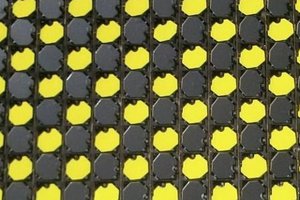

The main project goal is to have a wall mounted display of 4 characters made from my old highway flipdot panels. Whats a flipdot? you can do worse than look at FredericL's project https://hackaday.io/project/159415. From my point of view they are an awesome obsolete display technology that is wonderfully mechanical and with superb sound effects when they operate. The operating principle of magnetic remanence, see https://en.wikipedia.org/wiki/Remanence is a beautiful example of physics in action, and also enabled https://en.wikipedia.org/wiki/Magnetic-core_memory!

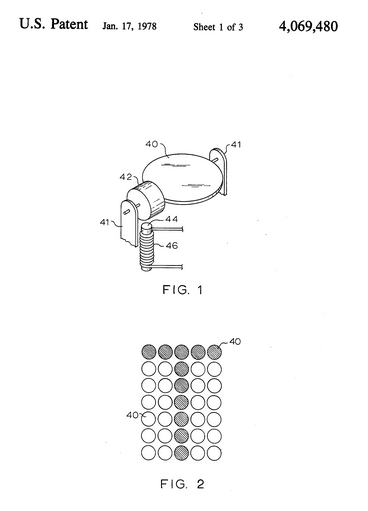

My panels are each 7 x 5 dots, and very large, about 240mm x 350mm, the dot size being about 38mm, so 1 1/2" in old money.

