I'm planning to do some automated endurance testing of Tardygrade later in August. I want to find out if it can whitstand a few hundred hours of movement without breaking down. I'm actually more worried about the drive servo than the 3D printed mechanism, but it remains to be seen which will buckle first.

I think PETG is a reasonable material choice for the 3D printed gears. It's quite tough and will probably not wear down easily. That being said, nylon would be even better. So I decided to try it.

I used Filamentum nylon FX256 for the tests. Not sure what is different in that formulation compared with other nylons, it's simply the one I happened to have at hand.

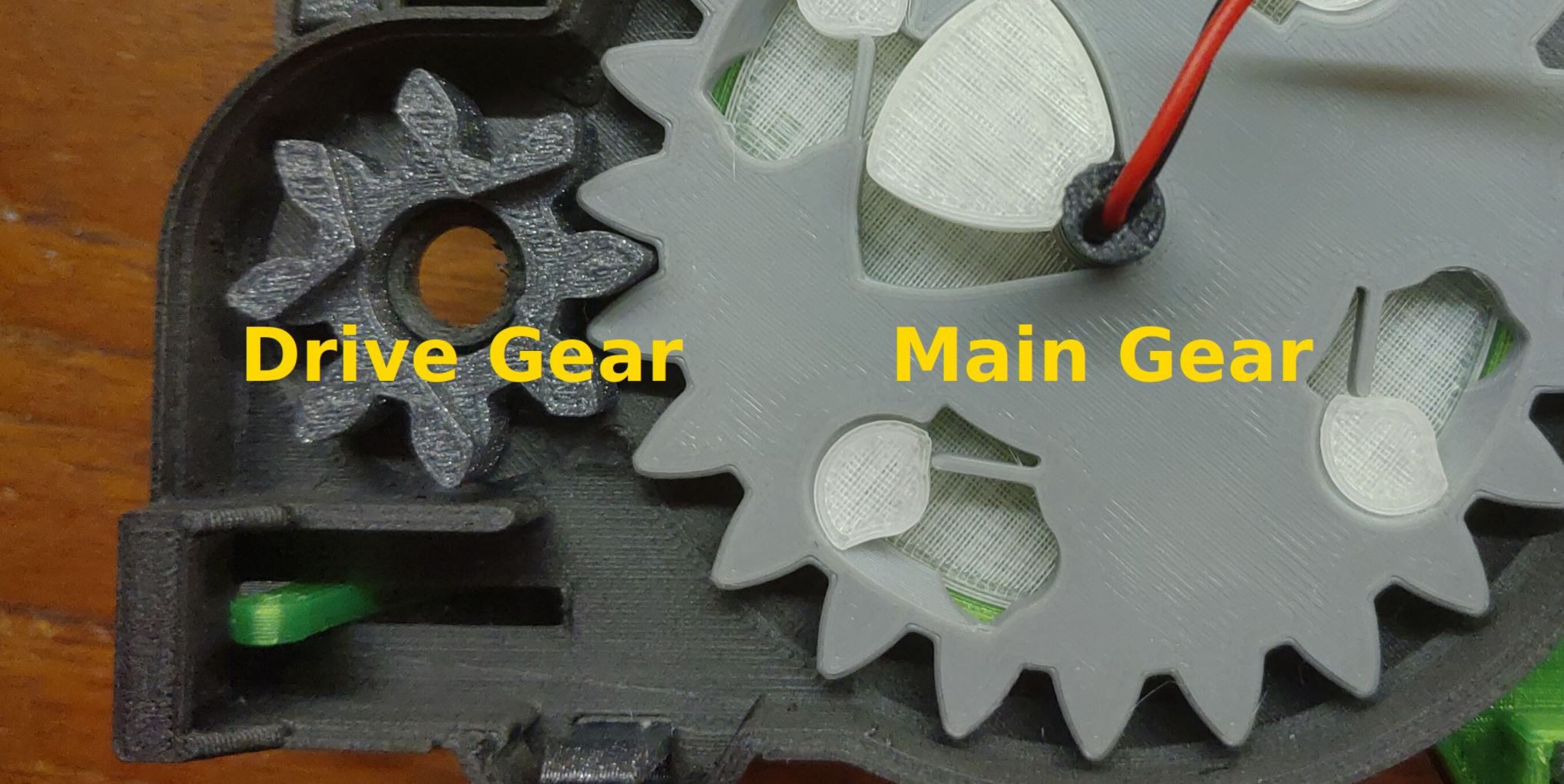

The small drive gear printed fine in nylon without any warping. But the main gear was another story. Most of the gear teeth would loose grip and start warping halfway through the print. I switched to a glass bed with glue stick but still got similar results. I also tried a range of different extrusion- and heat bed temperatures to no avail.

