Have I found the sweat spot of my direct extruder?

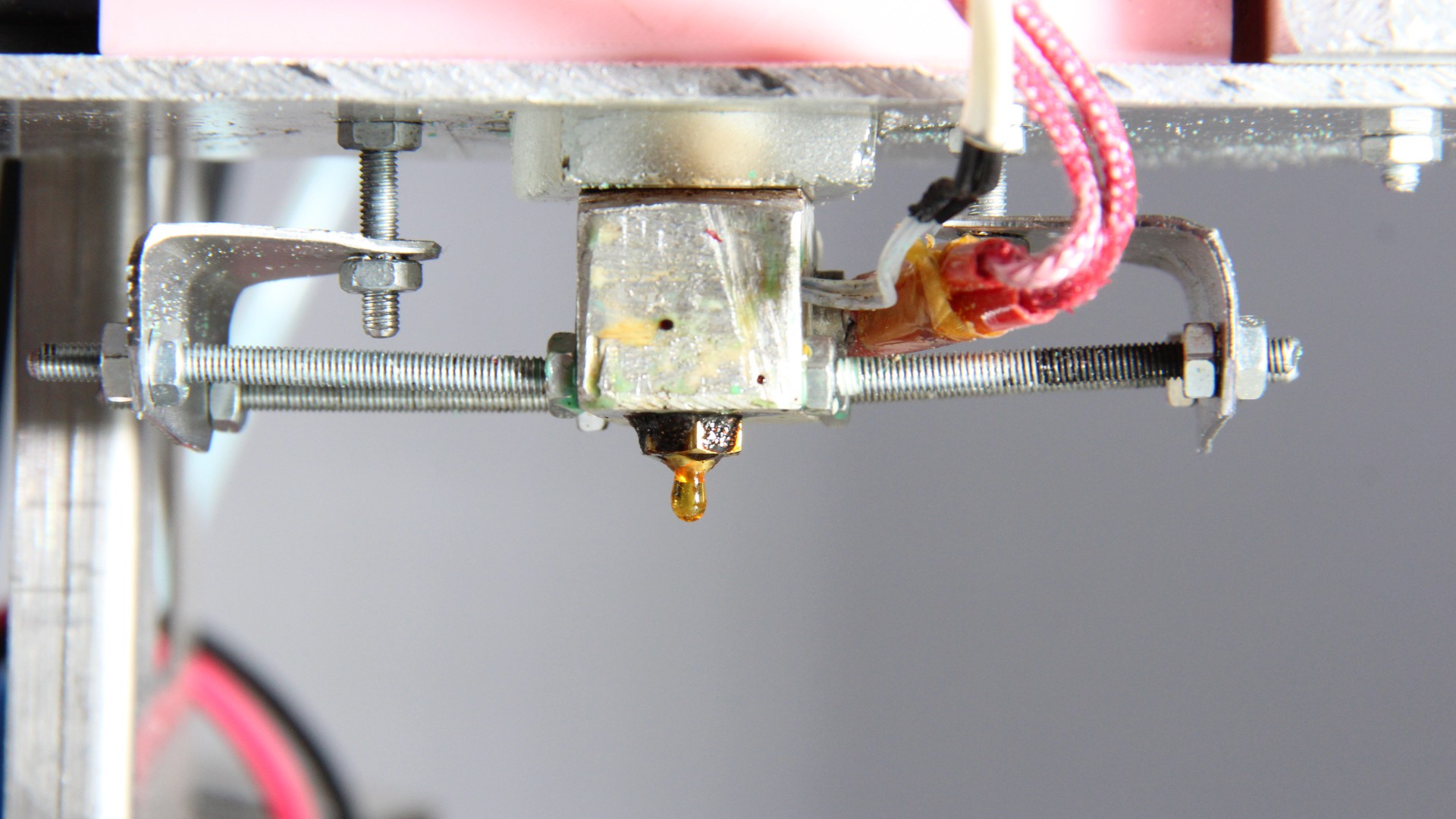

Printing PLA works fine. The raw material can be sourced from failed prints, pellets or waste plastics. Put it in a blender and sieve the grains - done. But what about using a raw material that is available in each hosehold? On a lazy Sunday afternoon,. sugar came to my mind. So let's check if that material melts at temperatures my extruder can reach. Yes, it does. So heat up the machine and put a couple of spoons full of sugar in the hopper. First thing I noticed was that sugar doesn't exit the extruder as a string, such as PLA does. Instead it is dripping out more like water:

