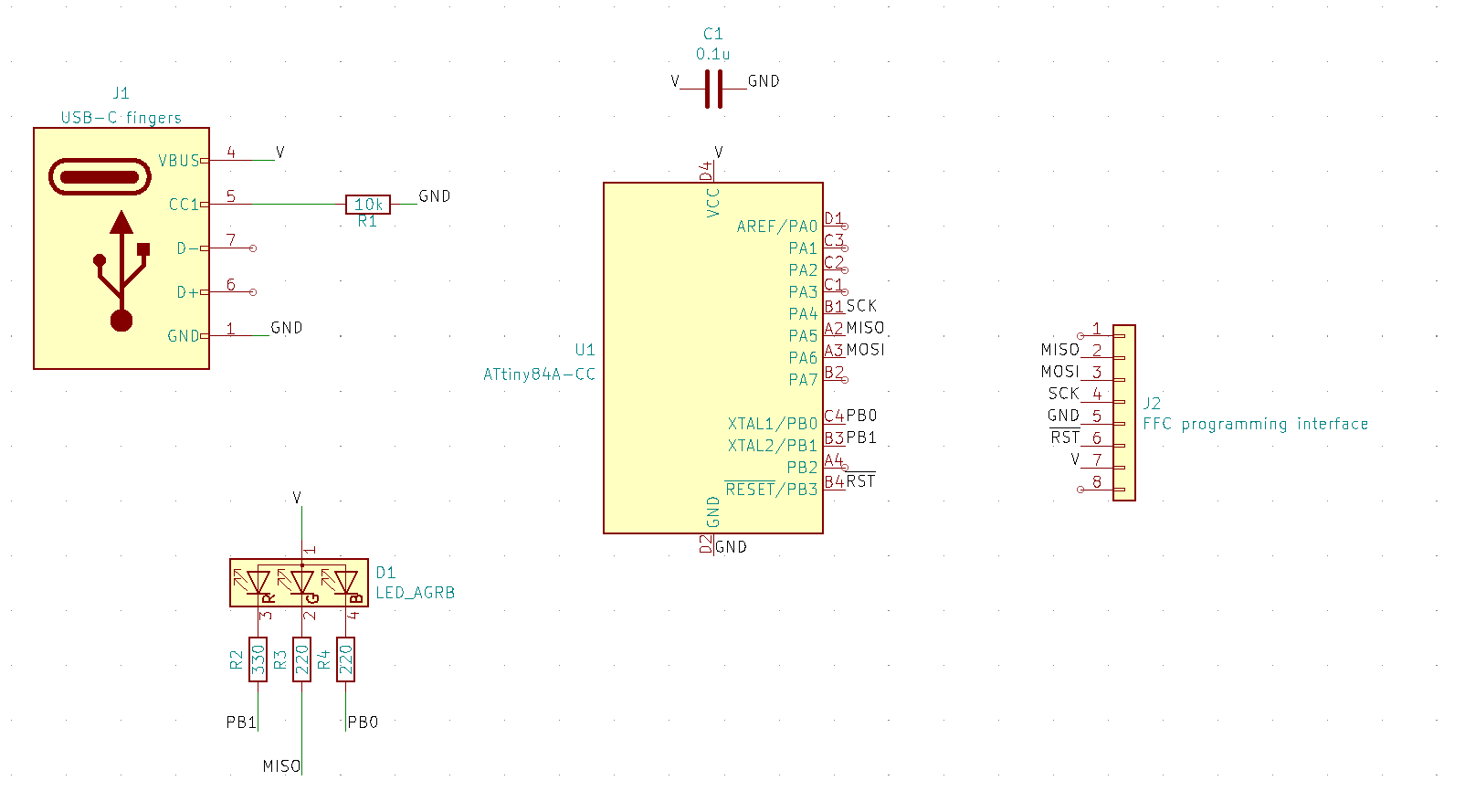

This is part of an ongoing series of projects involving creative interpretations of the USB mechanical standards. You've probably seen 2.0mm thick PCBs that fit in USB ports, and maybe you've seen 0.6mm thick PCBs that fit in USB-Micro cables. So what about USB-C? The plastic tab inside a USB-C port is about 0.7mm thick. I think [bobricius] has had success using 0.8mm thick PCBs; 0.6mm thick PCBs are way too loose. I haven't found a fab that will do 0.7mm (or 28 mil) PCBs unless you special-order an entire panel.

