There are a few thigs I didn't mention yet. Mainly because there is not much logical thinking in these ideas, simply creative brainfarts. Or copies of others' ideas...

Unconventional components

Most of the wired keyboards have 3 status LEDs in the upper right corner, however, most of the wireless keyboards do not. this leaves that upper right corner empty. I had to come up with ideas what I should fill it up with. Having the option to install the 3 status LEDs that is.

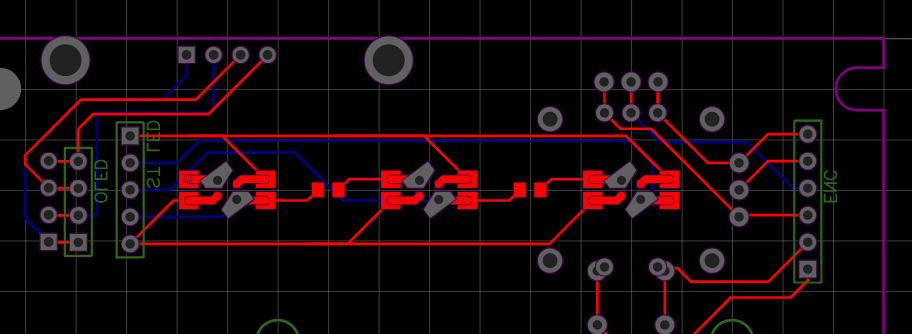

Right now I have support for I2C OLED displays in 2 sizes: a 128x32 0.91" and a 128x64 0.96" variant.

I also thought about some input devices as well. this way I ensured there are footprints supporting the common EC11 encoder and the XBOX thumbstick, although it is not clear yet if the latter will fit physically

Hardware structure

One of the main concerns of mine regarding the hardware assembly is the machining of a plate. The preferably metal sheet isolating the PCB from the outside world. You pop the switches in there and connect the to the PCB all at once. From the on, the plate is connecting the switches structurally, and the PCB eletrically.

This is not the way I'm planning to do it. Mainly because the plate has to be precise, otherwise the keycaps will show every imperfection amplified. That would suggest a CNC routing process, which I cannot do myself, and would be very expensive to have someone else do it.

Instead, my plan is to form a case which will cover the parts of the PCB not covered by the keycaps, and the switches would be held in place by the PCB itself.

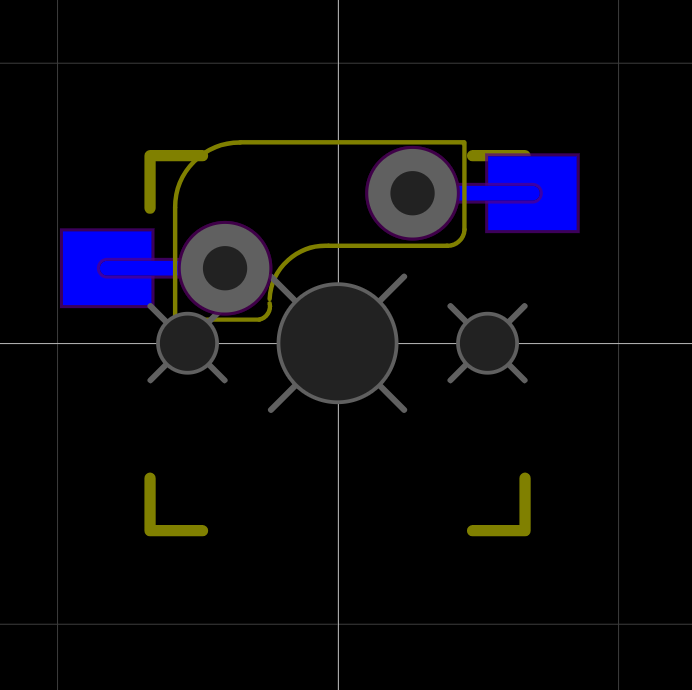

BUT... I would keep the possibility of using hotswap sockets as well. the end result is a footprint which is by default a solder mount. However, if we drill the holes for the switches' legs with a 3mm drill, we can solder in the kailh-style hot swap sockets. Great!

rOzzy87

rOzzy87

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.