First Things First

A full build video of the Mini-Hyperloop as well as function tests.

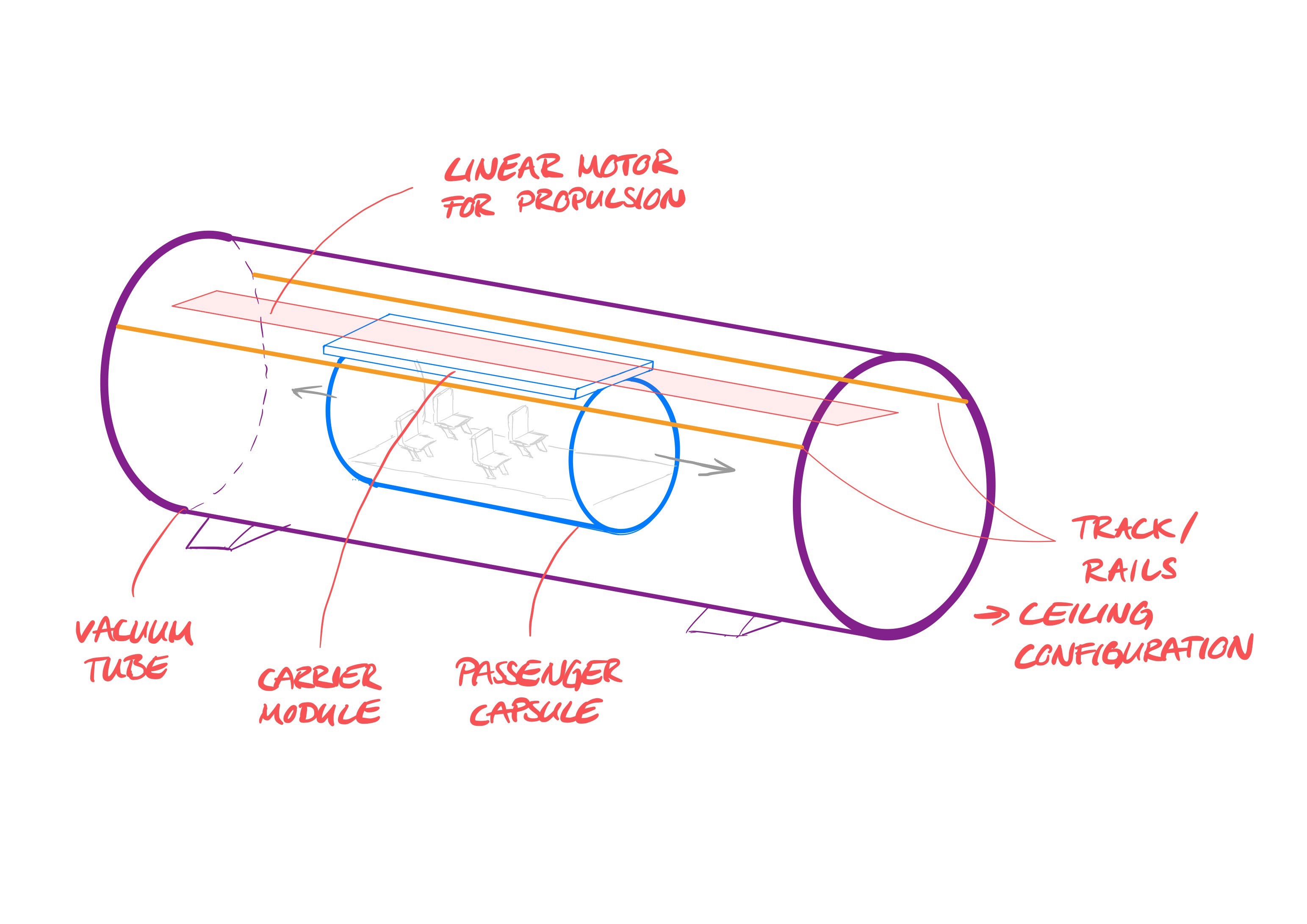

General Concept of a Hyperloop

The concept of a hyperloop consists of the following components:

The passengers or goods are located in a capsule - the Pod, which is moved along a tube by means of a linear motor. To make the transport as efficient as possible, friction in linear direction is minimized by a magnetic levitation system. To ensure that the pod can move through the tube as frictionlessly as possible, even at high speeds, the air pressure in the tube is drastically reduced, which significantly reduces the air friction, which is quadratic to the speed. This concept allows high speeds to be achieved efficiently and safely, enabling people or goods to be transported from A to B quickly, reliably and when done correctly: sustainable.

Motivation

Especially in recent years, it has become clear that globalization increasingly demands decentralization: You buy something online and you hardly realize that it has traveled halfway around the world in no time, only to land at your doorstep.

This complex logistics construct is based on ships, planes, trains and trucks, which are not generally associated with sustainable transportation. Especially the transport of goods and also people close to the city represents a heavy burden for the people living there.

