With increases in PCB complexity and component densities, selective soldering is a popular technique for mixed technology PCB boards containing a small number of through hole joints or components. You can use a selective solder machine to replace more time-consuming and expensive systems using wave or hand soldering with fixtures – systems that are also not as repeatable.

Reference equipment link:

Ersa Selective Soldering Systems

Vector Selective Soldering Machines

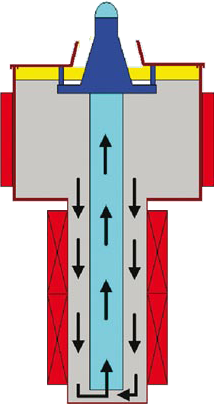

Mini Selective solder machine base on Electromagnetic solder pump. While electromagnetic solder pumps used for selective soldering have several functional advantages, at the same time they inherently have several limitations.

Advantages:

- No moving parts in contact with solder

- stable wave height

- maintenance free

- better than impeller solder pumps

- standup better to lead-free solder alloys than impeller solder pumps

- low nitrogen consumption

- do not wear out

- low cost

- Generates less dross

- Compact and easy to package inside machine

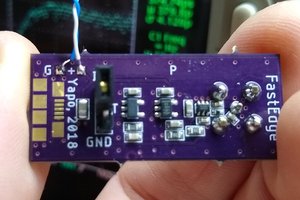

This project uses solder pot base on Electromagnetic solder pump link

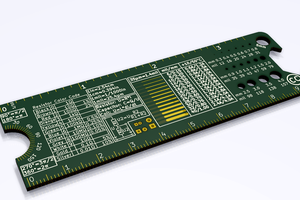

LongLife solder nozzle ,compatible with Kurtz Ersa

SPECIFICATIONS

- PCB holder and X Y Z-axis drive mechanism

Maximum PCB Size 320 mm x 250 mm

Minimum PCB Size 50 mm x 50 mm

PCB Thickness 0.8 mm - 3.0 mm

PCB Warp 0.5 mm maximum

Maximum PCB Weight 2 kg including components

Component Lead Length 4 mm recommended maximum

PCB Edge Clearance 3 mm for components ;5 mm for solder pad edge

Positional Accuracy ±0.01 mm

X-Axis Resolution 0.01 mm

Y-Axis Resolution 0.01 mm

Z-Axis Resolution 0.01 mm

Travel Speed (While Soldering) Programmable from 0.1 mm/sec - 50.0 mm/sec

Travel Speed (Between Points) 500 mm/sec maximum

- Solder wave and bath

Solder Types Both Lead-Free and Conventional Sn/Pb Solders; Second Separate Solder Pot Recommended

When Using Both Types

Nozzle Type 2.5, 3.0, 4.0, 5.0, 6.0, 7.0, 8.0, 9.0, 10.0, 12.0,14.0, 16.0, 20.0 mm Inner Diameter Nozzles Available

Solder Pump Type Electromagnetic solder pump

Solder Wave Height 3~6mm

Solder Wave Height Adjustment Controlled by Fieldbus (RS485/CAN etc.)

Solder Wave Height Accuracy ±0.1 mm

Solder Pot Capacity Approx. 8kg

Solder Temperature 4000C maximum (6000C optional)

Solder Melt Time at Startup Approx. 20 min.

- Controller and Optional accessories

Controller ...

Read more » martin.z

martin.z

Ted Yapo

Ted Yapo

Elite Worm

Elite Worm

Jan B.

Jan B.

Daren Schwenke

Daren Schwenke