I'm not really sure if there is much interest in a DIY version of this product. I've designed this device around the Squease Vest. Most of the products on the market are special made for their specific wearable garment. Most of these products are aimed at the medical and special needs field with varying costs and applications. I have no idea if Squease will make such a device in the future.

I've gone through a few iterations and the current version has some loose ends from other versions. That being said this is a work in progress and I wish to make a version with a smaller footprint in the future.

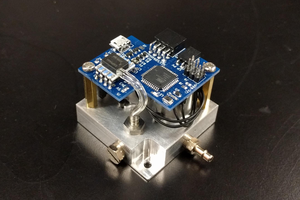

The device is powered by an ESP32 and the interface is a Nextion smart display model NX4024T032. BTW I really wish the Nextion software was easier to use! The ESP32 runs a simple air pump and pneumatic solenoids for air release. The pump and solenoids are driven by FETs directly from a level shifter. I didn't do much testing on driving the FETs from the EPS32 I/O pins directly. The level shifter was needed for reading sensors that where 5v so I decided to just drive the FETs from 5v instead of 3.3v.

The pressure sensor I chose was possibly improper. I posted about it here on the Arduino forum. https://forum.arduino.cc/index.php?topic=716249.0 Basically I'm being cheap and decided to use a BMP180 as a sensor with a small tube epoxied to it. Not what it was designed for but it does work for now.

It runs on 2 x 18650 batteries with simple 2 cell balancer. So why 2 instead of one? The first version of this I used 2 much smaller less powerful motors. I'm driving them on PWM of course. I have the motors ramp down as it reaches the desired pressure and attempt to hold it there. Even with this small system there is a slight air leak and it's possibly coming from the vest it self. I did a water test on the manifold and it's definitely not that. So the pump or air solenoids or the many air connections inside the vest. The leak is minimal at about 1psi/5min drop. So I wat the pump to hold that desired pressure for an amount of time. A strong pressure for this suit is about 3psi and up. Wanting this device to be quiet I wanted the pump to have short and low PWM bursts to hold that pressure. Well the super small air pumps couldn't inject any air unless driven at higher PWM to overcome that initial pressure. So I decided to over drive them with higher voltage and shorter PWM pulses. This worked very well however I was never satisficed with the inflation time so I stepped up to a larger pump. I decided to keep the overdrive method and this new pump works great. Even quieter than using to smaller pumps!

I'm also using more than one air solenoid because I wasn't satisficed with the deflation speed. The port for these small devices don't let much air out. I might step up this part as well if I do another version. You can see in the pic I'm using three but one is disconnected. The manifold had to be modified to fit the way I wanted so I lost one port.

I'm still a super novice in the coding department. Some stuff still doesn't work! I went through many version of the UI design. My experience with this is very limited as well but I do enjoy it. I like the way you need to be efficient with your space and still make it usable.

What it can do right now:

Inflate to a desired pressure for a time limit and then deflate for the same deration. It can sensor and report current vest pressure. While the vest is inflated it can sense your breaths (in and out) and show your breaths per minute.

What is can't do right now:

I wanted it to be able to have an ON and OFF deration including a MIN and MAX pressure. While designing it I thought I would want the pressure to go down to a minimum during the OFF deration. In testing I think I prefer a full release of pressure after a high pressure cycle. I did try to implement this but ran into issues with reading the pressure with the air valves open. This made it difficult to know when to close them and caused the...

Automatic Timed Inflation Device

This device is for automating a timed inflation/deflation cycle for an inflatable vest.

Boris van Galvin

Boris van Galvin

Craig Watson

Craig Watson

What an interesting technology, I never knew it existed. Seems like the same theory behind weighted blankets and "Thunder Shirts" for dogs.

Curious as to why you want to automatically inflate and deflate it? Is it therapeutic to go through repeating on- and off-cycles? Or is there some maximum amount of time you're only supposed to leave the vest inflated before taking a break?