Thus, the idea is to develop a transport system that makes long-distance as well as short-distance transport of goods fast, reliable, flexible and, above all, sustainable. The concept of the Hyperloop, a contactless moving vehicle in a vacuum tube, can be used to achieve exactly this. A Hyperloop is scalable, can be built in a wide variety of sizes, and thus can be used for a wide variety of purposes - besides the most popular: passenger transportation.

The concept of the Hyperloop can be used to transport different sized goods in a highly efficient, fast, flexible and sustainable way. Be it over long distances between cities or underground in cities, where it could be installed in already existing tubes.

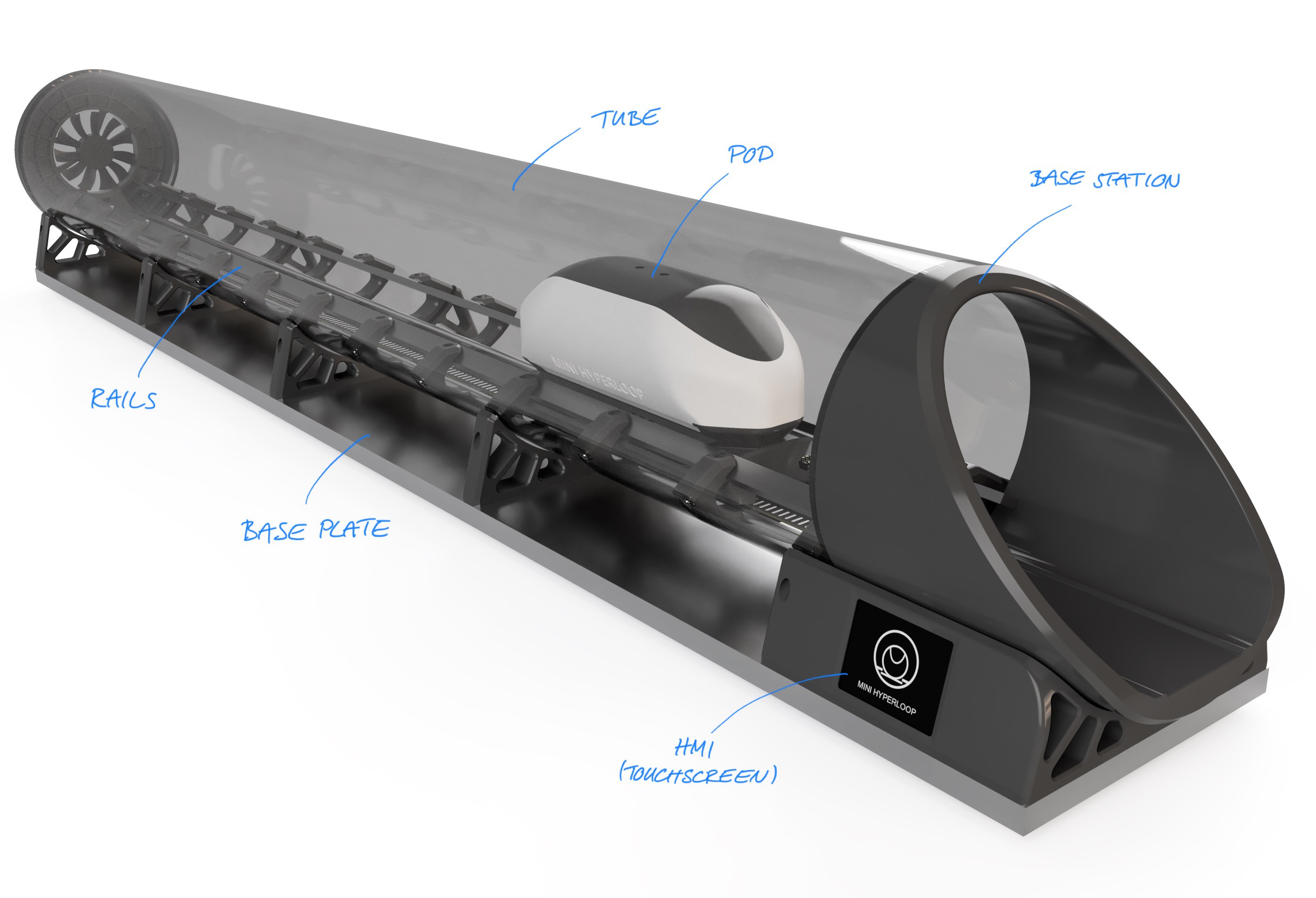

With the development of the Mini-Hyperloop I want to show that it is possible to implement this technology on a small scale. In this first version, a vacuum tube was initially omitted and the levitation system of the pod was supplied by a battery, which can be replaced in a further version by an inductive power transmission to make the system even more efficient. Nevertheless, this illustrates that it is possible!

Status Quo

The mini hyperloop has a driving distance of one meter. It is able to levitate as well as to drive up and down the track completely contactless. The tube is currently only for illustration purposes. The air pressure is not yet lowered here to minimize air-drag. In addition, the pod is currently powered by a battery. The system is controlled wirelessly by the base station located at the track, what enables positioning of the pod at different speeds as well as safety monitoring

Vision

The next step is to extend the track and achieve a higher speed of the pod. To achieve this, the linear motor and the levitation system are to be optimized. In addition, the battery is to be replaced by inductive energy transfer so that the pod is lighter and, above all, sustainable to manufacture - no battery.

