This project is a totally redesigned new version of the Trash Printer, which I originally built as just one part of my entry to the 2018 Hackaday Prize, which was for a trash-powered-off-grid-recycling center. I did eventually get it working, 3 years later, but not in time for 2018 Hackaday Prize finals.

This new design includes the original extruder head, but now also includes full documentation for the entire 3D printer gantry as well, so you can build the whole printer from start to finish!

This new design is cheaper, easier to build, and makes bigger parts than my previous two versions, and is fully open-source!

To give you context for what a breakthrough this new design is for me, it helps to understand how I got to this point. So gather around kids, and let me tell you the story of the Trash Printer.

It all started way back in 2016, when I first built the Precious Plastic open-source plastic shredder, using money from my Patreon. The shredder allowed me to shred up plastic trash into small flakes, and it's what got me started on this whole wild project.

In March of 2017, I built the Precious Plastic Extruder, and I was finally able to start extruding those shredded plastic flakes into... well, basically spaghetti. The Precious Plastic community has done some truly incredible things with this extruder, but making anything useful with it is time consuming and requires a lot of skill, and to be honest, I didn't really have the patience for it.

But the long strands of plastic that came out of the extruder looked a lot like 3D printer filament, and it got me thinking. The day I built the extruder, I took it over to the CNC router in my friends' shop, and I said, "I wonder if we could just strap this to a robot...?"

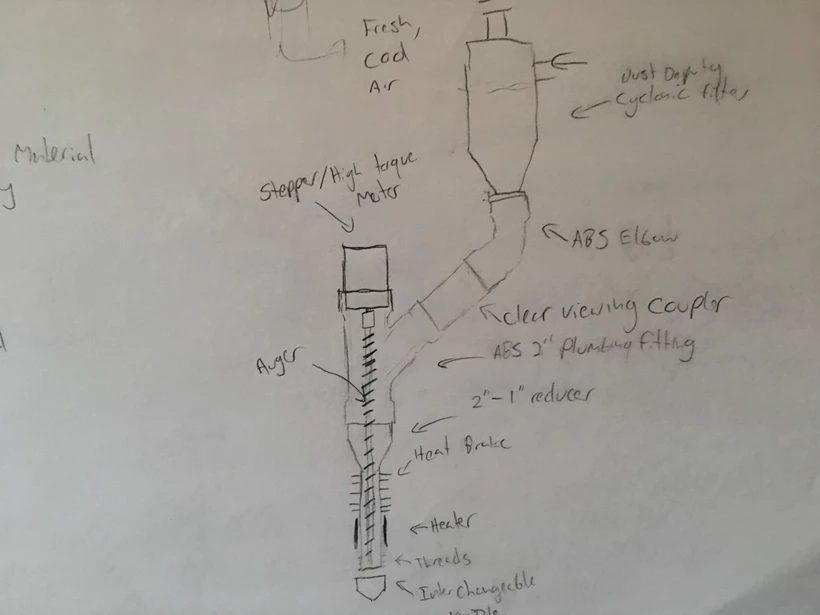

In December of 2017, I started making design sketches, taking what I had learned from the Precious Plastic design, and putting it on a vertical axis so that it could act as a 3D print head