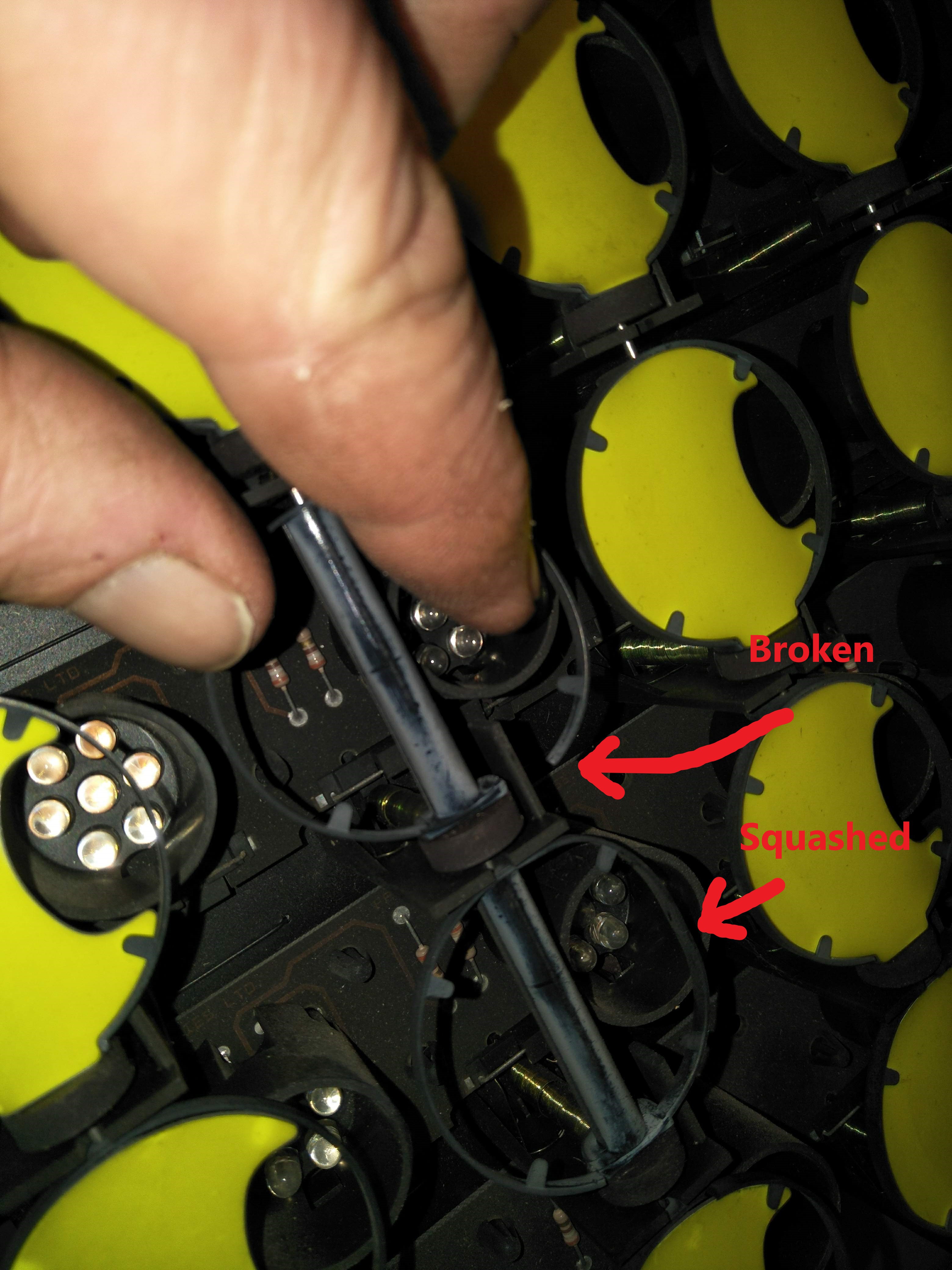

The panels were not in the best shape when I picked them up, and the 20 years that they have been in storage has not improved them. Luckily I have several boxes so I can mix and match parts to get 4 good panels.

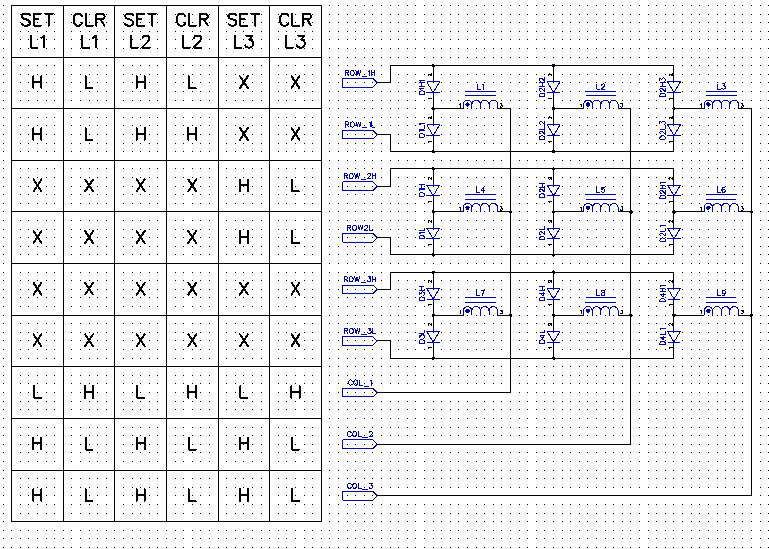

I did not find any driver electronics, but in 2015(!) did build an entire 4 panel driver board using motor driver ICs but it never worked so I shelved it. So I either have to resurrect it or build another driver.

Then I want to display seemingly random four letter words on the display chosen from a database of word associations. The original idea of the four letter word database I owe to akafugu, who sells the database as an addon for his VFD clocks: https://github.com/akafugu/FourLetterWord. I am not sure if he originated the concept of using the database, but I can't find an earlier example than his project punished in 2012.

I succeeded in my aim, I have a standalone display that will sit on the wall displaying random associated four letter words. There is much left to do, the housing is made from a 50 year old packing case I cut up, and I need to score a large piece of acrylic to put on the front. I would also like to use a Raspberry Pi as the driver, then I can use real databases, display messages, etc.

But it works, and makes the most beautiful noises as it displays a new word.

Here's a haiku to celebrate:

the display updates,

magnetic domains realign:

rain on a tin roof

Acknowledgements

Akafugu for his four letter word add-on board here which gave me the idea of the associative word database. I think he may have come up with the idea of using the Edinburgh Associative Thesaurus as a source of four letter words.

Diptrace for giving me an upgraded license with a limit of 500 pins for drawing the schematic. I like Diptrace.

Hobart Hackerspace for encouragement and various components.

Tom Harris

Tom Harris

Yann Guidon / YGDES

Yann Guidon / YGDES

Paul McClay

Paul McClay

Frederic L

Frederic L

tomcircuit

tomcircuit