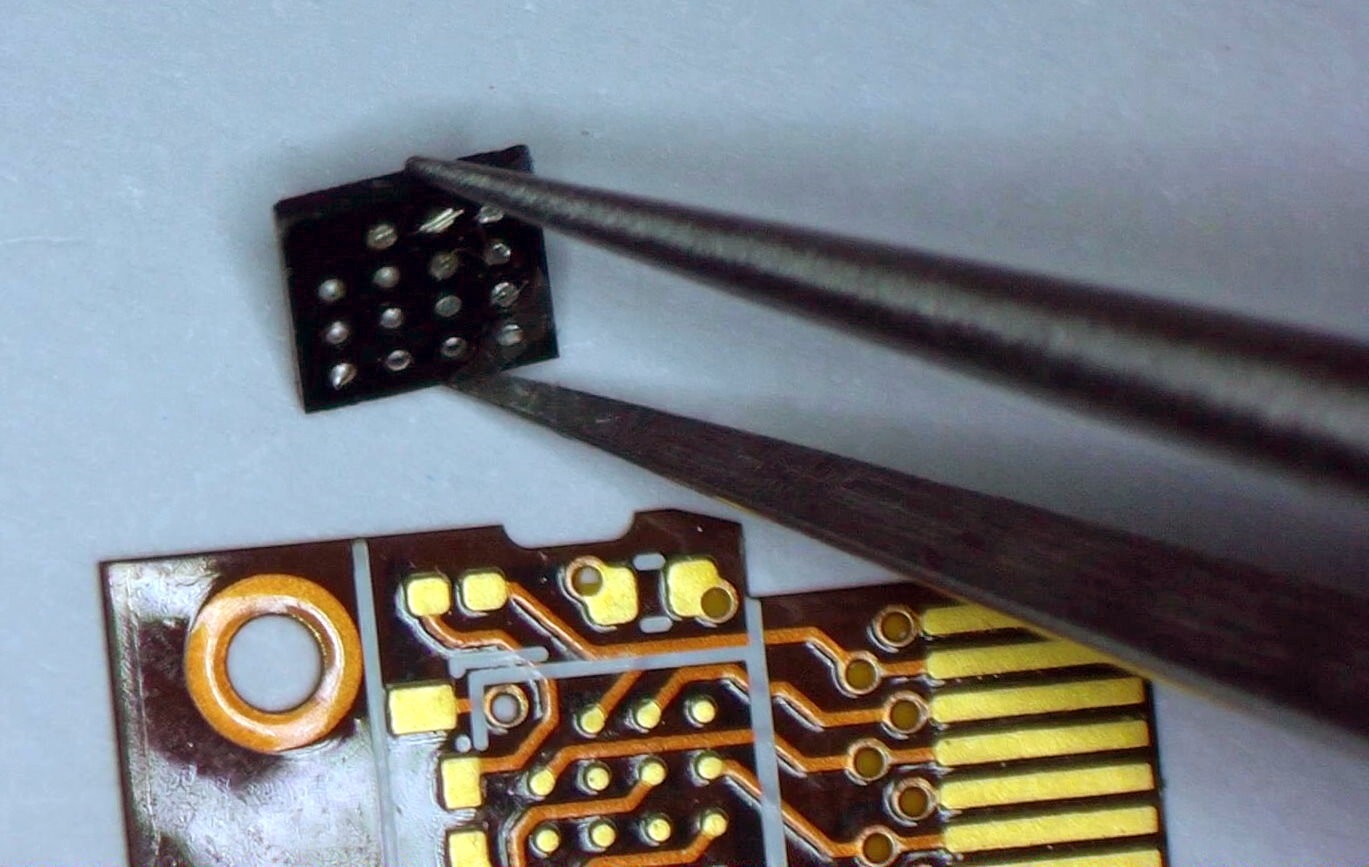

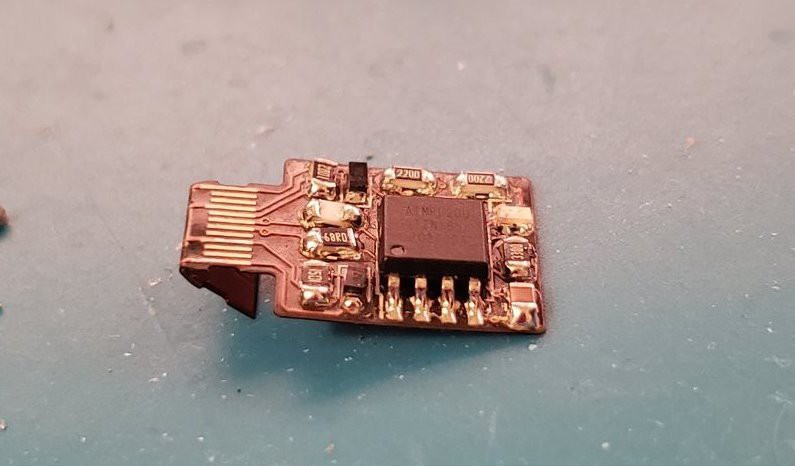

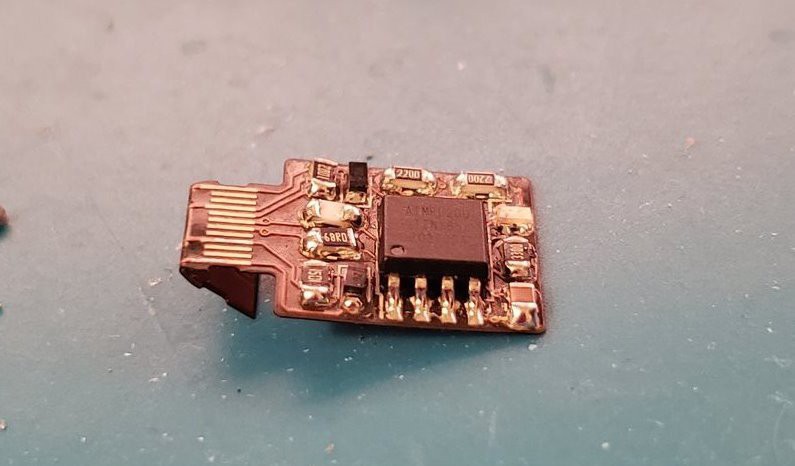

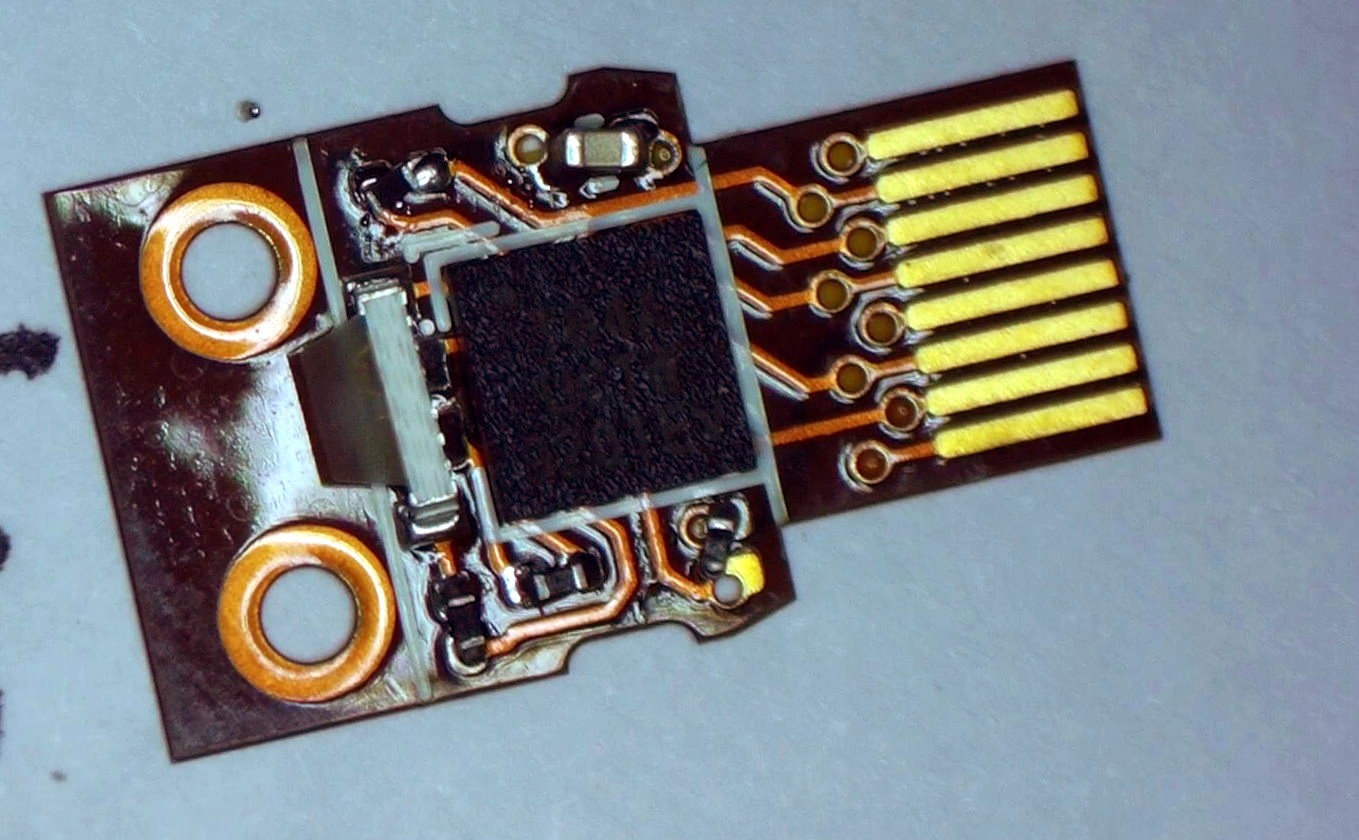

