Hello everyone and welcome to the WINTURER project page, the Wind Turbine for your Adventures.

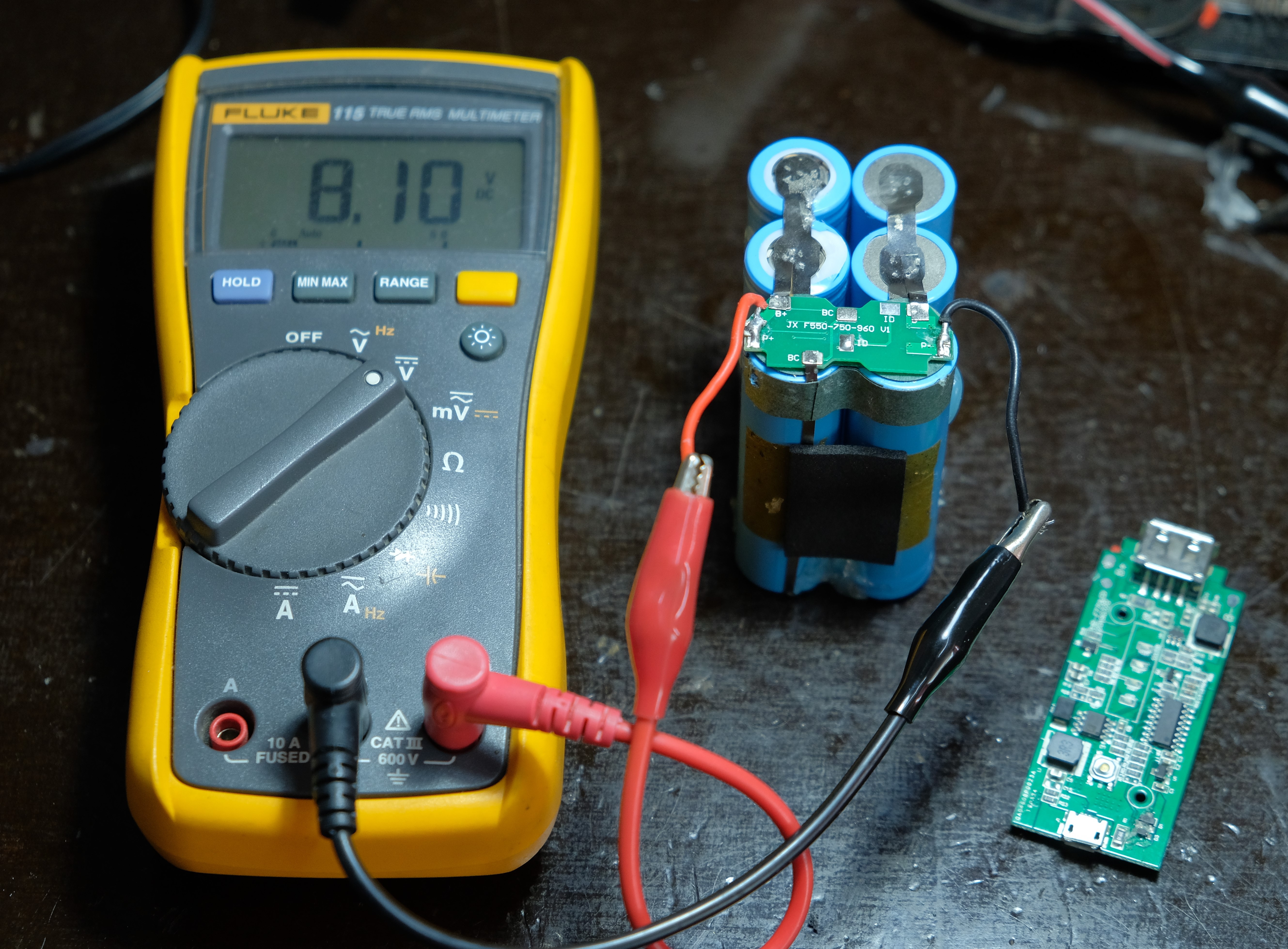

A few months have passed since I presented my first Portable Wind Turbine prototype on this platform. Its creation was inspired to provide a backup solution to recharge my electronic devices, during my explorations away from conventional power sources. Normally on my trips I take with me a 10000mAh (37Wh) PowerBank and a small 10W portable Solar Panel. Generally, the Power Bank is more than enough for me and the Solar Panel is a backup in case I use up all the power from the Power Bank and need to recharge my devices.

It happened to me that during an expedition a little longer than expected, I tried to recharge my phone and Power Bank when it had run out and there was no sun light at all. There was wind, but I wasn't prepared to take advantage of it. Suddenly, my phone had turned off completely and with it all the advantages of having it on (GPS, maps, possibility of communication in case of emergencies if I approached an antenna, the camera to get an interesting photo, an LED, etc...).

No matter what size of Power Bank you decide to take with you, at some point it will run out if things go off the rails and the return to civilization stretches out in time.

Solar panels also have their drawbacks, they depend on the Sun as is evident and they need to be perpendicular to solar radiation to extract their full potential. Many people hang the panels on backpacks and the orientation towards the Sun is a bit random which hardly contributes to generating energy efficiently. What if in your adventure destination there are no guarantees of having access to energy sources to charge your devices? Another aspect is that generally during the day we are on the move or in some activities while fulfilling our objectives and not precisely recharging our devices. As soon as it starts to get dark, it's time to stop moving and it's a good time to recharge, but unfortunately the sun light is gone. If there is any usable wind, this project may be a solution. Prototype 1 was my first proposal to take advantage of the wind to recharge my devices.

