Hi everyone,

I have been making some changes and now I share with you the files of some variations that I have been making. You can download the pieces from the files section.

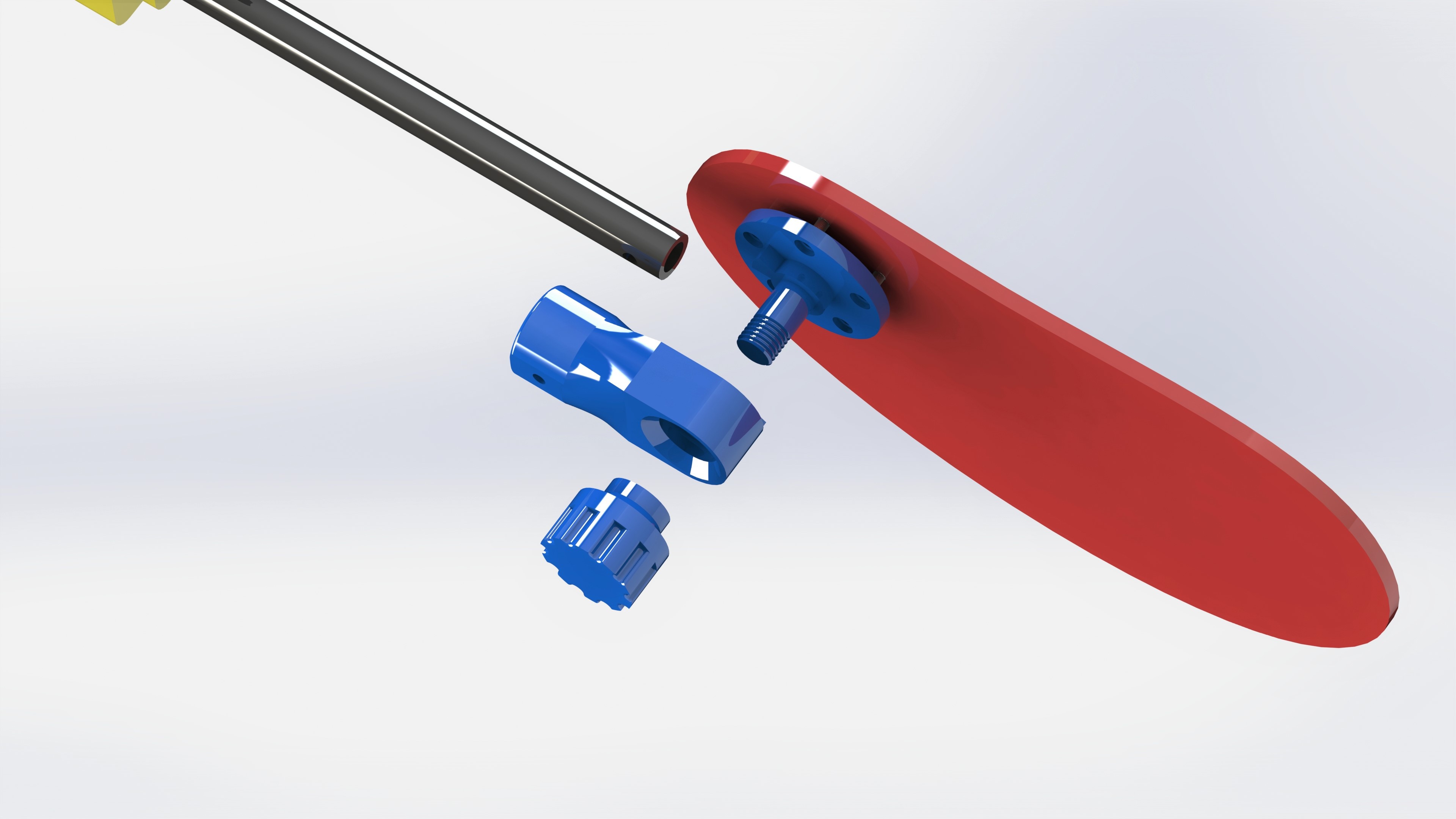

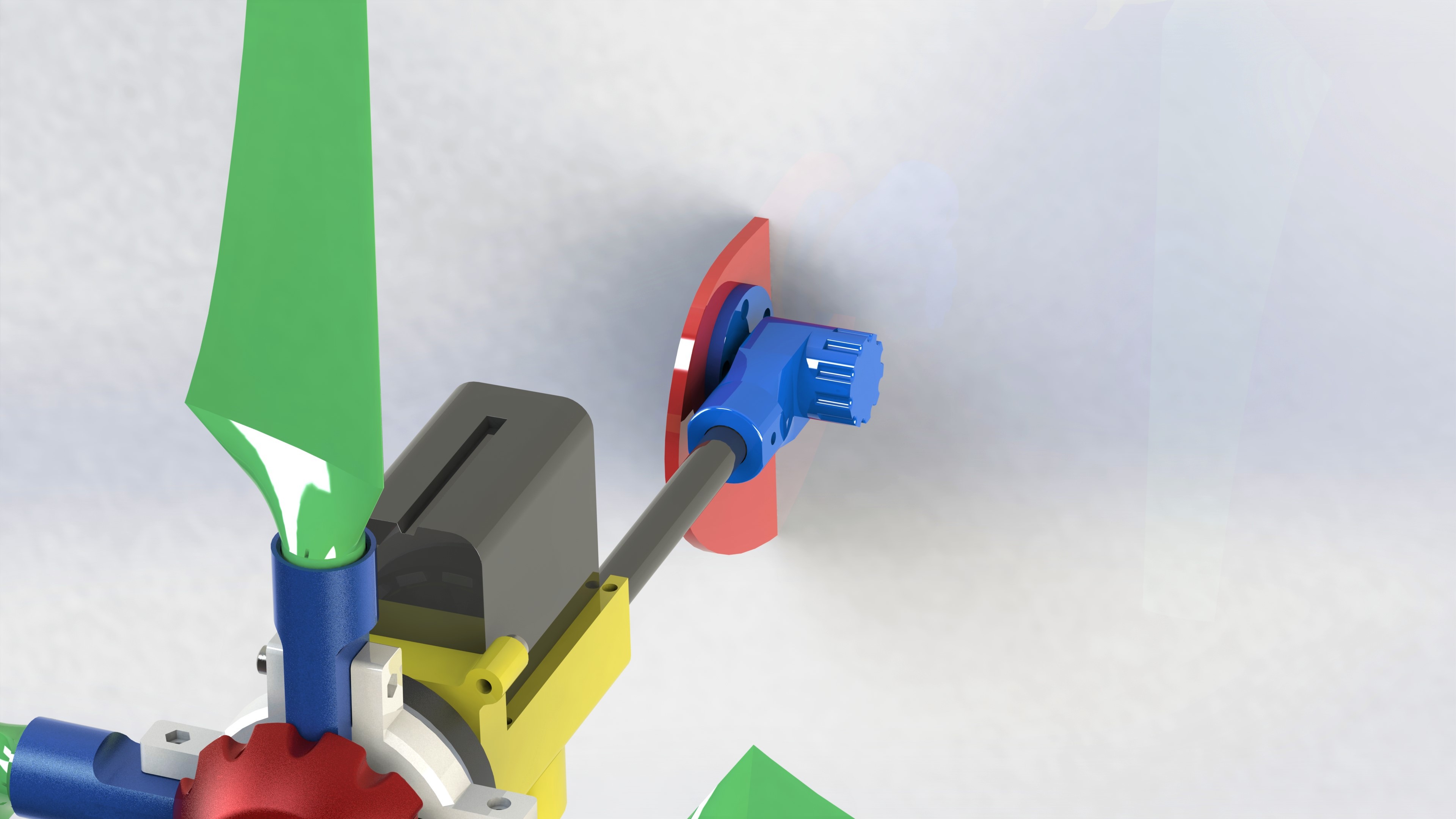

I have developed a new articulation system for the tail. With the new parts, the tail can rotate 180 degrees and can be held in place by its own weight. It is not necessary to screw and unscrew continuously, only at the beginning to assemble the assembly. The tail is now a bit bigger too.