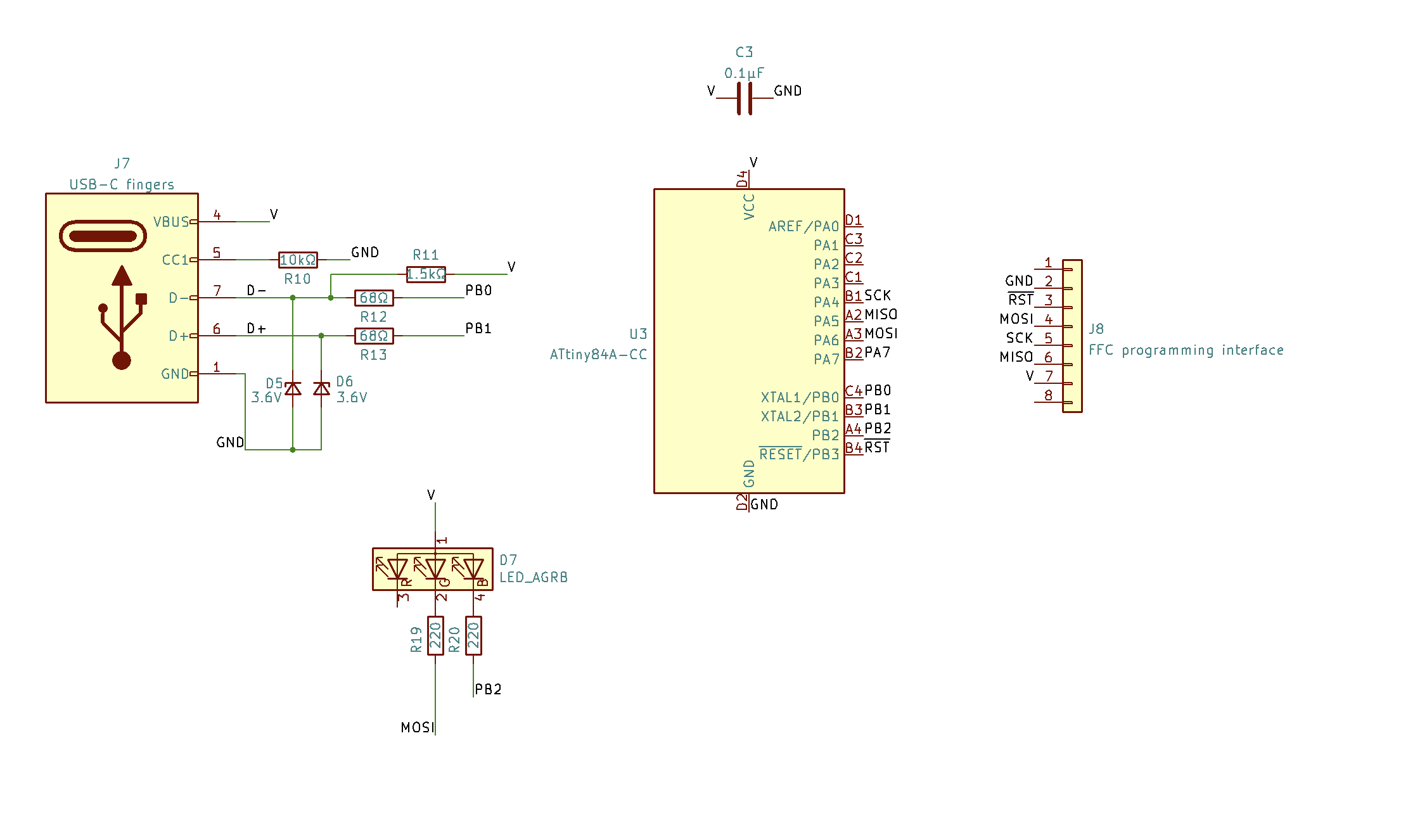

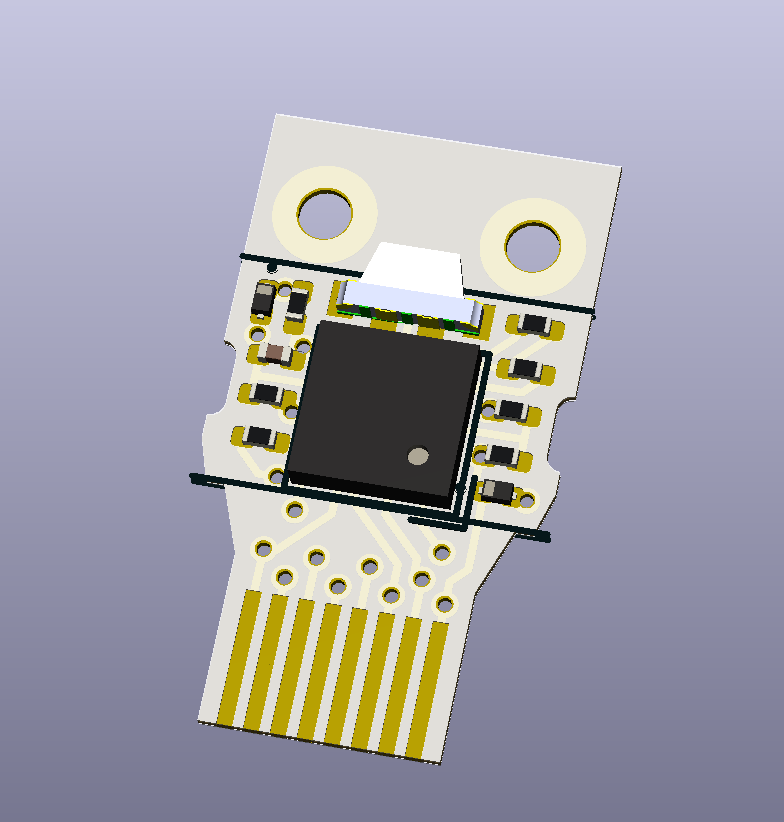

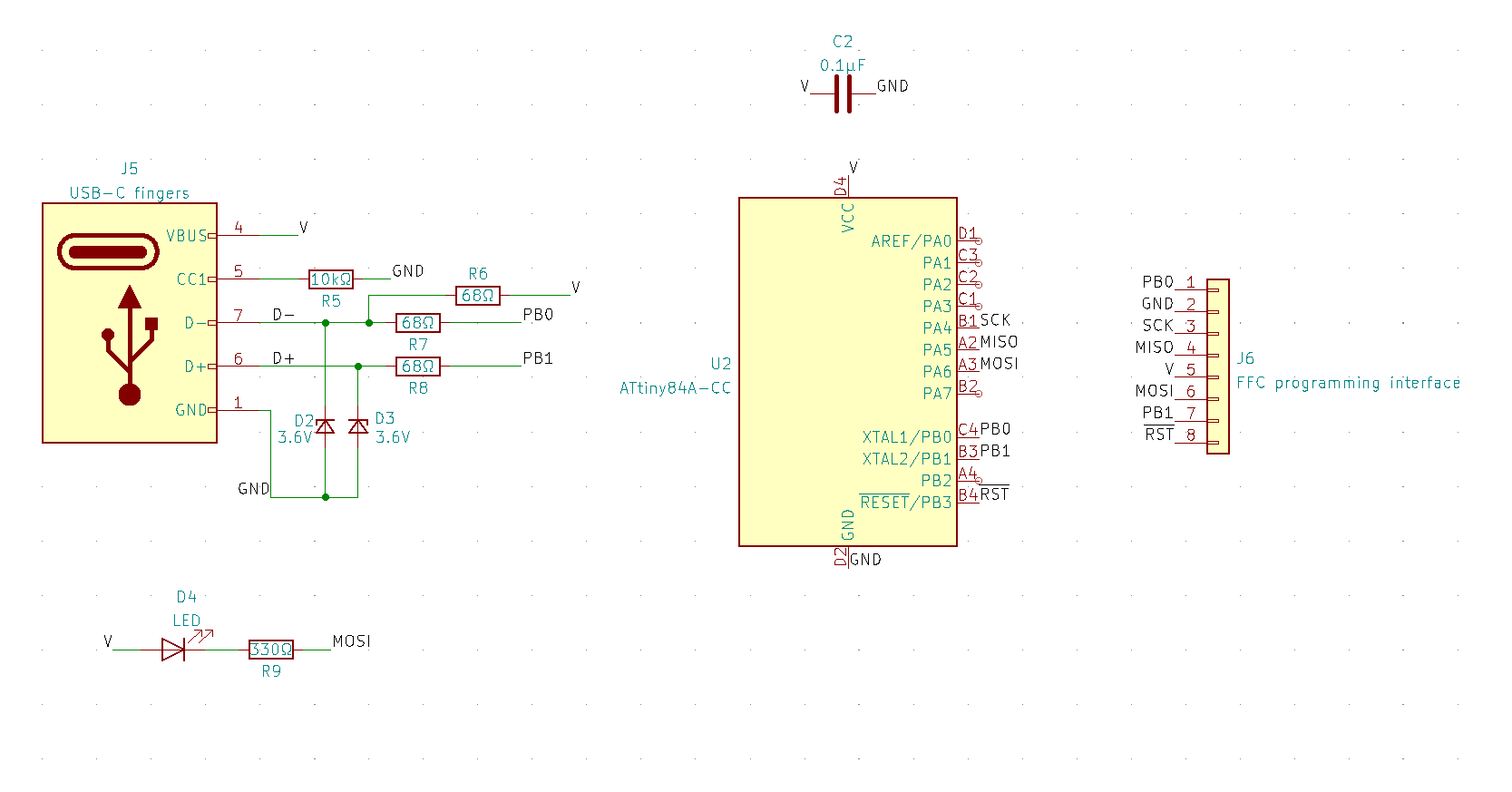

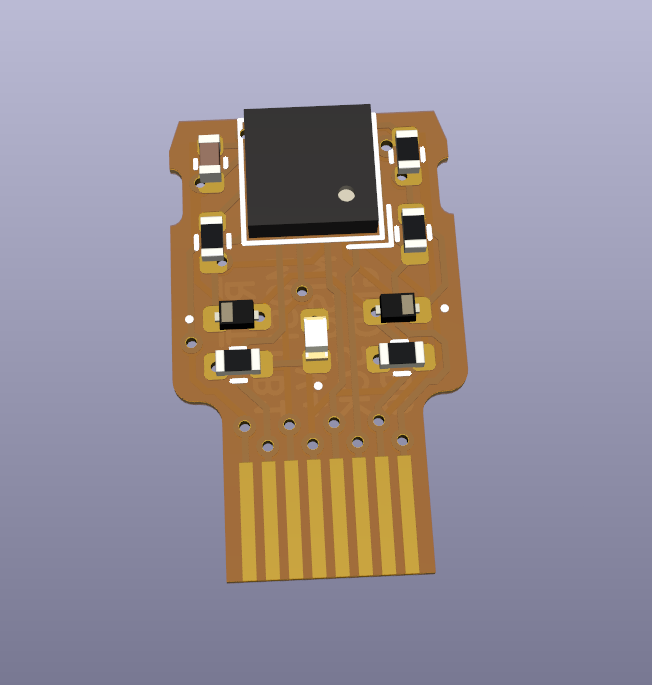

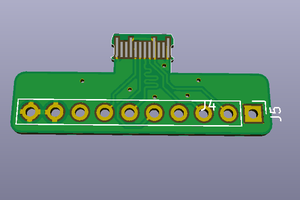

So, what other ways are there to reach 0.7mm thickness? My original plan was to join an 0.1mm flex PCB and an 0.6mm FR4 PCB, but then I realized: you know what else is 0.6mm thick? The ATtiny84A BGA package. Granted, there are only contacts on one side of the PCB, but that shouldn't matter with the symmetric USB-C pinout, right? ...Right? (foreshadowing)