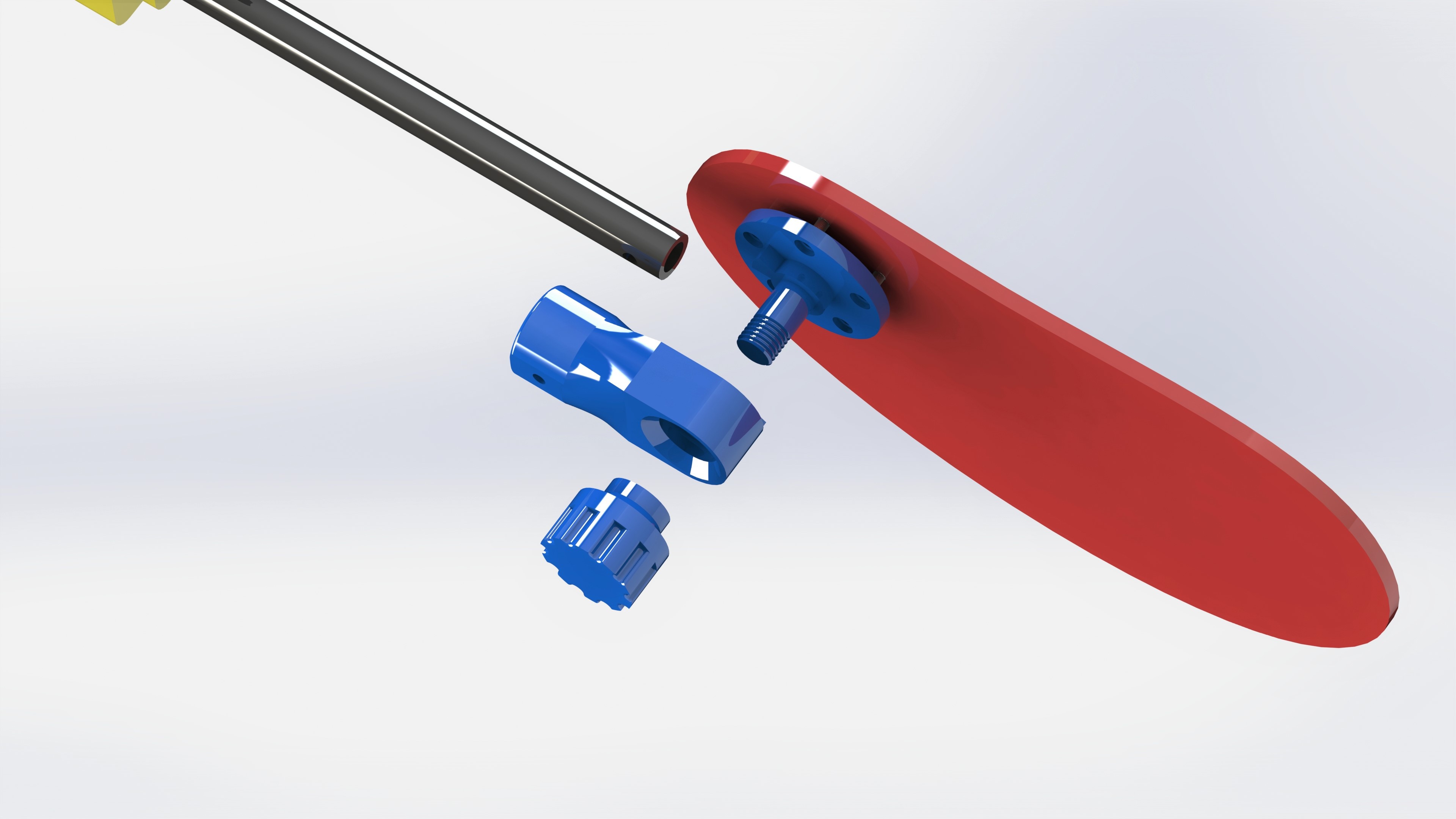

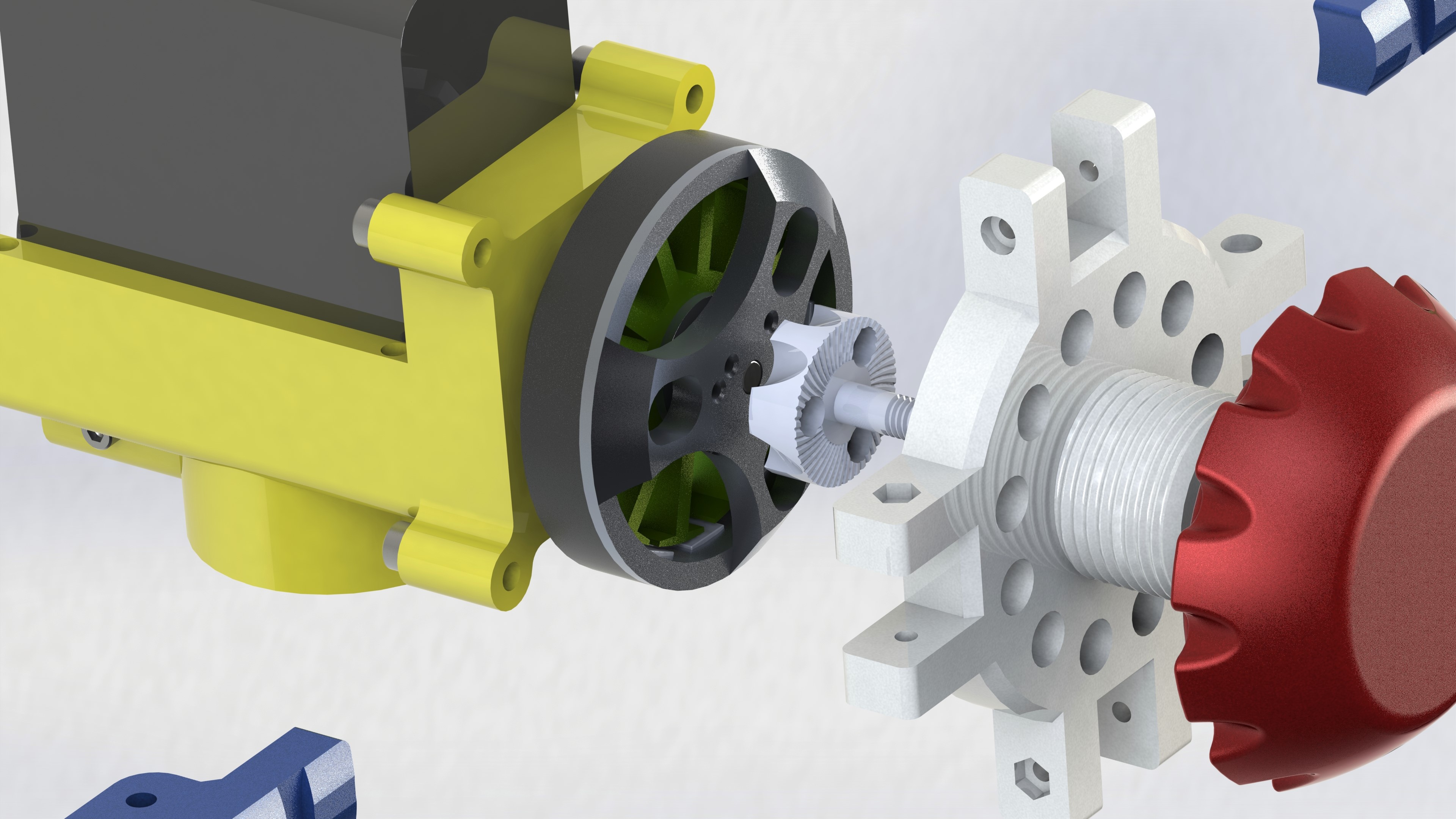

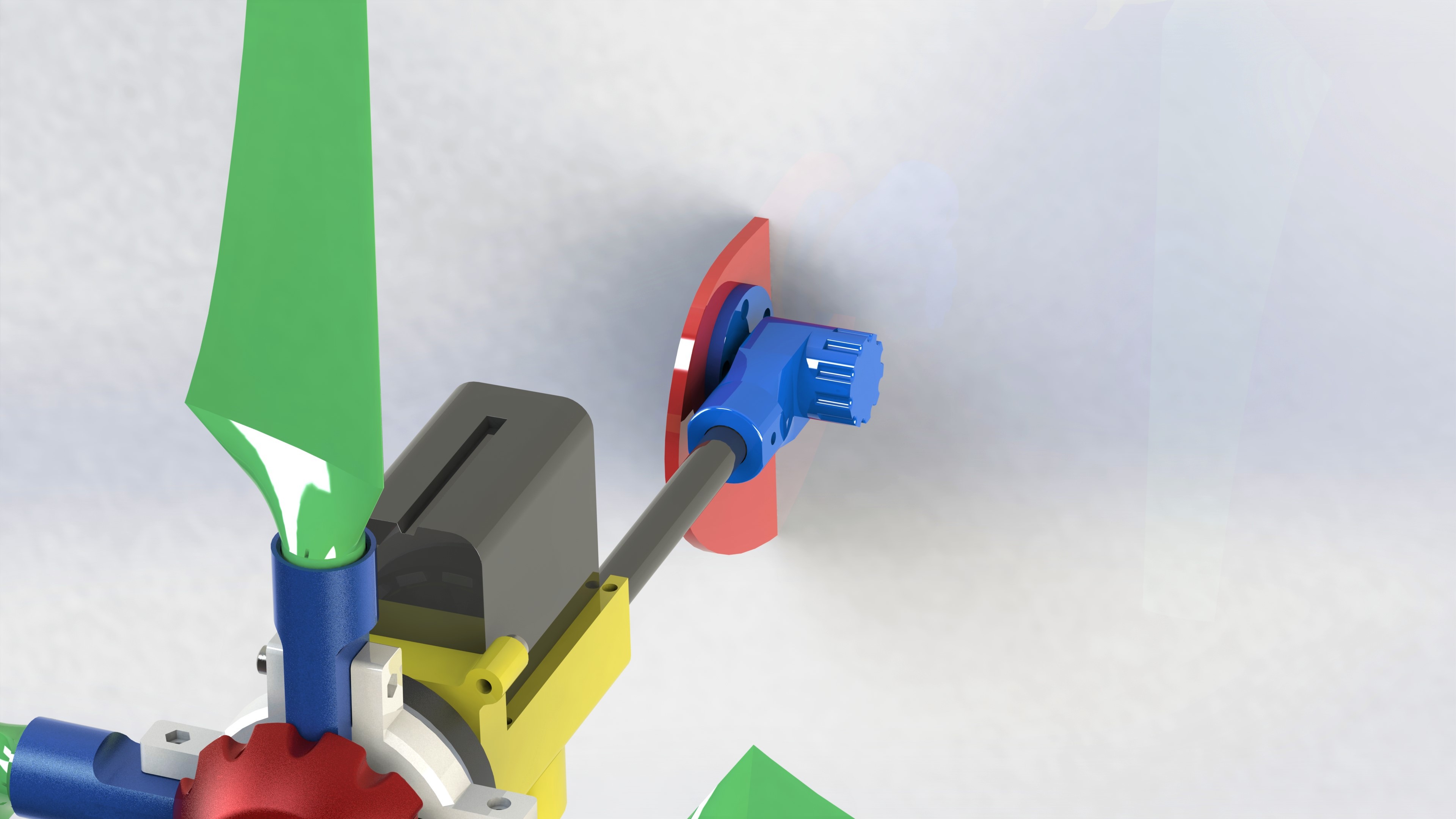

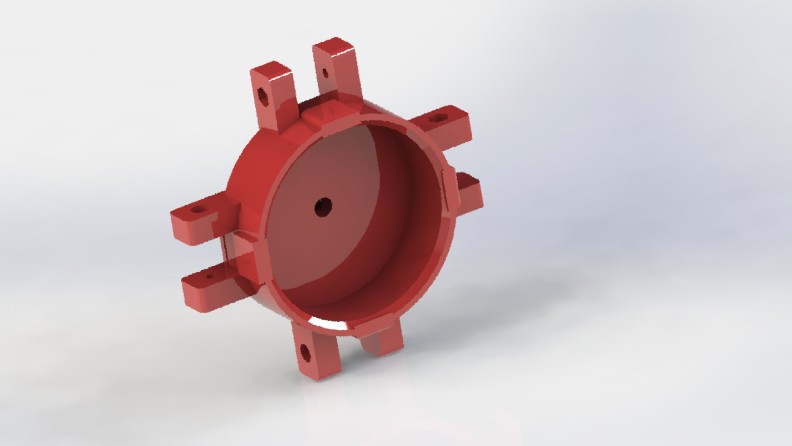

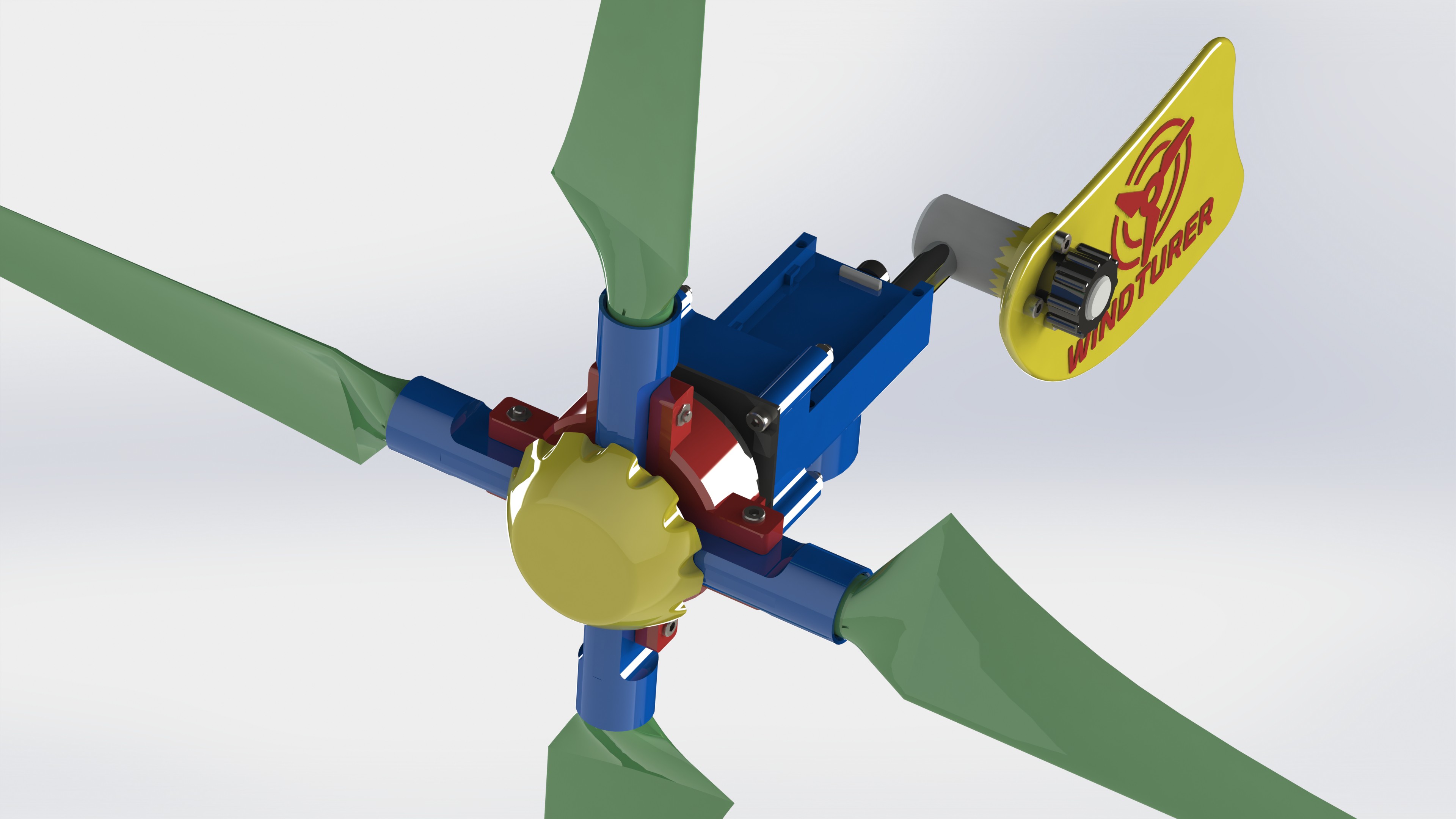

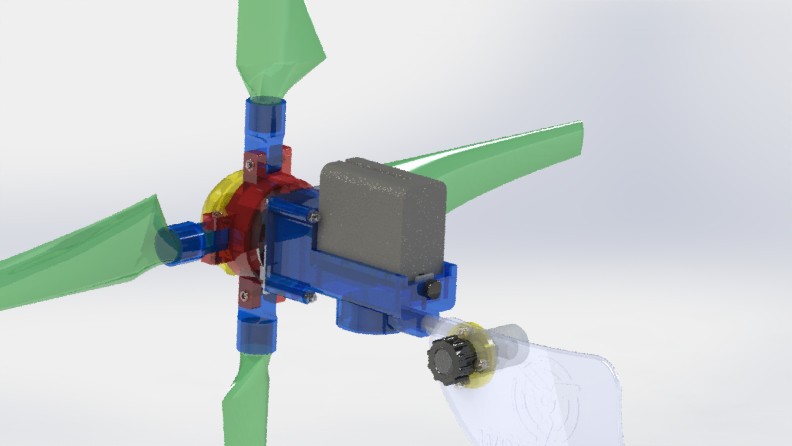

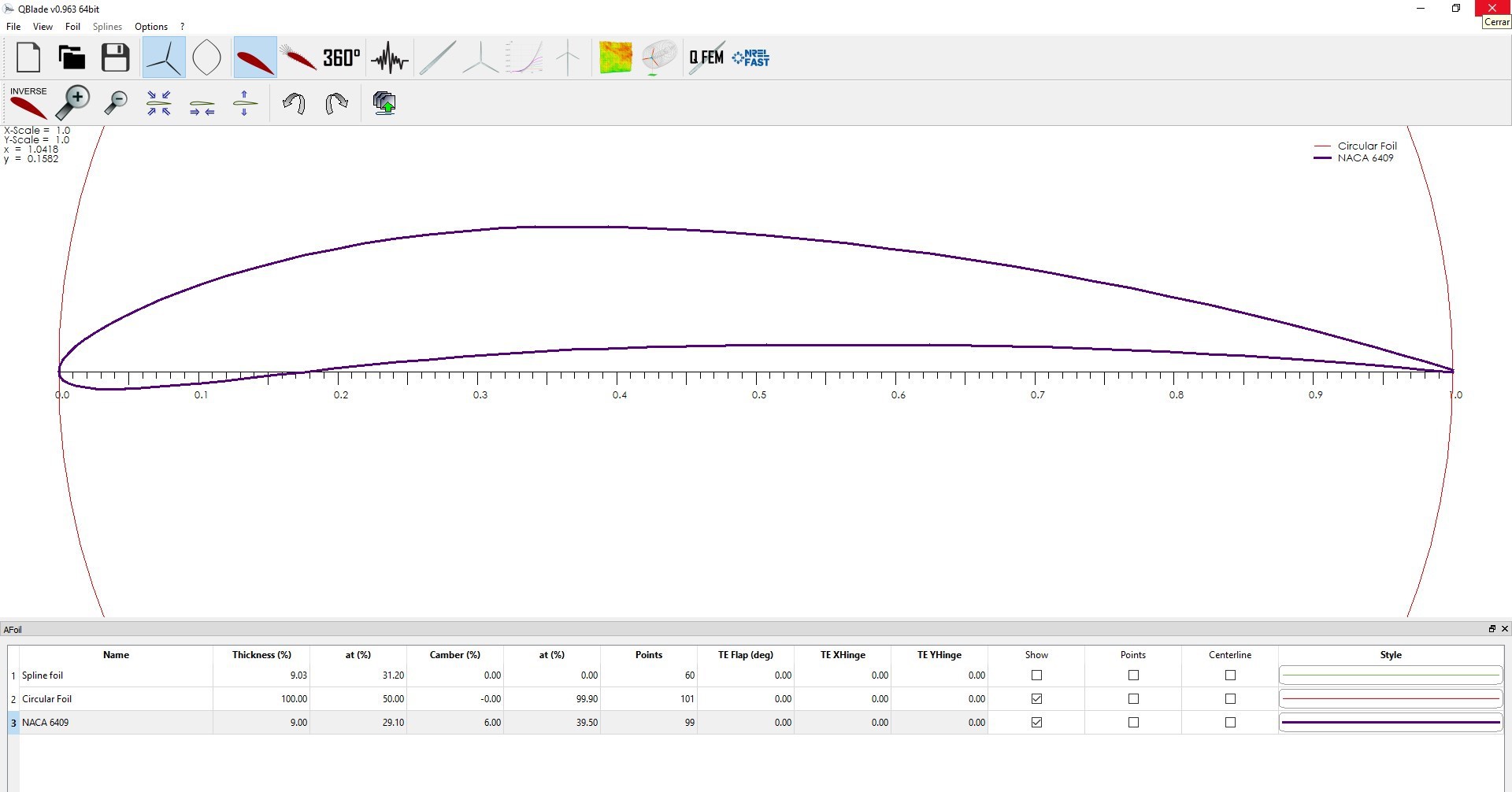

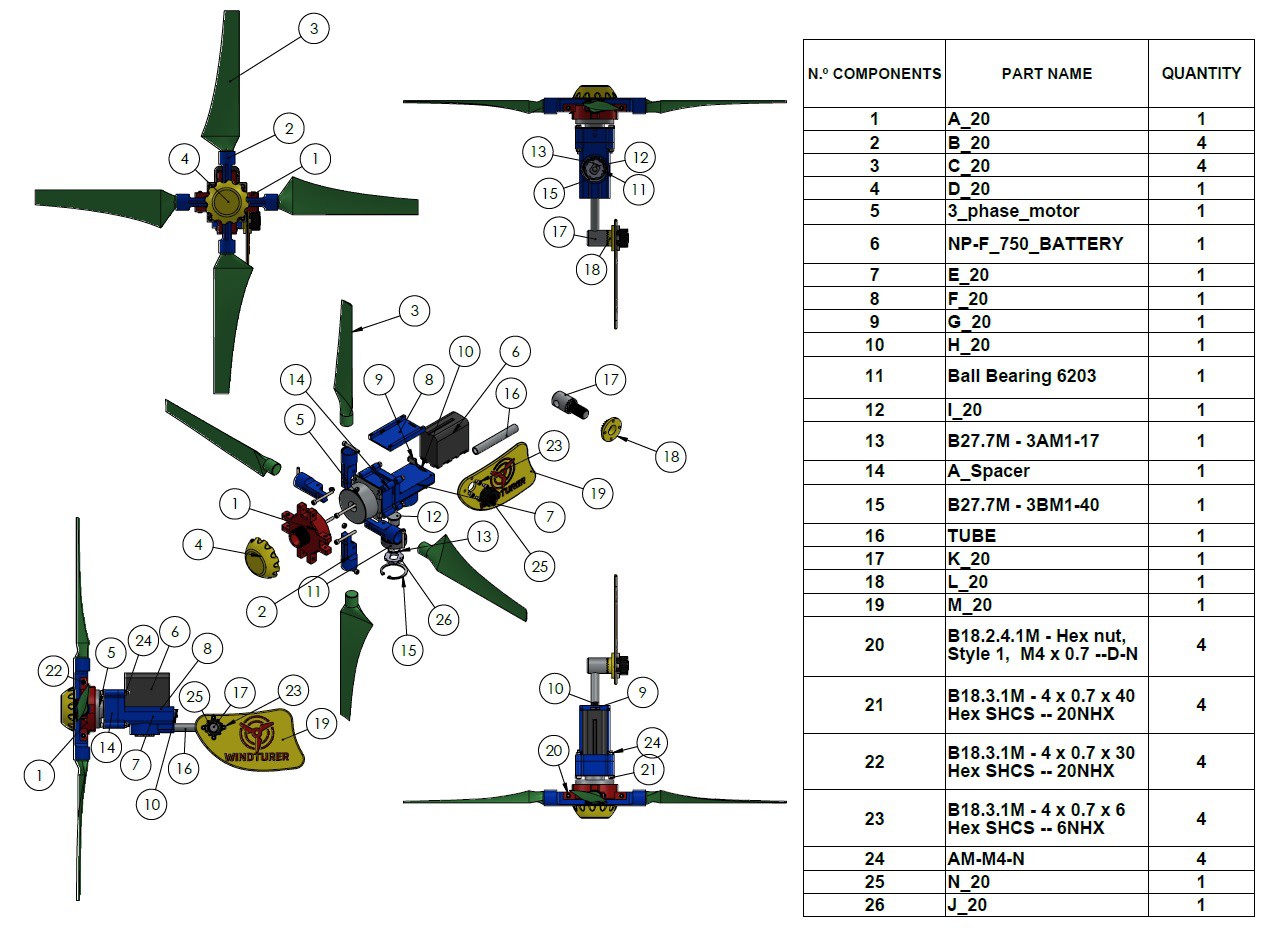

update note: I have been contacted by several Mechanical Engineering students and others interested in the original design files. I just uploaded them to GRABCAD at this link. I have spent a lot of time creating these parts. I hope they will be of great help to you!

I think there are many people in the World with similar needs. There are regions where access to conventional energy sources is very scarce and access to devices of this type could be a good alternative to keeping an LED lamp on at night or perhaps a small fan. There are also monitoring devices for meteorological variables, air quality, etc. that need energy sources for their operation where the sun is scarce. How about in disaster situations?

It is true that there is no wind everywhere and perhaps there is no other choice but to carry along 10Kg of Batteries and thereby have a certain “peace of mind”. But what if there is wind? Would you carry around a reasonably small, low-mass device that harnesses the kinetic energy of the wind to charge your most essential devices? If your answer is positive, then in this project you can find a solution.

What would be the drawbacks of a Portable Wind Turbine? Why apparently are there many people who are still not convinced to take one on trips? Why aren't there several proposals for cheap DIY solutions, free to modify, replicate, share without being subject to patents and all the restrictions on development that this entails?

The answers to these questions were the compass and the obstacles that I have had to face in this project. I summarize what I think below about the most common comments.

"A Wind Turbine that provides a "feasible" amount of energy needs to be relatively large and heavy. This is inconvenient if you have to carry it on your trips!" This is true, very...

