Intro

Where do you start when you have 1000's of drill bits in dozens of drawers, half empty drill bit holders, and inherited cigar boxes, that span 4 different standards?

Like every engineer, in excel.

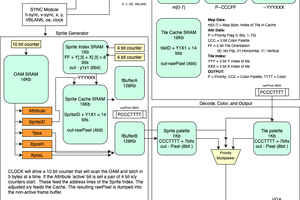

First, I compiled a list of the standard drill bit widths and lengths from 0.3 mm to 1/2 inch (244 different sizes). I wanted to mill pockets into wooden panels for an old tool box, and optimize size as well as readability / organization. I started writing some rules into excel about how wide and tall each pocket should be, and trying to optimize the number that wold fit into each panel. But after a few iterations of trying to draw these sketches into Fusion360, i decided I was going to automate everything with my favorite hammer - python.

CAD and CAM

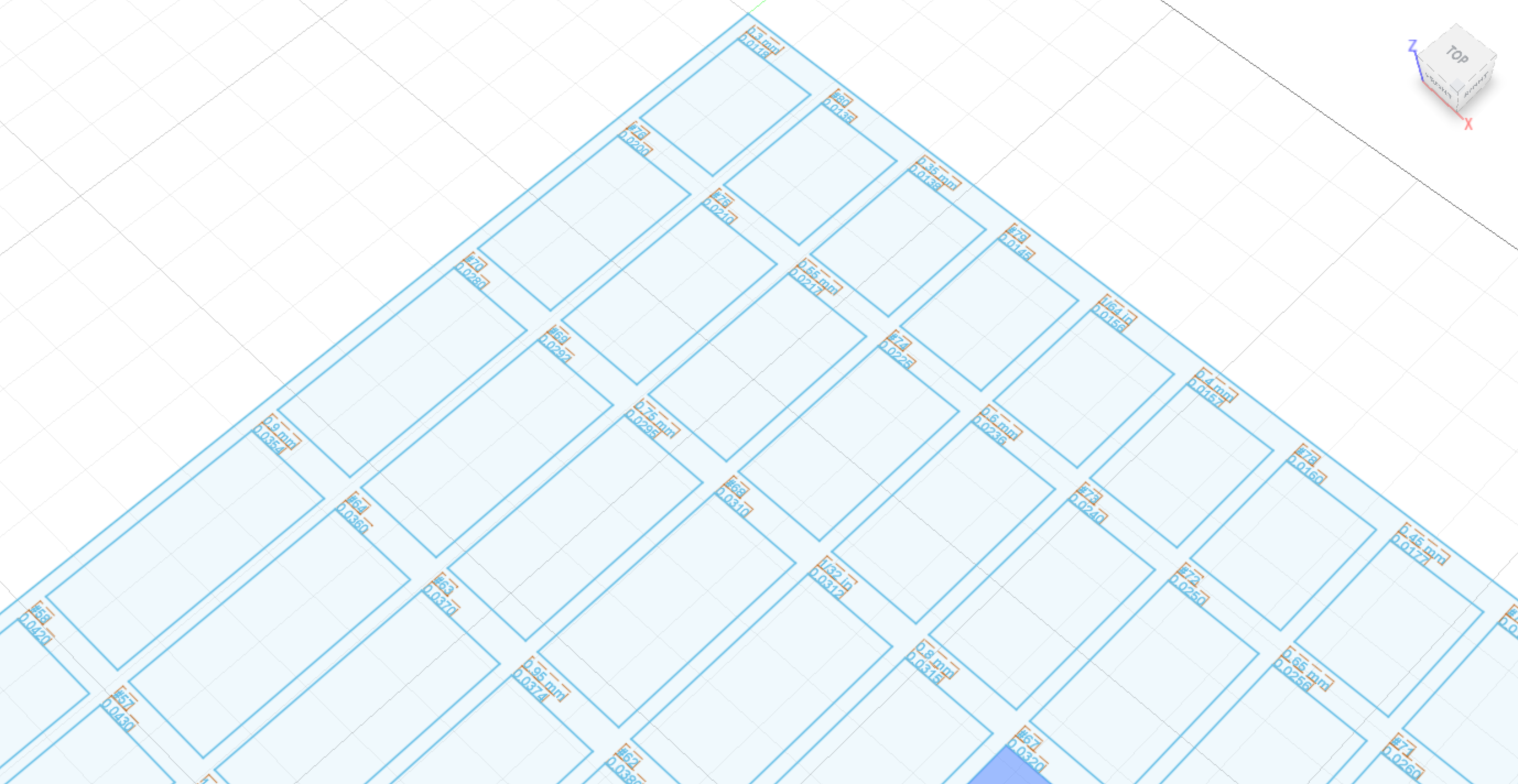

So I wrote a little python script to optimize the dimension of each pocket within each panel, and sketch the panels directly into Fusion360.