The thing was that the smaller drive gear printed with no issues despite having identical teeth. Could main gears tendency to warp have to do with its larger area?

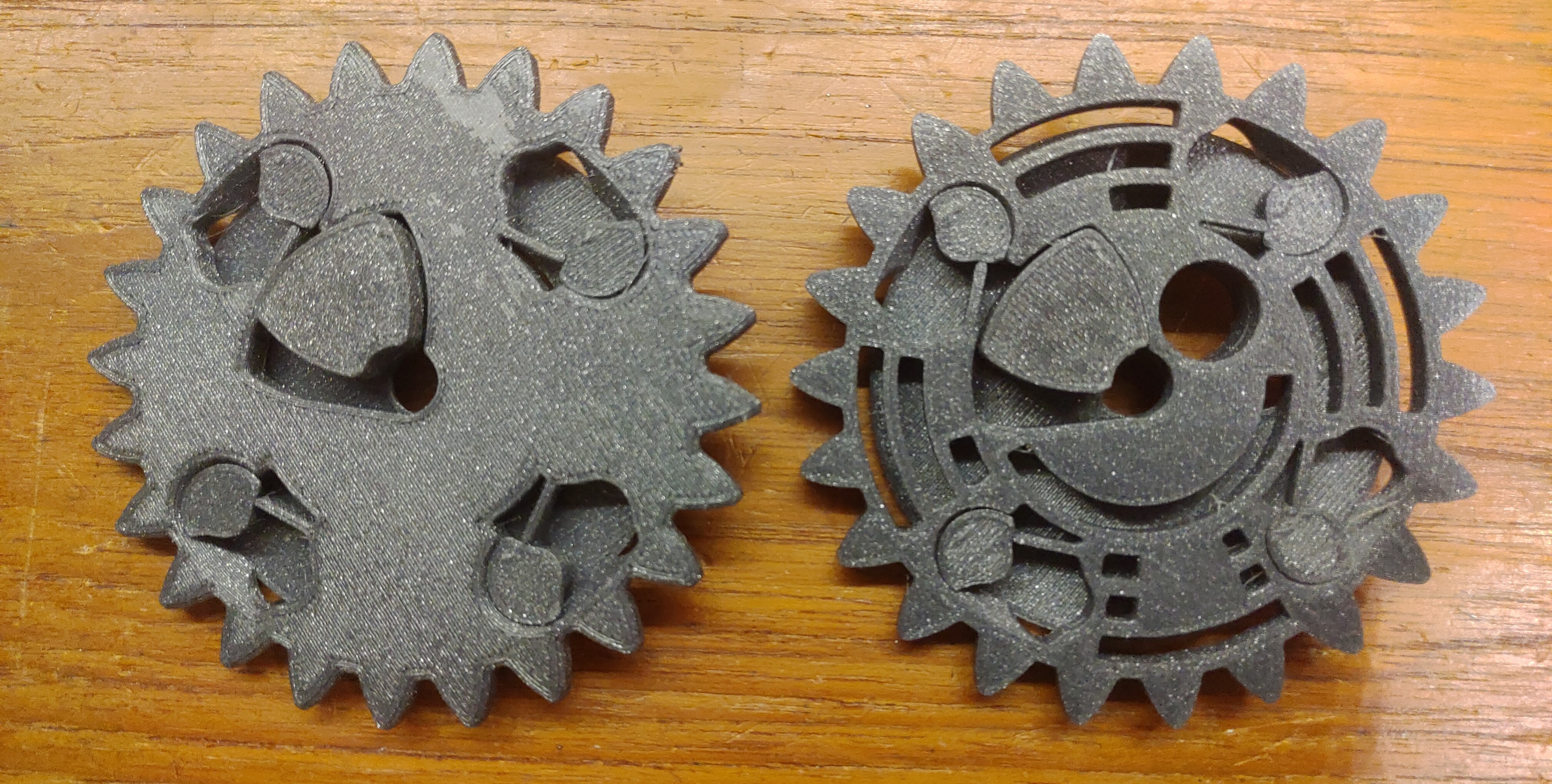

I decided to test that theory by modifying the gear by cutting ditches all through the gear. The idea was to avoid having a big slab of material in the center pulling on the the perimeter, and thus avoid warping.

The experiment wasn't as successful as I had hoped, if at all. Although there were fewer warped teeth on the modified gear, I only printed one so it might have been a fluke. Either way the warping was not eliminated.

A straight PETG gear is much preferable over a warped nylon gear. But I might still give nylon another go in future.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.