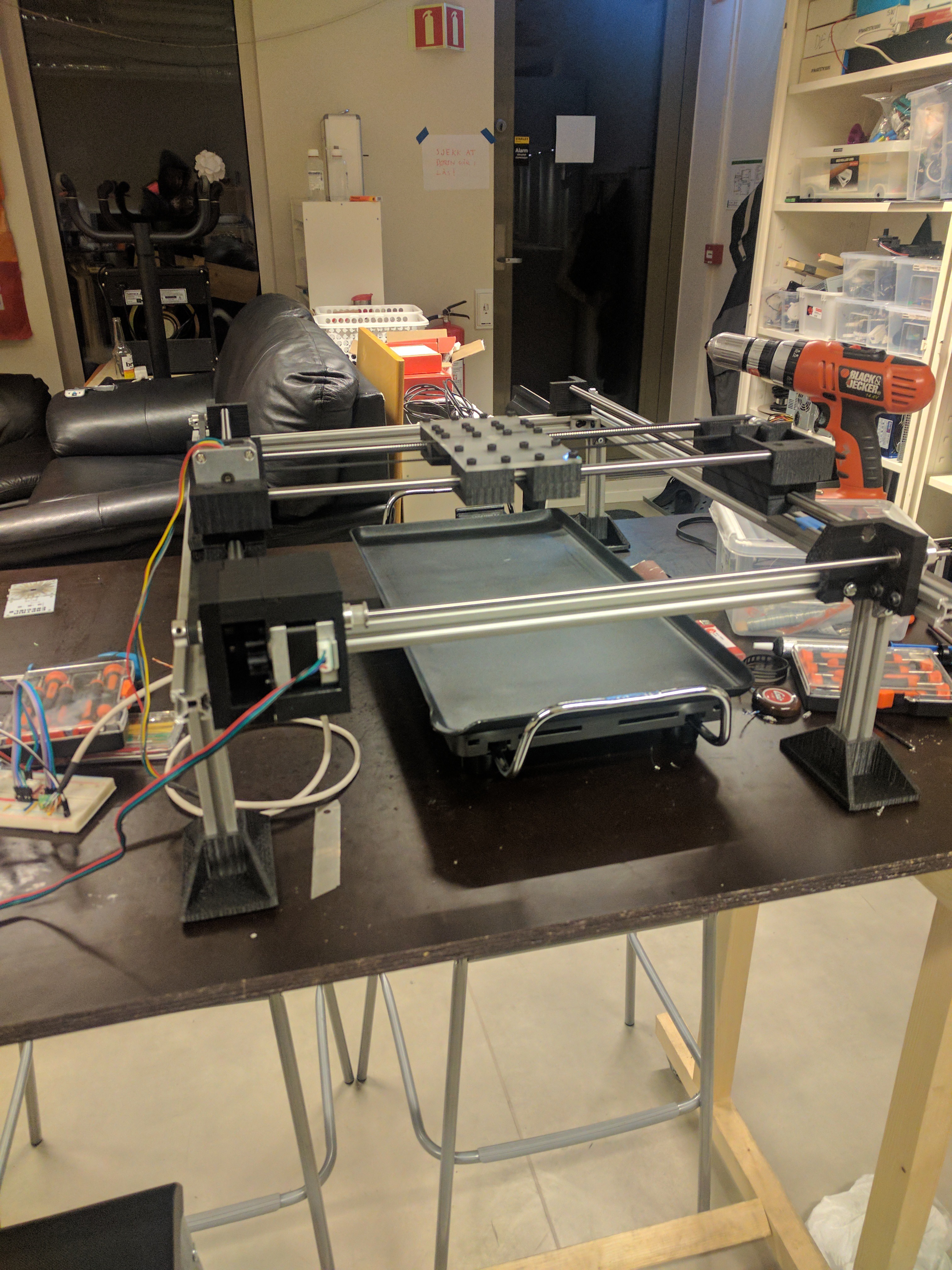

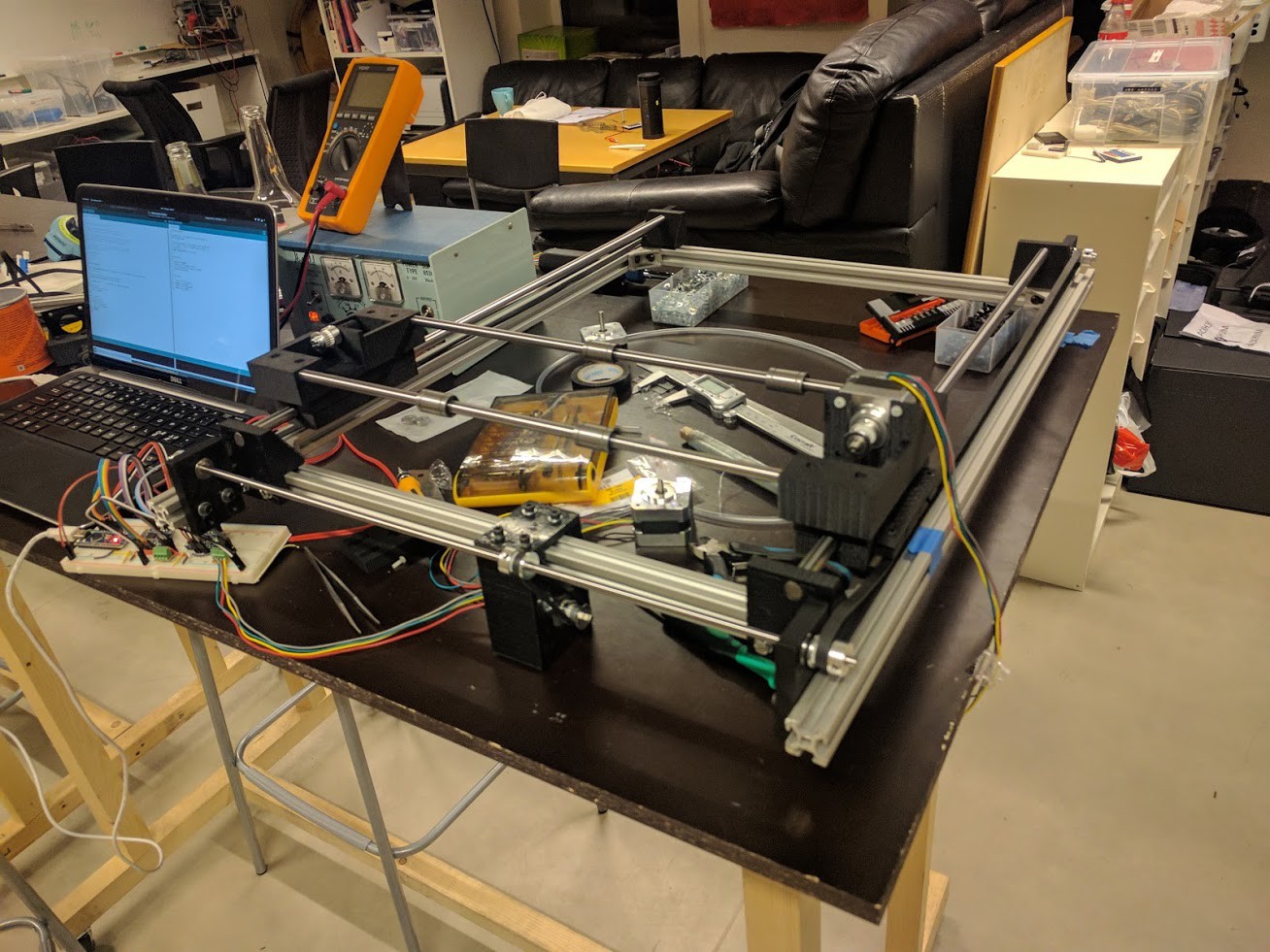

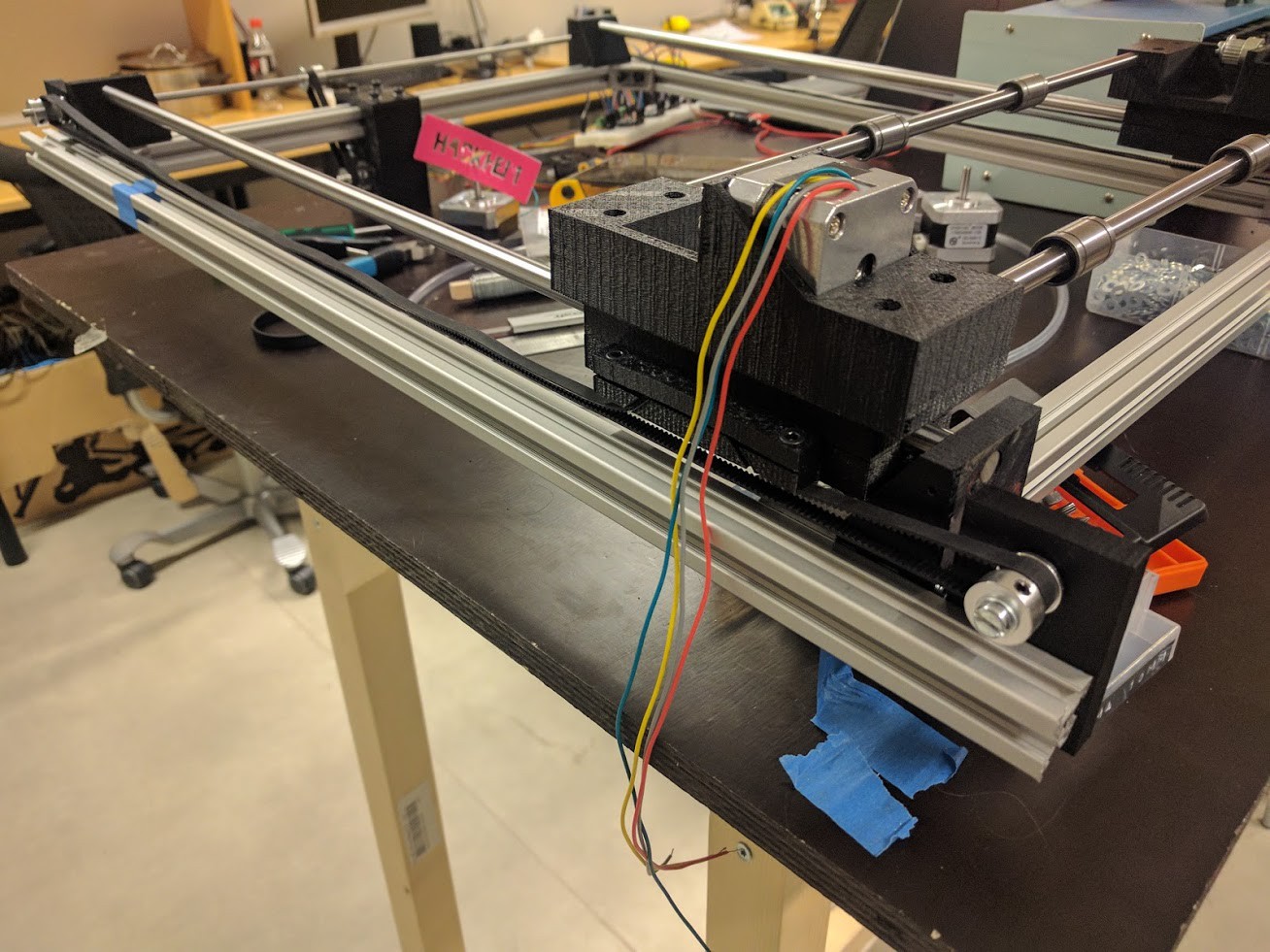

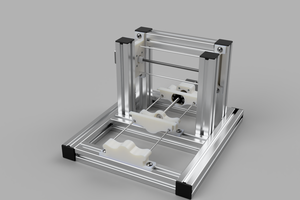

Alright: so what I am attempting to do is to build a two axis CNC that spits pancake batter onto a hot metal plate.

I'm diving into this project with minimal knowledge of this sort of stuff from before, I have pretty much no experience building similar things, I''ve tinkered and worked a fair bit on the 3d printers at the hackerspace I hang out at (hackheim) but thats about it.

