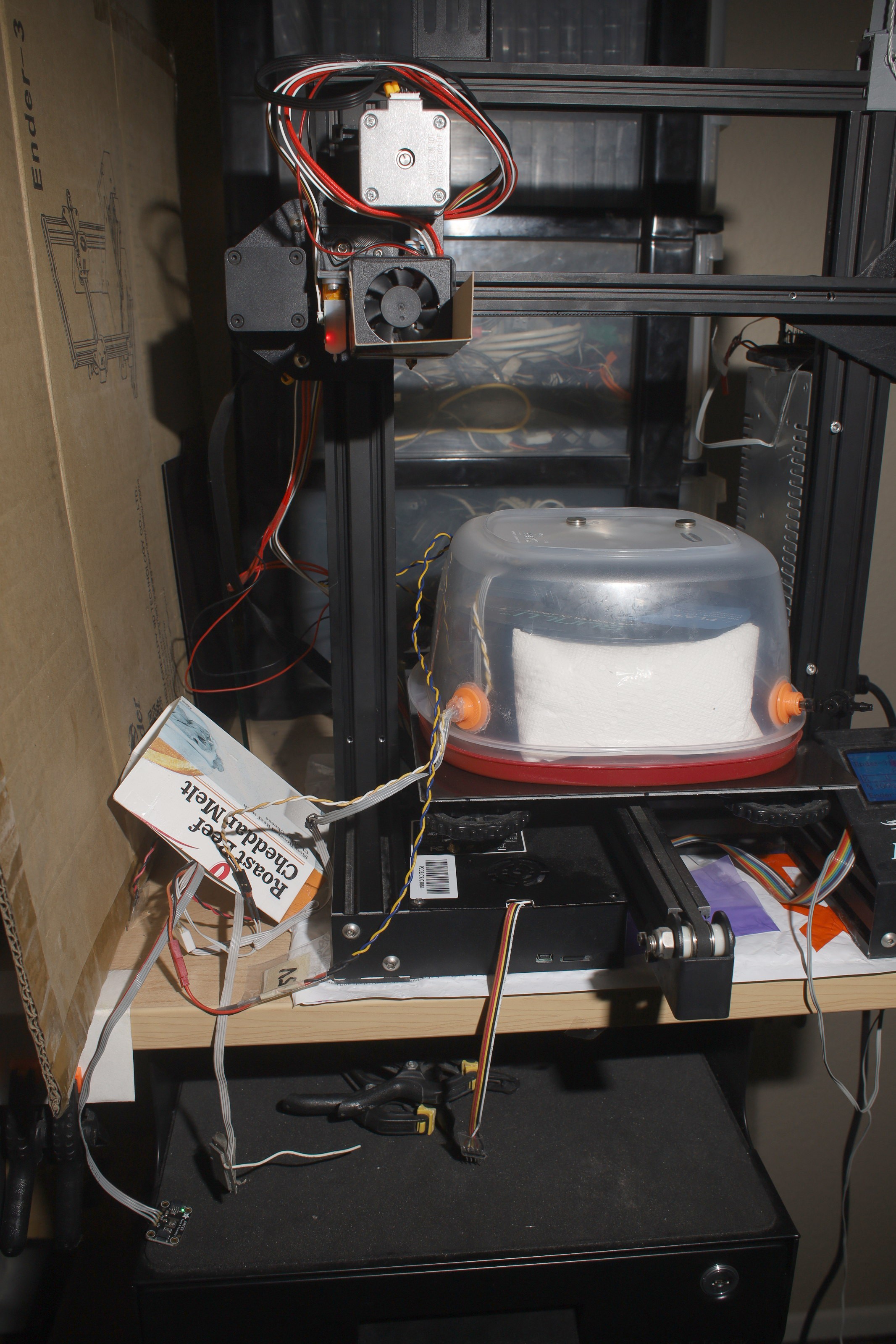

TPU got wet just from an extended period of printing. Keeping it dry in the last mile is unsolved.

To speed things up, the menagerie was moved to the good old print bed at 60C.

It became highly desirable to turn off the extruder fan & save on dust. A JST connector would do it.

After a few hours pulsing in 240W to keep the bed at 60C, the chamber reached an equilibrium it couldn't leave. 34C & 23% humidity on the inside was the best it could do. Merely opening the container sent the humidity up & the temperature down. This practice of drying filament on top of the print bed, in an open container was obviously a waste.

After throwing it back in the sun, it popped to 54C 15%. The sun was definitely capable of more heat with a lot less effort, but during far shorter periods. $3000 doesn't buy a back yard with constant sunlight. It may also be a problem of the desiccant releasing water when it's hot & more heat being transferred to the desiccant than the filament when it's on the print bed. A bigger container might allow better placement of the desiccant & better air circulation. A container that's wider than taller would allow more air circulation & a bigger fan, but consume more precious rent.

The best performance would come from keeping the desiccant cold & the filament hot, with air as a working fluid transferring water. There might even be a peltier cooler for the desiccant.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.