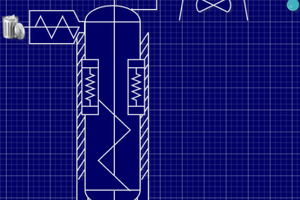

The M19O2 Oxygen Concentrator is an open source hardware project based on the well proven "Pressure Swing Adsorption" process, and inspired by the several other similar projects such as - OxiKit, OpenOx, Marut, RepRap and Project Apollo platforms.

This Data Sheet has brief details of the concentrator.

This Instruction Manual provides user specific instructions.

A detailed Assembly Manual is still work in progress and the link will be posted here soon.

Meanwhile, the M19O2 Git repository has all of the latest information needed to build and replicate the device - check the /engineering folder.

- VERSION 1 (α alpha prototype)

- The purpose of this prototype was to understand how the PSA cycle works, the parameters that affect its performance and efficiency, and identify shortcomings in the design.

- The Oxikit design uses easily available PVC plumbing components attached to a wooden and plywood frame. This makes it cheap, but also unsuitable for use in hospital / medical environments where wood and PVC parts are deprecated.

- The PVC sieves need a large number of parts which are glued together. PVC sieve assembly is a tricky process and results in leaking sieves which are prone to failure under pressure. The sieve construction also creates a very large void space at both the ends which affects performance.

- The molecular sieve zeolite material used is Sodium 13X. This has a relatively lower N2 adsorption capacity, which means building much larger sieves and using higher compressor pressure.

- The Oxikit design has copper cooling coils to lower the temperature of the air exiting from the compressor, but it does not employ any moisture separation stage.

- A large part of India has pretty high humidity throughout the year, with coastal locations having as much as >92% rH humidity. This high humidity severely affects the efficiency of the zeolite since it adsorbs moisture more than N2, but does not de-absorb moisture easily (requires an expensive, time consuming regeneration process).

- This causes a gradual, irreversible reduction in oxygen generation capacity of the machine. The lack of real time oxygen concentration measurement is a major drawback too.

- On the electronics side, the Oxikit code is based on the Arduino platform, and uses blocking “delay” statements to run the timing cycle. This is very inefficient since the microcontroller cannot be used simultaneously for other purposes such as oxygen measurement or safety and sensor interfaces.

- These shortcomings resulted in Version 1 producing O2 at 5 lpm and concentration between 60~70% which was way below our target requirements. After a month of trying to incrementally fix these issues, it was decided to abandon any further effort in improving the Oxikit design and get back to the drawing board for a fresh look.

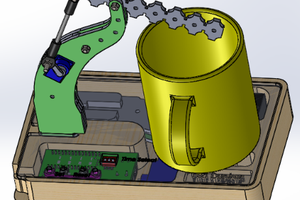

- VERSION 2 (β Beta prototype)

- For Version 2, we decided to switch from Sodium 13X to Lithium LiX zeolite. LiX is three times more efficient compared to Na 13X making it easier to reach target requirements. By optimising the design, it was possible to offset the higher cost of LiX by reducing the cost of the BoM. Based on the learning from Version 1, we also made several other important improvements. Version 2 was built on an aluminum extrusion frame with acrylic parts. To achieve higher output flow rate, a more powerful compressor was used. The PVC sieves were replaced with machined aluminum sieves which were more robust, compact, and had very little void space at the ends. The problem of high moisture content in the compressed input air was tackled by adding a moisture separator with auto-drain mechanism after the cooling coils. An additional canister of desiccant was added after the moisture separator to further reduce the moisture content in the compressed air. This stage was experimental to try out different desiccant materials and monitor their effect on machine performance. An inline temperature and humidity sensor was added...

Anool Mahidharia

Anool Mahidharia

Karsten Fuhst

Karsten Fuhst

oneohm

oneohm

Nickcasio

Nickcasio

Leonardo Zuniga

Leonardo Zuniga

I really like this. It's simple, clean, and easy to use, which is exactly what I was looking for.

https://www.mynorthsidehr.site