Tool Bar

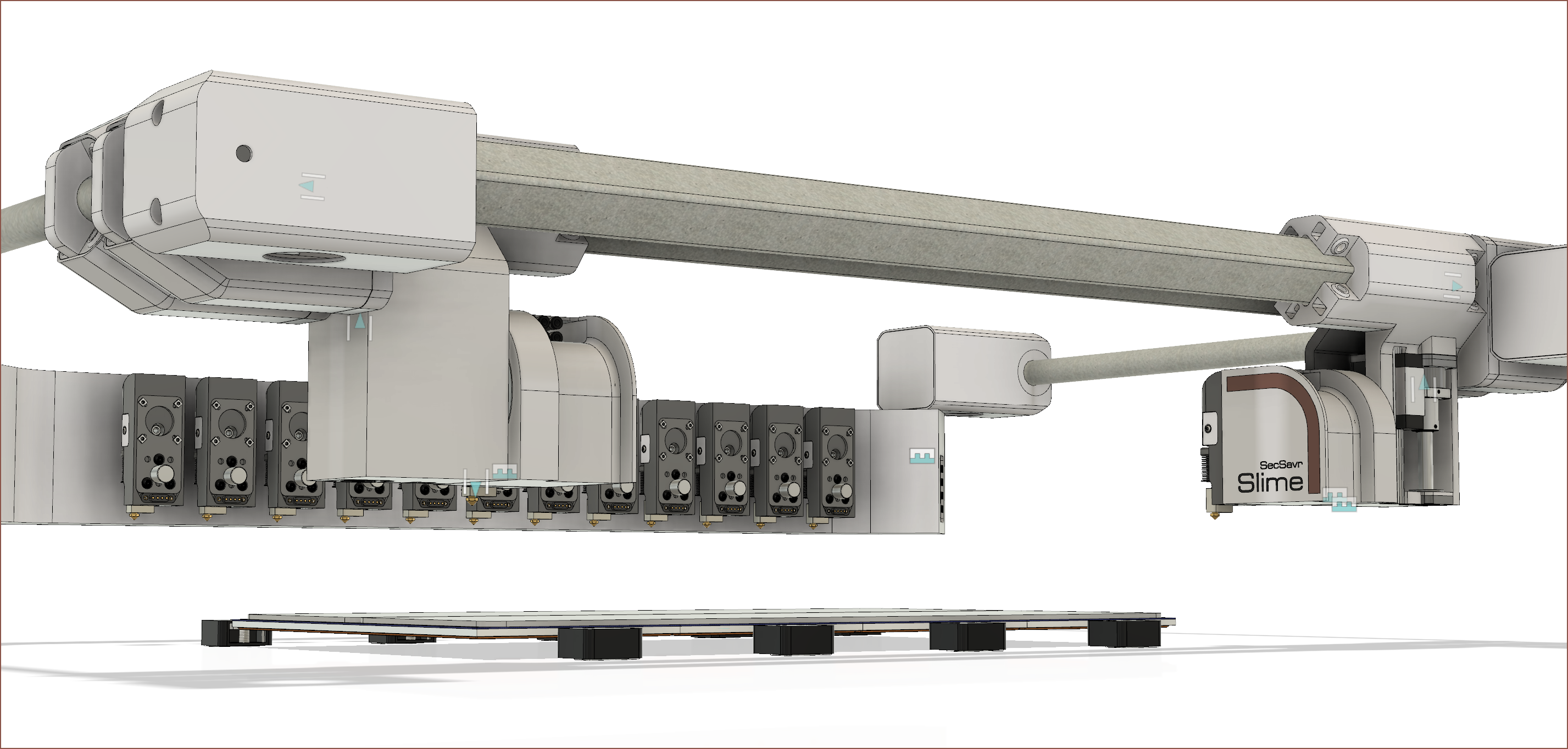

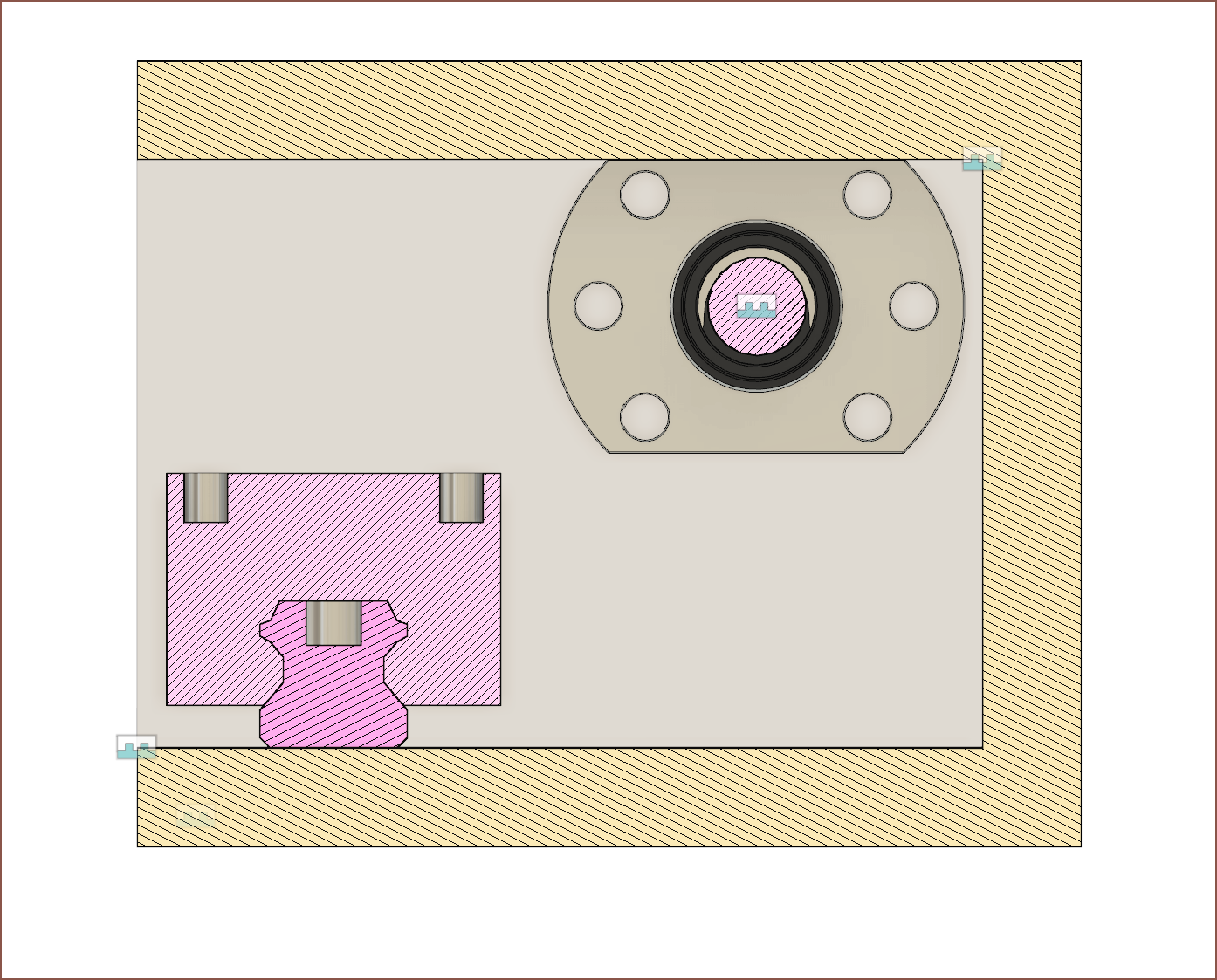

Before going to the mini Z axis assembly in the X Slider, I wanted to look at modelling a concept Tool Bar.

I added the Selects and a few Slights to check alignment.

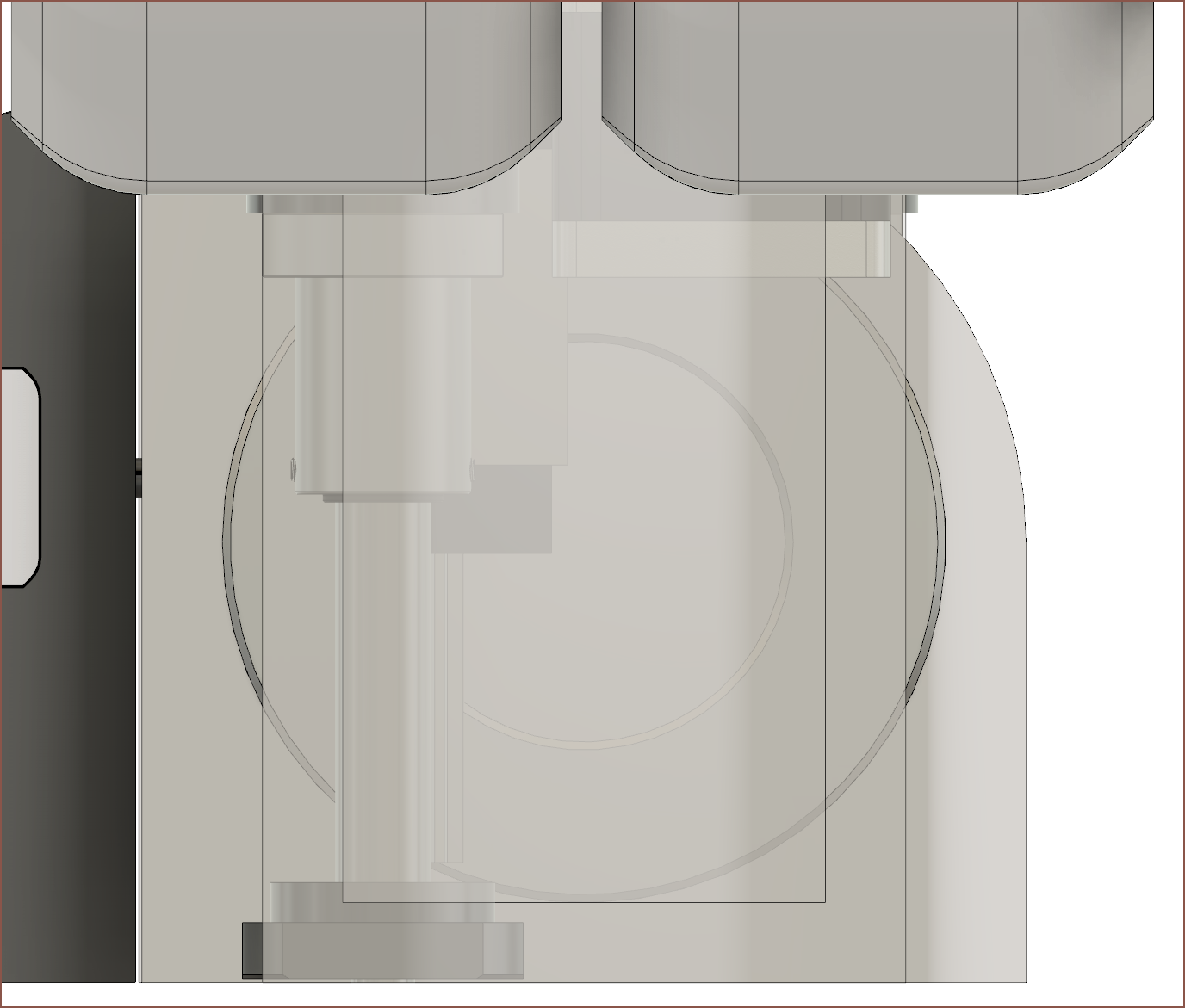

There's enough space for an 82mm tool and can be extended further if needed.

It seems that I can get 10 tools but not 12.

It seems that I can get 10 tools but not 12.  I reduced the distance to 65mm and it still wasn't enough. This is when I realised that the implementation of the X Arm and V Axis could make or break getting 12 tools installed.

