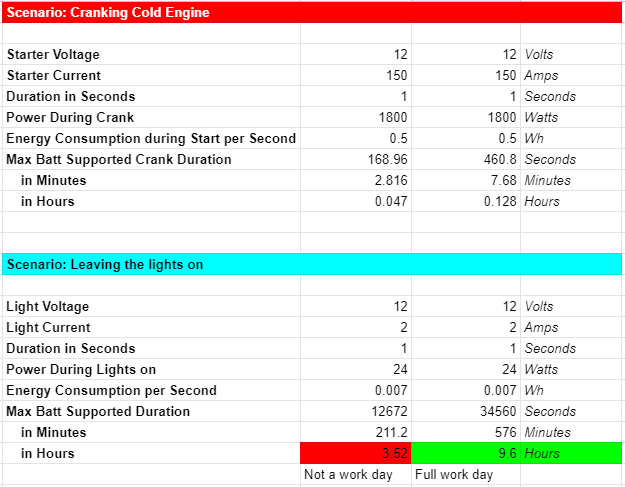

A typical motorcycle battery costs between $100 and $250. I usually - I admit - go for the cheaper option because I always plan to drive this thing at least once in a while - which I usually don't. What thing you ask? My 2008 Triumph Speed Triple 1050. A rather hefty bike that wants to go fast in a straight line but requires some serious courage to go around corners quickly. The 1050cc engine requires a bit of oomph to be moved and as such the starter is stronger which in turn requires a powerful battery with a lot of cold crank current / cold crank amps.

A lead acid battery that's sitting around is dying. Always. Apparently, based on my brief research, sulfur deposits on the lead which eventually causes a short in between the cells. This is especially true when the battery looses charge at the same time. A sulfur overgrown battery makes die even faster and reduces the current it can put out.

