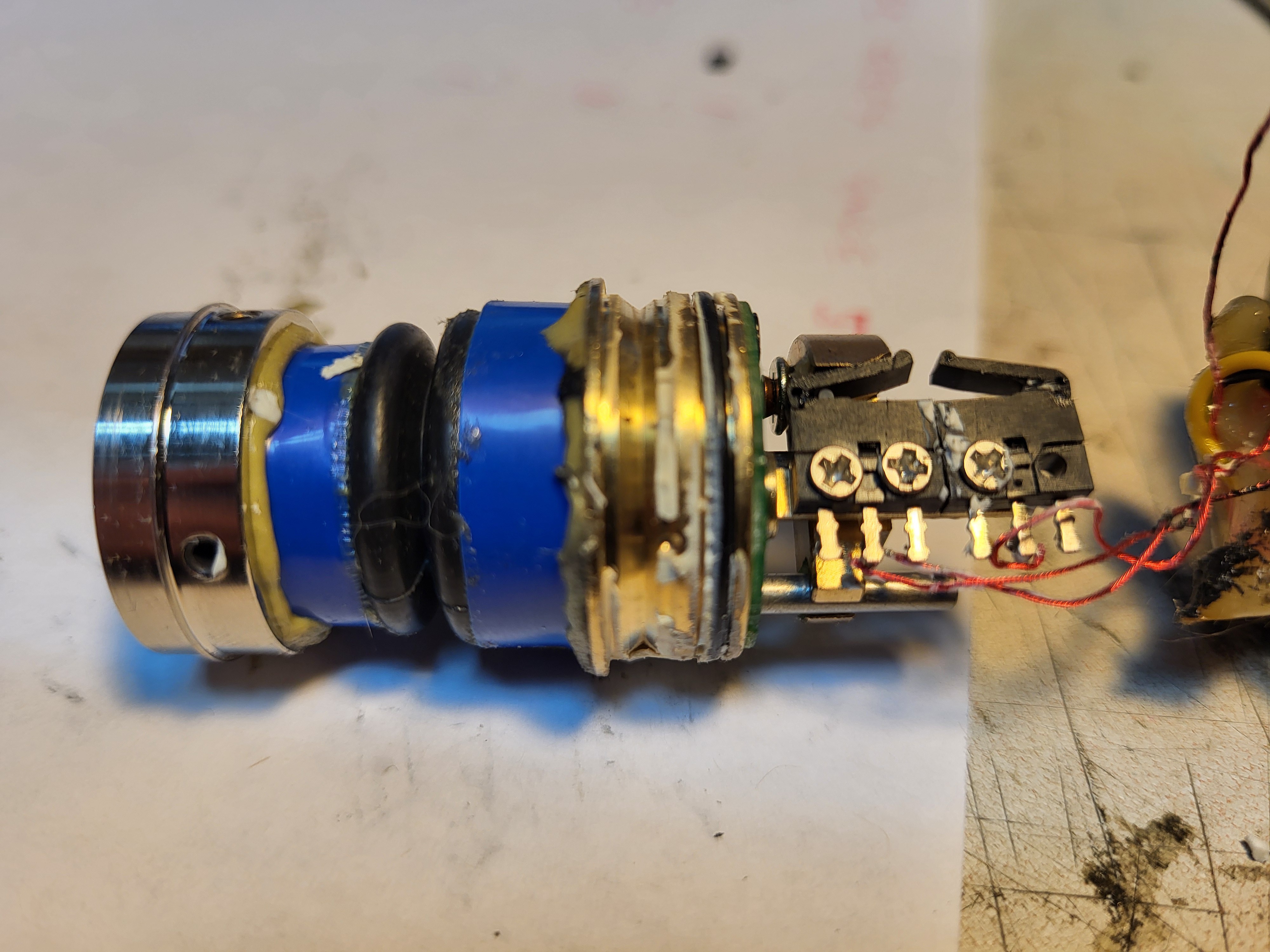

I purchased a lower cost tool setter, figuring if it is bad I can at least experiment with it and make something better. The mechanicals are not terrible but the electrics are crap. I think that some earlier iteration of these had a piezo electric tip, but this one just has two tiny plastic microswitches, one of which came with a broken wire. In service it does seem to give about 0.002" (5 micron) repeatability so it will do for now. I don't expect it to last.

I found some code on the forums and simplified and adapted it. The original code has a touch-off step then updates the tool offset each time without storing to the tool table. It also has you hard code in your tool setter and tool change positions. As neither of these are fixed forever positions on the Shoptask, I reworked it to use G59.3 origin for the tool setter and G28 for the tool change. I also added a retry loop for when I have to juggle different holders to make the tool reach, and have it updating the tool table with the spindle-nose to tip length. That last bit isn't actually necessary but at least I can dream about an array of fixed tool holders. This way as part of my setup I can quickly touch off the tool setter location in G59.3 (if it has been moved) and save my tool change location with G28.1 in a place where I can get around the work and not collide with anything.

Code is here. EDIT: check the next code checkin. I had to remove the retry logic as it crashed the gcode emulator in LinuxCNC when I actually used it in anger.

Alastair Young

Alastair Young

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.