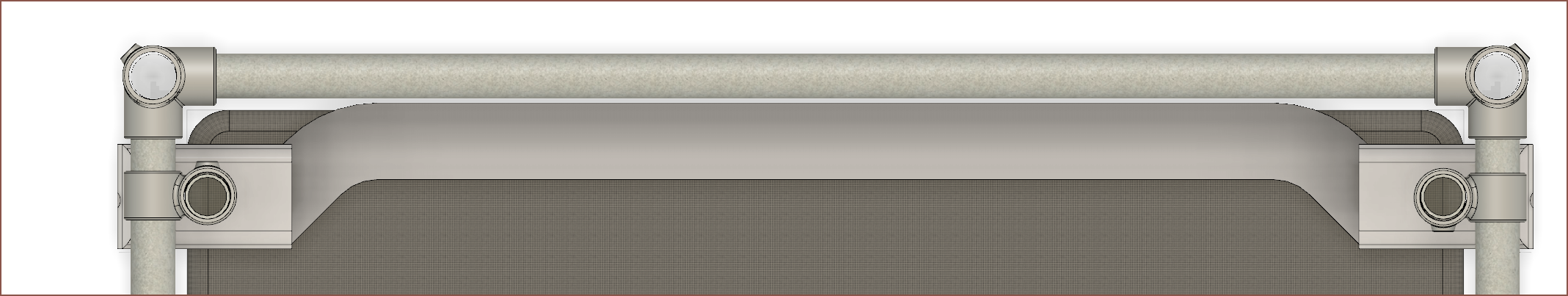

I reduced the distance to 65mm and it still wasn't enough. This is when I realised that the implementation of the X Arm and V Axis could make or break getting 12 tools installed.Ex Armu

(said with a Japanese accent, referring to the anime Ex-arm)

