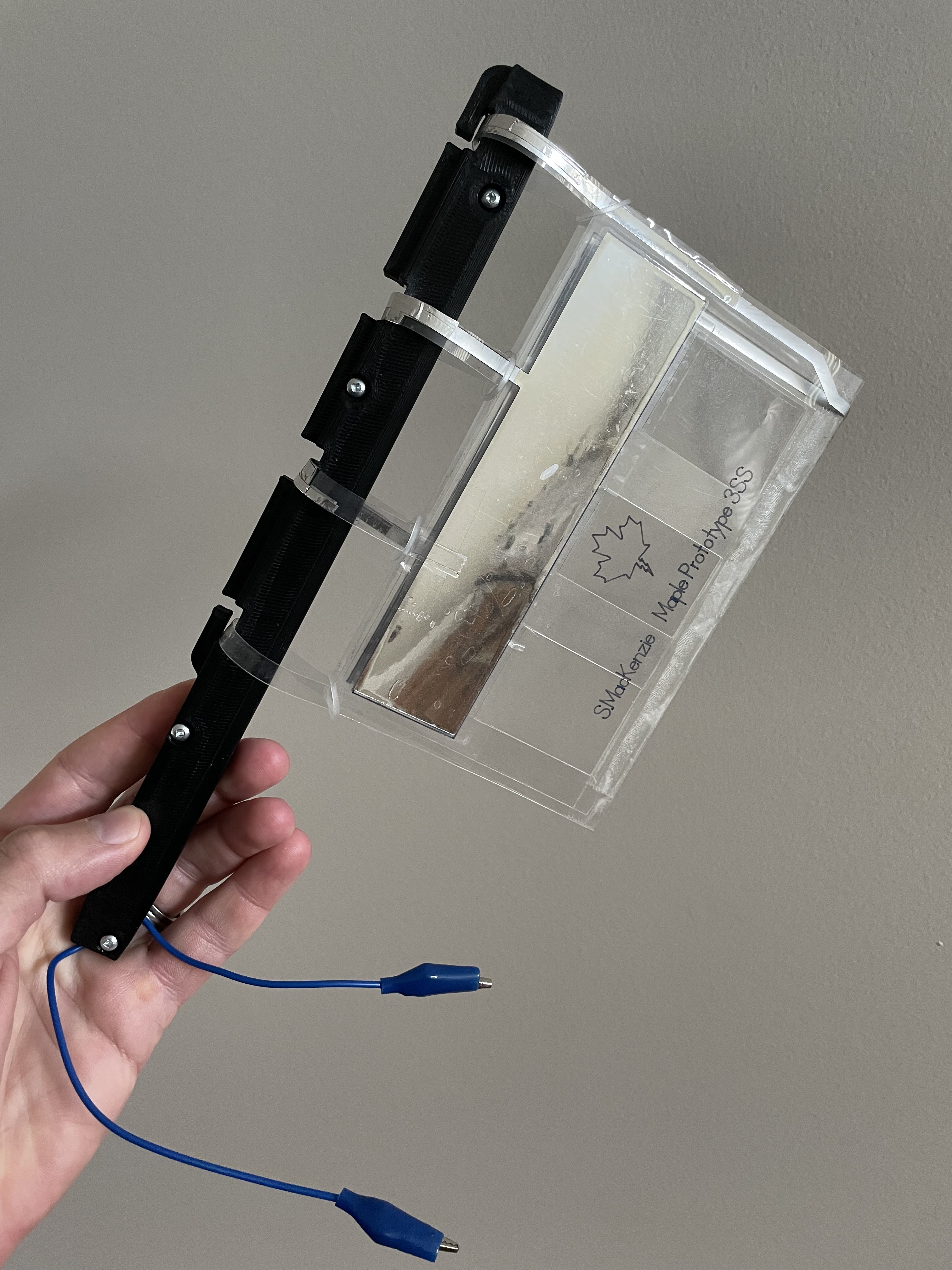

The poor humidity performance and unreliable switching was persisting, so at this point I decided to get rid of the surface contact switches altogether and replace them with diodes. I also changed the design to get better separation of the oppositely charged areas, and started trying different materials and insulating the generators with tape. I also bought a Cricut cutting machine to make the generators more quickly with the time I had available. I tried some designs with the diodes housed in a 3D printed mast, and very simple 3 or 4 diode harvesting circuits. This is a 3-sector design, with no storage capacitor:

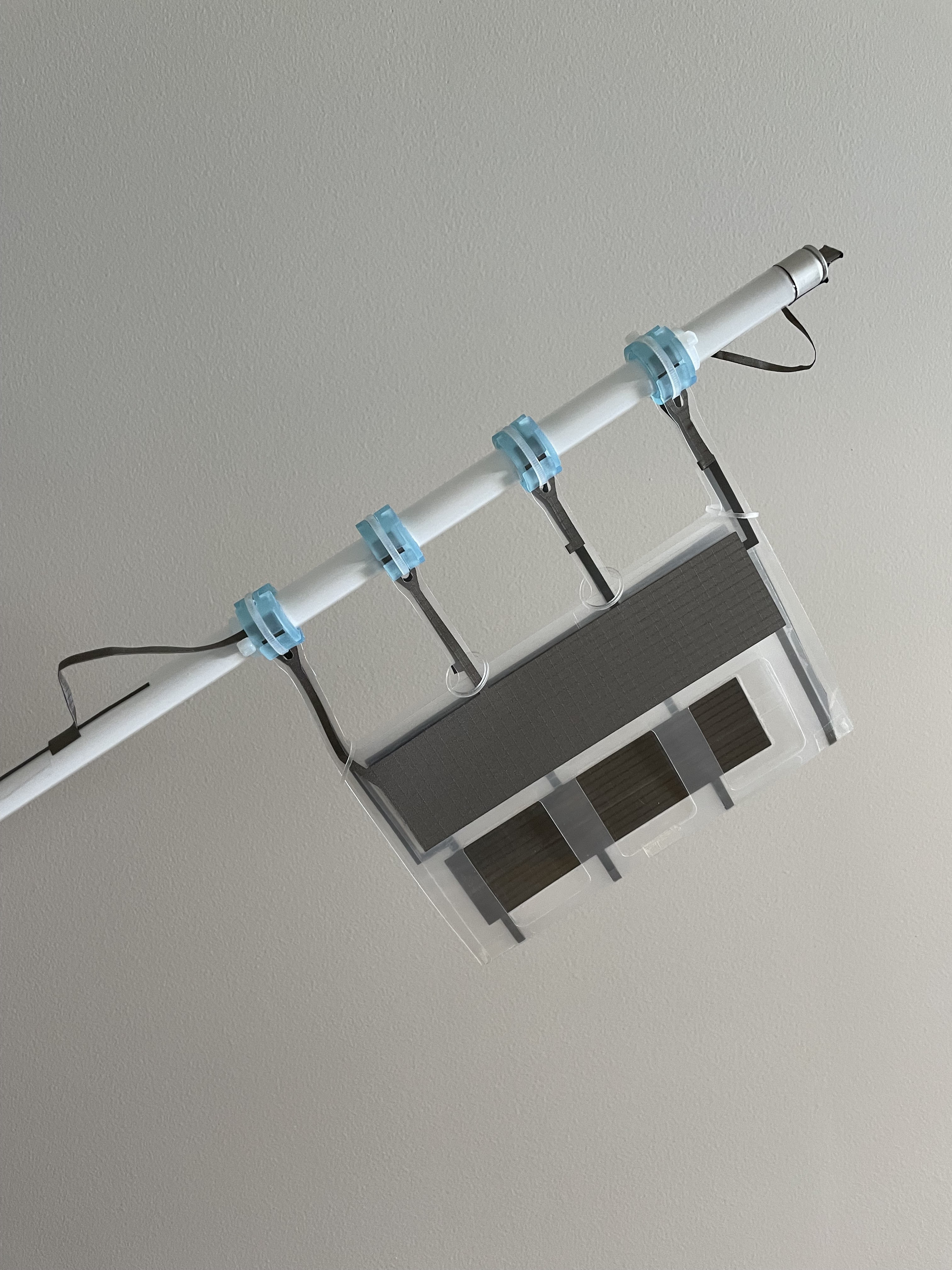

The design later progressed to having the diodes mounted in small 3D printed swivel rings that can slide over the fluorescent light itself, or over a piece of acrylic tubing if I want to try powering some other kind of load. The rings are 2-pieces, and are put together with a small zip-tie, which squeezes the ring a little bit and pinches the electrical connections between the diodes and the conductive film. You can see on these generators, I'm using small elastic bands to restrict the distance that the generator opens in the wind. One nice thing about this design, is that the electrical connections are secure, and there are no sliding contacts or subject to repeated stress. The use of diodes instead of surface contact switching allowed for a design with all the oppositely charged surfaces to be very physically separated, which really improved the performance in ordinary air humidity. Variations of this overall design are still among my favorites, but they require a high resolution 3d printer:

Stuart MacKenzie

Stuart MacKenzie

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.