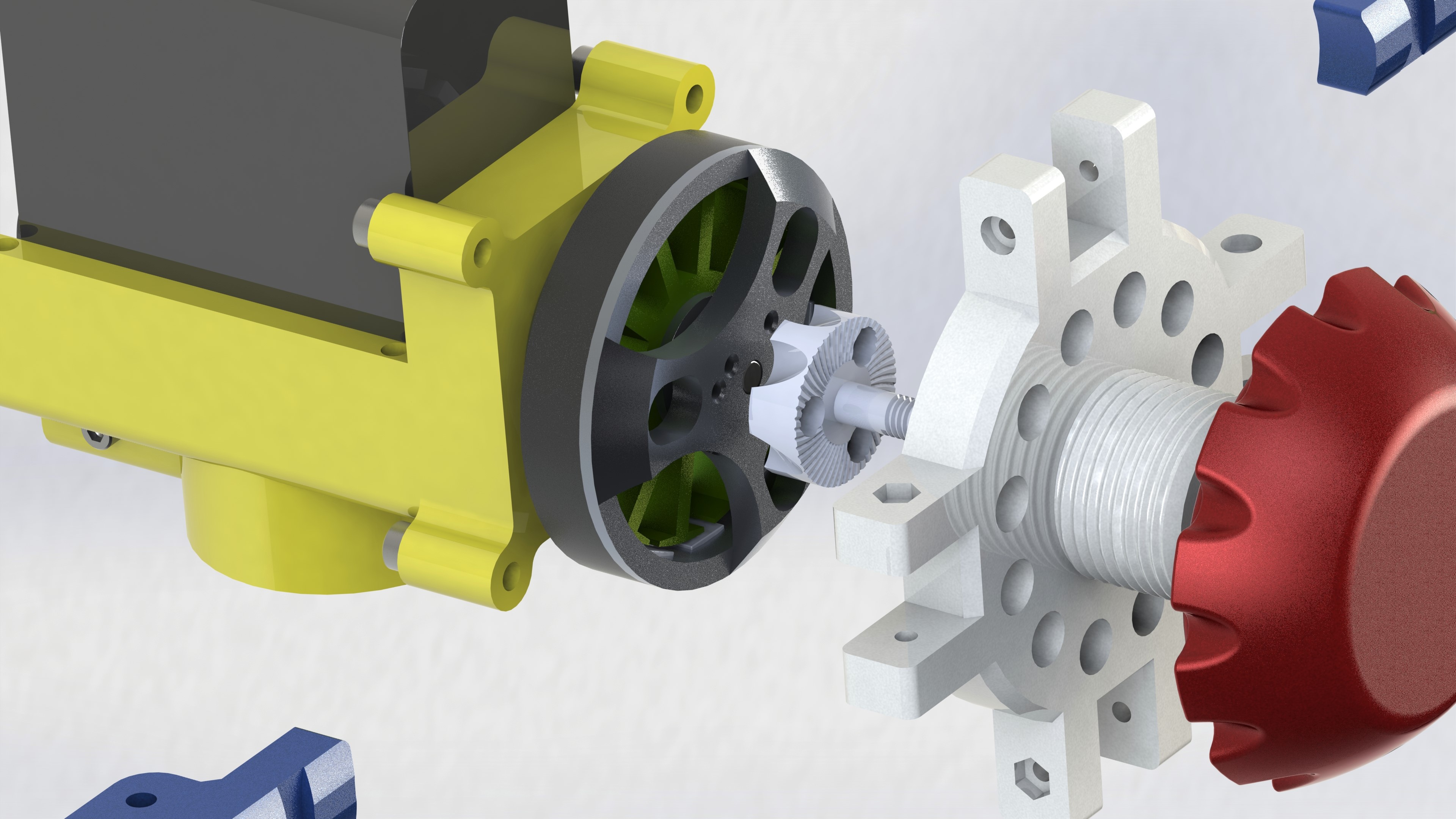

I have developed a coupling piece to be able to use BLDC motors of the type used in camera stabilizers. To date I have not found any other alternative motors to use as generators that do not have to be modified to deliver the necessary voltage at low RPM (350-550) and that meet the size and weight

requirements. These Gimbals motors are not the ultimate ideal solution since they have windings made with a very thin gauge of wire, which causes a somewhat high ohmic phase resistance (10-20 ohms).

Any other more effective solution requires transformations to the motor windings which can be intimidating for some. If you find a generator solution that you think might work, let me know in a comment.

In the following video I show you how, using the motor from the following link, you can easily turn on a fairly long 12V led strip by running the WINDTURER with an ordinary fan.

I have my doubts about being able to do these tests with wind in an open environment without a regulator. The leds could burn out! Note that when the Windturer is running at no load the RPMs are much higher until it stalls. Always try to put a load on the WINDTURER that allows it to start easily but the RPM does not get out of control.

In particular I used a Gimbal motor like this: https://aerialpixels.com/shop/motors/brushless-gimbal-motors/iflight-rc-ipower-brushless-gimbal-motors/ipower-gbm5208-180t-brushless-gimbal- motor-dslr/

Parts for the new assembly are designed based on the dimensions of this electric motor.

Any motor with similar characteristics will work correctly. Unfortunately I have noticed that they are becoming scarcer since fewer and fewer get to make their own GIMBALS.

I'm currently testing one of the RCTimer brand on a garden non-articulated WINDTURER variant (https://rctimer.com/gbm8108-gimbal-brushless-motor-90t-for-red-epic-ect-p0459.html) and the results are somewhat better. Unfortunately they seem a bit expensive. In the future I will develop my own version of a 3D printed generator.

See you in a next LOG, good luck to all!

adriancubas

adriancubas

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

In order for this not to happen, the tripod needs to be completely level, which can be difficult and has happened to me too. If the front end is a little heavier than the rear, you could increase the infill percentage when printing the tail or maybe make the rear tube longer. In this version that I present to you in this Log, the tube and the tail were transformed. An immediate practical solution may be to angle the tripod slightly towards the direction of the prevailing wind. The tendency of the Windturer will always be to return to that position when the wind is not blowing.

In the videos that I have published you can see that the tripod that I use has a central mechanism (tube with a mechanical rack) that raises and separates the Wind Turbine from the legs of the tripod itself. In my case I had no problems that the blades could collide with the legs. I hope I have helped.

Are you sure? yes | no

I am not sure if you had any of these issues but I am finding the front is a bit heavier than the back and not balancing well over the tripod bearing thus it is having a trouble pointing into the wind. Do you have any ideas how to correct this? I suppose I could weight the back in some way. Also, the blades seem to hit the tripod legs, so I may need to make some sort of pier structure to correct this.

Are you sure? yes | no