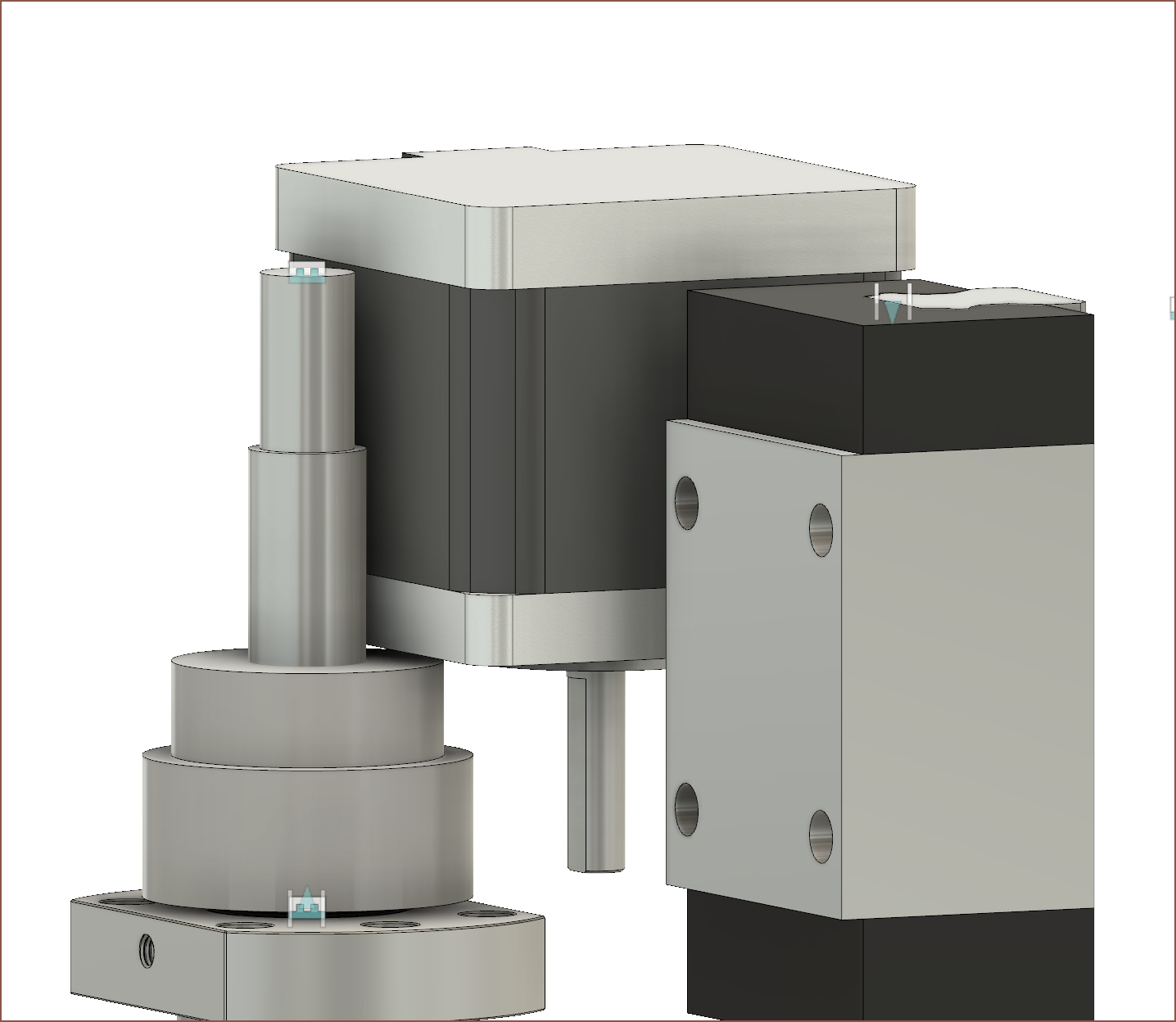

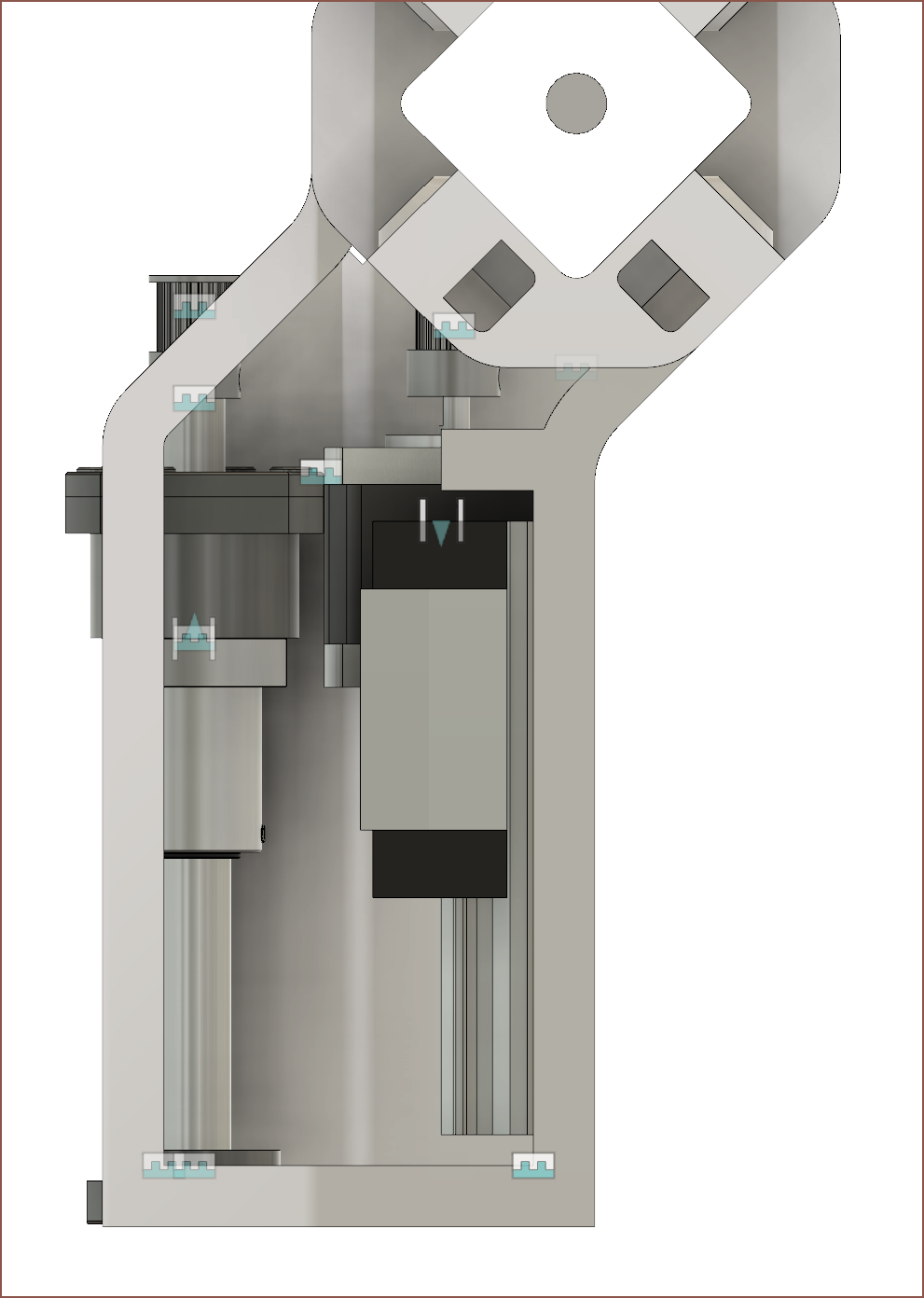