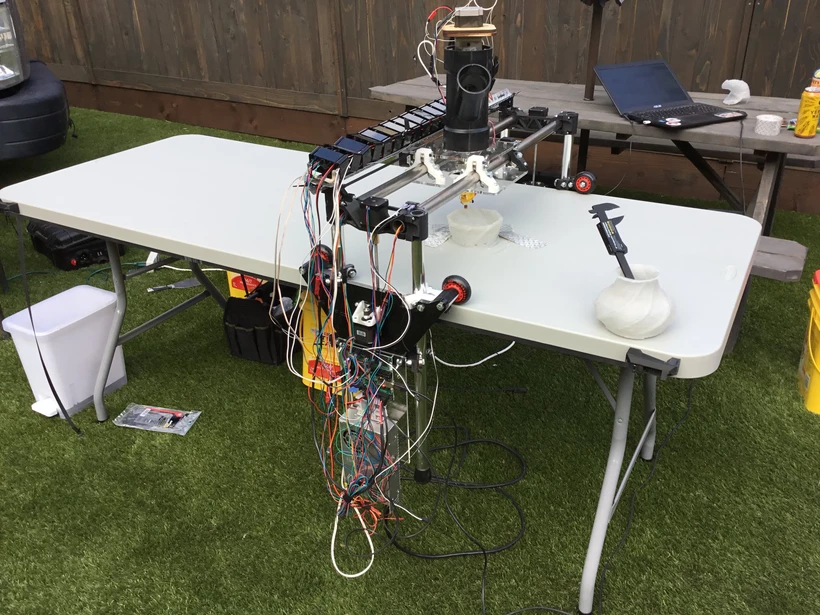

In February 2018, I started asking my friends who knew about 3D printers how I might go about getting the extruder actually moving. At the time, I knew basically nothing about how 3D printers worked. With A LOT of help (Big thanks to Darcy N, Molly M, Jonathan D, and Nathaniel G) I 3D printed the parts to build the MPCNC (Mostly Printable CNC) designed by V1engineering. I picked that gantry because it was cheap, 3D-printable, and it used common, hardware store parts.