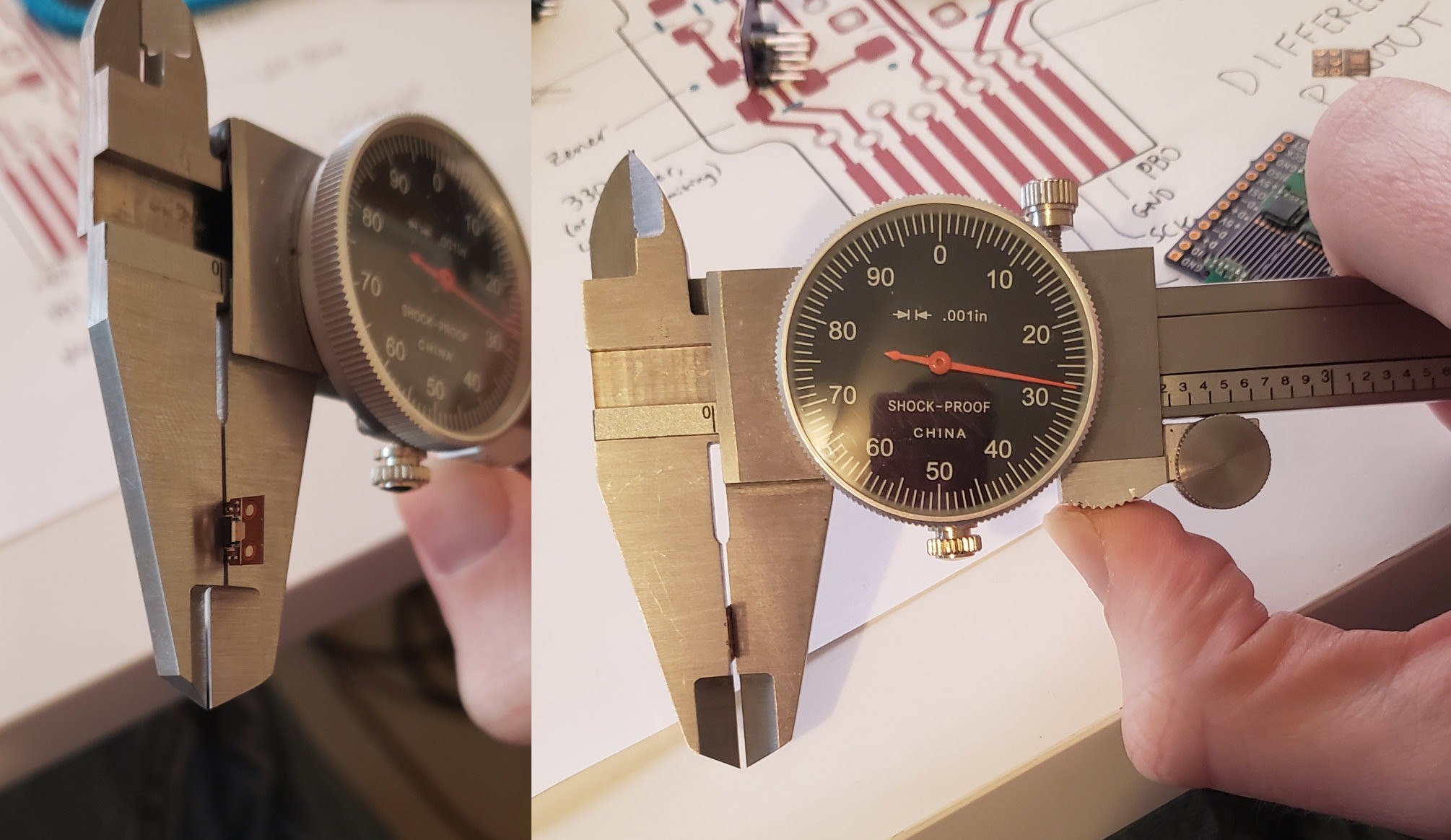

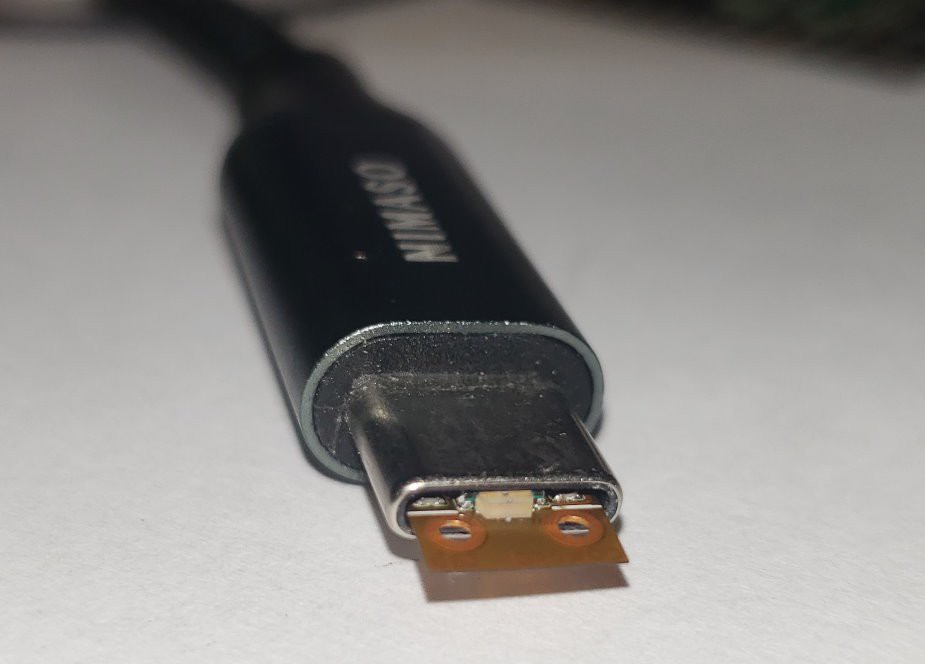

The 3mm-square ATtiny acts as a stiffener for the flex PCB, and it comes out to 0.7mm on the dot! I only have an imperial set of calipers as seen above. The dial shows 0.0275 inches, which is 0.6985 millimeters. This looked promising as a cursed connector! I discuss it further in this project log. But, moving forward, there is a major change: switching to a folded-over PCB.