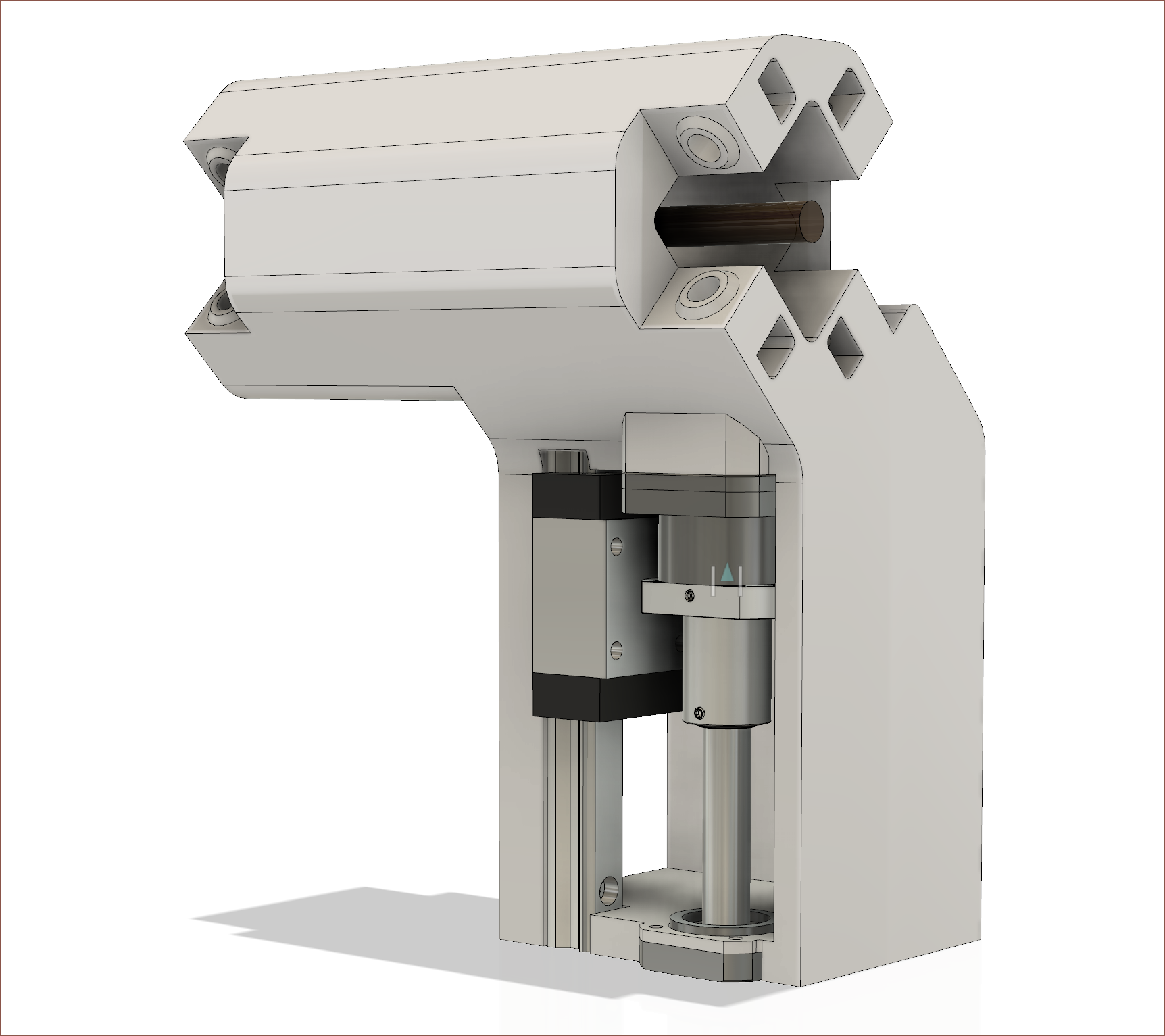

Started off by placing the components like this.

