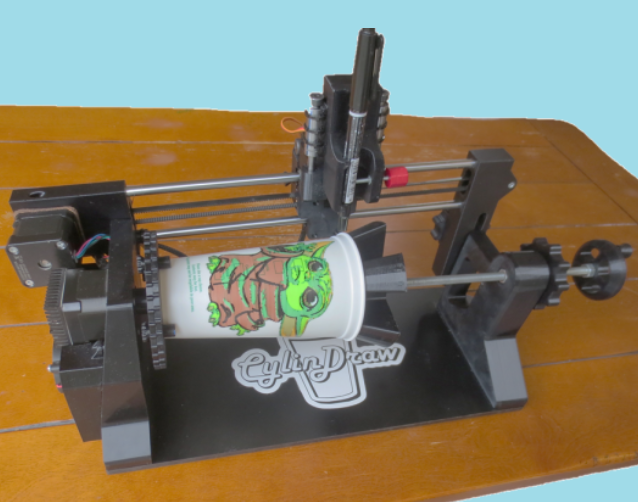

I came across a project that uses an x/z/a rotary setup to draw or engrave on the surface of a cup. It is mostly 3D printed and appears to be very well thought out. They even have there own software that can convert a bitmap to a stippled pattern ready to be drawn. I don't think you could use there software with my rotary axis, but it is nice to see others working on new rotary software.

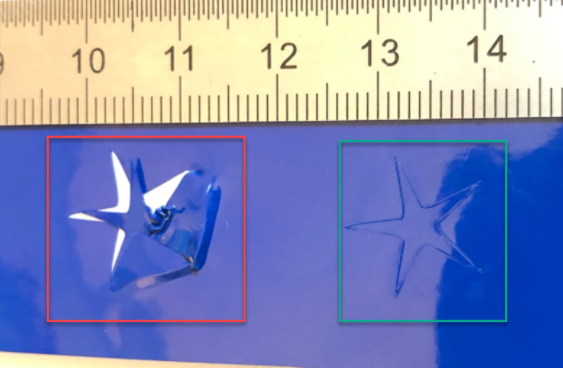

I also came across this blog post about a drag knife. They are using a tool called dxf2gcode to convert vector drawings directly into gcode that corrects for the drag knife offset. It looks like an interesting tool, and worth a second look. I had trouble previously when I tried loading a large svg file into fusion360, it bogged down and was running painfully slow. It would be good to have a new drag knife tool that can handle large files.

That blog has several interesting posts hiding in it. Search it for laser, cnc, and drag knife and you will find them easily enough.

There are rumors that LightBurn will be adding drag knife support in the near future, and possibly support for pens and engraving bits (drag bits). This would be great, lasers, pen plotters, drag knifes, embossers, and drag bits are all basically the same thing. There are small differences but one program should be able to support all without adding a lot of extra complexity.

*** Edit, I tried dfx2gcode and it seems to be a reasonably well thought out tool. However it is designed for LinuxCNC and not GRBL and is using some more advanced gcode calls that grbl can't work with. I'm sure with enough effort you could write your own post processor to work, but a quick search online and it does not seem like anyone has done this yet. Also this is a post processor tool, there is little logic there to work out part placement or scaling of the design so you need to think that all through when making the dfx files.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.