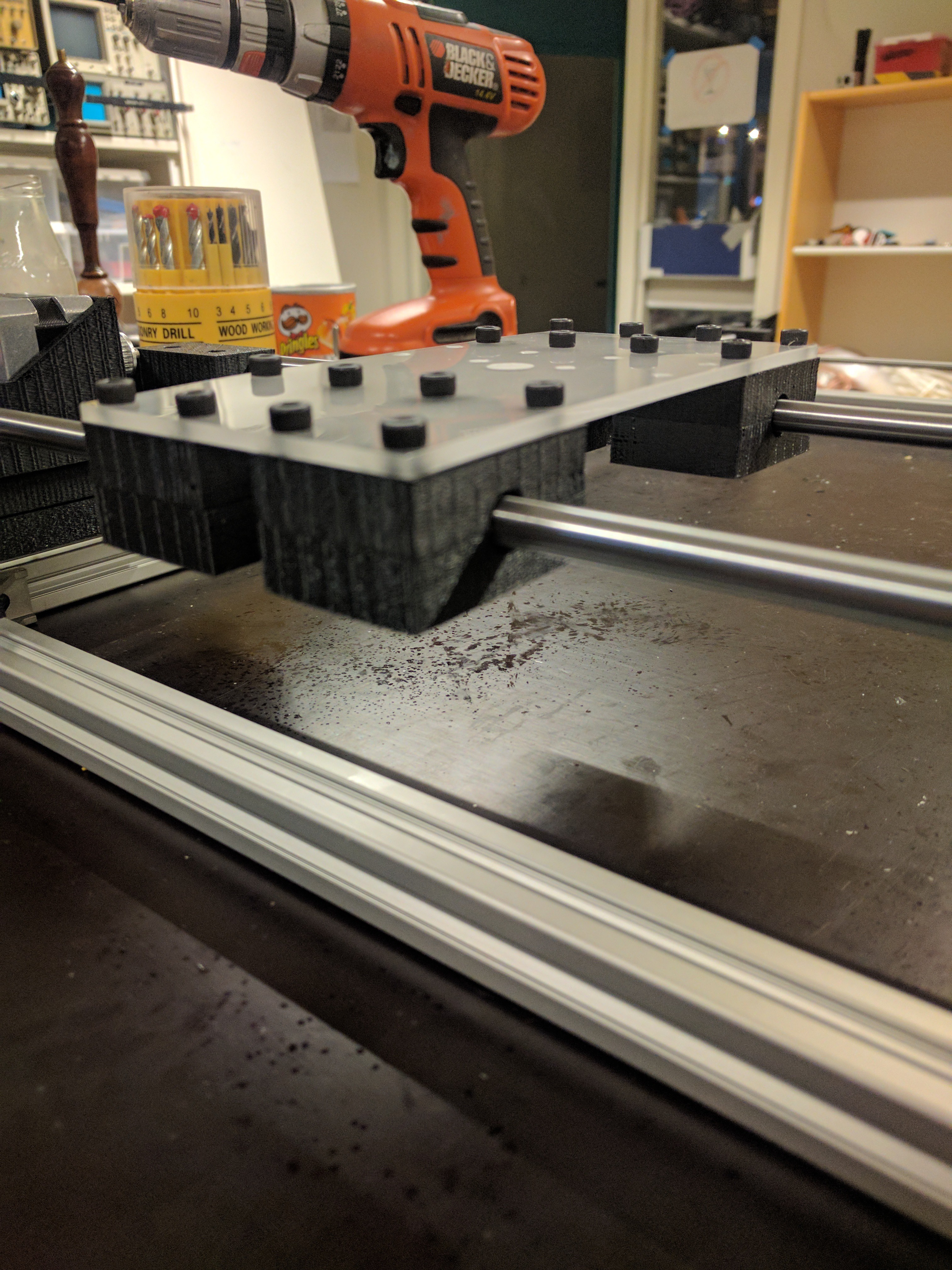