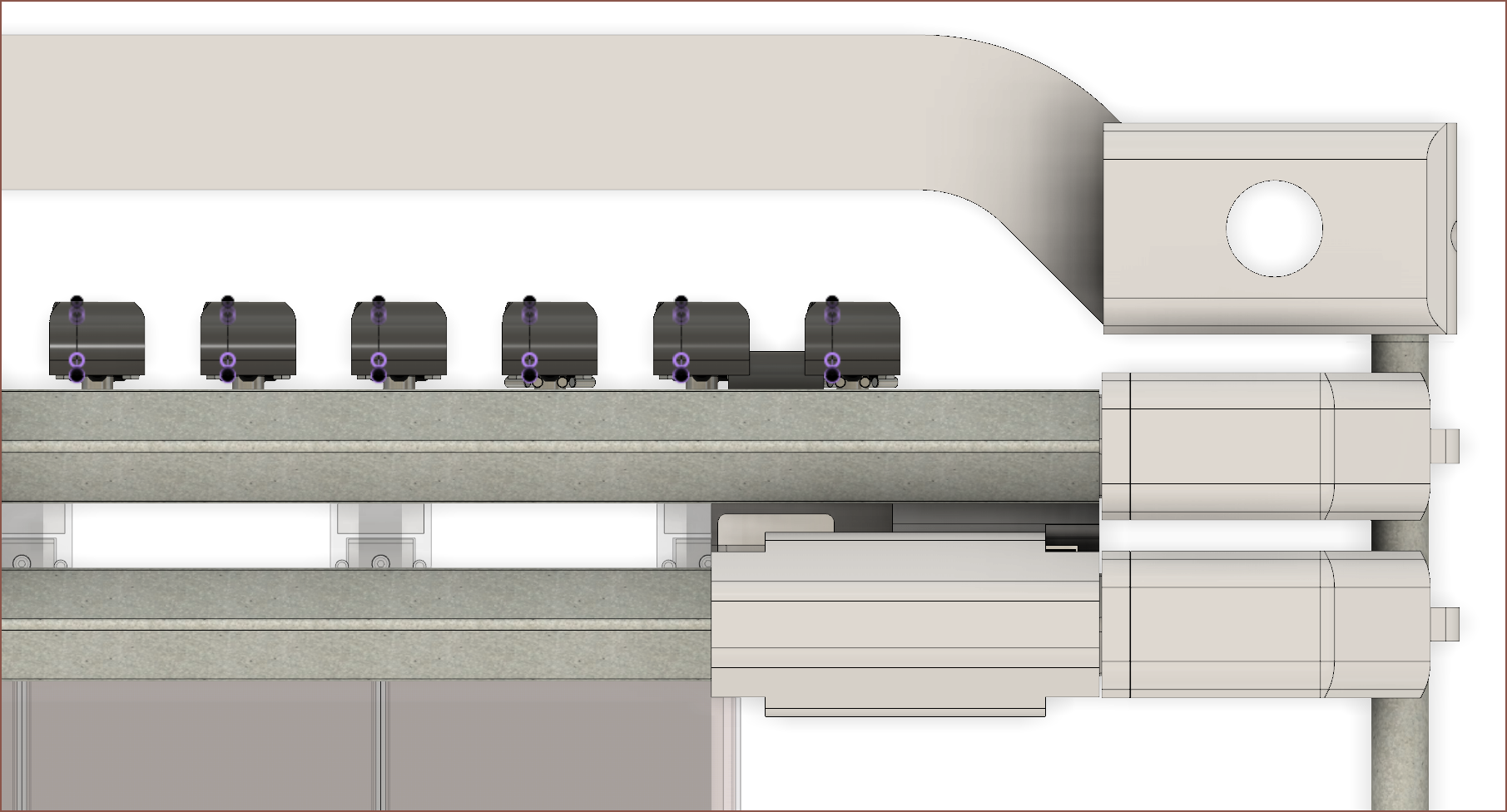

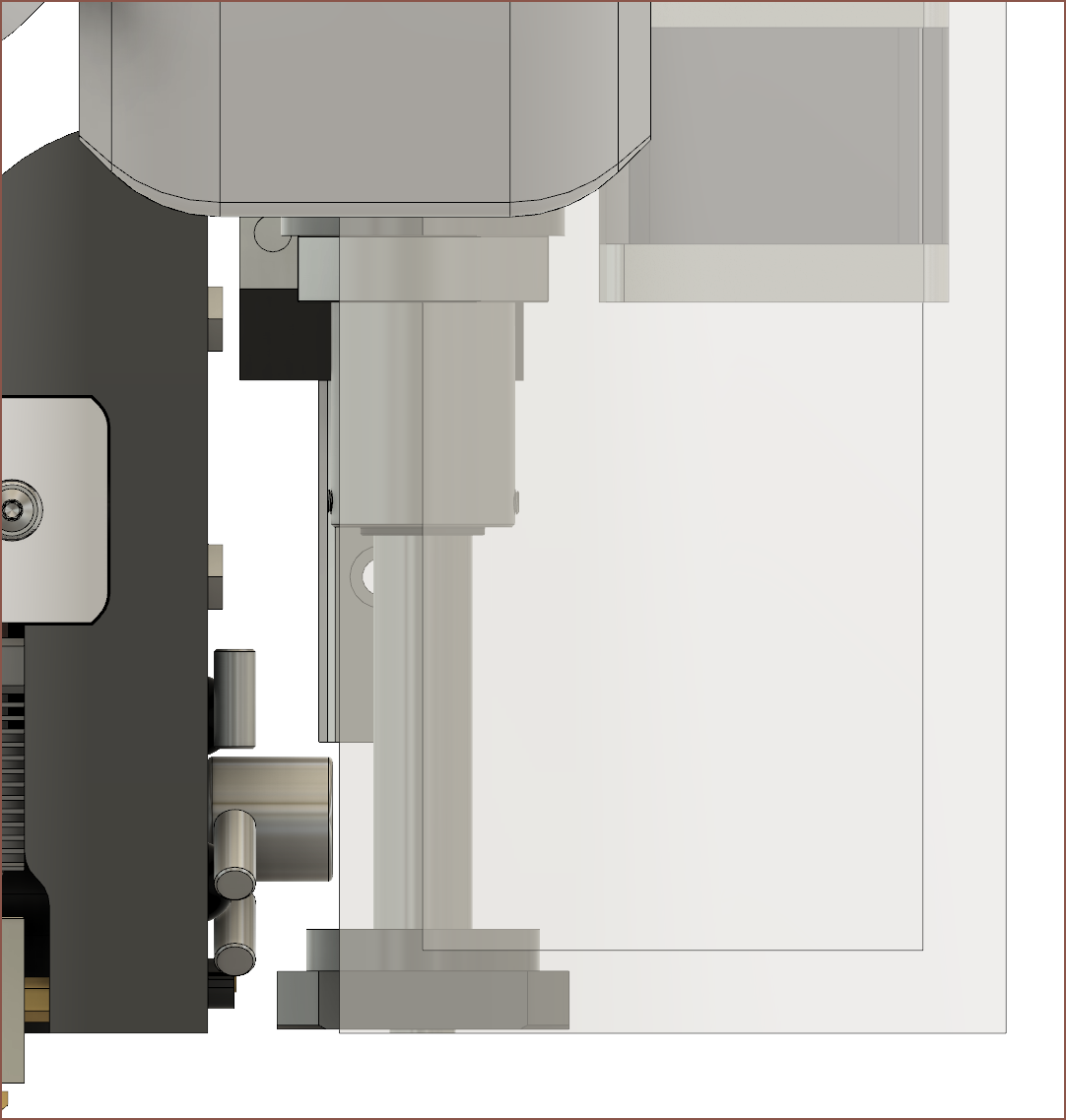

Started off by placing the components like this. I was wondering if I could use a 10mm ID pulley and then fix the ends with 8mm ID bearings, but the motor and pulley were too large for that idea. So I looked at how these are supposed to be installed and found the bottom set on Grabcad [Part 1, Part 2]

I was wondering if I could use a 10mm ID pulley and then fix the ends with 8mm ID bearings, but the motor and pulley were too large for that idea. So I looked at how these are supposed to be installed and found the bottom set on Grabcad [Part 1, Part 2] and put it in the model.

and put it in the model.

The magnet of an adjacent tool would clip it though, so I did some tweaks.