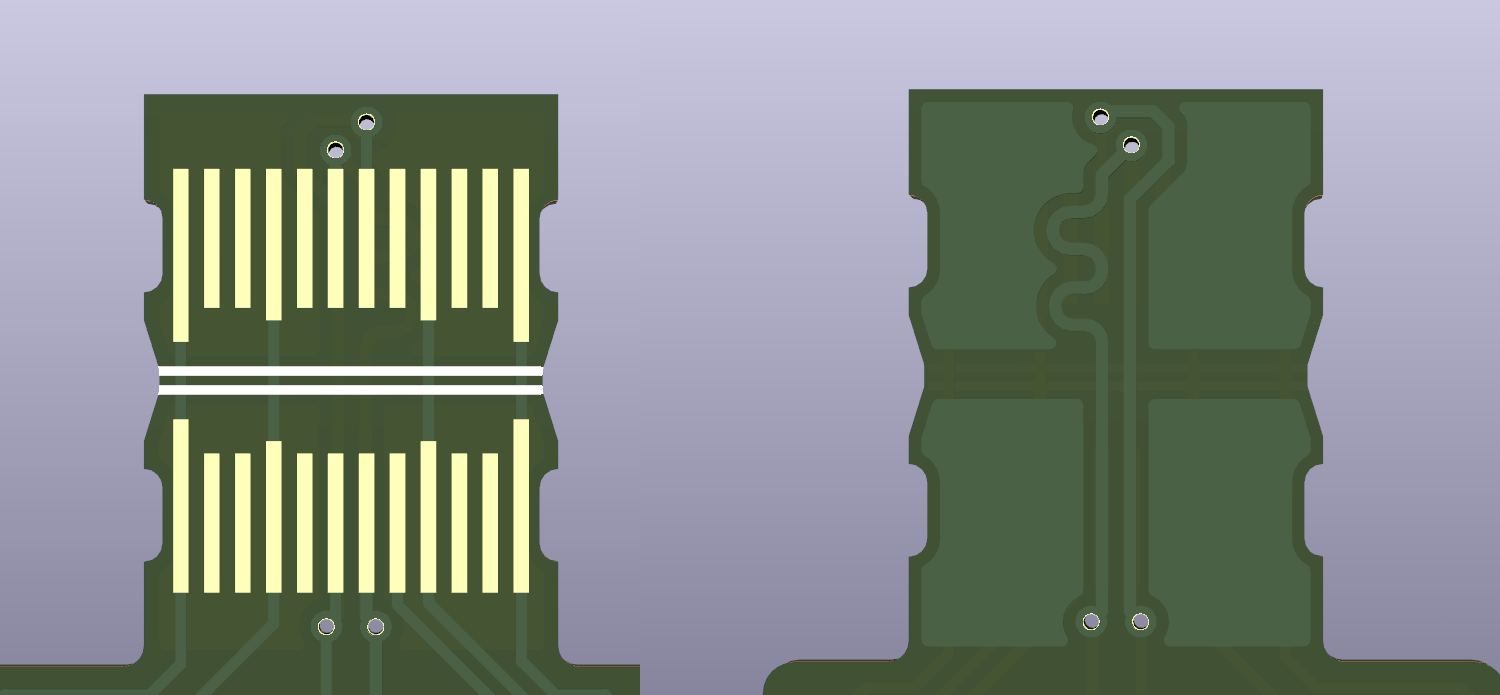

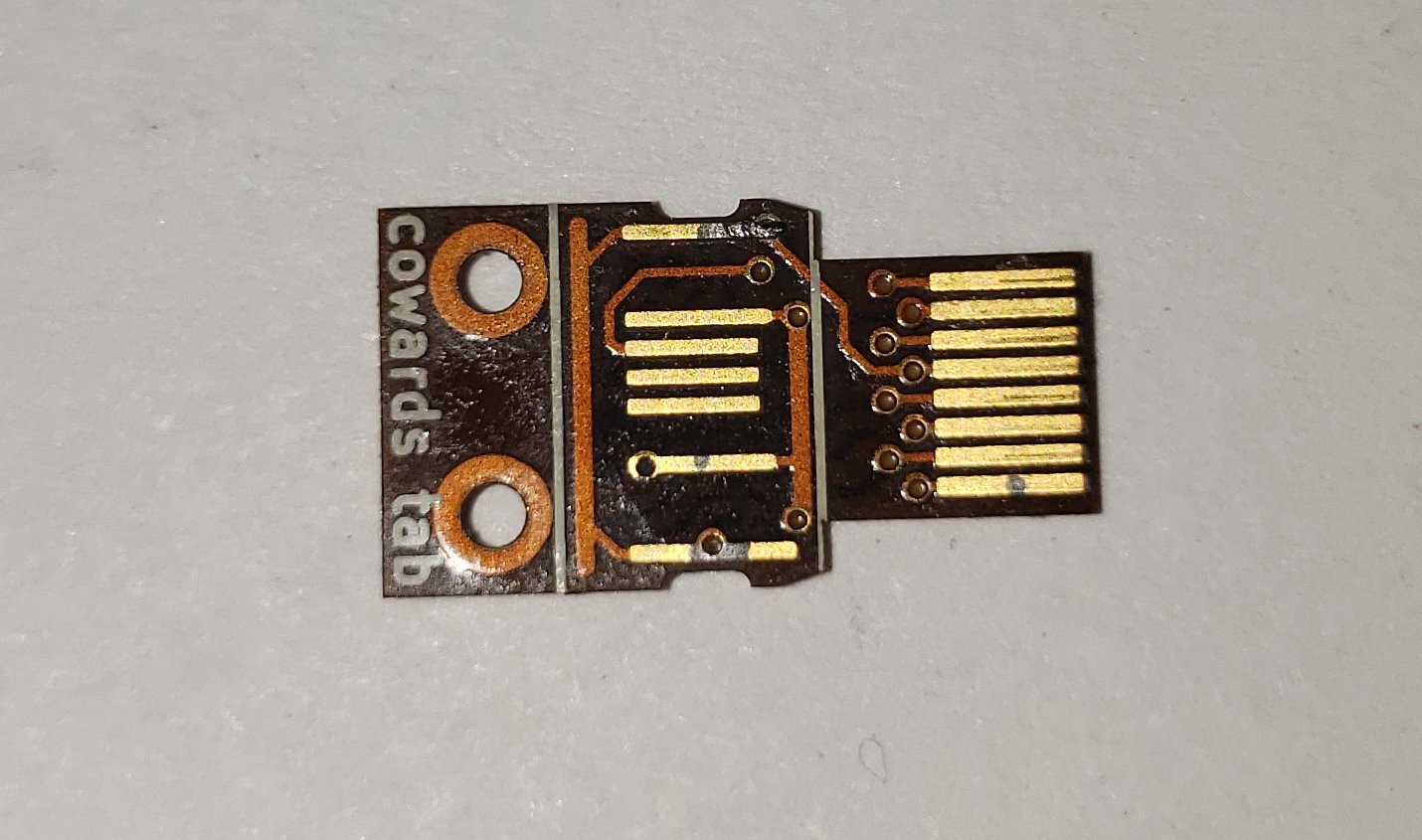

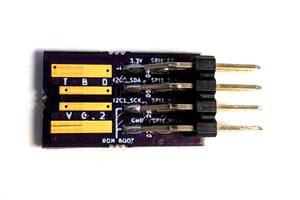

From a structural standpoint, I think this is going to work based on these designs I tweeted about.

With OSH Park flex, this results in a connector that's approximately 0.9 mm thick. Other vendors default to thinner polyimide substrates, which would get this back to 0.7mm. But honestly I'm not concerned anymore with adhering to the 0.7mm thickness; if I'm making unsanctioned USB connectors, may as well go all-in!

Sam Ettinger

Sam Ettinger

ajlitt

ajlitt

Gee Bartlett

Gee Bartlett

Stephen Holdaway

Stephen Holdaway

Alan

Alan

Do you think this could be used to hide microcontroller malware inside USB connectors? Are devices like these capable of transmitting data to an external IP address?