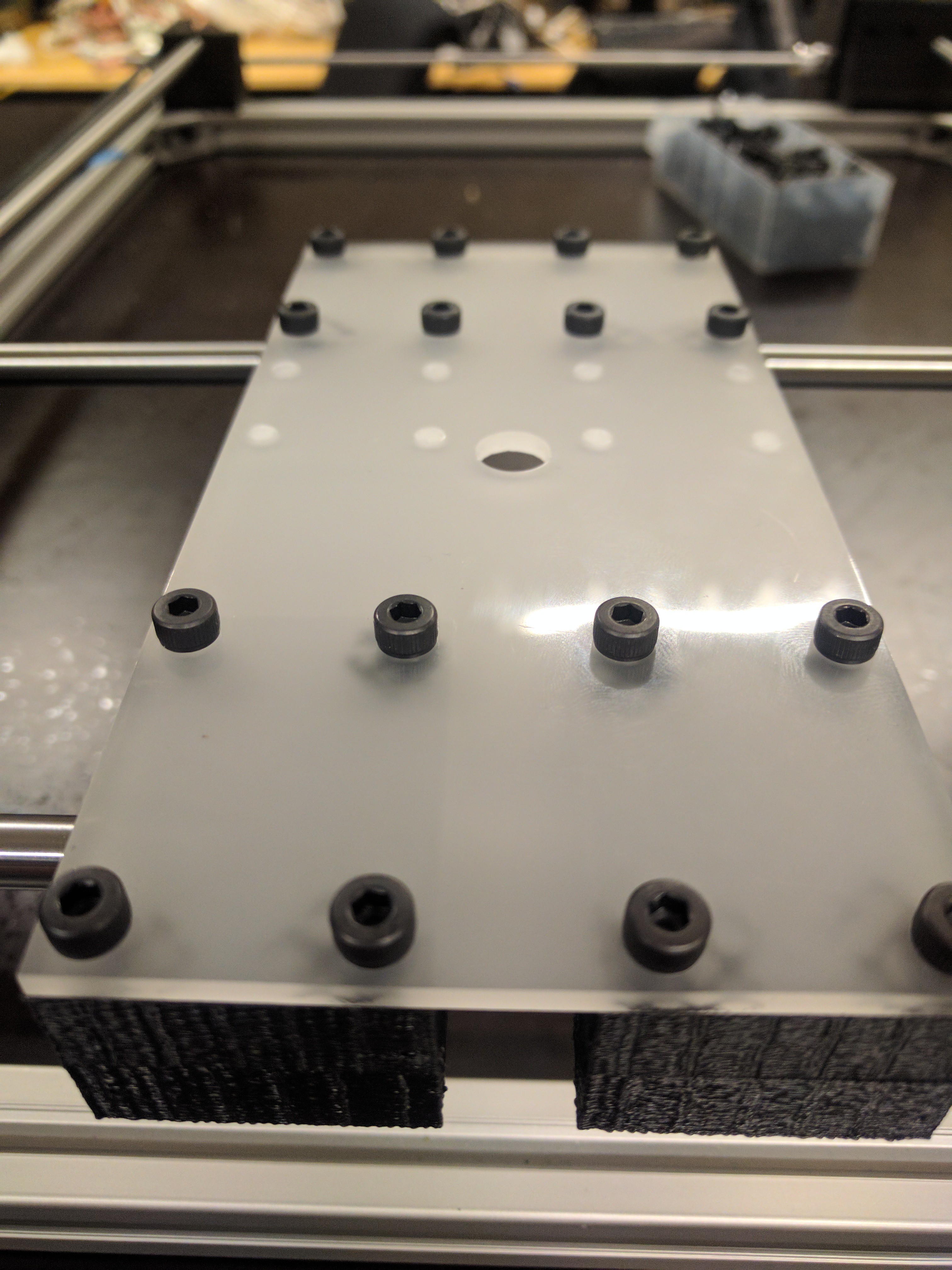