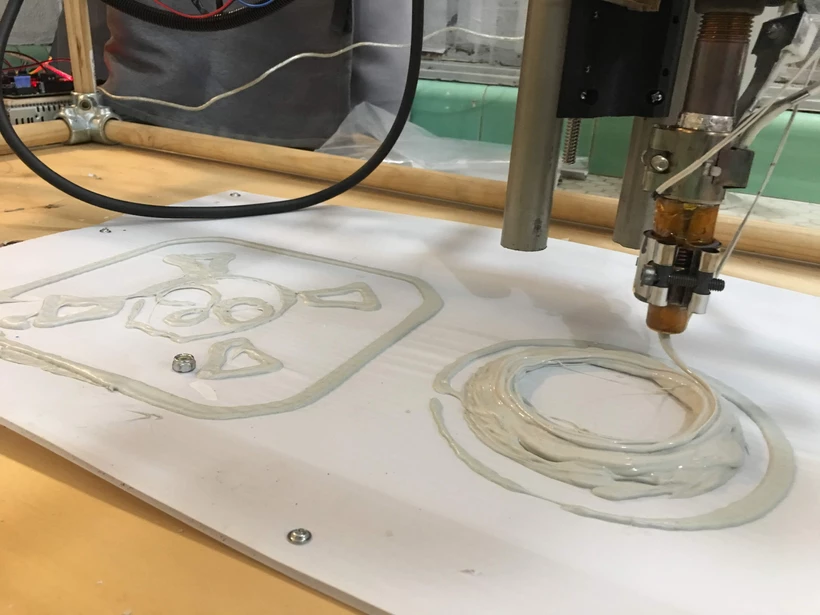

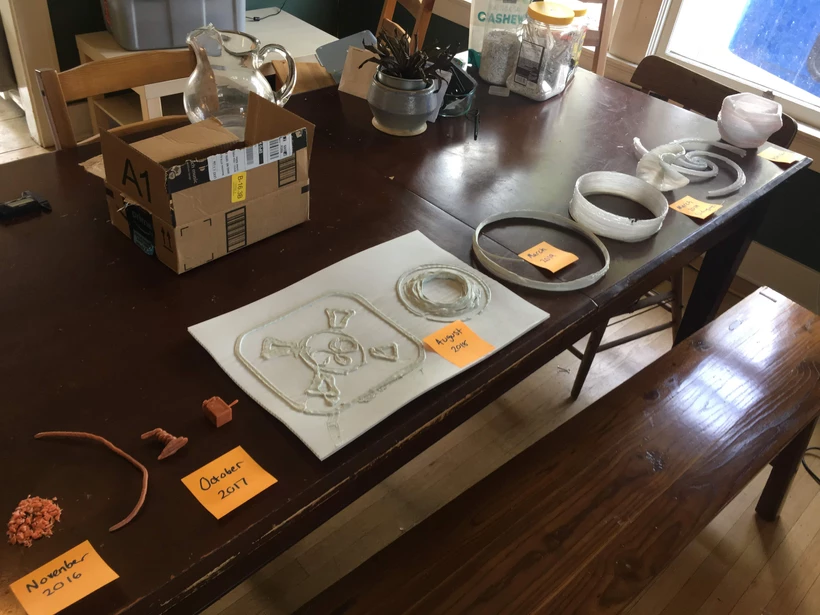

My goal was to figure out how to build a fully functional Trash Printer by October of 2018, as just one part of my submission to the 2018 Hackaday Prize. It proved to be a lot more difficult to do than I had hoped, and by the time the deadline for the Hackaday Prize arrived, I had only succeeded in building the gantry and getting the printer moving for the first time, making these first, very basic shapes.

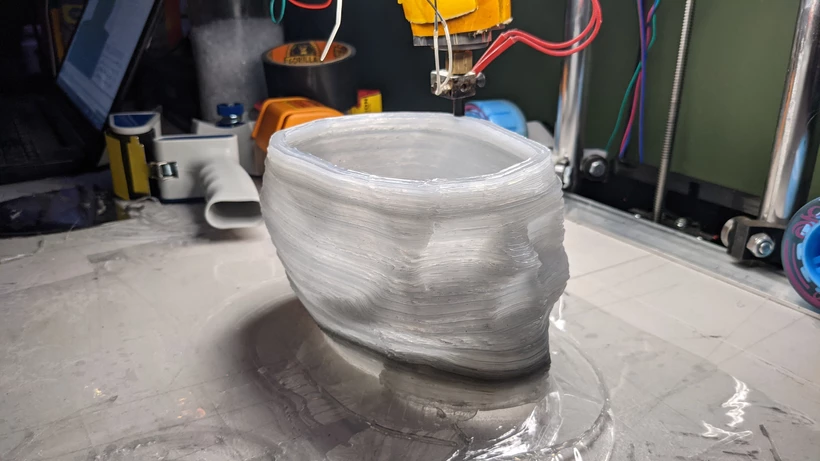

The deadline came and went, and I failed to make it to the finals, and I gave up on it for a while. I wasn't able to even look at it again for a few months, but in the spring of 2019, I finally made my first actual prints, with actual layers, which were the first things you could really call "things".

After that, my prints improved quite quickly, but I was still limited to pretty basic shapes, and the prints weren't very consistent. I started using shredded up polypropylene test tubes as my feedstock, which provided a nice, stable, clean material to test with, even though it wasn't really the same as using post-consumer household trash, which was always my goal

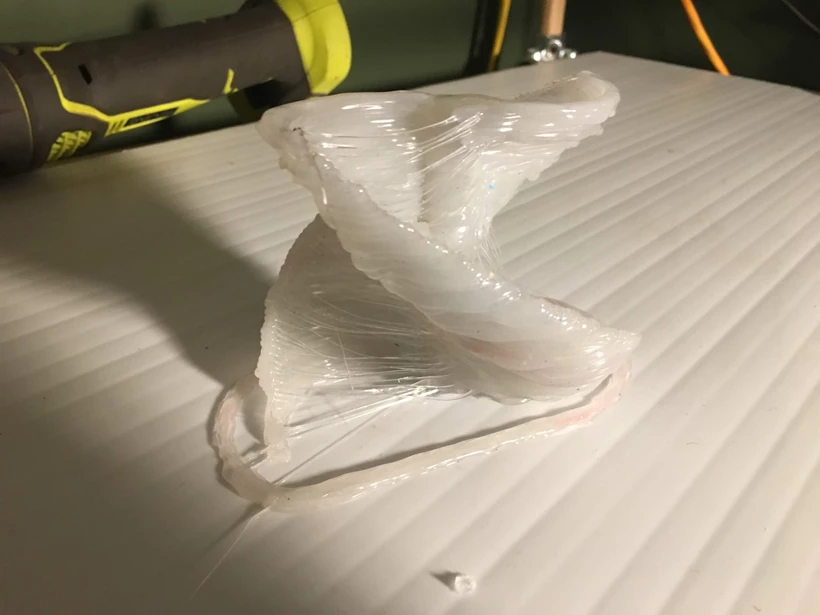

One of the first things I ever printed was this little, 4" tall "wind turbine". It was a promising proof-of-concept, but hardly functional. Still, it did prove to me that the concept was workable, and until that point, I hadn't really been sure if what I was trying to do was even possible.

