So I have wanted to investigate adding a baffle to my smoke exhaust fan for a while now, and I finally found the time for it. My fan has a 20" blade, so in theory moving out from the center of the fan we should see air blowing out from 0" to 10", and the idea is that past 10" the air actually gets sucked backwards through the fan.

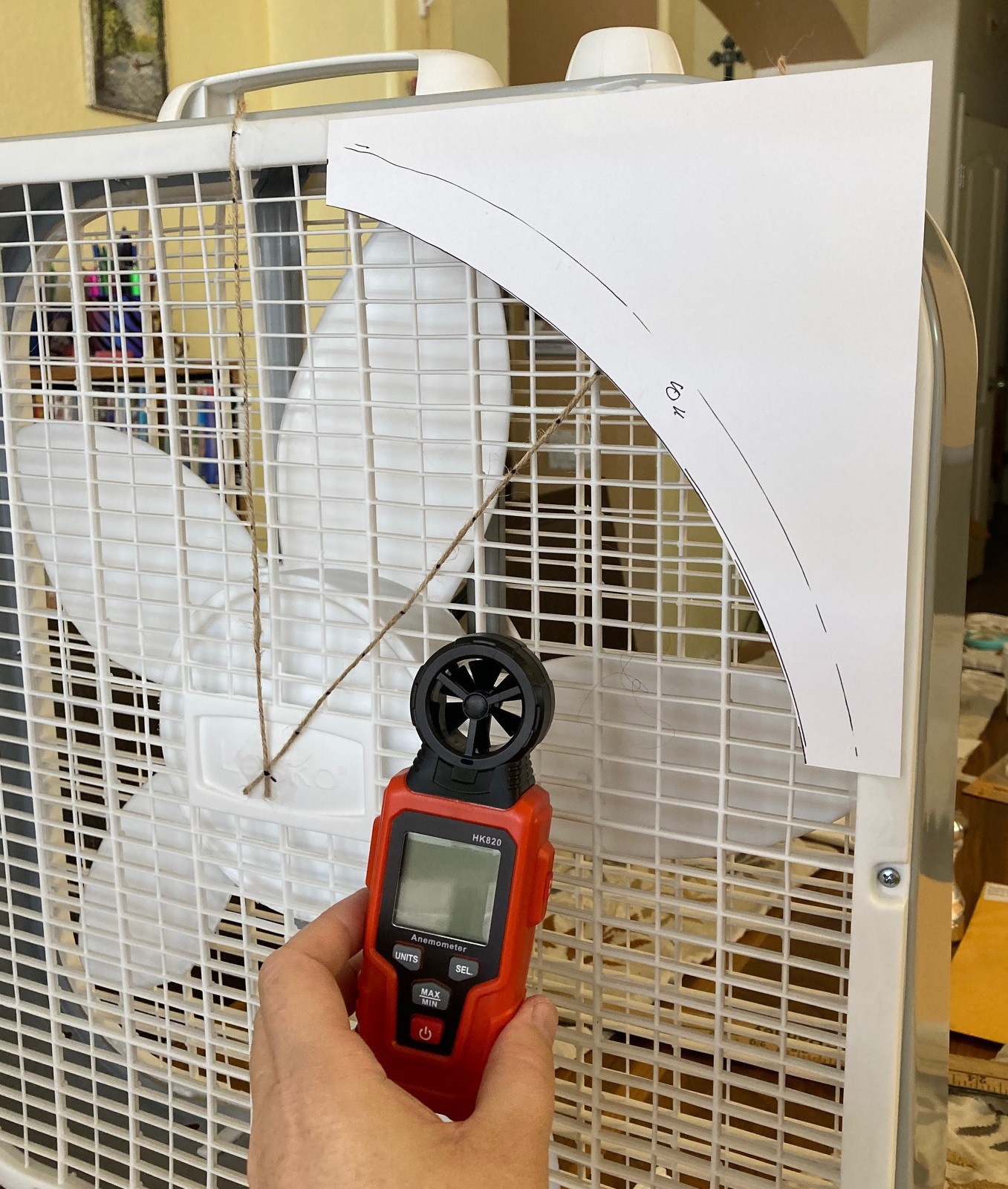

To measure this I picked up a cheap handheld anemometer from Amazon for $6. This works well with a few exceptions. For one it reads out bogus values when the fan is not moving. It also does not have a direction indicator on it to tell you what way the air is moving, so you have to watch the fan carefully and not just look at the display.

