One question that comes up alot is: “Why would you use this tool for UV curing, when you can use 5$ UV flashlight from eBay?”. Let's take an empirical approach to that question.

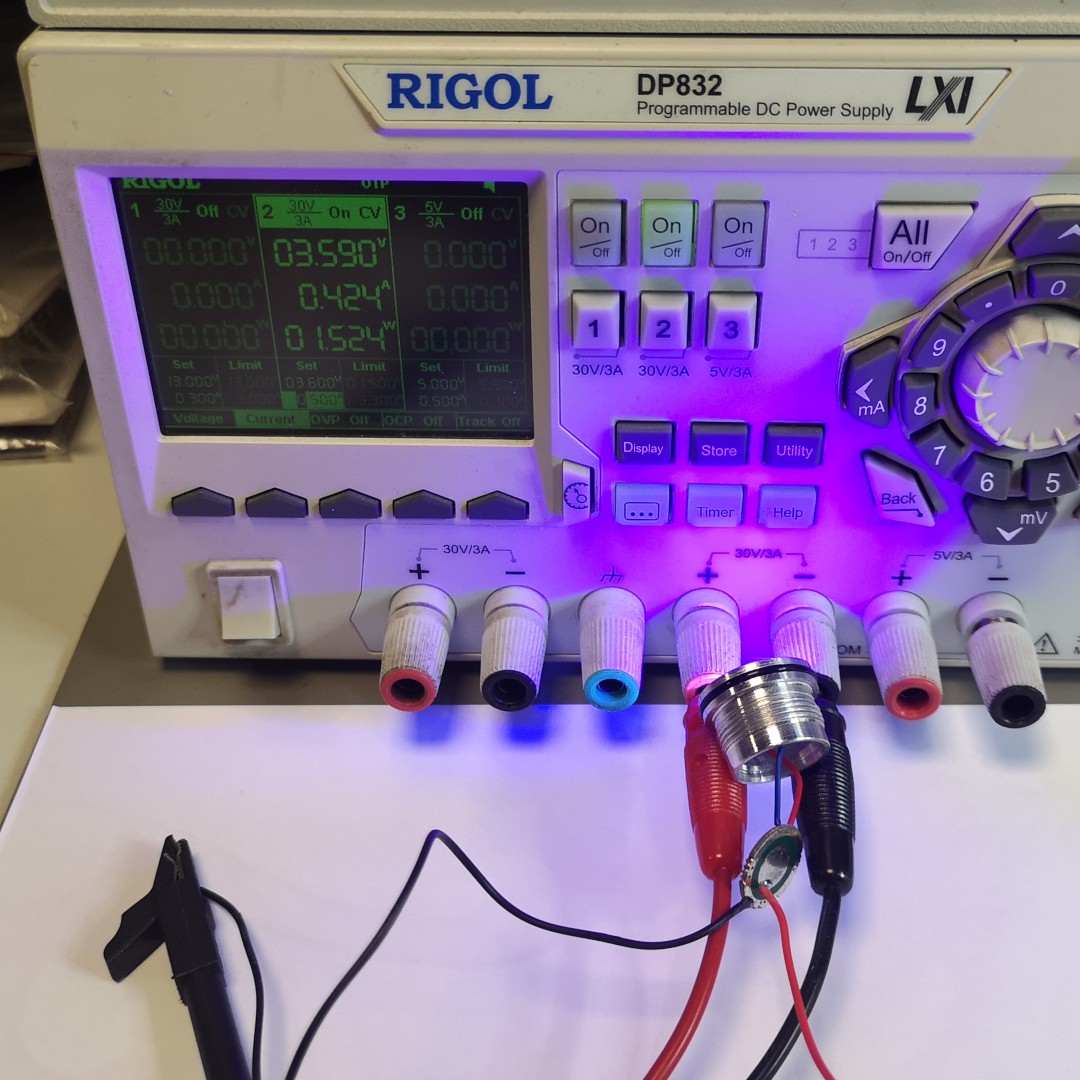

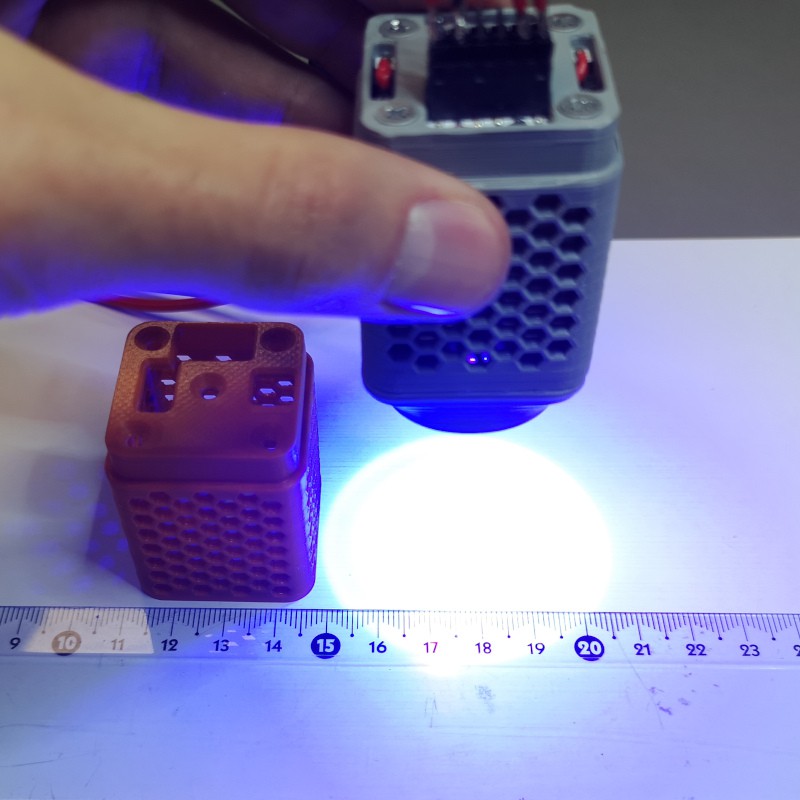

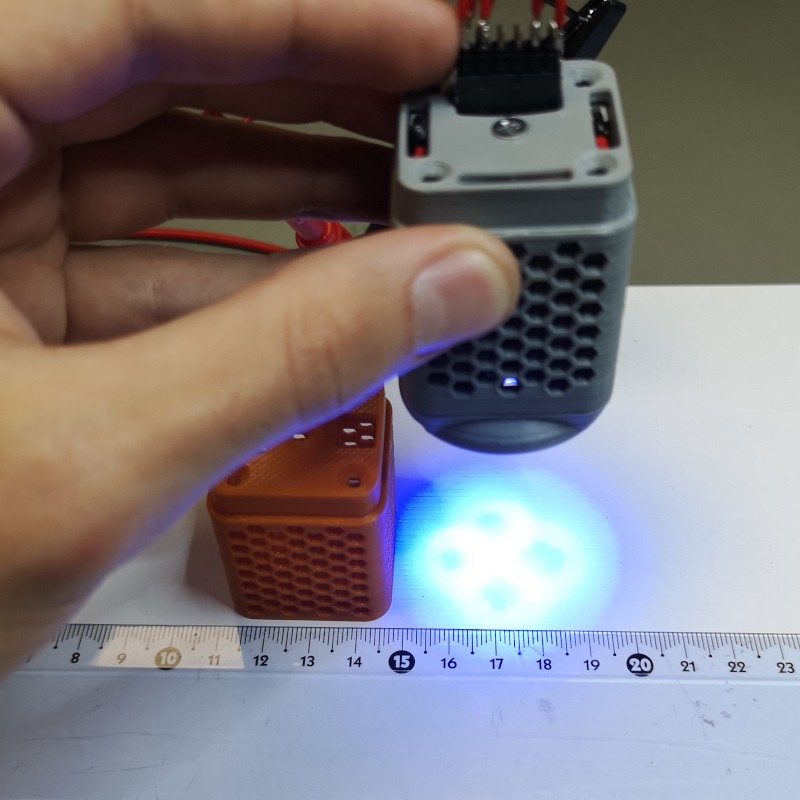

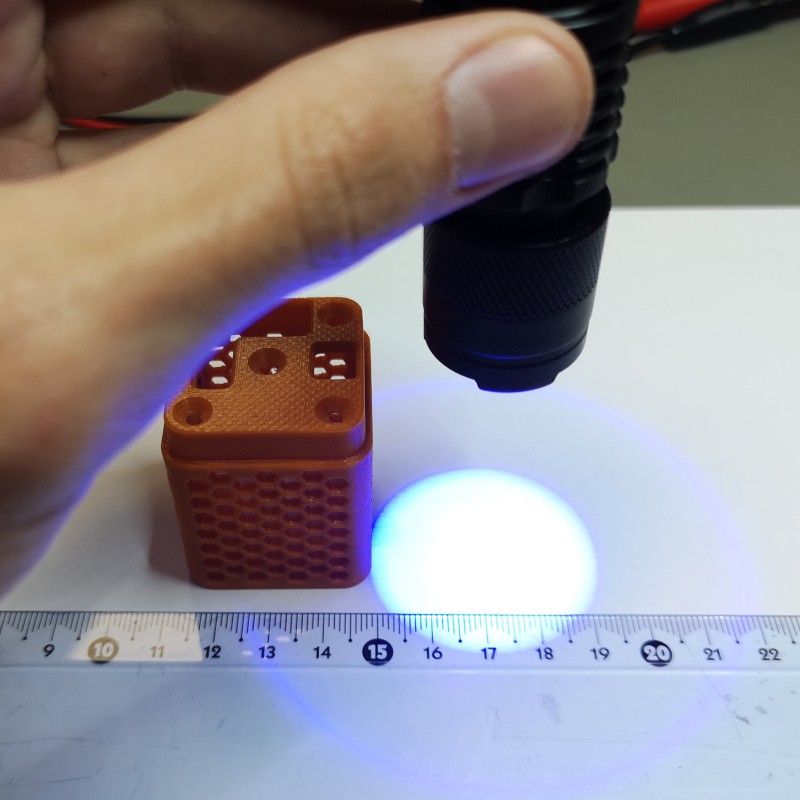

Pictured below is a 5$ UV flashlight. It has an aluminium case, adjustable lens and accepts a single Li-ion AA battery. Led with a heatsink and a driver board is also shown.