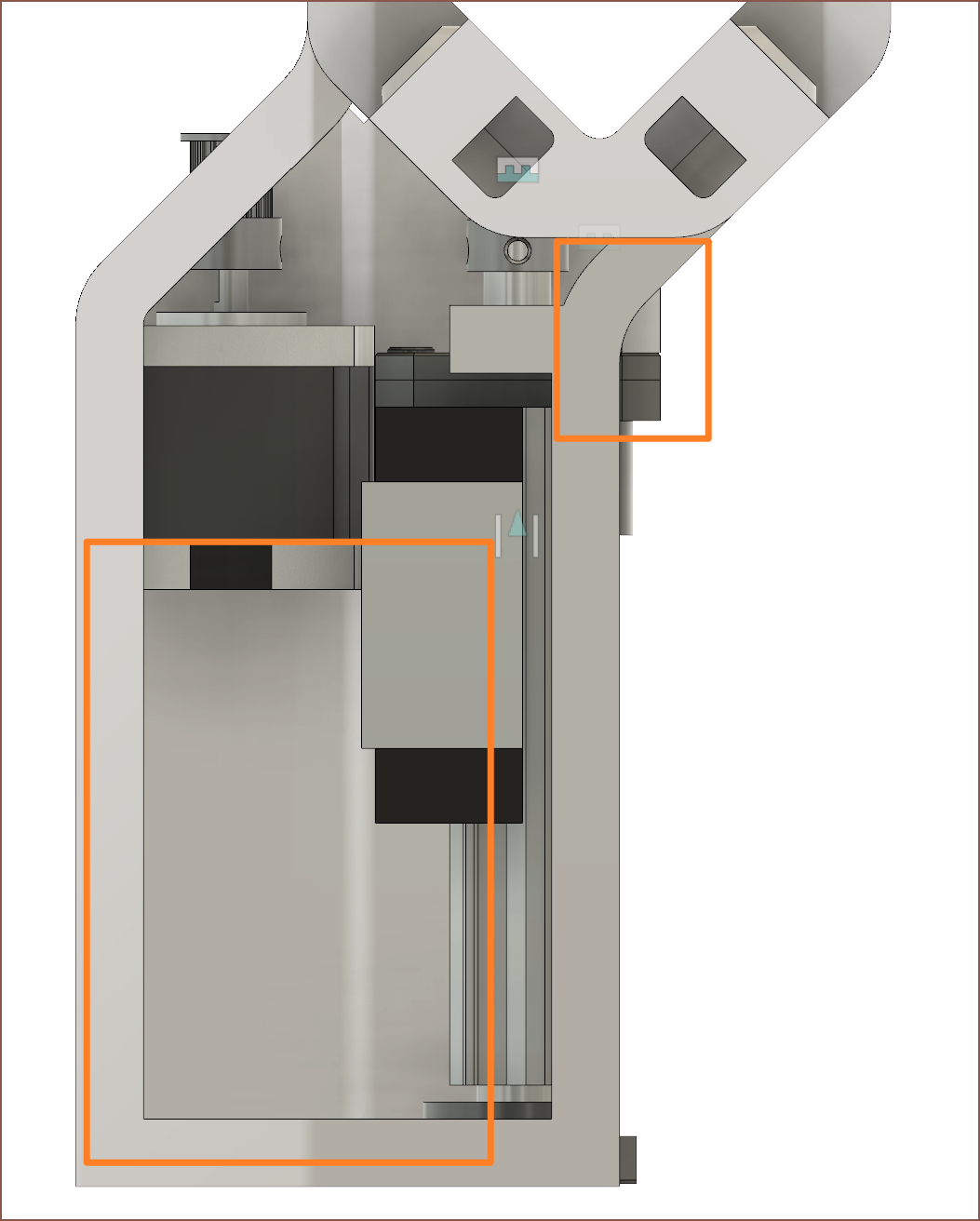

The magnet of an adjacent tool would clip it though, so I did some tweaks. Eventually, I had this. I took a page out of my time with the Anycubic Linear plus in that the carrige can extend a few millimetres past the end of the rail without issues. This is so that I could go down to a 100mm linear rail.

Eventually, I had this. I took a page out of my time with the Anycubic Linear plus in that the carrige can extend a few millimetres past the end of the rail without issues. This is so that I could go down to a 100mm linear rail. I then had the idea to swap the sides of the ball screw assembly around so that I could get a face to screw in (top right) and a larger amount of free space for the V axis.

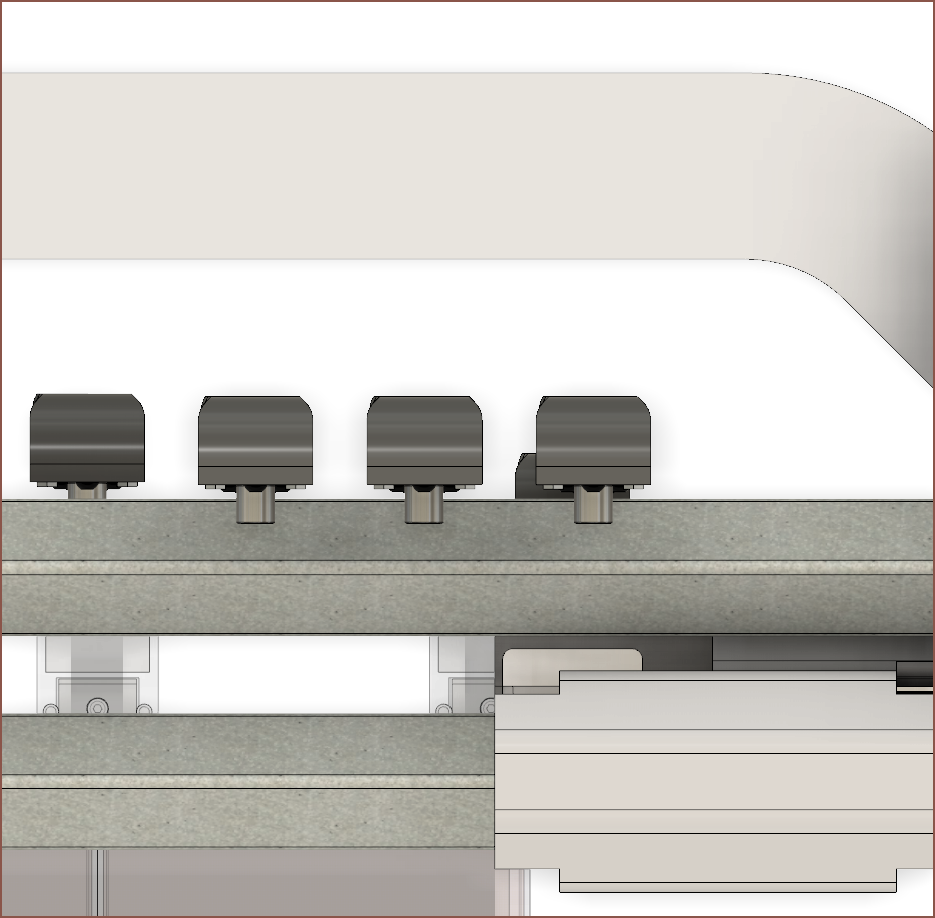

I then had the idea to swap the sides of the ball screw assembly around so that I could get a face to screw in (top right) and a larger amount of free space for the V axis.More space needed