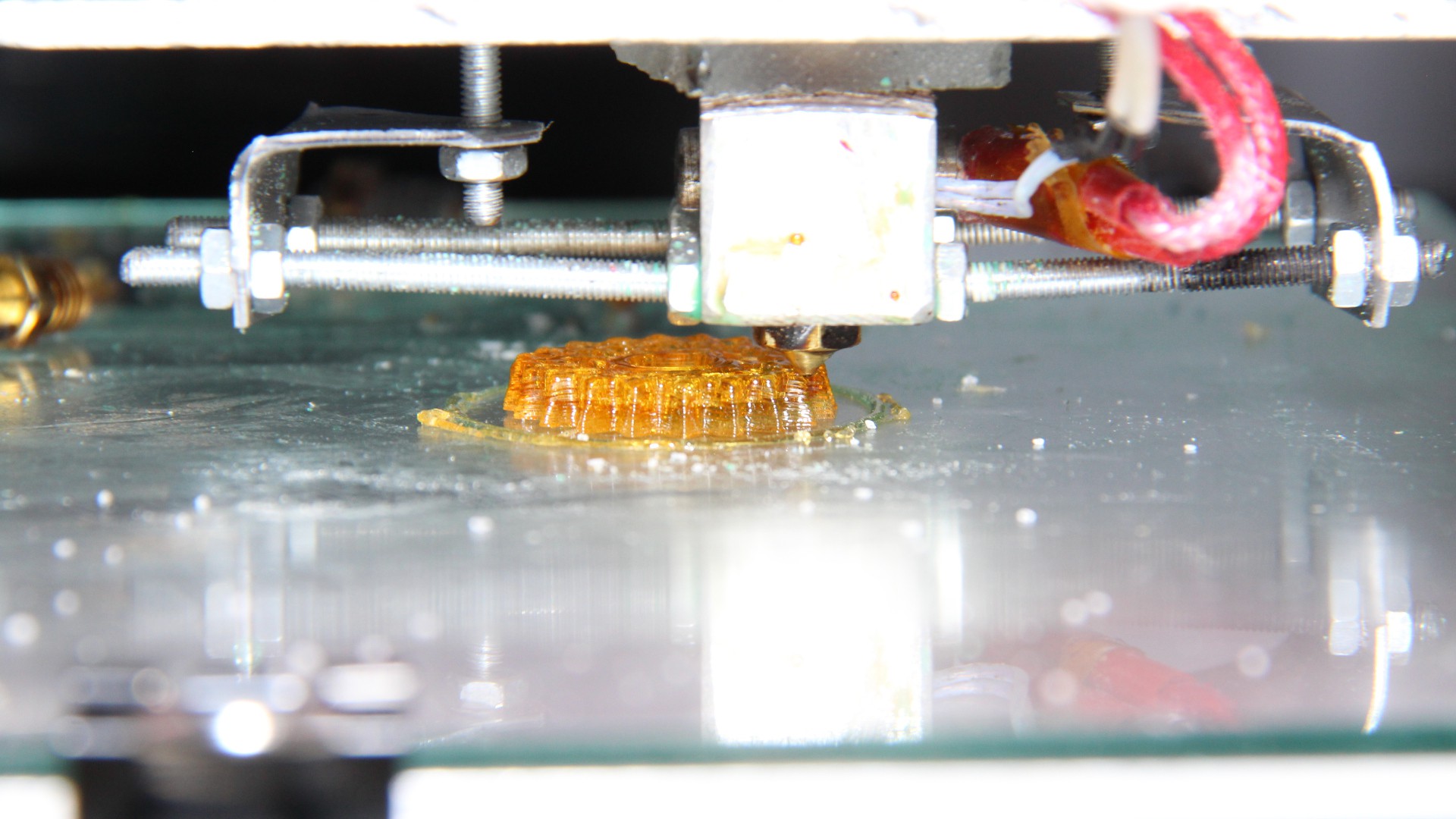

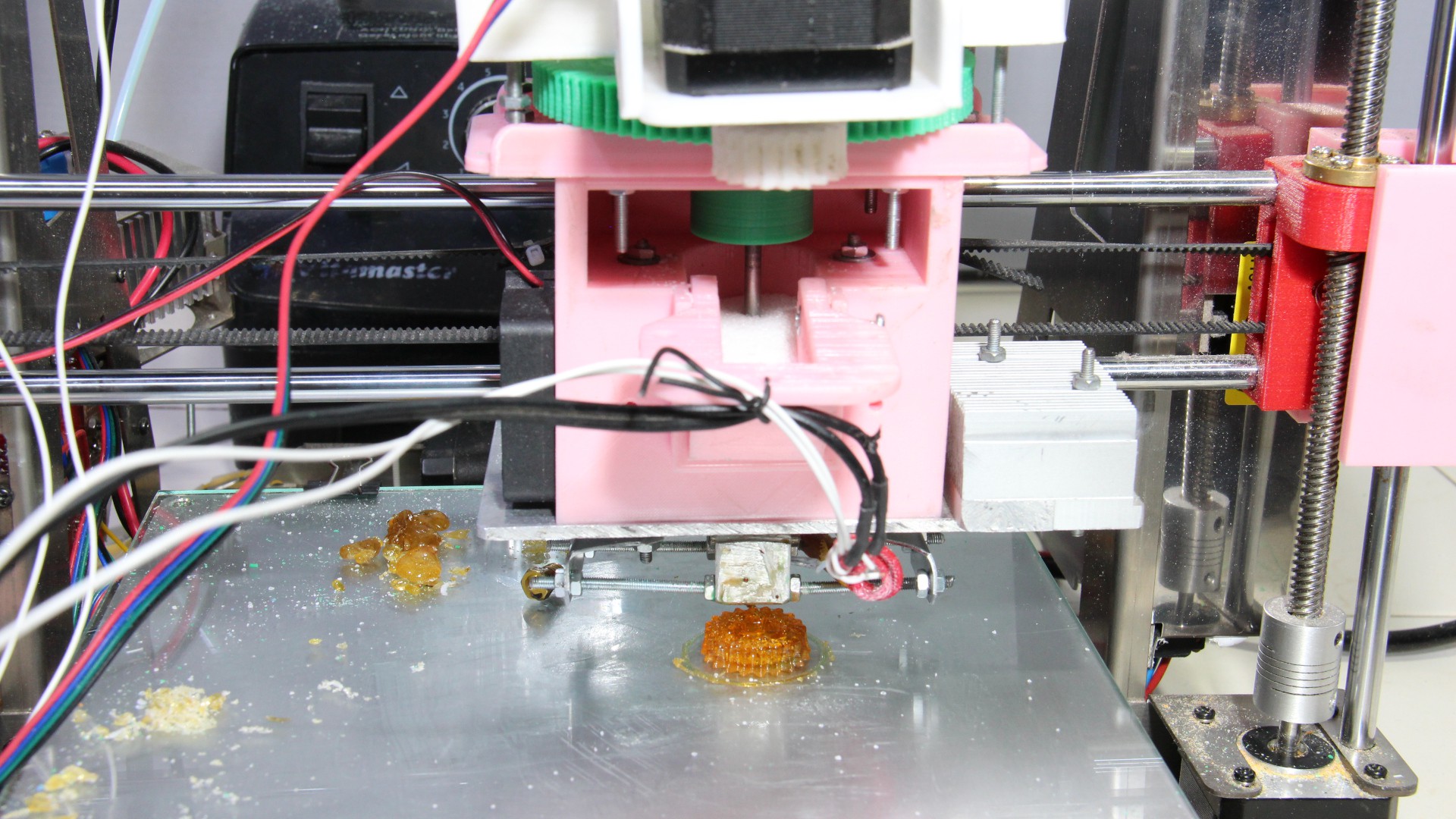

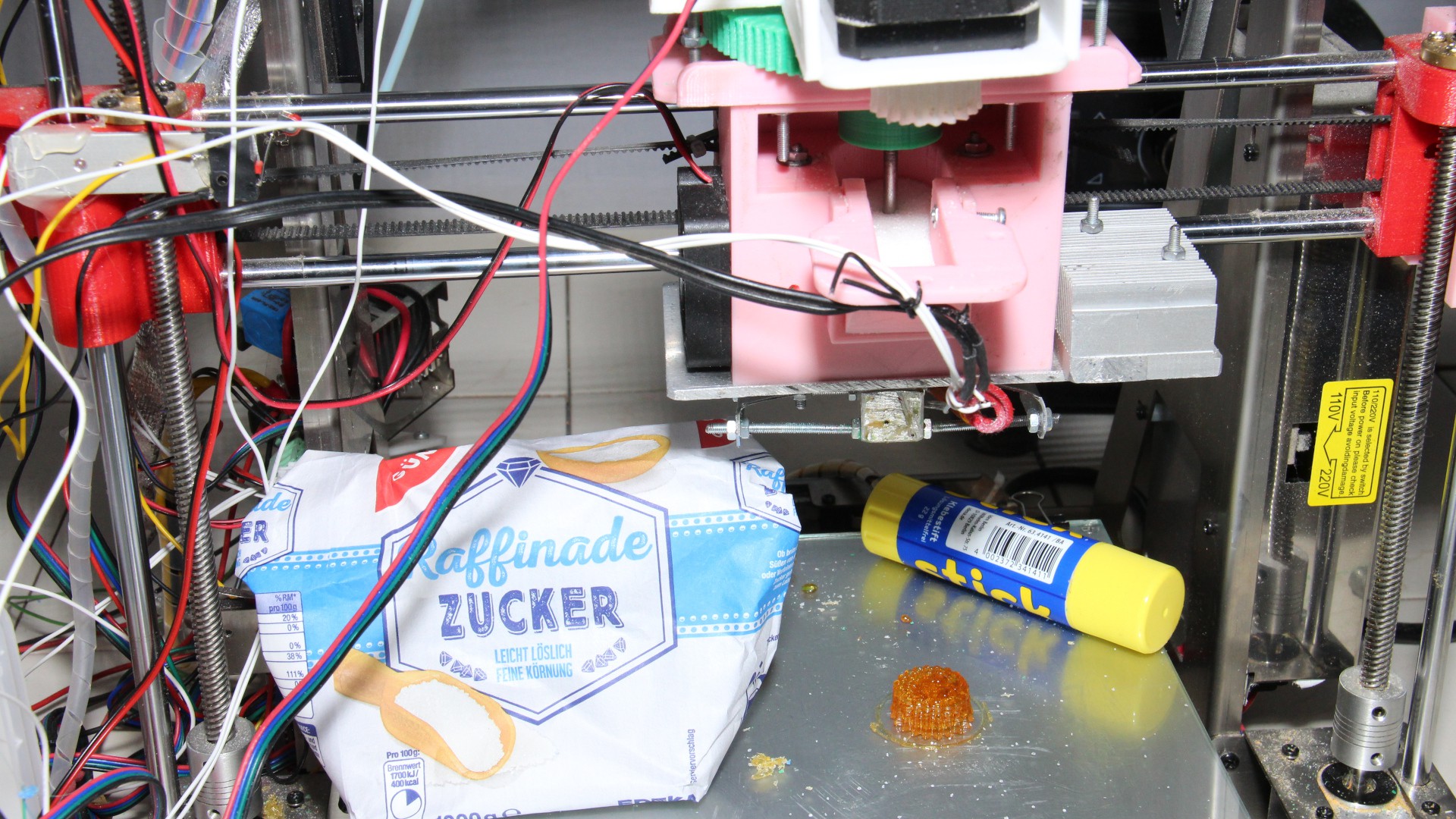

Well, now that there is sugar in, let's give it a test run anyway. Getting a first layer stick to the print bed worked in the third run. I swapped to a different wood screw to get a higher extrusion rate. The layer of glue stick grew thicker with each run. Finally the printer made it:

While the print grew layer by layer, I have adjusted the flow rate. It was tricky to do so, because of the very different properties of the extruded sugar. Due to the more water like viscosity and the high surface tension, the top layer always looked a bit rough. Nevertheless the gear grew:

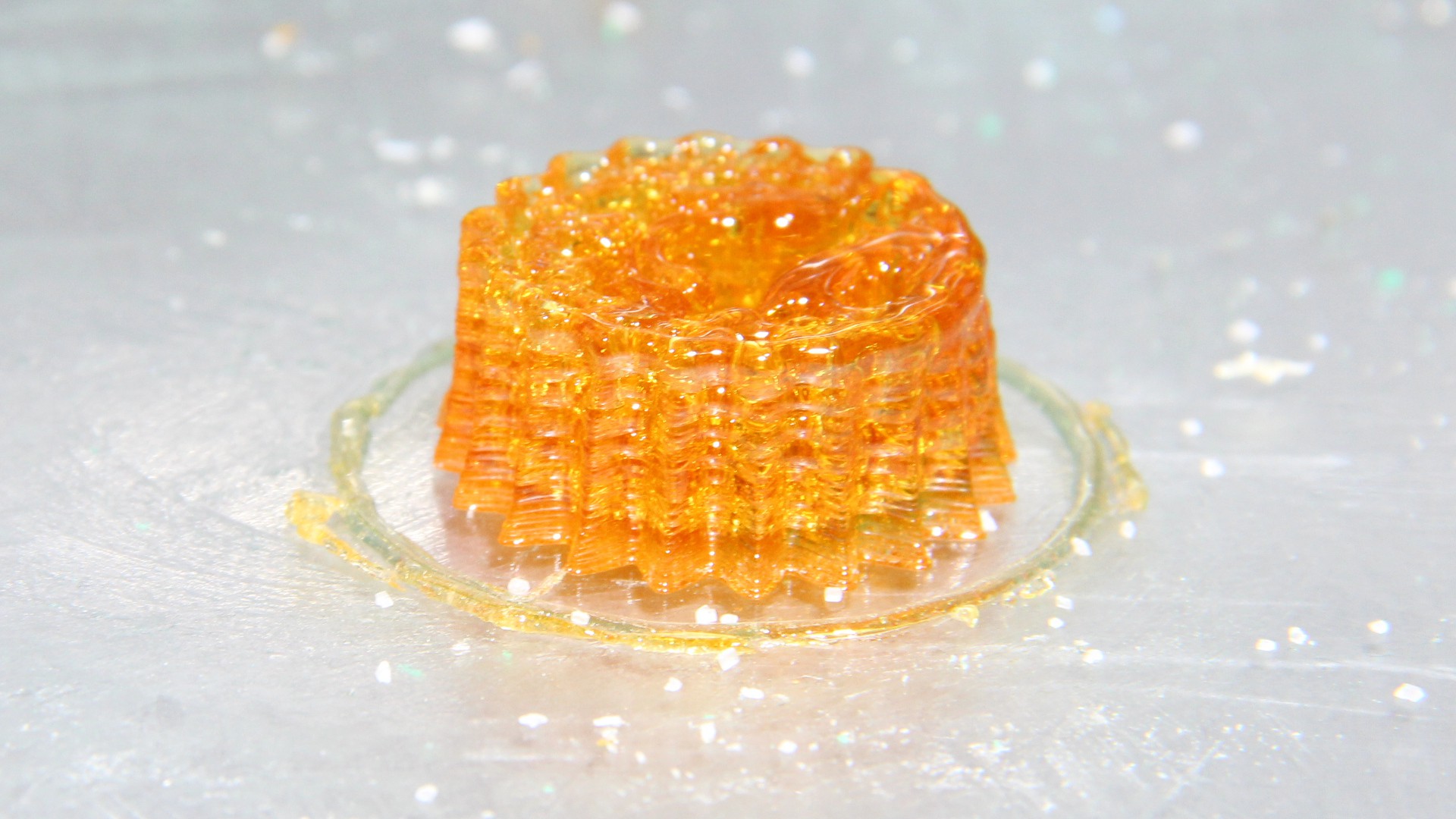

The final result is far from being perfect, but keep in mind it was just a lazy Sunday afternoon project:

There is more than just one kind of sugar available in a supermarket, maybe that there are better recipes for the "sweet spot". Sugar is too brittle to be turned into filament, so there is no way around a direct granule extruder if you want to print with a brittle material like that. It would be a great material for water soluble support structures.

Norbert Heinz

Norbert Heinz

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.