|  |

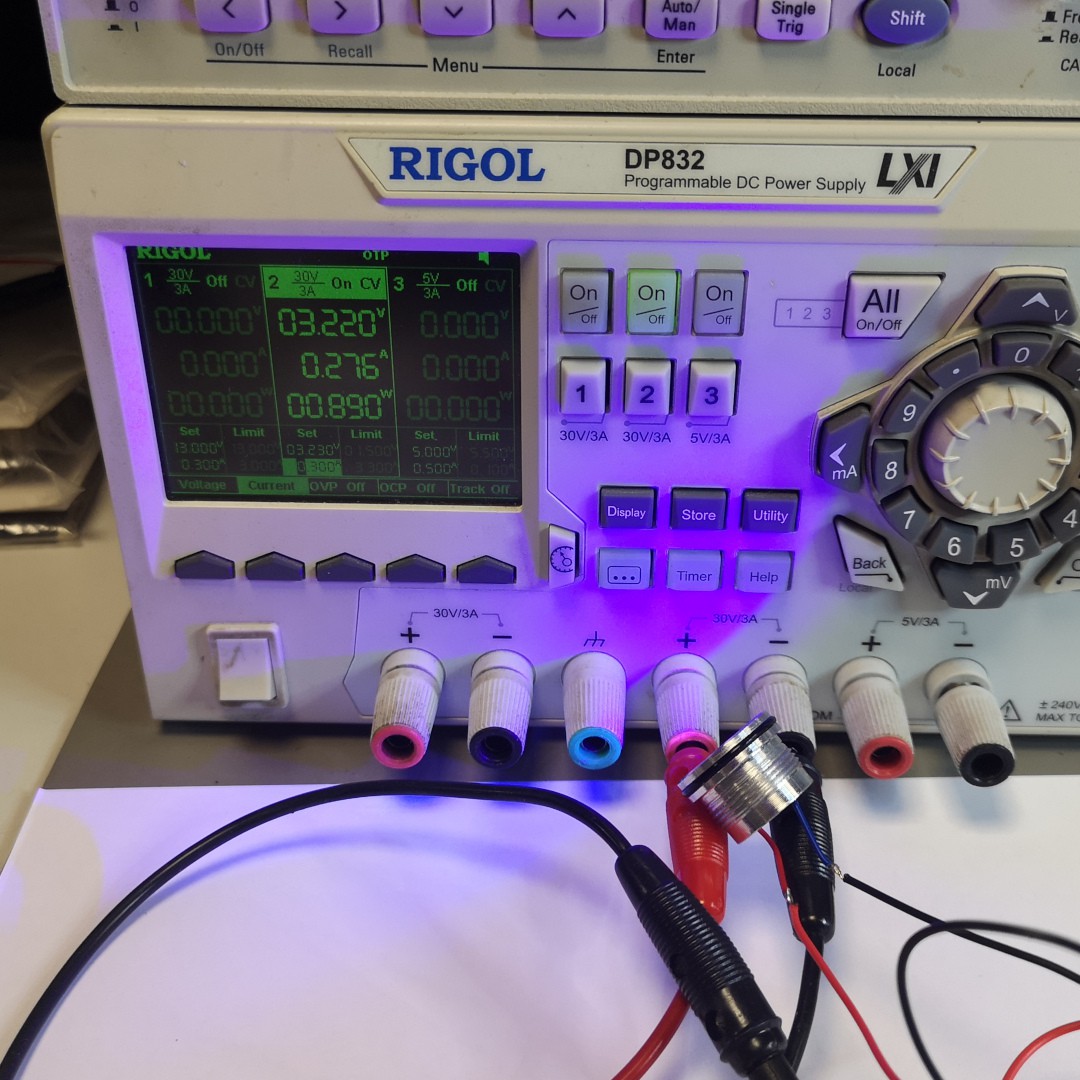

If the LED module is connected to 3.6V(nominal voltage of a single li-ion cell) it draws 420mA or 1.5W of power. Measuring voltage on LED diode with voltmeter shows forward voltage of 3.23V. When LED is powered with that voltage, it draws 270mA or 900mW of power. That means that the driver circuit has efficiency of 60% with above input parameters. If we assume 30% efficiency of wire bonded 3535 LED, that flashlight has radiometric power of 270mW.