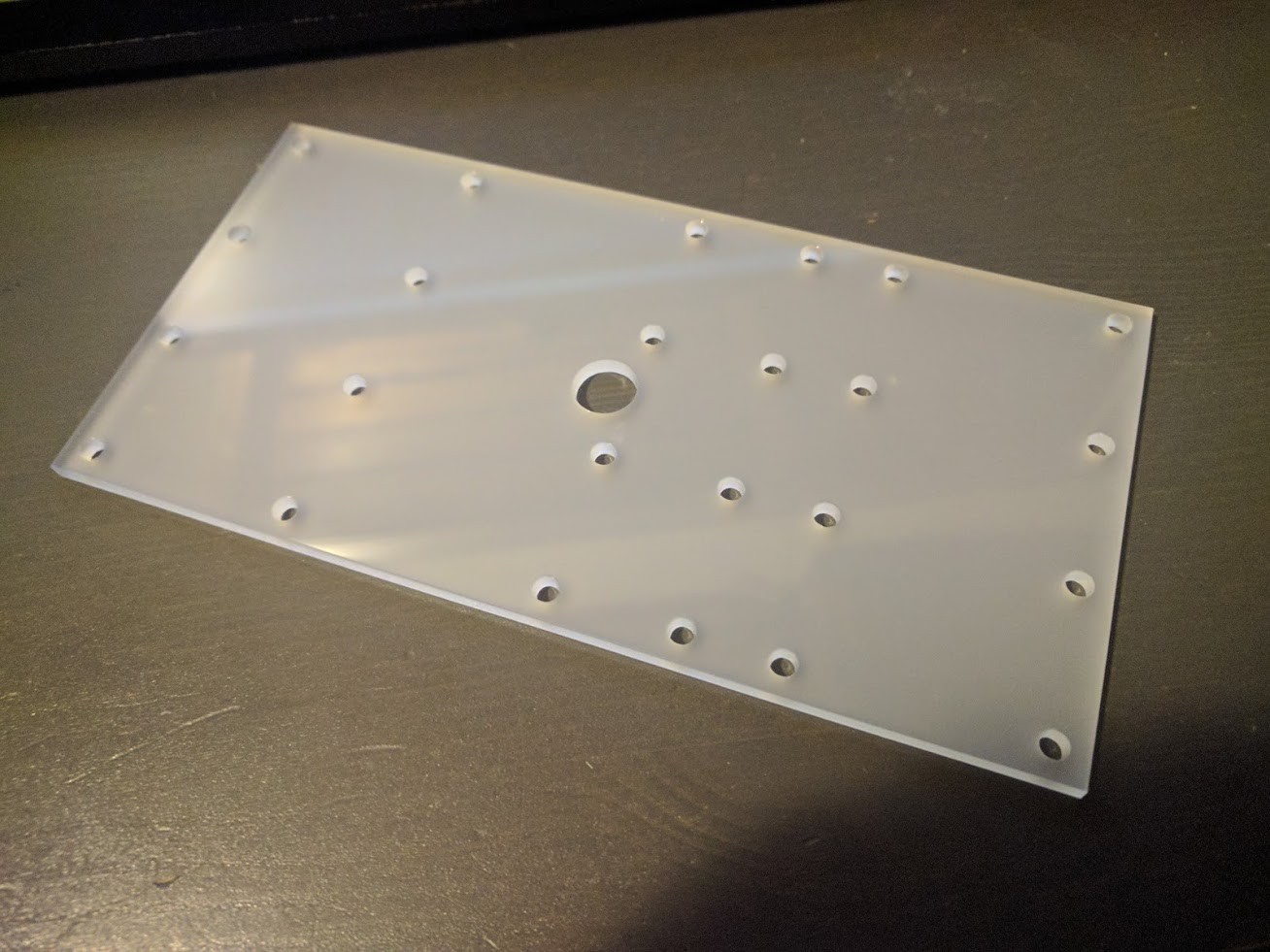

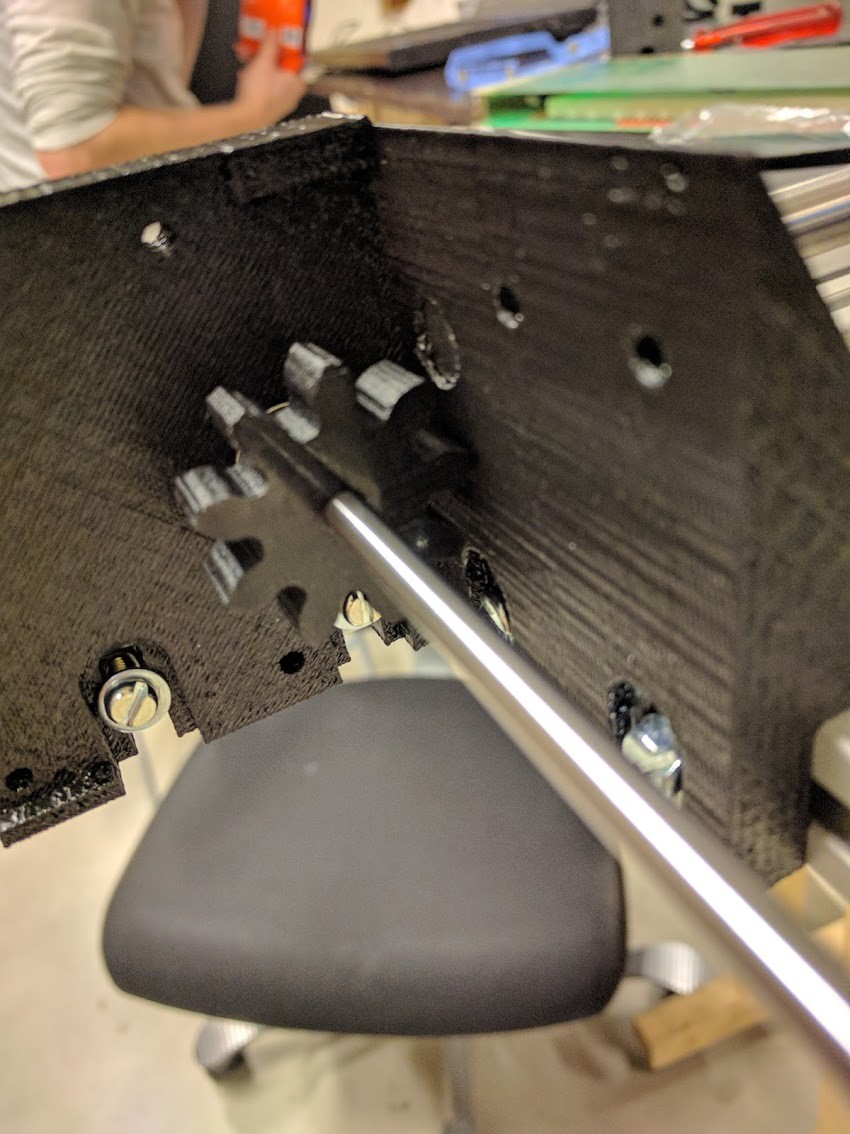

