Our car uses CAN bus for device communication. APPS sends current pedal position over

the bus as well as diagnostic information regarding any errors that occurred during its

operation.

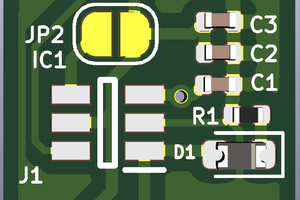

APPS is a part of the front-box - a PCB stack that’s located at the front of the car which we

already covered in this article - thus it has to follow a certain pinout that allows for easy

debugging and connection with other boards that’s space efficient and easy to disassemble.

Manufacturing

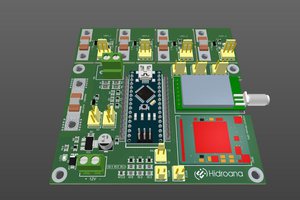

PCBs designed by our team are manufactured by JLCPCB- a hardware production

company that specializes in batch PCB production. You can create PCBs with up to six

layers, and order a batch size that fits your needs. Batch production is beneficial since

during PCB assembly, many things could go wrong and the board could get damaged, that’s

where excess copies come in handy. If unlike us you don’t enjoy assembling PCBs, JLCPCB

has got you covered as PCB assembly is also a part of their offer!

You will be forwarded to the order editor where you’ll find plenty of options to customize your

batch of PCB to fully meet your needs. Firstly you’ll need to upload your gerber files archived

into .zip or .rar format.

PUTMotorsport

PUTMotorsport

mbsg99

mbsg99

ElectroBoy

ElectroBoy

Onur Şurgun

Onur Şurgun