|  |

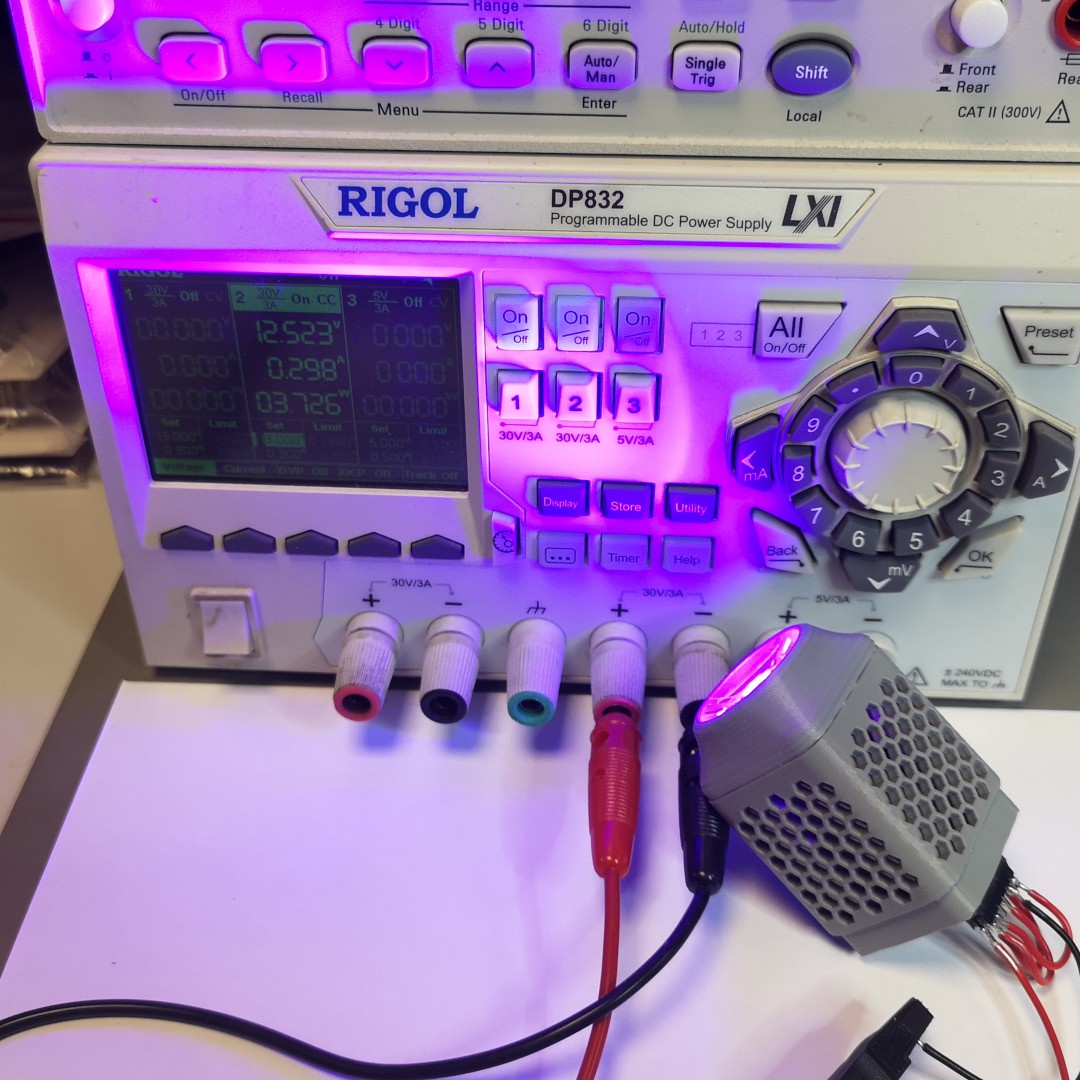

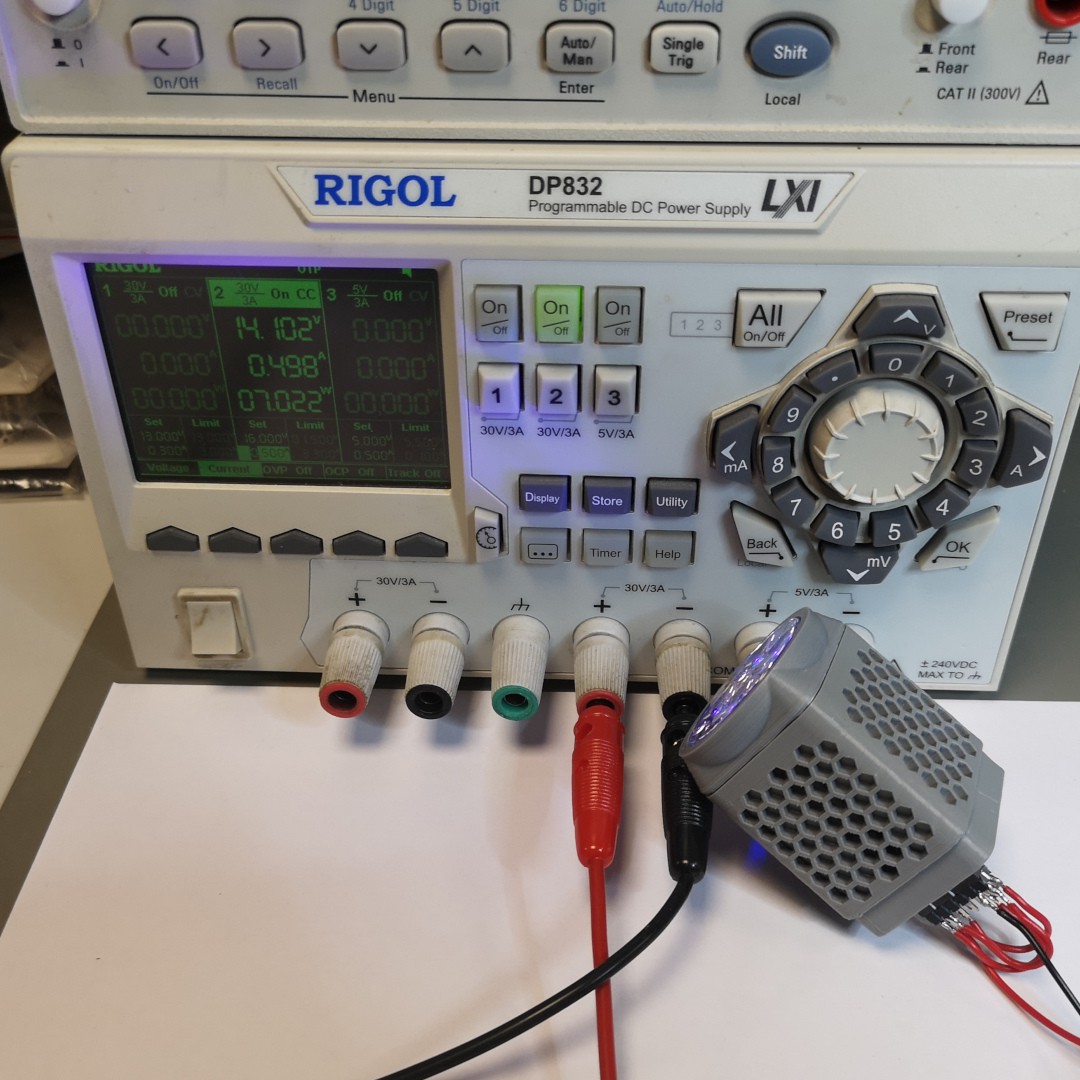

For comparison, PQ2N LEDs of Photon 400nm LED module consume 3.7W of power. With assumed efficiency of 45%(refer to datasheet) for CSP LEDs we get radiometric power of 1670mW. On the other hand LTPL-C034 LEDs on 365nm LED module consume 7W of power. With assumed efficiency of 30%(refer to datasheet) for wire bonded 3535 LEDs we get radiometric power of 2100mW.