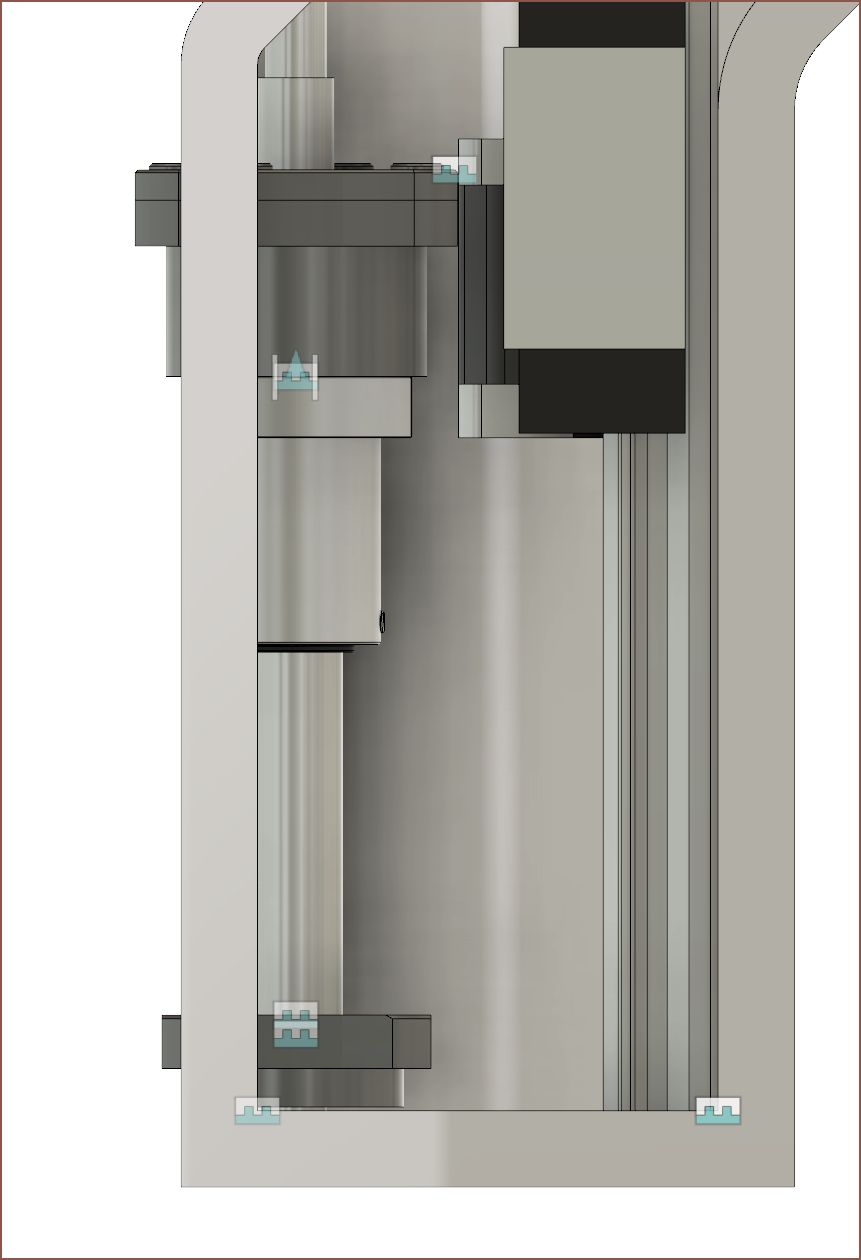

As you might be able to tell, the linear rail carrige is very close to the centre of the bearing, meaning that no shaft of any considerable size would be able to fit.

As you might be able to tell, the linear rail carrige is very close to the centre of the bearing, meaning that no shaft of any considerable size would be able to fit. Some shuffling later and I got somewhere towards a better solution.

Some shuffling later and I got somewhere towards a better solution.

Some more refining and I got the above. I was able to go down to 140mm, which is 20mm shorter than where I started. I also brought the 150mm linear rail back for component stiffness.

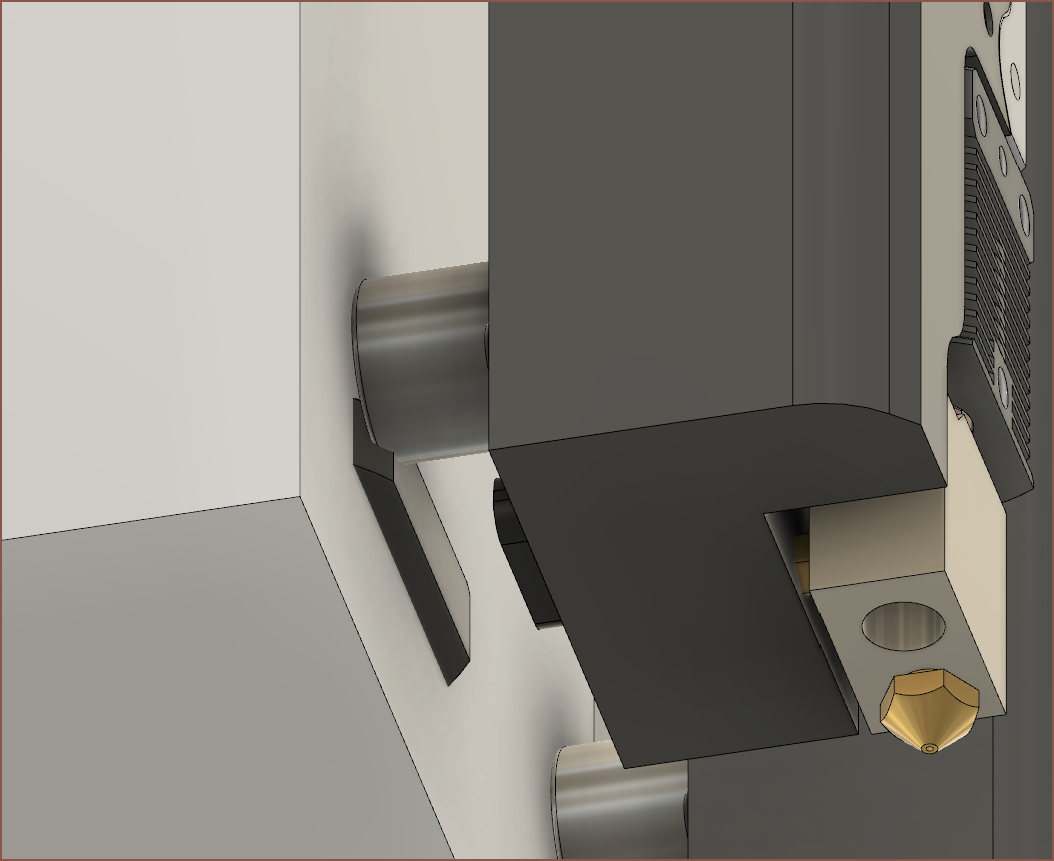

V Axis

Now I need to figure out why multi axis CNC's need so much torque for rotational axes in the first place and then obtain a solution that fits in the space provided.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.