To take measurements I secured two pieces of string to the fan, one going vertical and one at a 45 degree angle along the diagonal. Then using a yard stick I marked out radiuses from 0" to 13" on both strings so I had a reference for measurements that would not interfere too much with the air flow.

Measurements were take with my anemometer in m/s with the center of the fan located over the center of the mark on the string and the back of the anemometer flush with the fan grill.

For a baffle I cut out a 9" diameter circle from a piece of cardstock and cut it square. Then when measuring air flow with the baffle in place I simply taped it to the edge with two pieces of scotch tape, lining it up on my 9" mark on my string. This is held in place by the reverse flow of air from the edge of the fan, you don't need to worry about it blowing away.

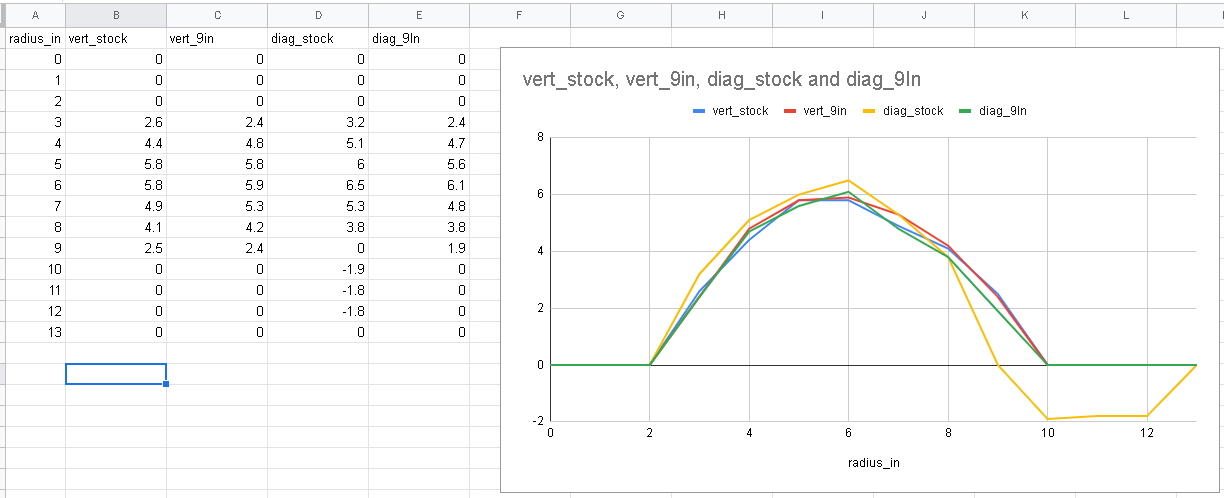

Enough talk, time for some data. Here are the air speeds across each profile with and without the baffle in place. You can see that the vertical and diagonal profiles are almost identical except in the corner without the baffle. In that case at 9" the air comes to a stand still and after that it starts blowing backwards through the fan.

The area under the curve shows us how inefficient these corners are. If we removed the box from the fan I predict that we would loose 30%-40% of the air to this reverse effect, so the box is critical. The baffle is not as important because the surface air of these corners is small. Given the area of our box is 20*20 = 400 square inches, and the are of the positive air flow is 3.14*10*10 = 314 square inches, then the area with inversion is only 20%, and if our losses on that are are 30% then the total loss is only 6%. That is an under estimate, since the inner portion of the fan is not moving any air, but that is a relatively small surface area. And of course I'm just eyeballing the losses in the corner, it could be greater or less than 30%.

Anyway I need to decide if I'm going to get fancy here, or just tape a few pieces of cardstock to the corners. But in any event there is some benefit to adding a baffle.

Also I measured the air flow out past the edge of the housing, there was no measurable air movement so the box was effectively stopping air from being recirculated from the rear back to the front of the fan. Finally I moved my baffle out to the 10" mark, right at the very tip of the blade, and at that point I still got some air inversion so the baffle was not fully doing its job. There is a reason to make the baffle smaller than the blade of the fan.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.