Here were the result:

Not too bad. I exported the sketches as DXF files and imported them into a CNC machine at my local makerspace.

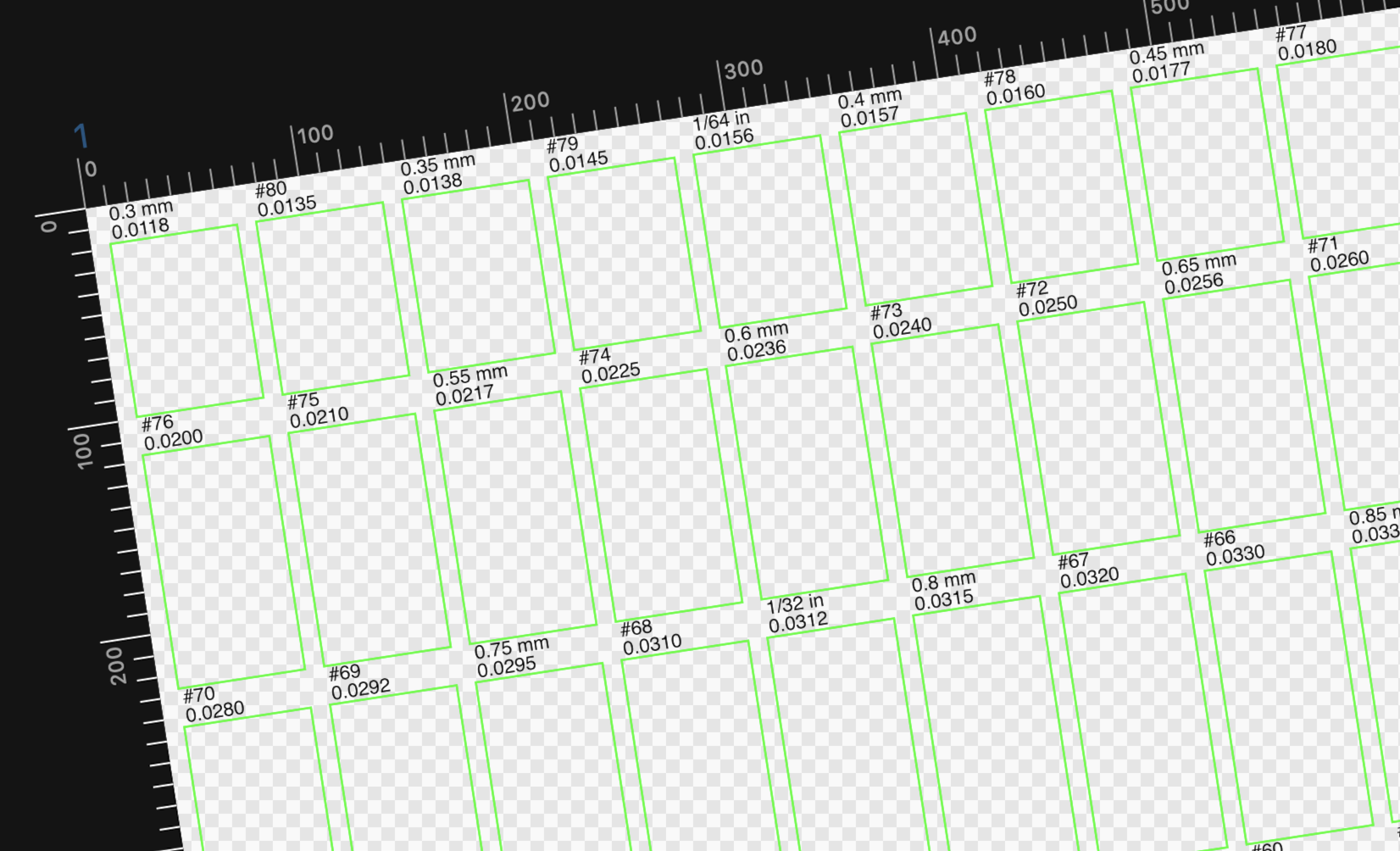

But DXF files don't have good support for text, so I had to rewrite my Python script to export SVG files so I could burn the labels on the laser engraver.

I used a color (green) that the laser engrave doesn't recognize for reference lines - so that they wouldn't be burned.