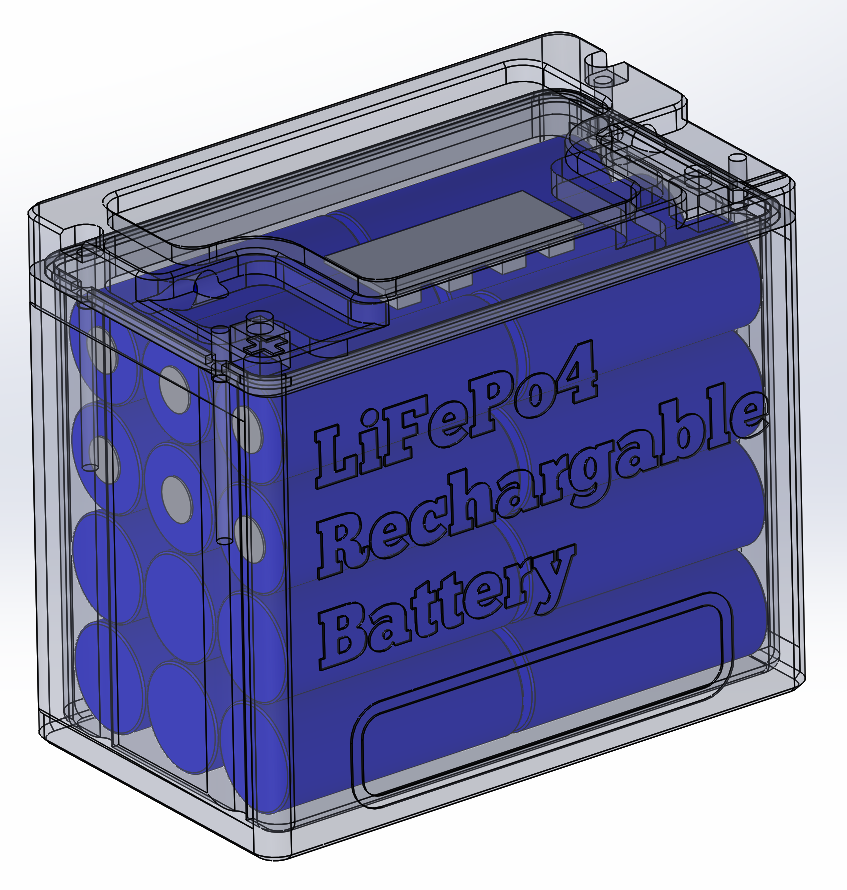

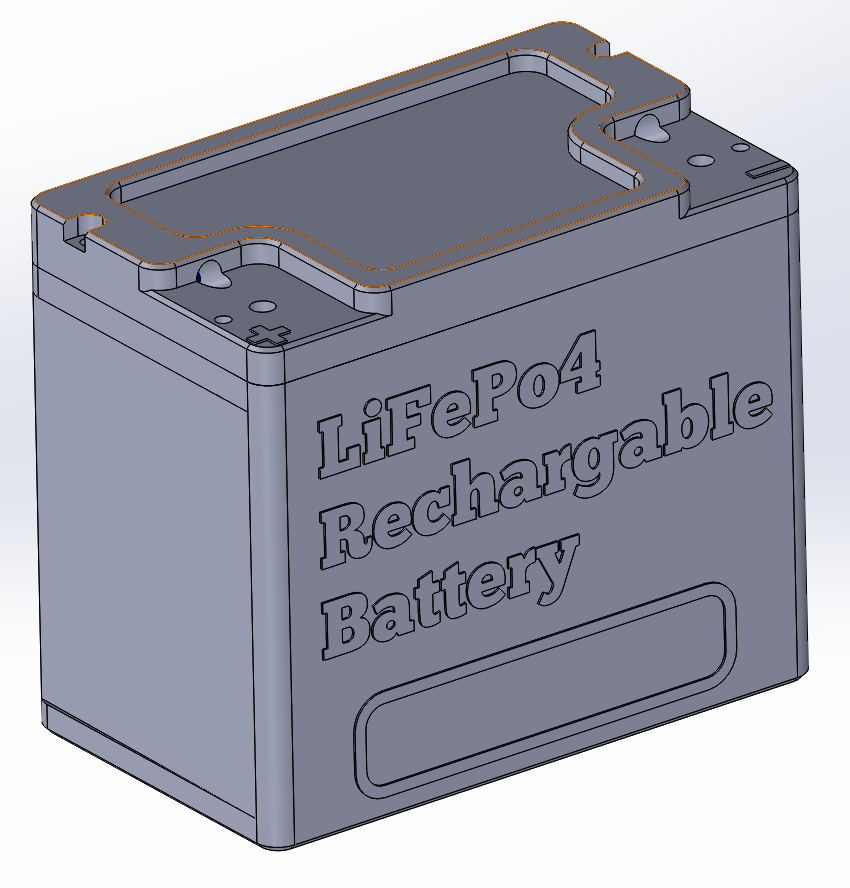

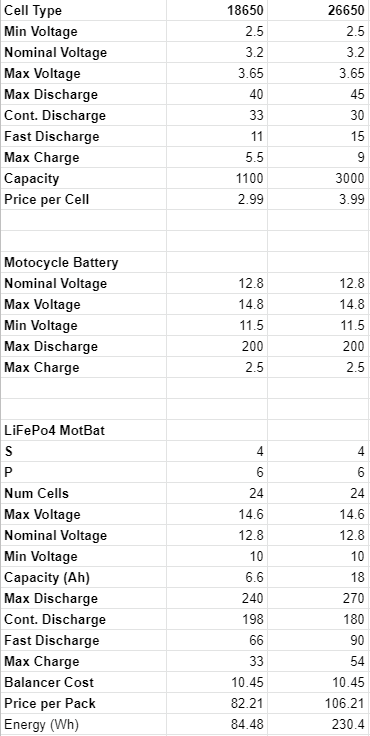

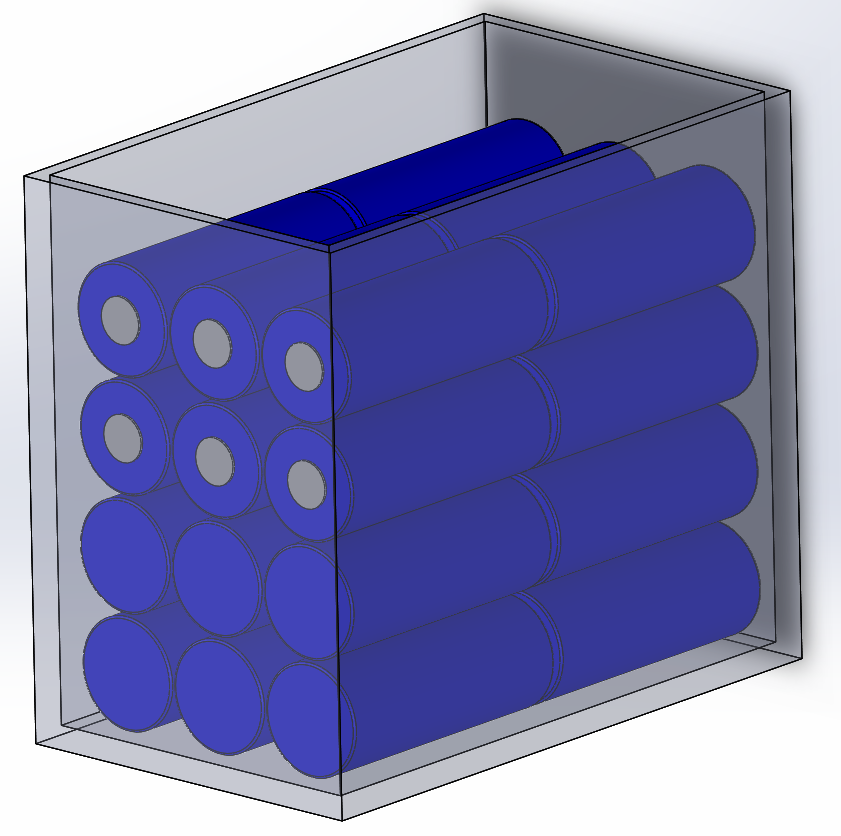

My plan is to get rid of all this antiquated technology and use something more sustainable and durable like LiFePo4 cells. New(er), much more durable, and very hard to kill.

DISCLAIMER: Batteries are generally dangerous to work with. Once shorted, it's easy to cause a thermal runaway which is likely going to cause a fire or worst: an explosion. This is equally true for over-discharging as well as over-charging. And the latter is one of the primary considerations when putting LiFePo4 batteries to work in an automotive environment: A car generator's charge controller assumes the battery is fully charged at 14.7 Volts but a 4S LiFePo4 battery's max charge voltage is 14.6 Volts. Doesn't sound like much but could present a hazard.

Timo Birnschein

Timo Birnschein

andyhull

andyhull

Neal

Neal

Eric Hertz

Eric Hertz

I am also interested. However rechargeable needs an e after the charg

Cheers