Once this is achieved, the first test installations can be set up, whereby the scaled Hyperloop can be used for high-speed transport of goods over short distances. For example, sensitive goods could be transported quickly from A to B in hospitals in this way.

There are no limits for further developments, the only important thing is to "do it" :-)

The Mini Hyperloop

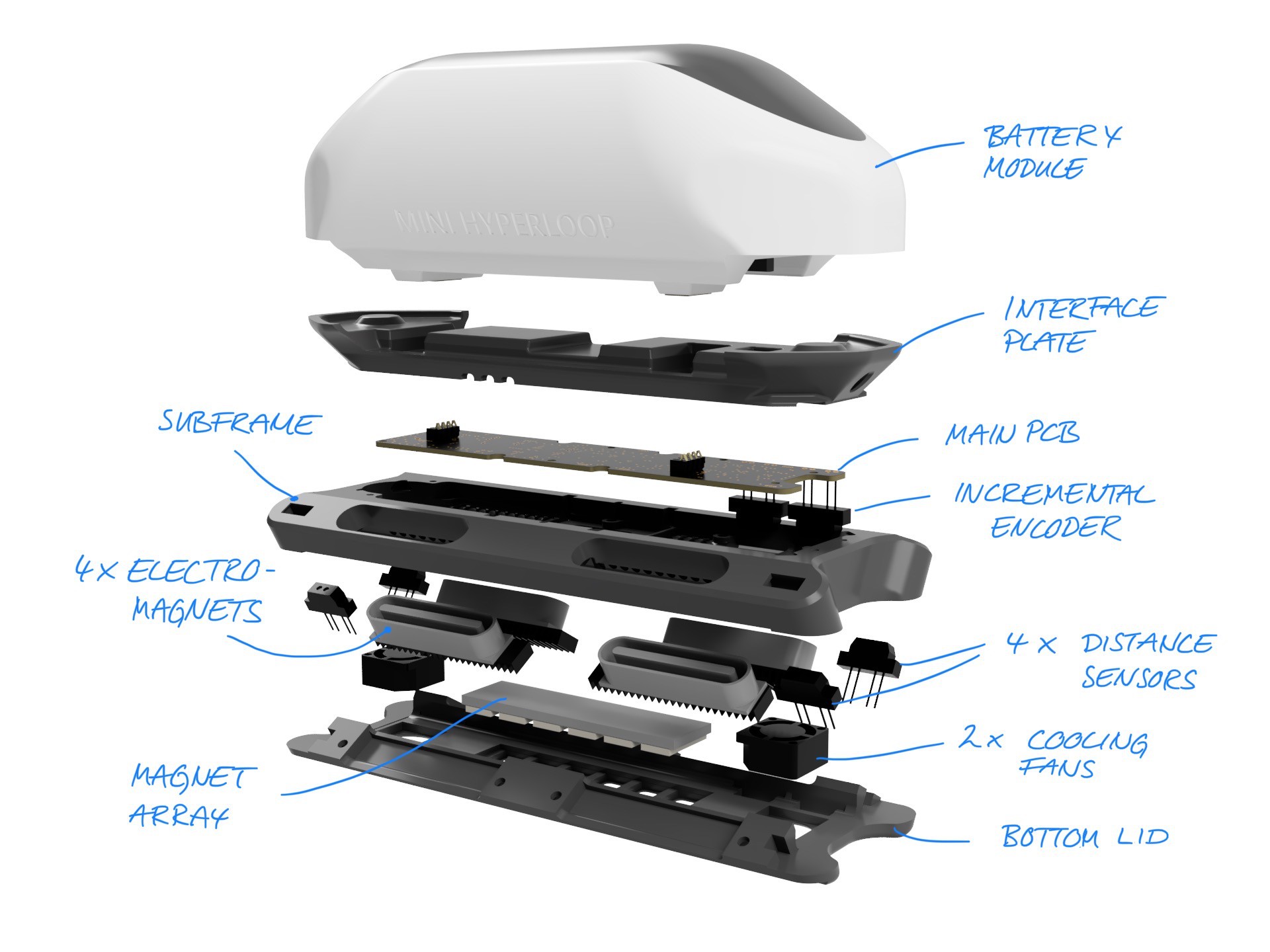

The Mini Hyperloop consists of a magnetically levitating Pod and a track with long stator linear motor which allows for magnetic linear propulsion.

Pod:

- Levitation magnets with electronics

- Battery

- Magnet array for linear motor

Track:

- acrylic tube (no vacuum in this version)

- passive tracks

- long-stator linear motor

- linear motor control

- BLE connection with pod

- Control unit (Touch screen HMI)

→ For pictures of the actual prototype, check out the Build Log as well as the Build Video :)

→ For pictures of the actual prototype, check out the Build Log as well as the Build Video :)

Adrian Prinz

Adrian Prinz