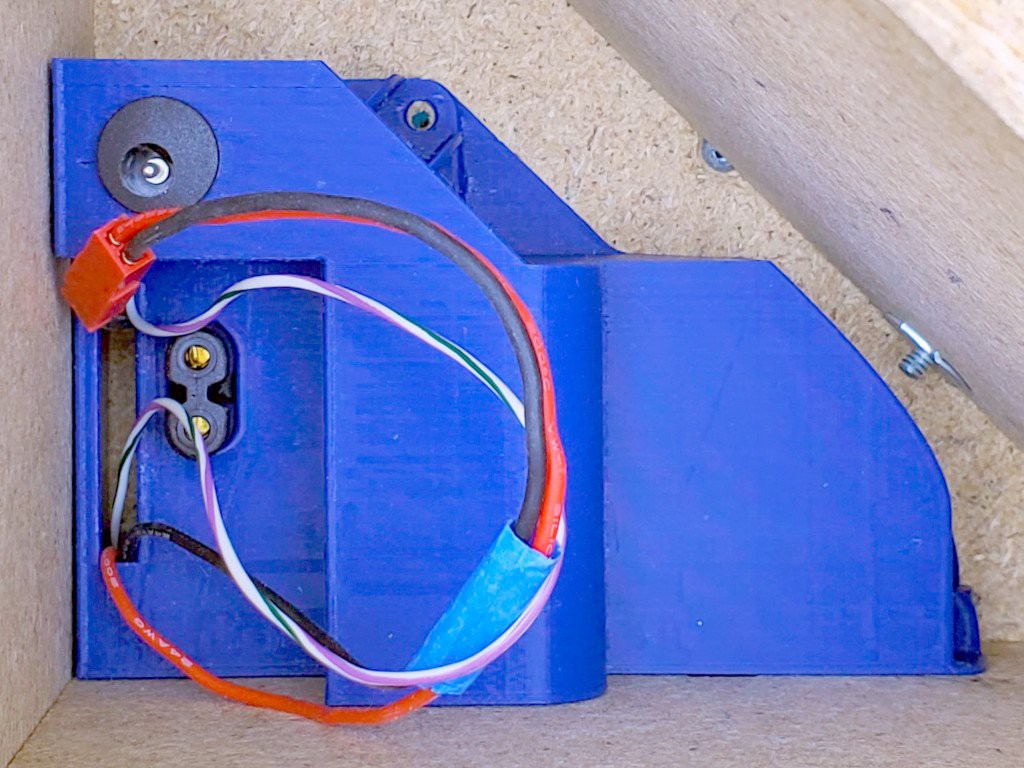

- inlet - because I wanted a clean box exterior without a hardwired cord (hardwired out the top was an option)

- fuse

- switch

- relay-switched outlet for "spindle"

- logic-switched relay

- US ungrounded, polarized outlet (NEMA 1-15R)

Not rocket science.

I figured that could fit in something less than all of the volume of the upper compartment, leaving some room to stash stuff like the power cord and most of the dremeloid cord. I started out thinking that would get done with a simple partition to divide the space into AC (closed) and storage (open). But I didn't come up with a simple partition that seemed like a good use of the space. Which got me thinking about a less simple, more conformal, probably 3d printed, enclosure for the AC stuff inside that compartment. Which lead to greed for the most space for storage which meant fitting the AC stuff into the least space without crowding stuff that shouldn't touch or mashing soft insulation between hard parts.

For this iteration, I decided to use a double-insulated power brick with a C8 inlet for the benefits of having that already robustly enclosed/insulated and also the more compact power cord vs the common grounded 15A "IEC" type (i.e. C13) cord.

