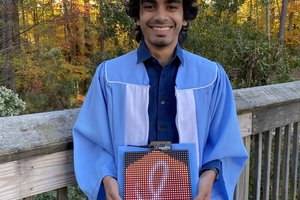

My friend Sean and I spent the last year creating an interactive LED cube kit for the Raspberry Pi. It is covered in 192 individually programmable LEDs and packed with electronics, from a microphone and speaker, to a hand gesture sensor and orientation sensor. We also created a simple web-based interface so people can easily run their own Python scripts on it, or just choose from the built-in applications we include by default. We launched it last month on Kickstarter, and it’s been just amazing how many people have backed us!

We've already shared a behind-the-scenes look at some of the hardware and software we created for the prototype LumiCube, over on Hackster.io

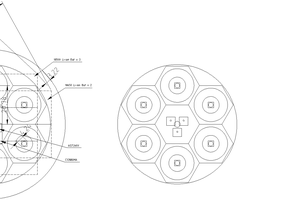

Over the next few months we will be refining some of the electronics and enclosure design, before kicking off our mass manufacturing run. We thought it would be nice to share some of that story over here at Hackaday.io, where we can go into a bit more detail than will fit in our updates on Kickstarter.

As always we are keen to hear from the community. If anyone out there has comments or thoughts on what we are doing, please do get in touch!

Matt

Matt

mlos

mlos

Idrees Hassan

Idrees Hassan

Aileen Xi

Aileen Xi

Hoyoung Lee

Hoyoung Lee