By the Summer of 2019, I was printing simple vases pretty consistently, but not with real trash, and not anything very big. I kept messing around with settings, and testing out new motors, upgrading from a NEMA23 stepper motor to a NEMA23 with a 5:1 planetary reduction (I'm now using a 15:1 reduction), in order to get more torque.

I decided that I needed a bigger gantry too, so I upgraded to a "LowRider2" CNC gantry, also by V1engineering. With the LowRider2 gantry, I was able to print larger, taller parts.

Over the Winter of 2019, I was even able to print much more complex parts, like this mushroom lamp, which took 17 hours, all told.

In the Winter of 2019, I started working on my own custom gantry design.

I've always wanted to release the plans for the Trash Printer to be fully open source, fully documented from start to finish, like the Precious Plastic Machines. When my design was just for the extruder and people had to figure out how to get it moving themselves, it made a really high barrier to entry, and to my knowledge, no one actually ever built one (besides my friend Darcy).

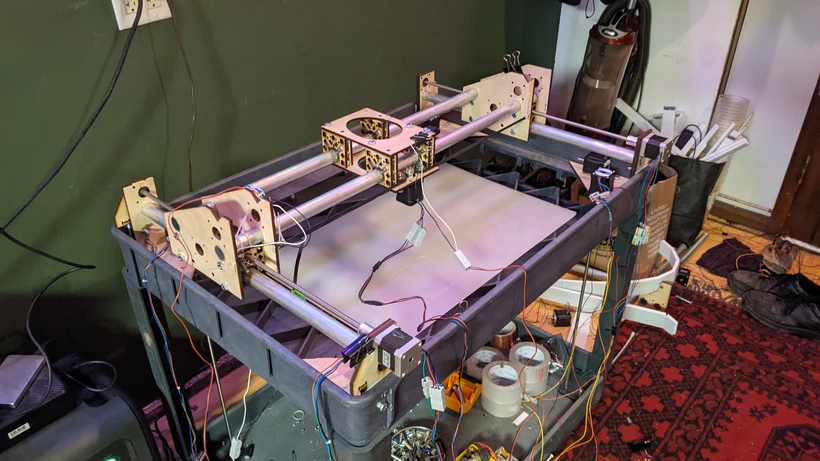

So, I started playing around with this new gantry design, built around a Polypropylene service cart and laser-cuttable parts. I even started building a prototype.

But then, the pandemic hit, and the Trash Printer went into storage for almost a year and a half.

I finally got it working again in the late Summer of 2021, and I started really dialing in the settings, making much more complex objects than I ever had before.

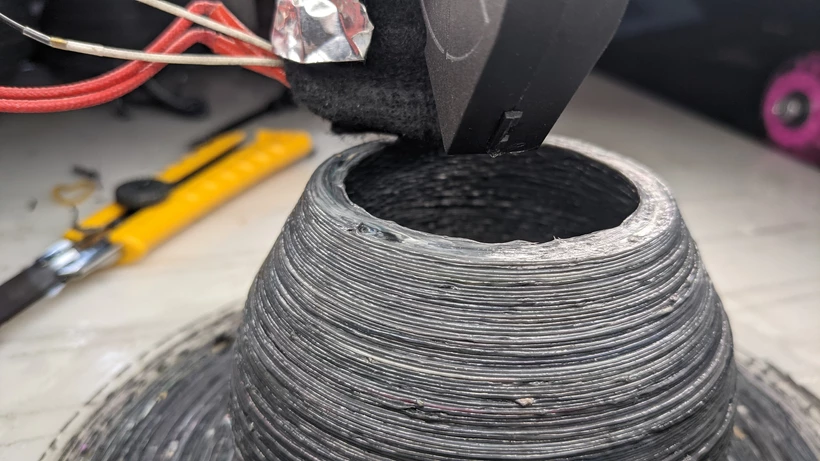

I was starting to run out of clean test tube flakes, and so it was finally time try to print stuff with my real, actual trash - take out containers and coffee cups that I had saved from my actual recycling bin.