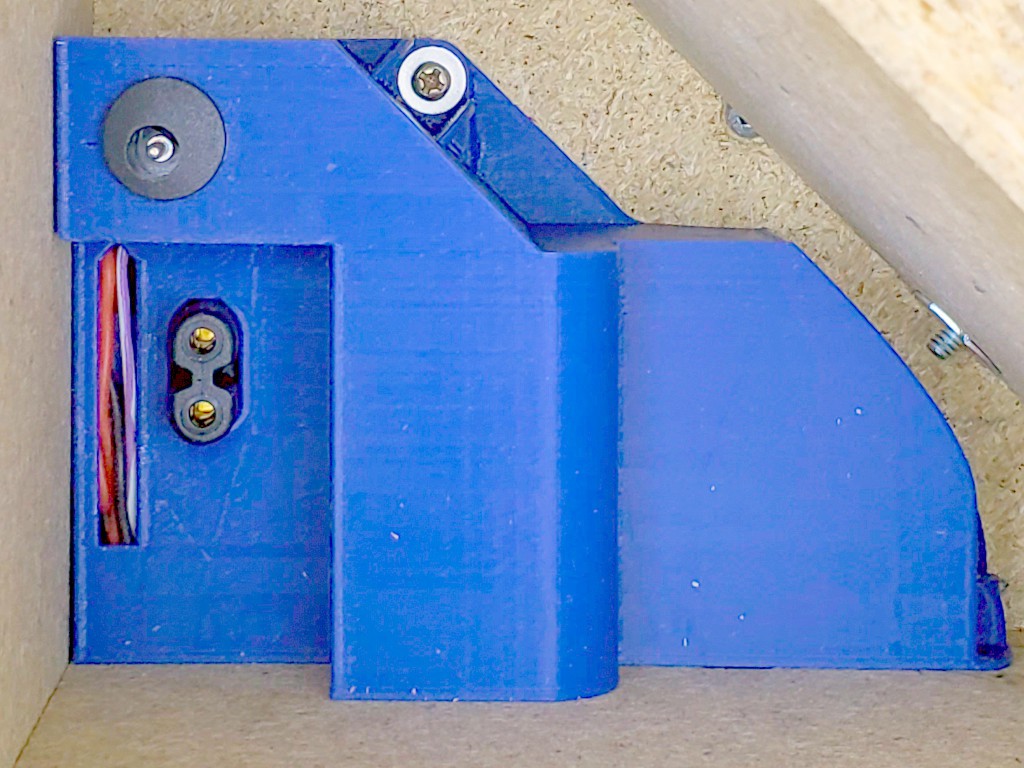

The Unified AC Widget fits into the corner with the power supply.

The DC-out cord from the supply could be cut down to the minimum needed to make the connection.

The DC-out cord from the supply could be cut down to the minimum needed to make the connection.

Cutouts in the back wall of the box expose the interactive bits.

Stuff inside is compact without crowding.

In addition to the inlet/outlet/fuse/switch out the back, this includes a ̶b̶u̶t̶c̶h̶e̶r̶e̶d̶ right-angle C7 plug for the power brick, the red connector for 12VDC power down to the low voltage electronics & motors below, and the mostly hidden connector for the logic-level spindle enable signal coming back up. A second tap off the DC input jack feeds the relay coil, relying on the relay & trace separation on the circuit board for galvanic isolation from the high voltage stuff.

If I build this configuration again, I'll get a right-angle plug for the power supply instead of farting around for the usual longer-than-expected time to make one with random dimensions.

I should probably use insulated quick-connects or some such to make this unit itself more nearly something like double insulated.