|  |

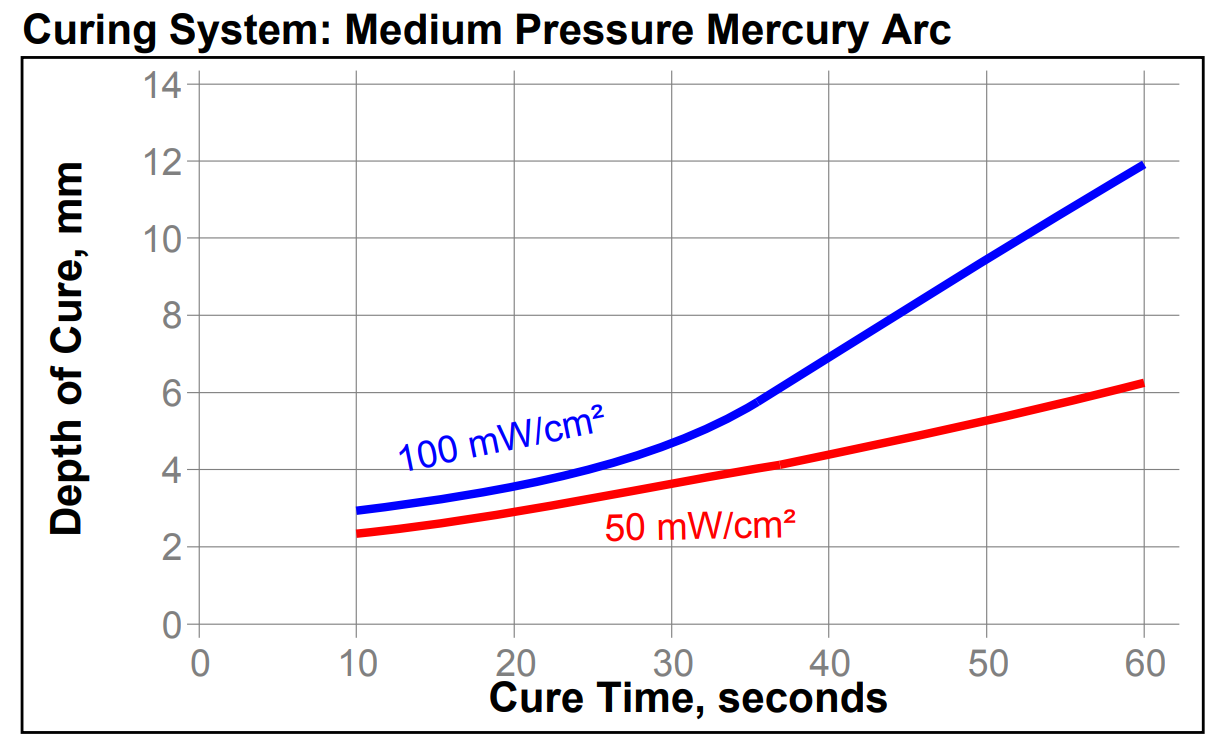

If we take a look at technical documentation for LOCTITE AA 3494 light-cure instant adhesive we can see a plotted graph that shows cure time vs. depth of cure when irradiated with a light source of 50 mW/cm² and 100 mW/cm². It is obvious that a light source with higher power density is needed to reduce cure time and to cure thicker layers of adhesive.

To estimate power density we need to measure illuminated surface area first. It is measured from a height of 5cm(typical object curing height) and then divided by total radiometric power value. For 5$ flashlight average power density of 21.5 mW/cm² is estimated, for 400nm LED module 59 mW/cm² and for 365nm LED module 107 mW/cm² respectively.

|  |

|  |

*5$ flashlight does not have a reflector so a good amount of light is wasted. This is indicated by large circles of light outside the central light spot shown on image above. Adjustable lens functions more like a collimator.

**Since Photon LED modules have temperature sensors, initial LED current can be increased to achieve higher radiometric power levels since most curing applications take less than 5 minutes. For continuous illumination above stated power levels are maintained.

***Those 5$ UV flashlights are modified "regular flashlights". The reason why they are not most optimal choice for UV curing is that they are designed to house one(single die) LED.

CONCLUSION: 5$ Flashlight is good enough for curing thin layers of UV adhesives but not suitable for larger surfaces or thicker layers of encapsulating compounds. Considering Photon has higher output power, built in battery charger, support for external triggering, is open source and has material cost of 40$ or less it looks like a logical choice for people that use UV curing products on a regular basis. Especially considering that a professional equivalent like CL32 costs around 1000$.

Mile

Mile

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.