As a result of the last print test I spent many hours by finding the right way how to ensure the best possible heat distribution/consistency across the print bed surface. Problem was, some areas of bed surface were under or over heated.

I ended up with new halogen shielding and quite simple procedure how to tune it. Unfortunately, current design of the topFrame limits me in making heat distribution good enough for the whole print bed area. As a result of that I must use smaller print space in the Y axis for further testing. It will be around 130mm instead of 150mm. But good is, that it should not be problem to fixed that. So, the final working area will be still 150x150mm 😉

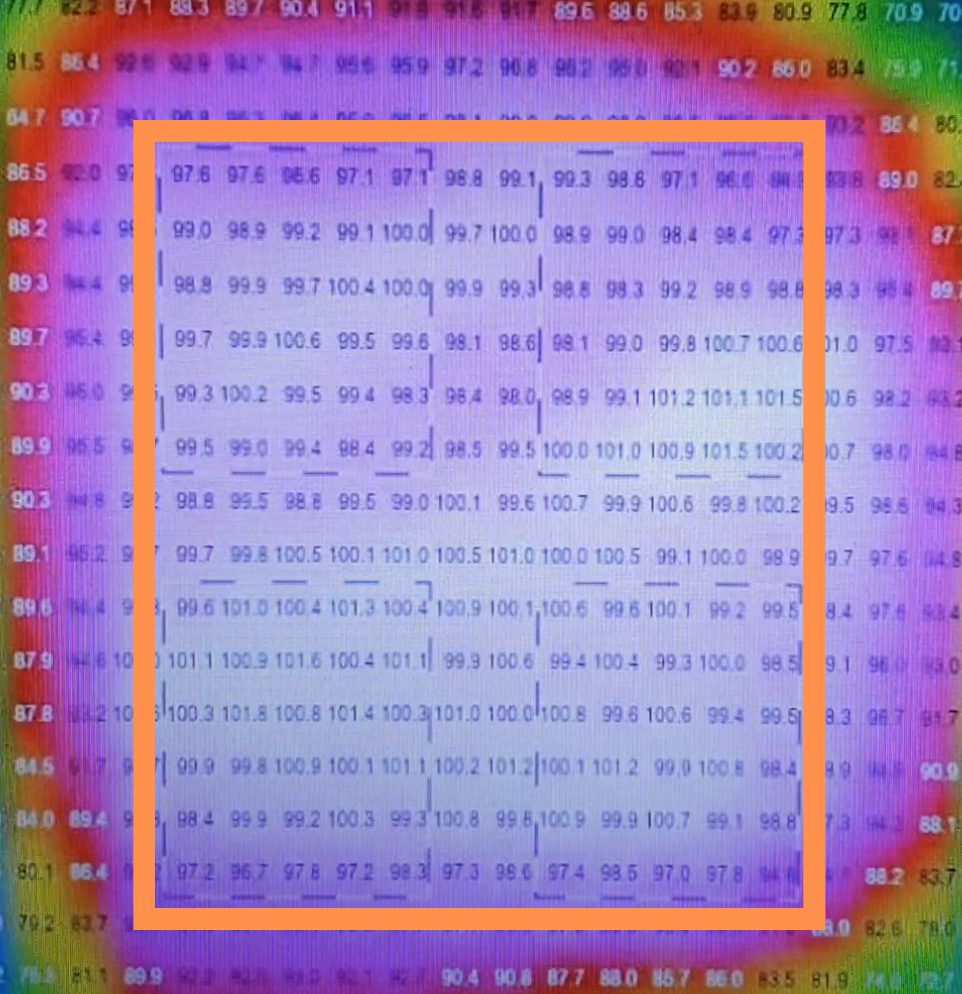

Here is the pict of what I am talking about. The orange rectangle is the 150x150mm effective print area - it is rectangle because of camera view perspective. I need to have the temps diffs max about 2.5°C. Therefore, the top and bottom row inside the rectangle is a bit problematic. The test was done for 100°C.

When I checked video from the last print, there was a diffs range up to 5+°C :-o

I will make the next print test in coming days.

Tomas Starek

Tomas Starek

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.