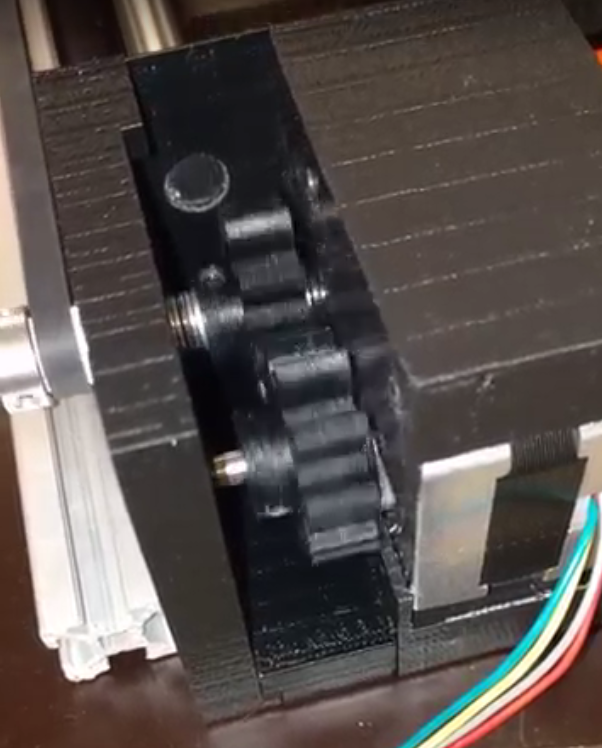