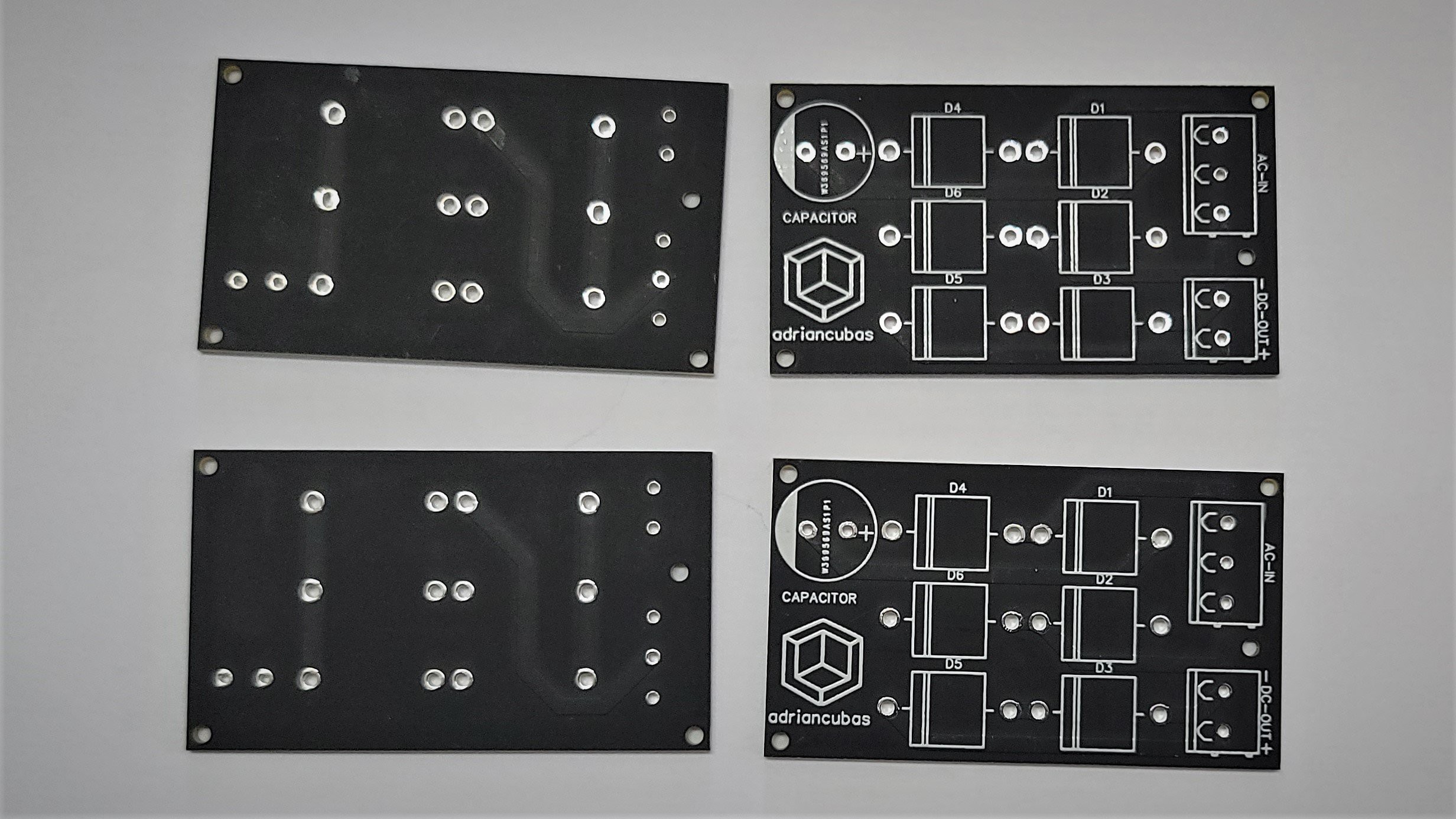

adriancubas

adriancubas

Marius Taciuc

Marius Taciuc

DrYerzinia

DrYerzinia

Matej Gurnak

Matej Gurnak

Said Alvarado Marin

Said Alvarado Marin

Hi Adrian,

This is BRILLIANT !