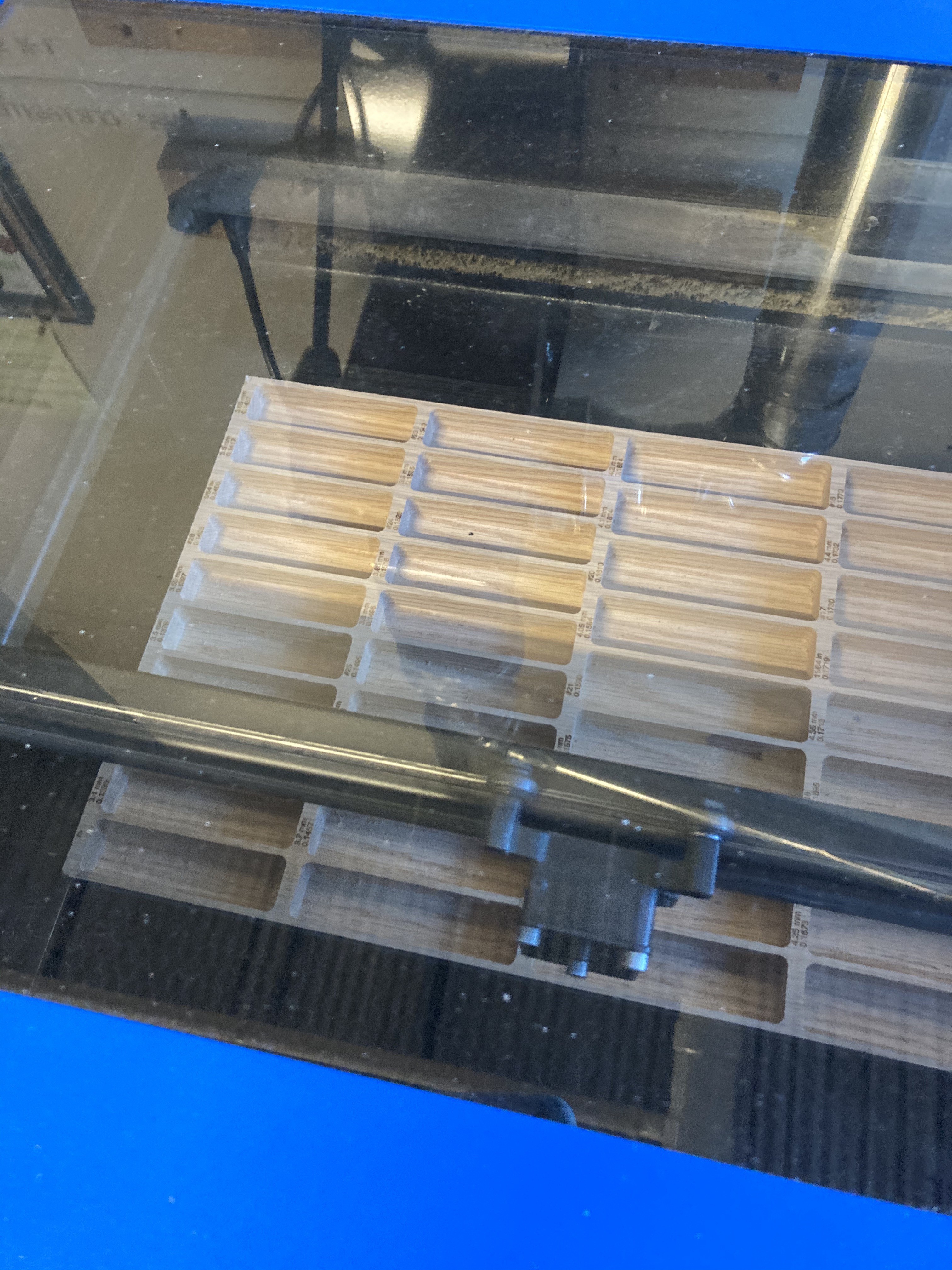

The results weren't too bad initially, but I wish they were clearer after staining.

And after installing the first three panels into the first drawer, we have something that's starting to come to life!

Software

After finishing and staining 5 drawers, I had another challenge on my hands - sorting the piles of drill bits. I needed something that would make sorting and maintaining organization quick and easy.

