I found that most of the desktop CNC's I know of won't fit into my requirements. Many of the CNC kits are too large and cost more than I'm willing to spend. Even the popular open-source CNC routers such as PrintNC are not suitable for my application, being optimized for bigger, customizable volume rather than precision.

I started looking around at my usual shopping destination, Aliexpress, where some choices became apparent. My budget allows for it, so I discarded the options with a plastic frame. Here are some of the options I looked at:

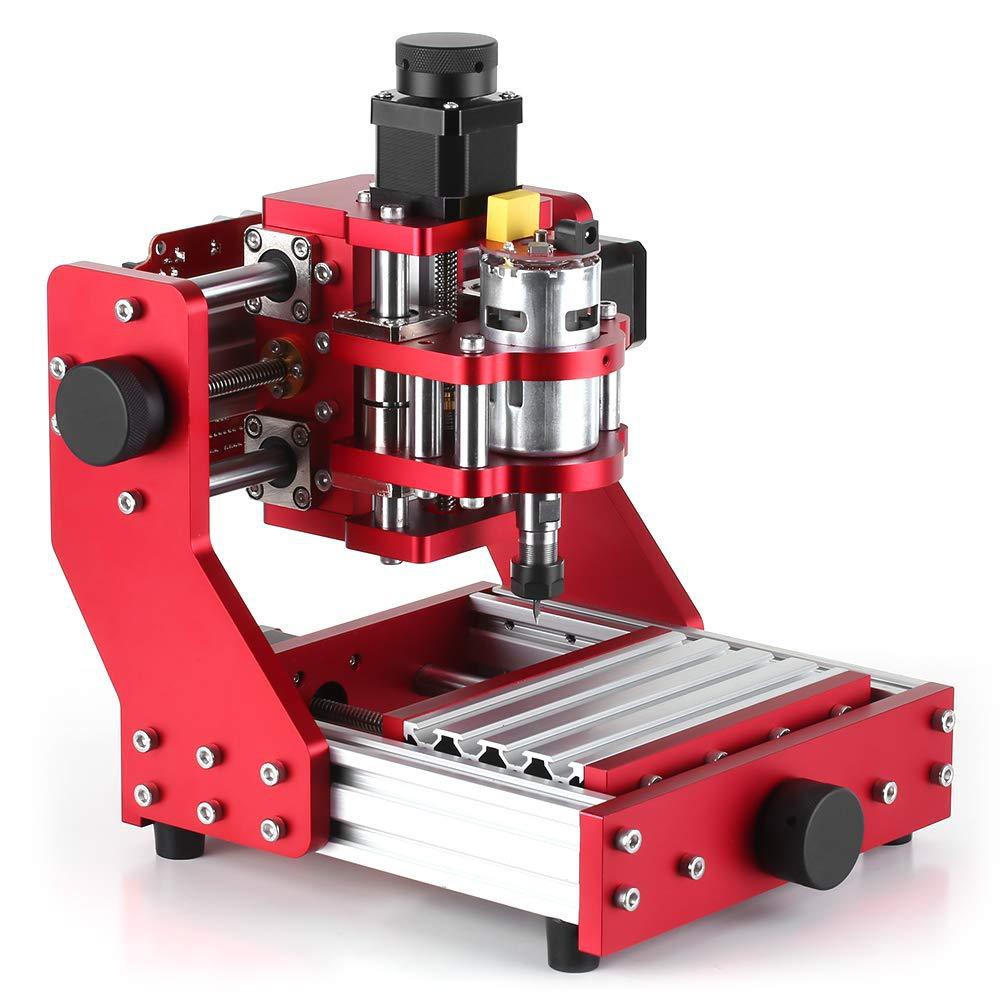

1310 is the smallest frame I considered. It features a sturdy-looking aluminum frame. It is so little I find it somewhat adorable. I even found a video of it milling aluminum, though equipped with a much beefier spindle than the often featured 80W one. What concerns me about this one is the bed size - I can't imagine having enough space for fixing stock in place.

1419 features a similar aluminum frame but has a much larger bed. Both this machine and its little sibling feature trapezoidal screws. Striving for precision, I started looking for something with superior ball screws.

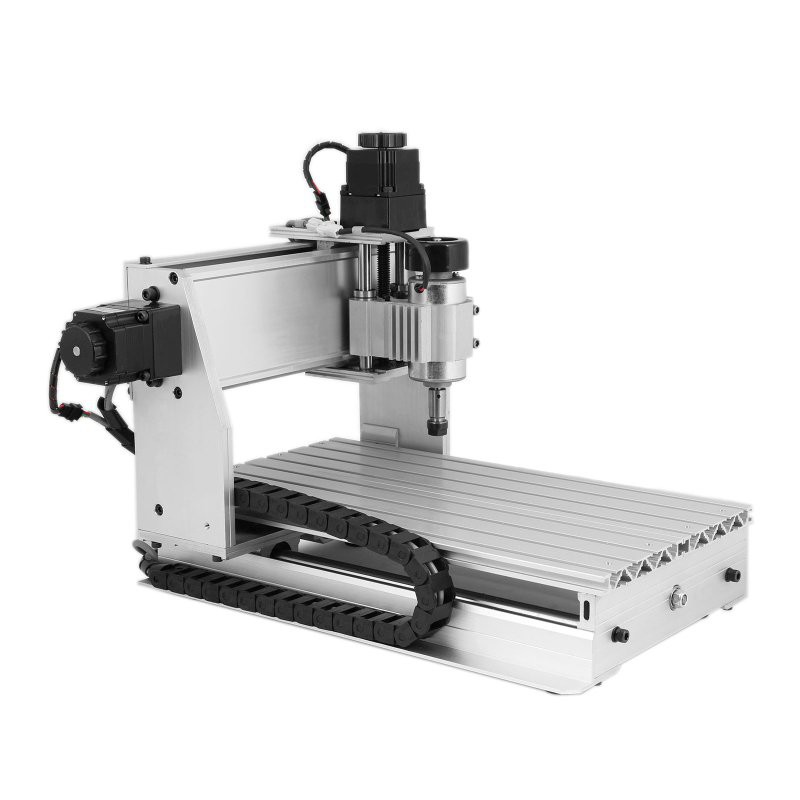

The next thing I found, a model called 3020, ticks all the right boxes.

It has a rigid frame with a comfortably sized bed and ball screws. It seems to be produced by a Chinese company called LY Group.

There seems to be quite a variety of 3020 sized CNCs. Let's go through some of them.

If you search for 3020 on eBay, many machines feature unappealing beige color but otherwise seem quite ok:

More often, you will find machines without that coat, just plain anodized aluminum.

I find it somewhat reassuring that this very same frame is inside the Desktop Mill from a reputable manufacturer of professional CNC's, Haas. With a nice enclosure and controls, it sports a price of 6,995€.

I eventually decided to buy the frame with a little bit different design and is not so common as the other types.

For it, I paid a total of $410 with shipping. That for a frame with steppers motors, TB6600 drivers, and ball screws on all three axes. I also really like the presence of supported rail on the longest axis.

With all this, I should be on the right path towards somewhat precise CNC machining.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.