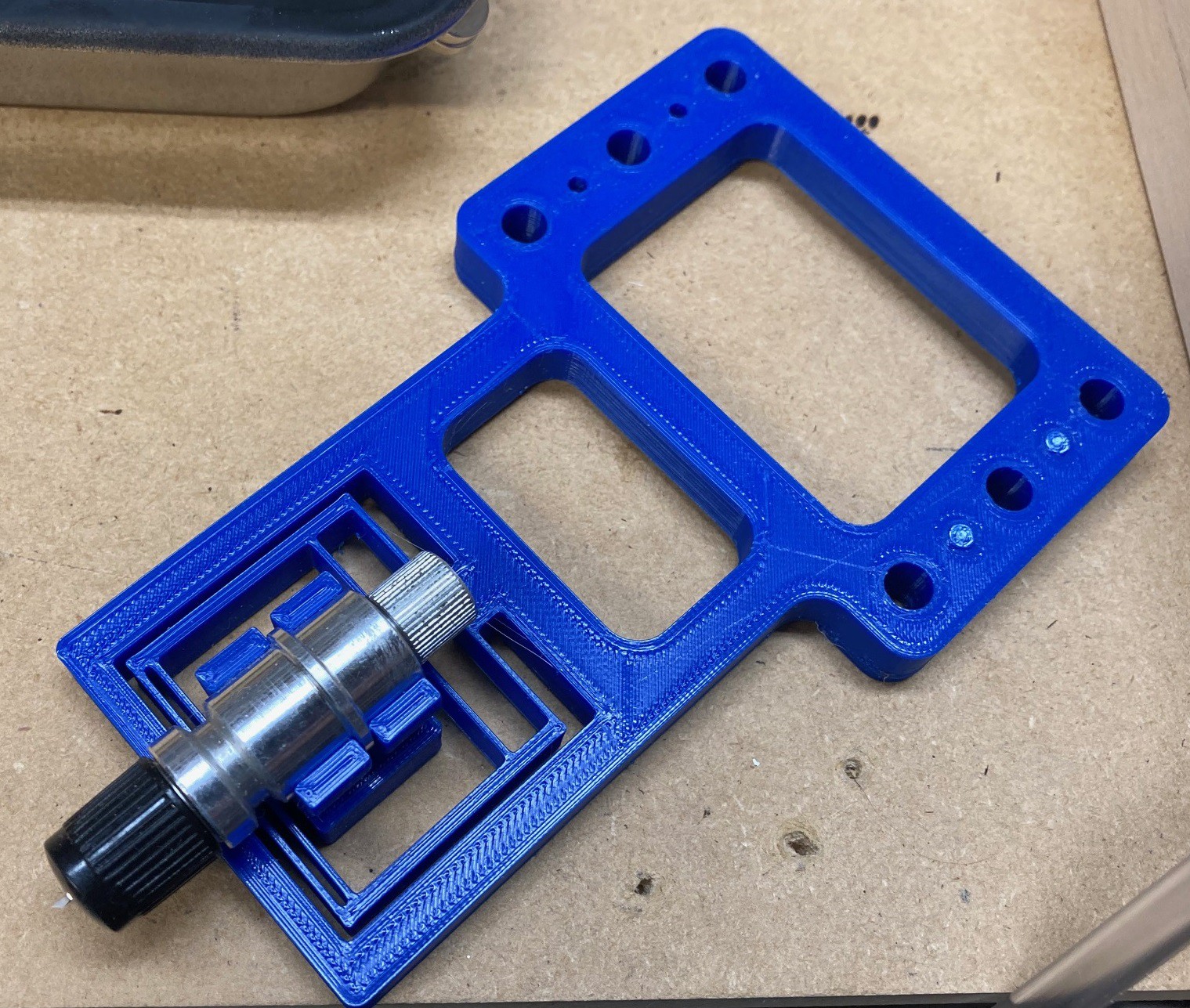

I picked up a small drag knife when I first built my machine, but I never worked out how to use it. Now that I'm messing with the laser I thought it would be good to dust it off and work out the kinks. The knife I have is similar to a Cricut cutter with a small 4mm diameter blade. I have it mounted on a 3d printed flexure to help if the tool contacts the work surface.

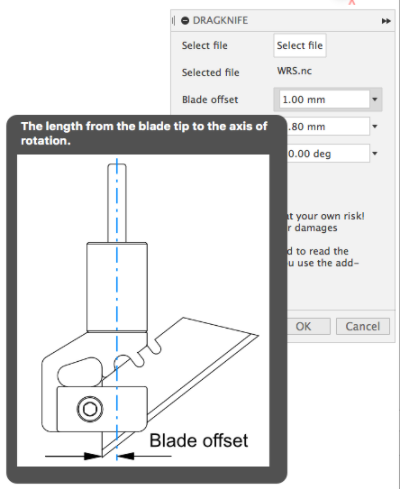

These small blades have an adjustment on the top that extends the blade a fixed amount. Typically you would extend it just past the depth of your material and then lower things so the blade holder is just in contact with the surface of the material.

There are larger holders that use a box cutter blade and in this case we usually lower the blade to the surface of the base material and leave excess clearance at the top of the blade. You can typically raise and lower the blade a bit in the holder to change the blade offset (the amount it trails behind the pivot) to adapt to different material.

In either case if we try to cut a right angle then the rapid change in direction of the cutter at the corner will cause a small tear in the material to be cut, and if you are really unlucky it can cause the cutter to bind up and break. We can work around this by either rounding all corners in our cut file or we can add a program step where the cutter is raised up so it just drags on the surface of the material then perform a circular motion with the tool to reorient itself properly.

GrblGuru has a nice video that illustrates how all of this works. There tool should be able to take any outline and adapt it for use with a drag knife. It is something I need to look more into.

I wanted to use Fusion 360 for my CAM work, and I came across this nice looking drag knife plugin by Peter Böker. Not only does it take care of the corners it comes with some great documentation on how to make it all work well. It does cost around $10 but if it gets the job done then it is a small price to pay.

Anyway I need to spend some time actually cutting things out to make sure this all works. But at least we have a start on trying to work out the details.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.