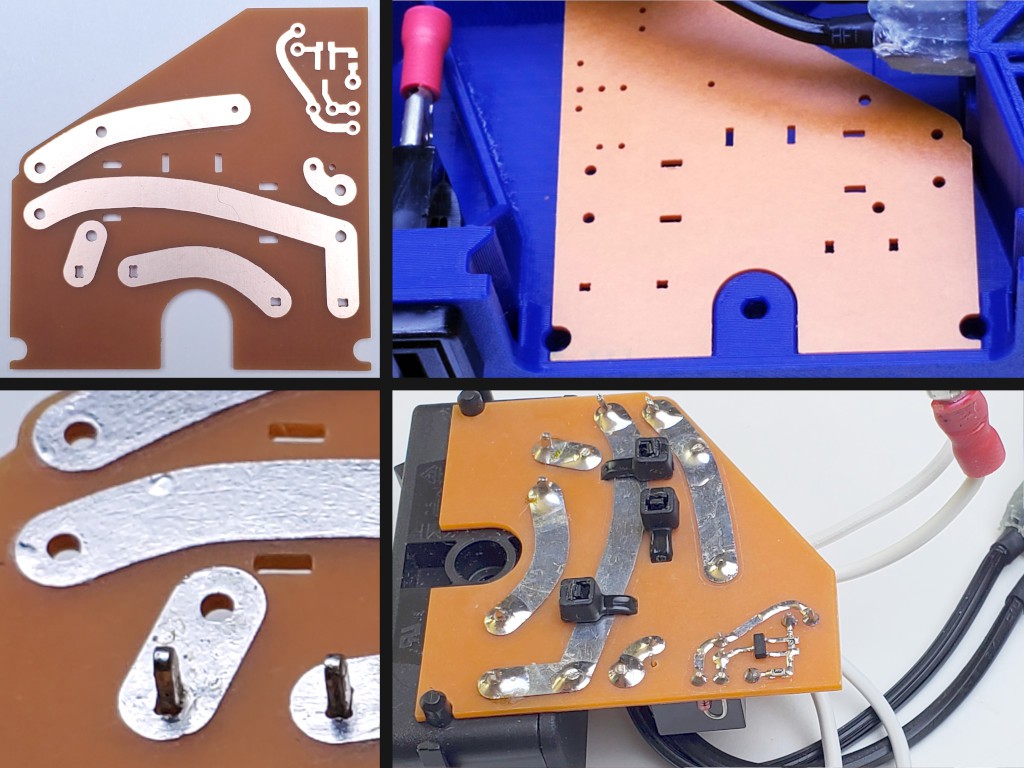

The circuit board helps compactify this and make it less of a crammed jumble of wires. That was something of a flag day for the project:

Minamil mills a circuit board for itself

I think that's kind of a thing. Part of the RepRap quest is (was, now that manufactured 3d printers are cheaper than BoM for DIY) the self-replicating machine that can make its own wiring. Here, with very little additional hardware, a 3d printer can print a very little sidekick that can make circuit boards.

Lessons learned from earlier iterations include:

- this needs to be disconnectable from the writing that stays with the frame

- dis/connecting stuff in the bottom of a deep hole is hard

- hoping a bunch of extra wire can be randomly stuffed into a small space isn't a great plan

As applied in this iteration, that looks like:

When worlds don't really collide

I burned a lot of time sorting this out and some more time starting a few drafts of long(er)-winded writeup. Bah. Here's the short version:

Along with wanting more free space up top for storage, I also wanted to fill less of it with a less bulky power cord than the usual 15A three-conductor "IEC" cord (C13) and I had an attractive candidate.

That cord has a plug that's a lot like a C7 plug that would fit the power brick, but polarized. "Polarized C7" cords are easy to find in abundance. Polarized C8 inlets? Not so much. In fact "Polarized C7/C8" does not exist in the IECverse. Polarized "C8" inlets exist (e.g. top photo) but not nearly as easy to find or in such abundance as the plugs. (So where do the things the plugs plug into come from?)

-and-

My dremeloid rotary tool has a polarized ungrounded plug. Apparently because I live in the US (North America). Why? Dunno. It's marked as double insulated and the same thing is sold in other highly regulated markets with an unpolarized plug. The US (NA) retains a concept of polarized ungrounded power and receptacles accept polarized plugs. I supposed that's a good thing for old school Edison-type lamp sockets in fixtures that wontonly expose the threaded cup. But the same receptacles also accept unpolarized plugs so the receptacles didn't force the maker's choice of plug, and the same maker sells the same tool with unpolarized plugs elsewhere. Shrug.

So: US(NA) -> polarized plug; polariized plug -> needs polarized outlet; polarized outlet -> needs polarized inlet.

Alternatively, I could have cut down the neutral blade to fit an unpolarized outlet. But I was already publishing my progress at this, and that seemed like the sort of thing best done in private. Or I could have fed the polarized outlet from an unpolarized inlet, but that would ... just No.

If I wasn't bent on using the less bulky cord, or living in the US(NA), I could have used any of many lovely integrated inlet+fuse+switch units and moved on. If I lived somewhere else, I'd have spent a lot less time never learning that this was an issue at all.

(aside: For whatever their reasons, people want a polarized ungrounded appliance power inlet receptacle/plug and fie on the committee who would stop them from having it. For various reasons, the apparently accepted pirate C7/C8 variant was a poor choice. But I'm going to punt from writing any more about this.)

Paul McClay

Paul McClay

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.