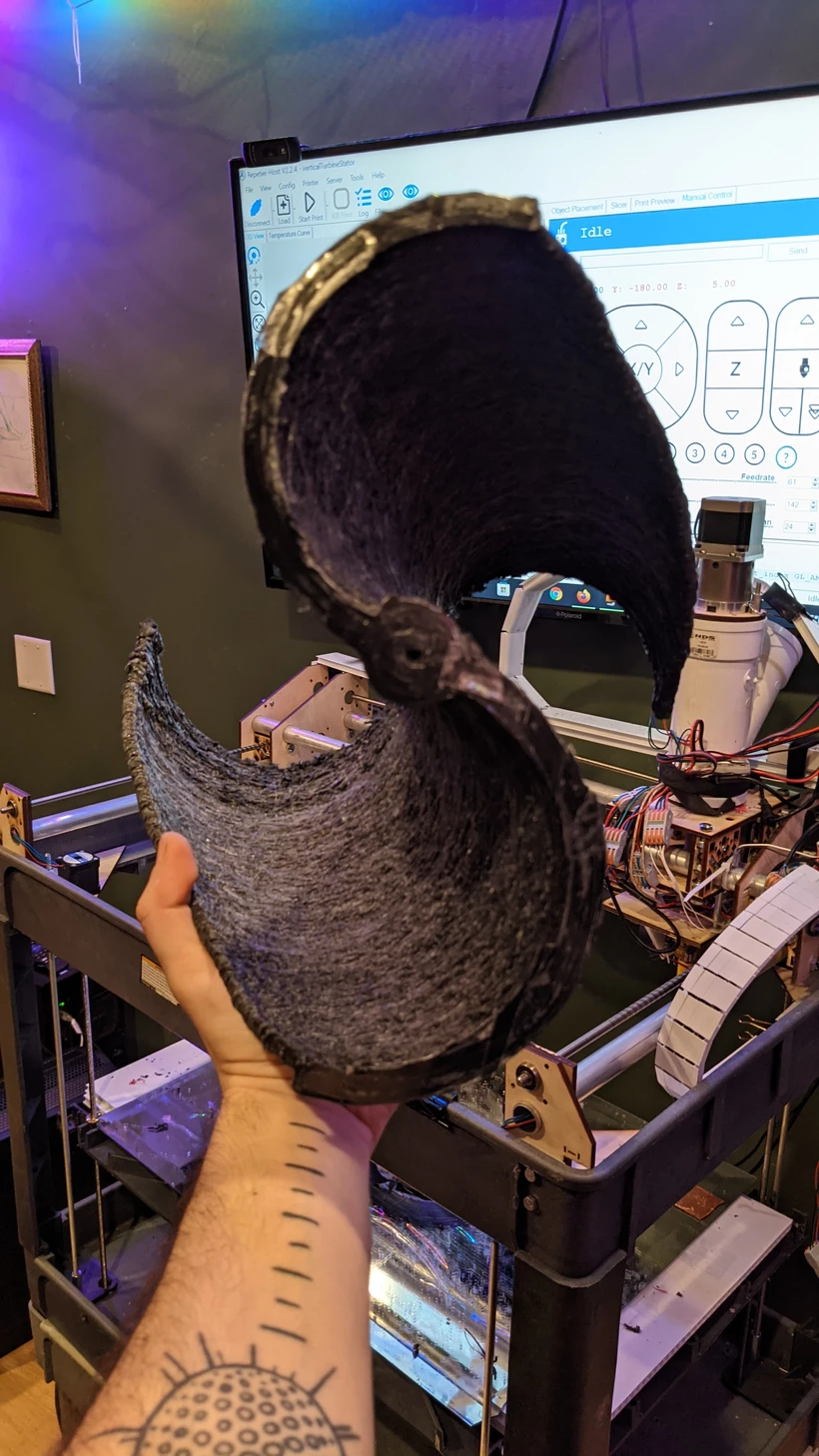

And it worked! My mixed trash prints with this nice gun-metal gray color, and I found I could dye it a nice black by adding just a little bit of charcoal dust from by biochar reactor.