Luckily, i had just read about a bluetooth digital caliper on a HackADay comment, and found these for a reasonable price:

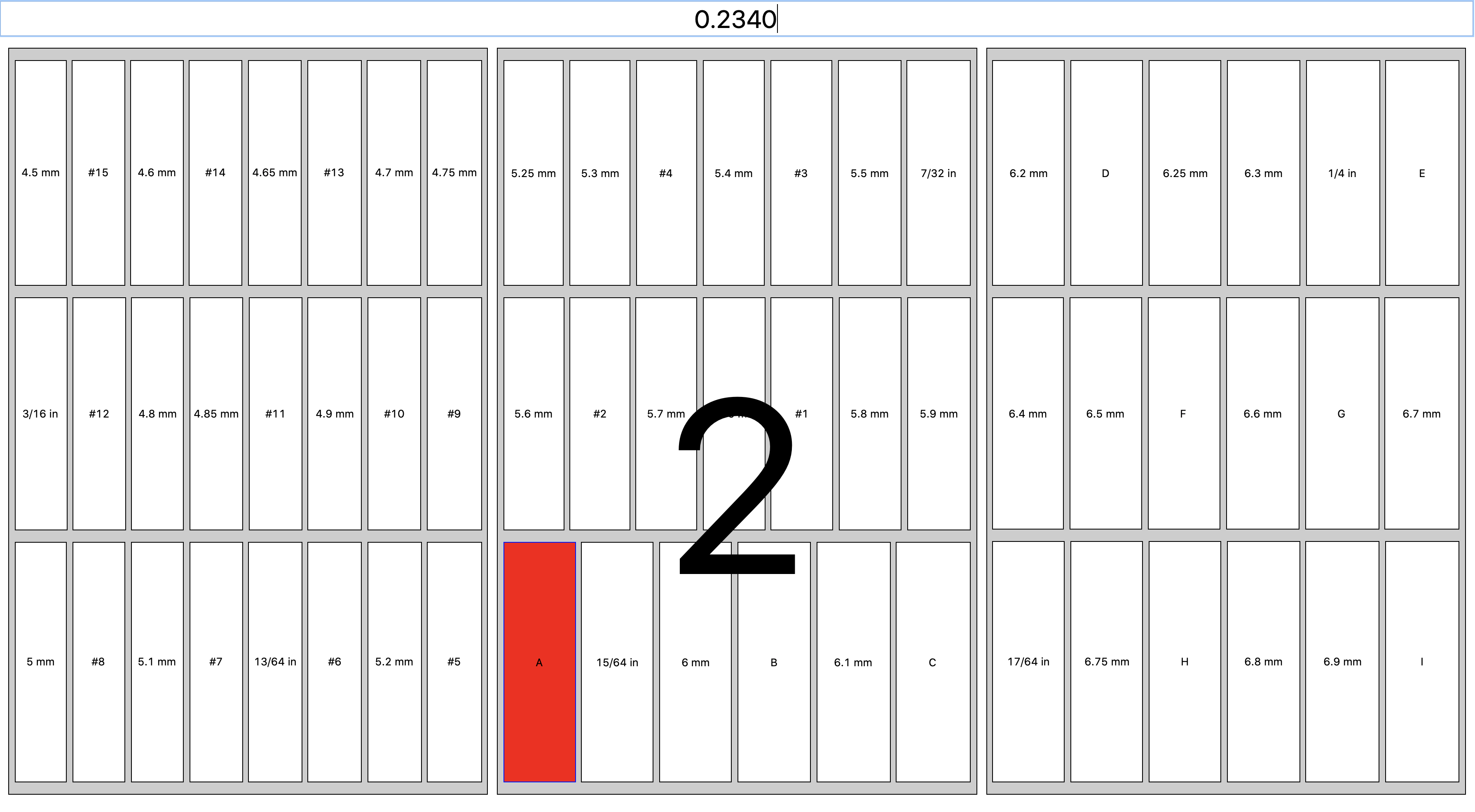

So i wrote a little GUI in Python that would highlight which pocket was nearest to the dimension read by the caliper. It'll also work in reverse, so if you're looking for a #21 drill bit, you can just type it in on the keyboard, and it'll show you where that drill bit is at.

And mounted a raspberry pi to the back of a monitor.

And within a few hours, I was able to organize all the drill bits in the shop.

The digital caliper is great - every time you press the 'capture' or 'trigger' button on the top (where my finger is at in the photo above), it types the value into the entry field like a keyboard, and completes the entry with a return character. I use that return character to reset the entry field for the next measurement.

Things I'd like to improve -

Although the digital caliper works great, the latency can be a little slow at times, taking up to a second before the entry is sent to the computer. Additionally, the digital calipers don't shut off automatically. The bluetooth function shuts off after a few minutes of inactivity, but the screen will stay on indefinitely until the battery dies if you don't power it down.

Also, the labels on the pocket are not very visible after staining. I've filled them in with a white crayon, which improves the appearance, but i'm still not happy with it. If you have any ideas for improving the visibility, i'd love to get your feedback.

Oh, and there are a few drill dimensions that will never get filled because the digital calipers round to the nearest 5 ten thousandths of an inch, and the neighboring bit sizes are closer to the rounding error.

Austin Adee

Austin Adee

Øystein

Øystein

The Big One

The Big One

Very Clever Austin !