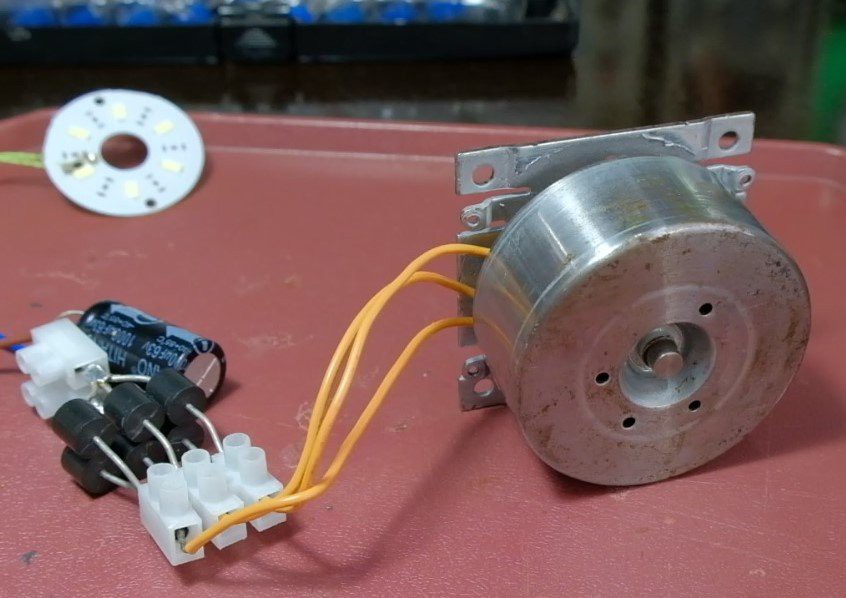

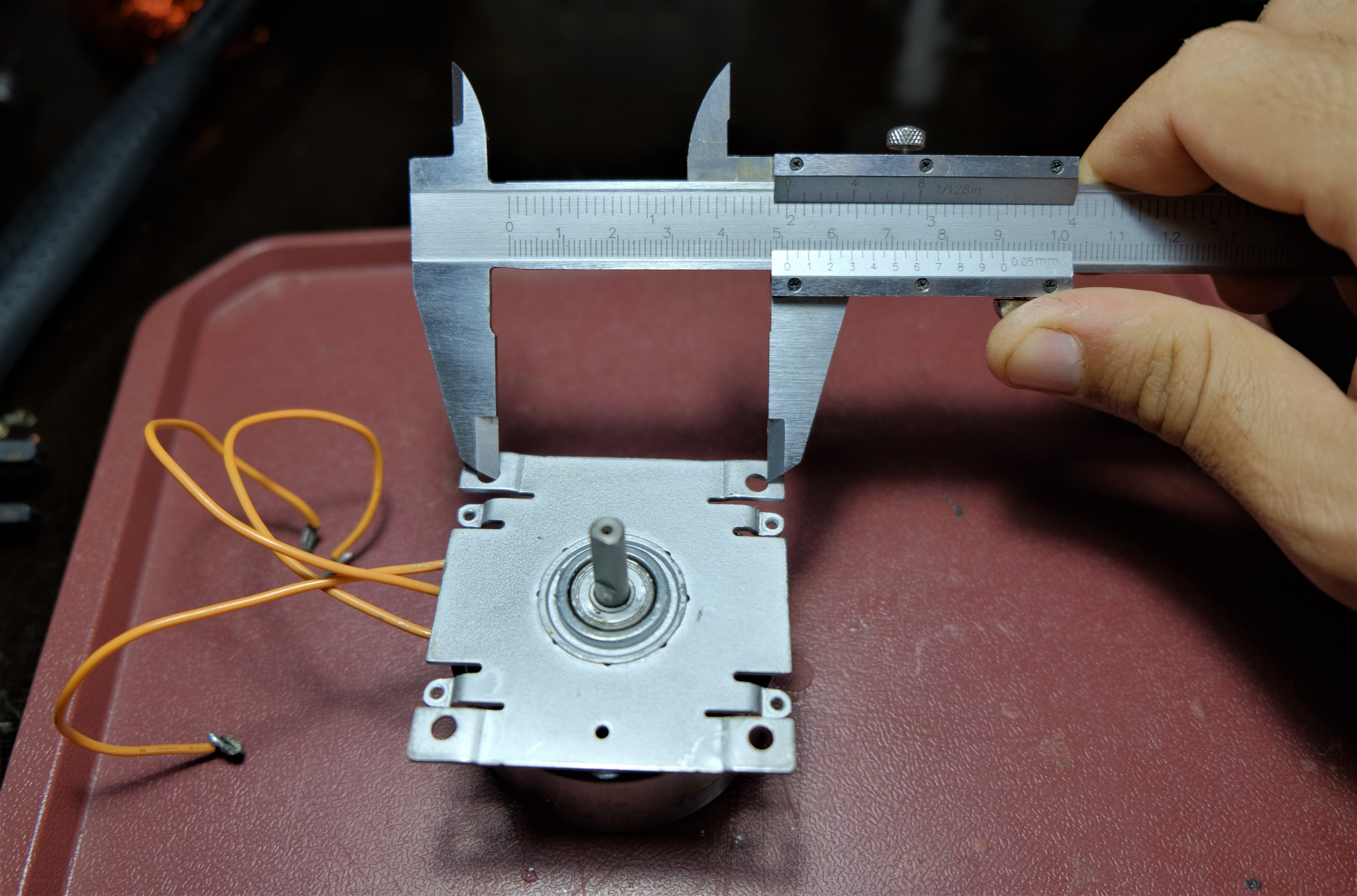

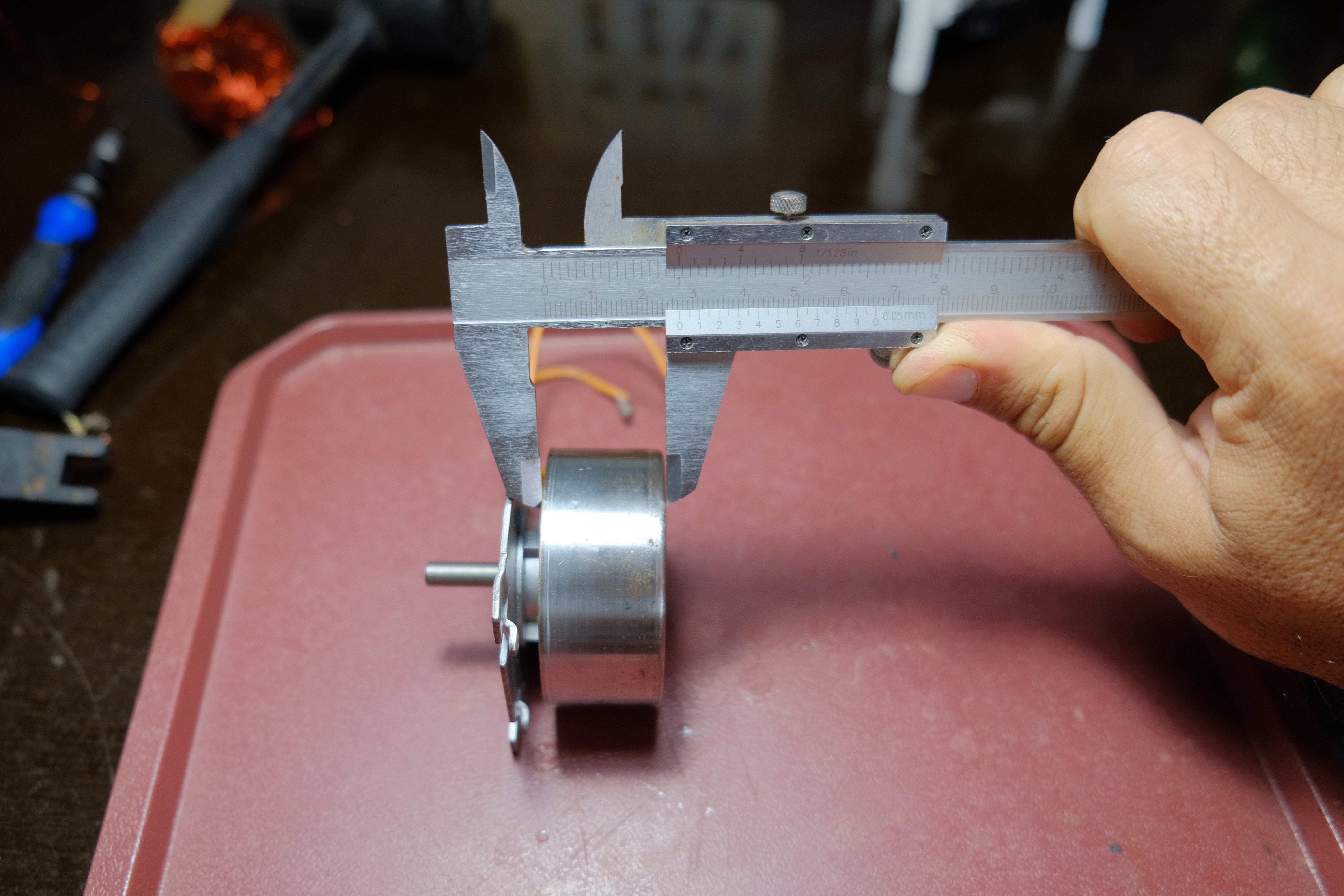

I downloaded the files and discovered that I could not obtain the specific motor here in the UK.

I did get a motor and proceeded to up the design stl files. Also I couldn't get hold of the battery pack you mentioned.

I decided what the heck, updated the design to fit it all together. What I also discovered was that the thread on my tripod is not metric. I did order some nuts and then created a captive nut block which then had a captive M6 bolt. The piece that sits inside the bearing has melt/push M6 'nut' (can't remember the actual name) which then this can connect to.

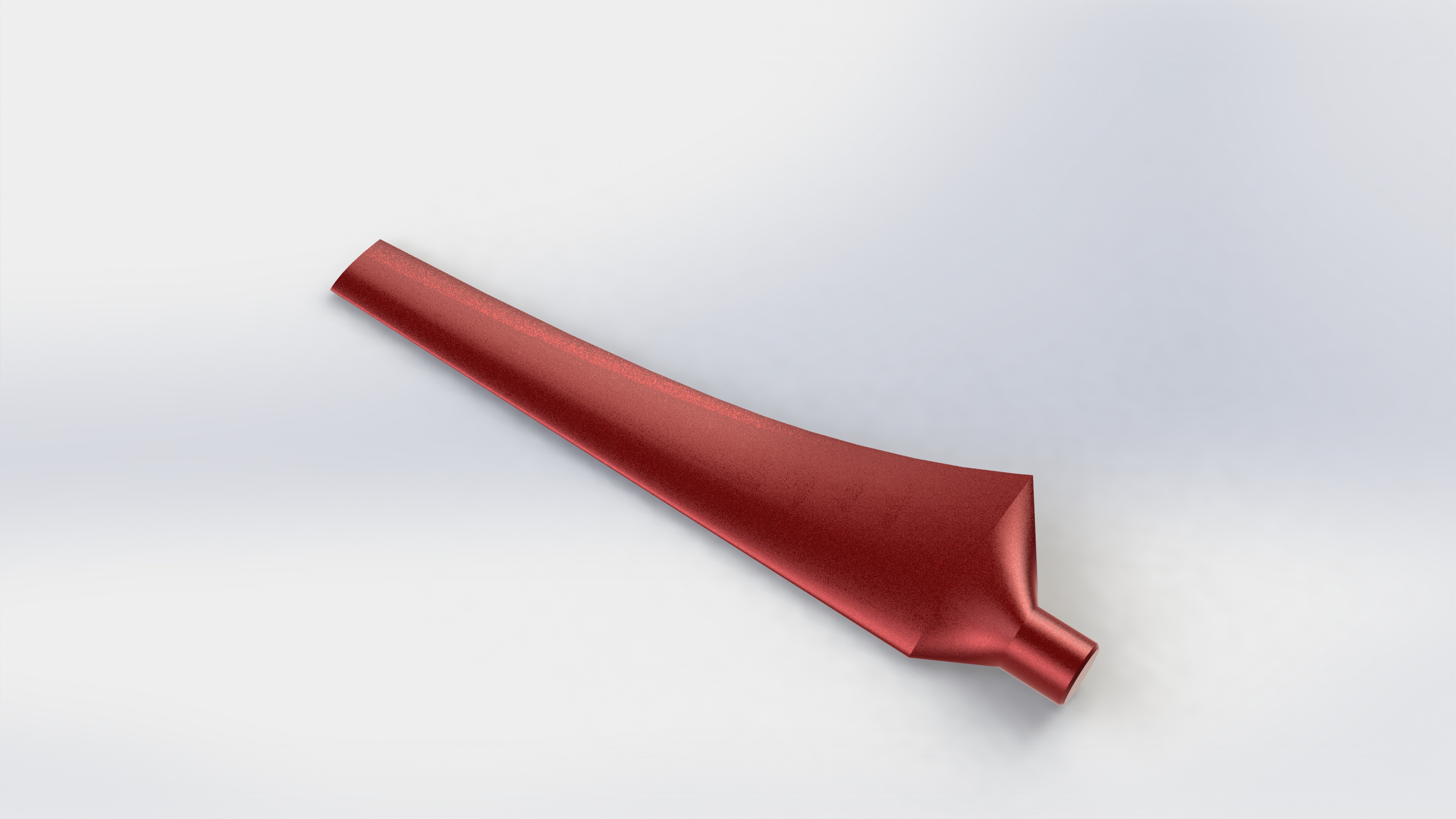

The Turbine blades must have a sturdy raft and it must have the supports also put it, I discovered this as after a few attempts to print the them. Note I am lucky in having a 3D printer that can print up to 25 cm I printed them standing up. Also they are honey combed at IIRC 25 % thus keeping them light and strong.