Now that I knew that I could actually print actual things with actual trash, I started thinking about how other people could replicate this idea. The problem was that making good how-to documentation for the Trash Printer is incredibly time consuming, and the fact that it relied on the V1engineering designs made it confusing at best to explain, and dependent on external documentation that could change at any time.

The only part of the design that I really had control over was the extruder, and without the robot to move it around, the extruder isn't very useful.

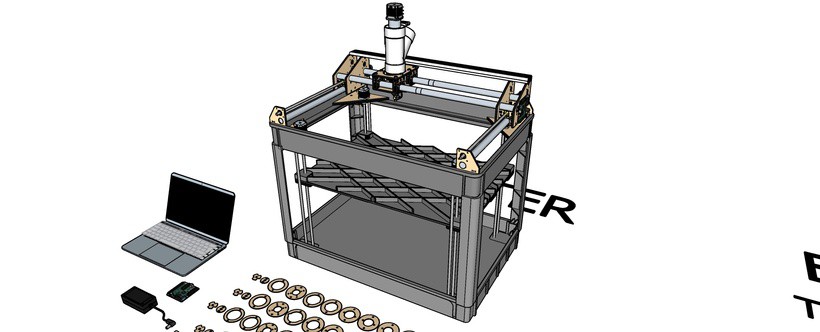

So I finally revisited this design that I had started working on back in 2019, that used a polypropylene service cart as it's frame, and laser cut parts. Compared to the LowRider2, which takes 40-60 HOURS to print all the parts for, this design can be laser-cut on a Glowforge in 20-40 MINUTES, out of 3 sheets of 1/4" plywood.

I didn't think it would actually work, though, being the first CNC machine that I had ever designed, and at multiple stages in the build I had convinced myself the design was fundamentally unworkable.

To my surprise, when I finally hooked up all the motors and I gave it a shot, it worked! Not only that, it worked better than it had ever worked, and it was cheaper, easier to build, and made taller, better parts.

Most importantly, it is now of my own design, which means that I can make it fully and completely open source, not just the extruder, but the whole dang printer.

In the Spring of 2022, I was finally able to print this enormous, functional wind turbine, printed out of my real trash. What a difference 5 years makes!

So that's the story of the Trash Printer, so far.

The next chapter of this story is up to you. The new design packs flat, uses commonly available hardware ad parts that can be laser cut, CNC routed, or 3D printed. It has a build area of roughly 18" x 18" x 20", and is designed to work with plastic flakes exactly the way the come out of the Precious Plastic Shredder, with no further processing required.

It could still stand to be greatly improved, and I invite you to help me do that! This was the very first 3D printer that I ever built, and I am by no means a 3D printing expert (If you are, you can probably tell).

Your knowledge, ingenuity, and skill could transform this from neat idea into a truly workable and disruptive technology, that changes how we relate to our plastic trash.

Attribution is not a requirement on this project, and I encourage you to just do whatever you think will help, without asking for permission. But if you do replicate, remix, or reinvent this design, please leave a comment, and/or send me photos of your build and the stuff you build with it, so that I know that all the work that I put into this project didn't go to waste.

If you want to learn more about this and my other projects, check out my Patreon, and this album I put together of the evolution of the Trash Printer! None of my Patreon is pay-walled, it's free and open for everyone, but if you do become a Patron you'll get monthly project updates, and it will help me build cooler stuff faster. You'll also get access to a private Discord.

You can also check out my working model for this new printer on the SketchUp 3D Warehouse.

Sam Smith

Sam Smith

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.