For the echosounder I need to create a housing that has the following specifications:

- Waterproof to a few meters

- Can be opened and closed

- Contains feed-through for cables or connectors

- Cheap, preferable made from off the shelf parts

Now I designed and built several subsea housings in the past as it is part of my job, but these are always custom made at a professional machine shop. Usually they consist of Delrin plastic tube with special shaped end-caps that have double o-rings seals.

There are a few examples around of people who built waterproof housings, and most of them use standard PVC parts as available in any hardware store. The one I like a lot is this one:

https://thecavepearlproject.org/category/diy-underwater-housings/

Not only do they use standard parts, the result looks really good.

First I thought this concept was not usable for me since these PVC parts are produced and sold only in the US, but recently I found that they are sold on Amazon and actually by Formufit online as well and shipped worldwide (as far as I can see)

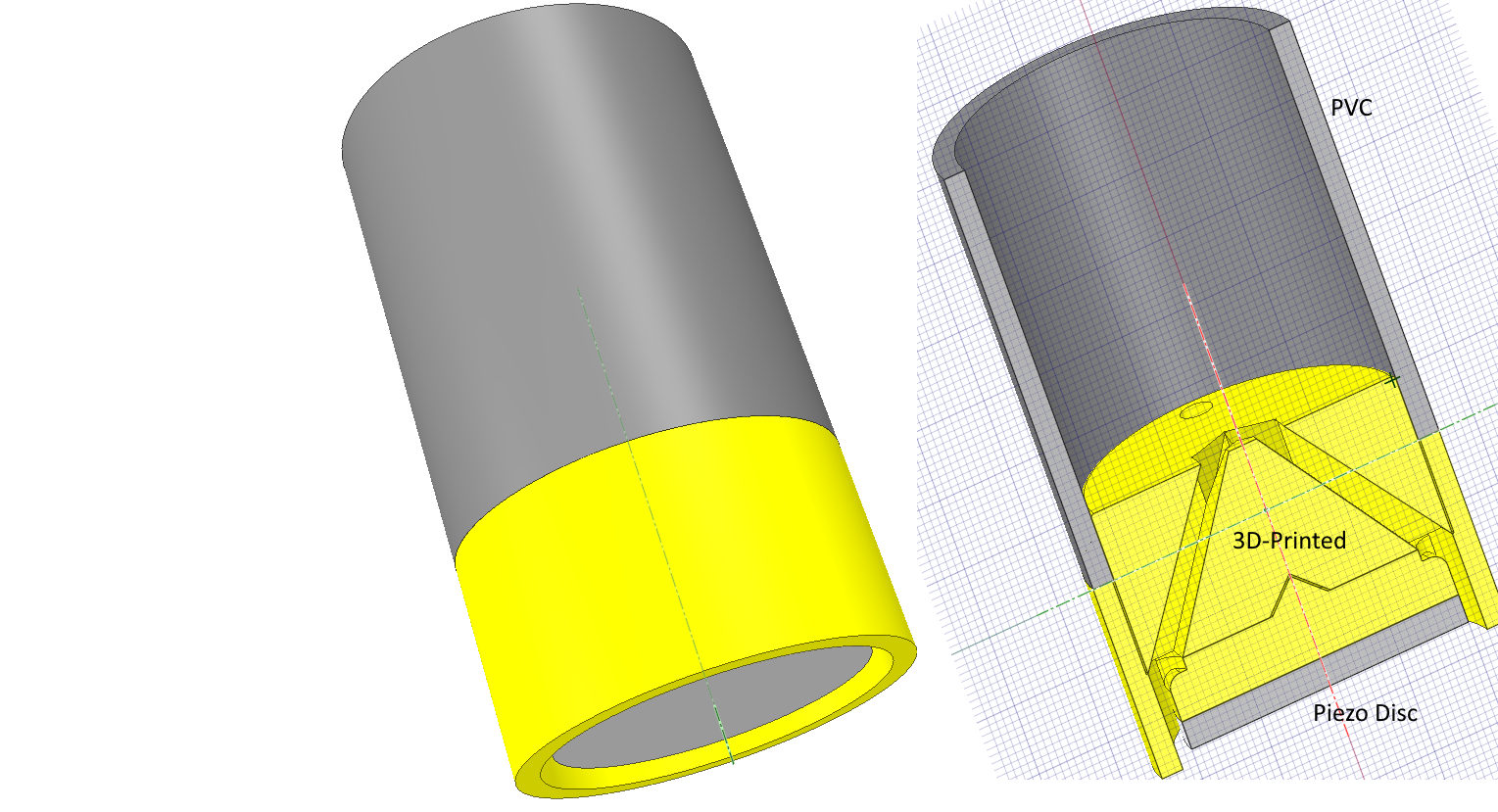

But this also may be over-complicated for my design. So I just started by drawing the piezo-disc, and the the nearest size PVC tube I could find (50 mm) to see what i could do with my 3D printer.

The grey part is standard PVC, the yellow is what I intend to print. The channels as visible in the cross-section view will be used to pour the epoxy or PUR resin in, which will seal the transducer element. The idea is that the 3D printed part will form the backing on the transducer. And when I print this using a 30 - 50% infill with honeycomb structure it will be both very stiff, and filled with air which will block acoustic reflections from the rear.

Remains the top section, which I'll have to close in a way that it can be opened.

And yes, the transducer end works out as intended. After soldering a thin coaxial wire to the piezo disc I can glue it on the base.

Cees Meijer

Cees Meijer

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.