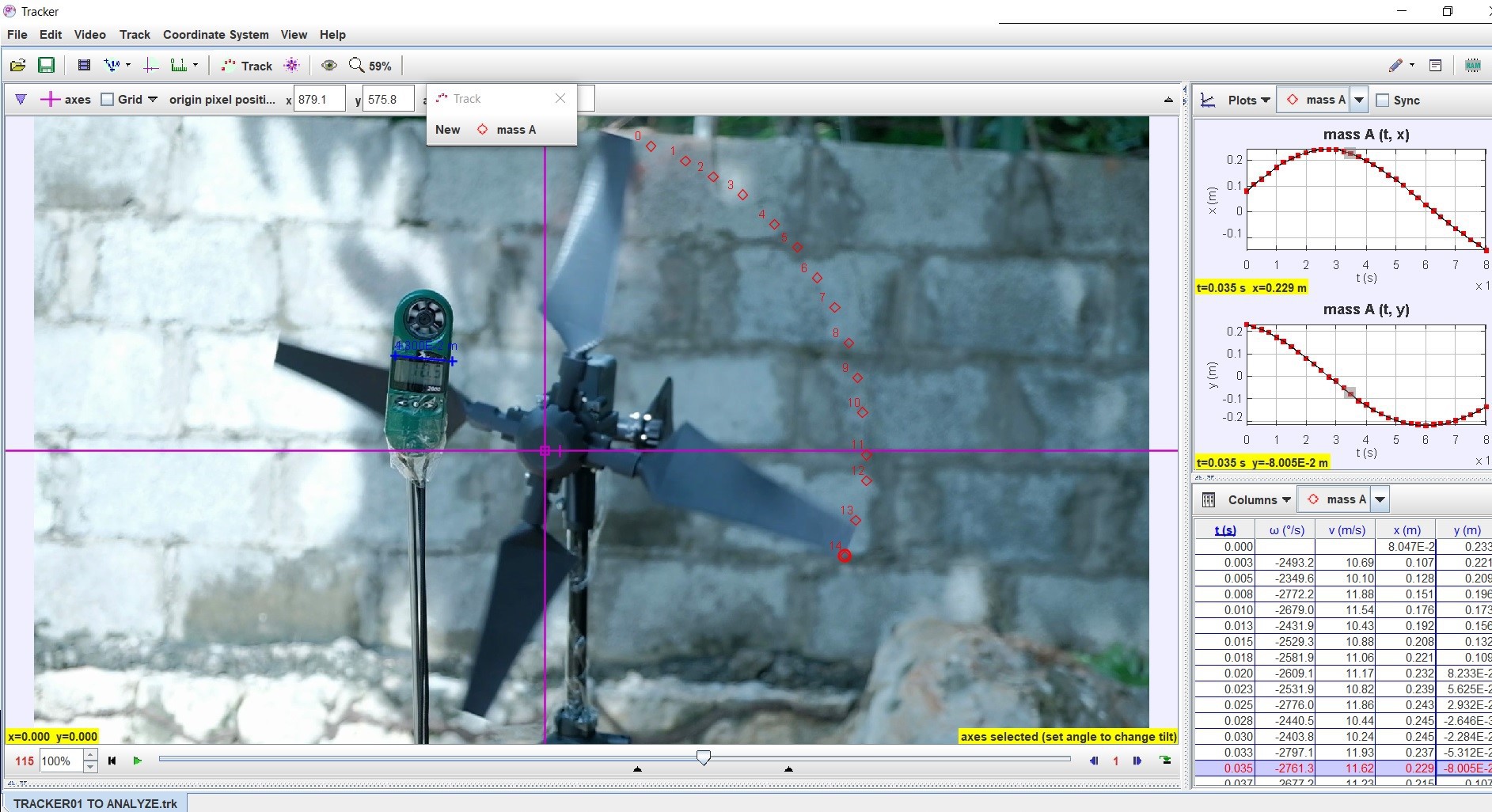

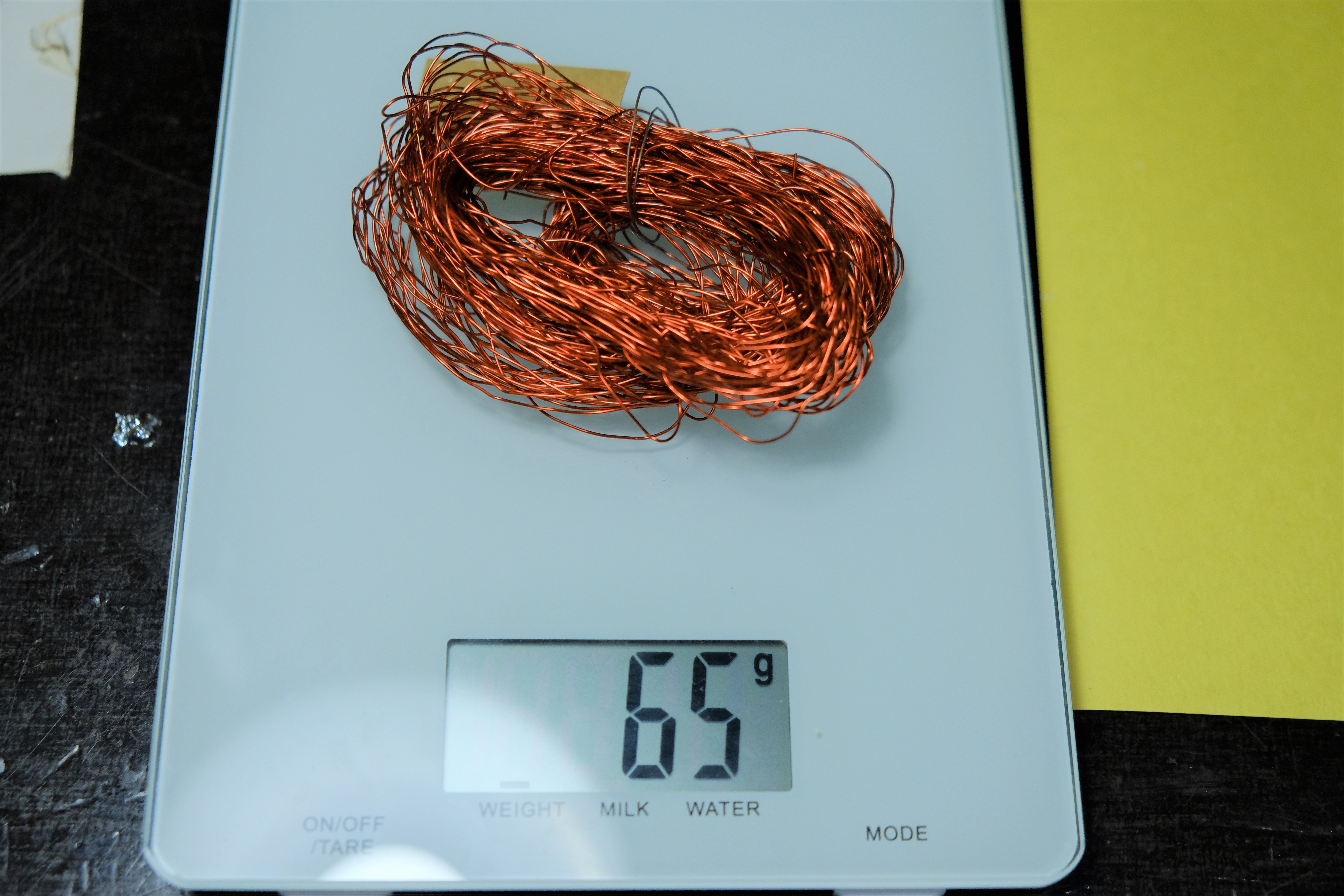

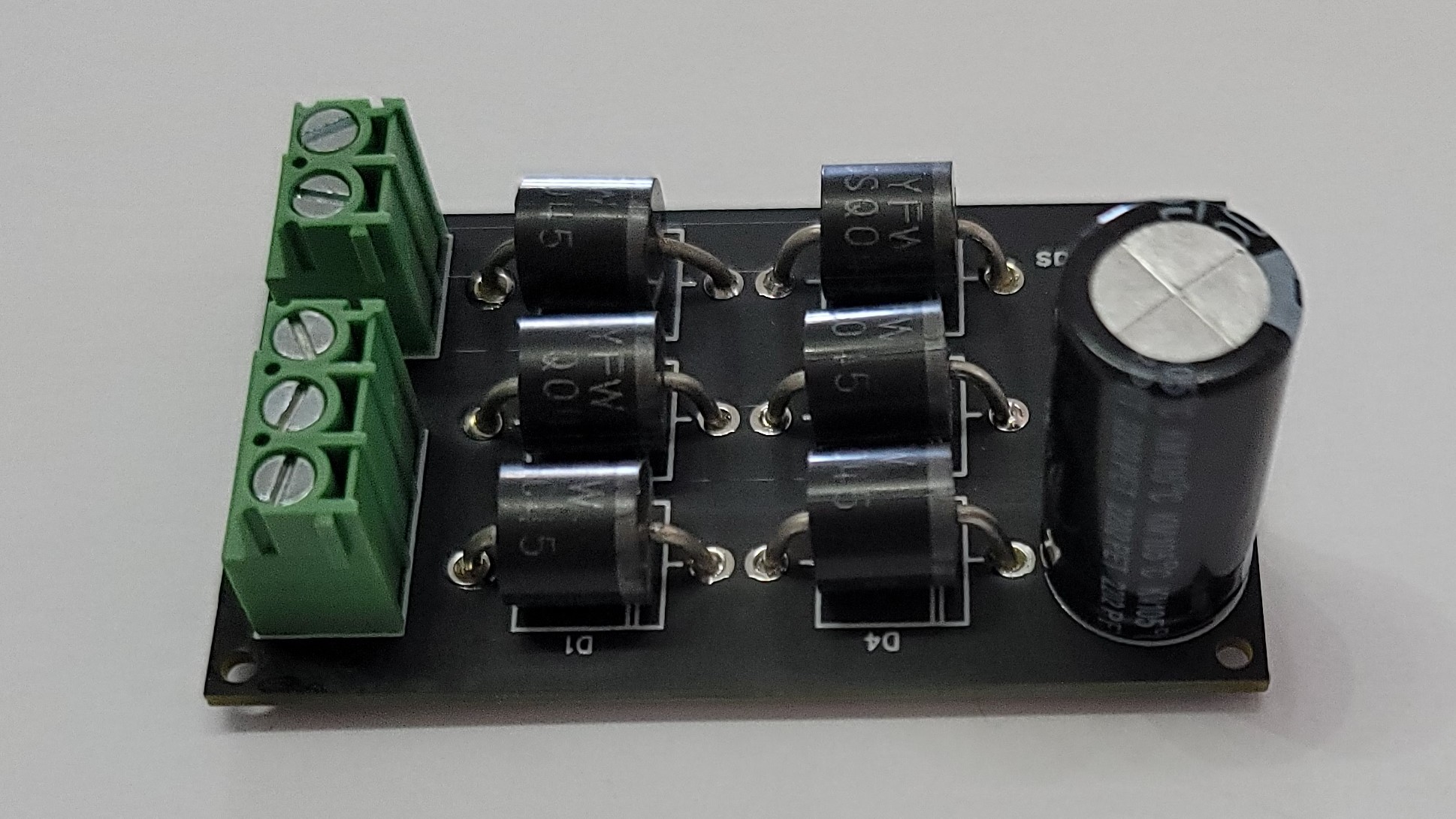

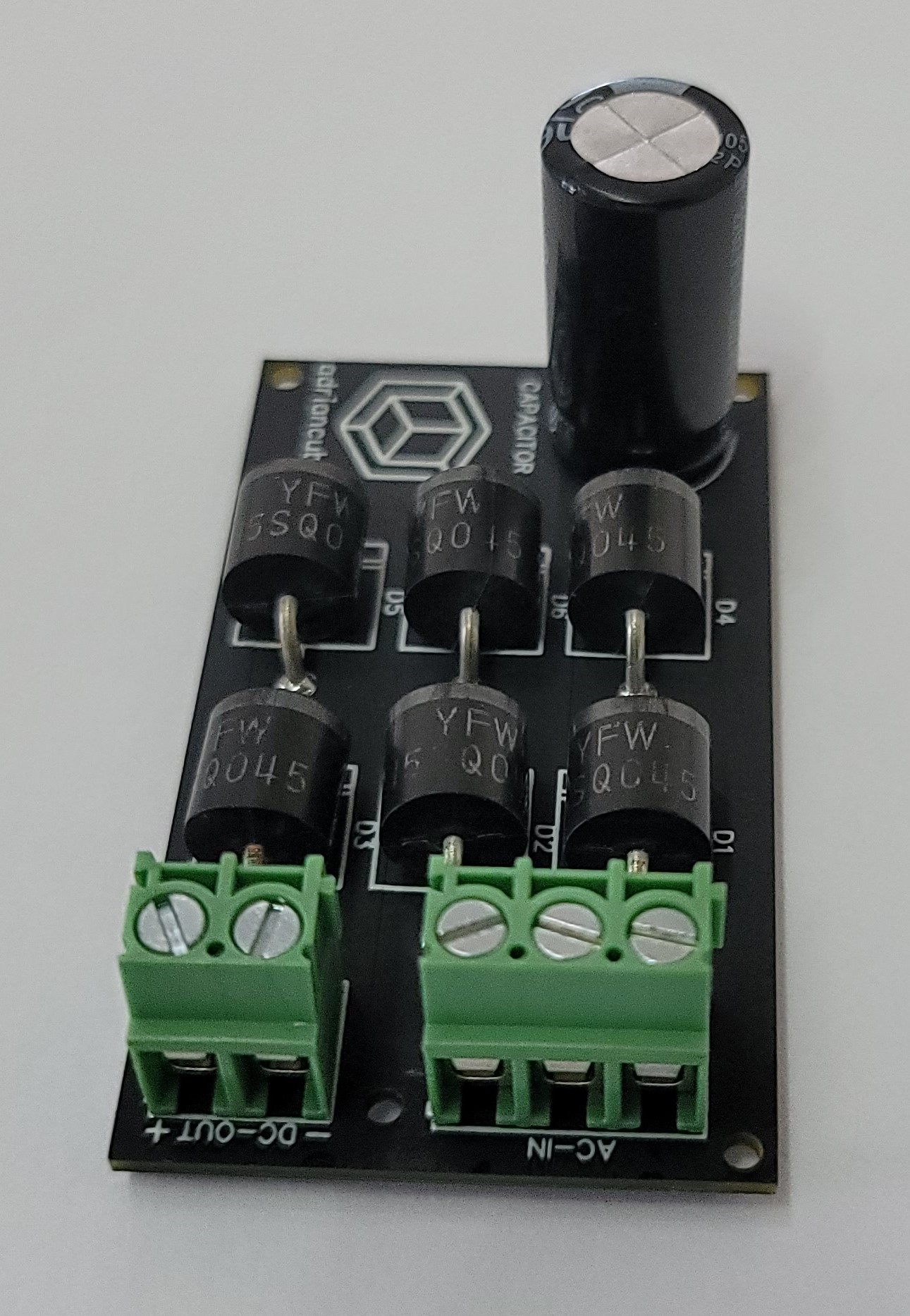

I created a Shottky diode based FW rectifier and then added 2 x 6800uF Caps. Unfortunately The max Voltage I have seen is 1.2 V. There is nothing wrong in your design, my poor choice of motor. I am now printing a new nacelle to connect to a Stepper Motor I have at hand and see what happens.

The great thing about this is that on every step I learn something new which one of the reasons for doing this ! :)

Thank you Adrian !