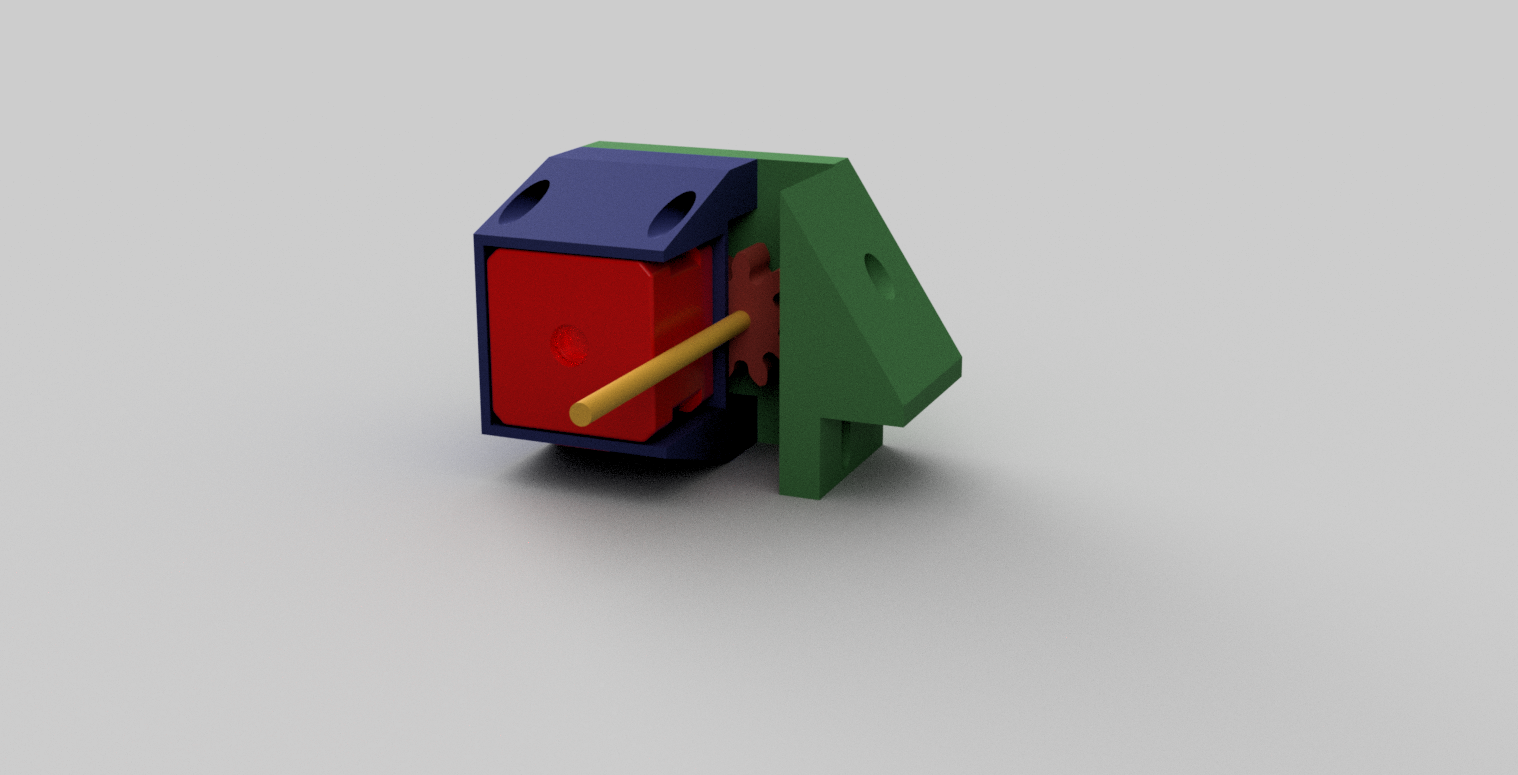

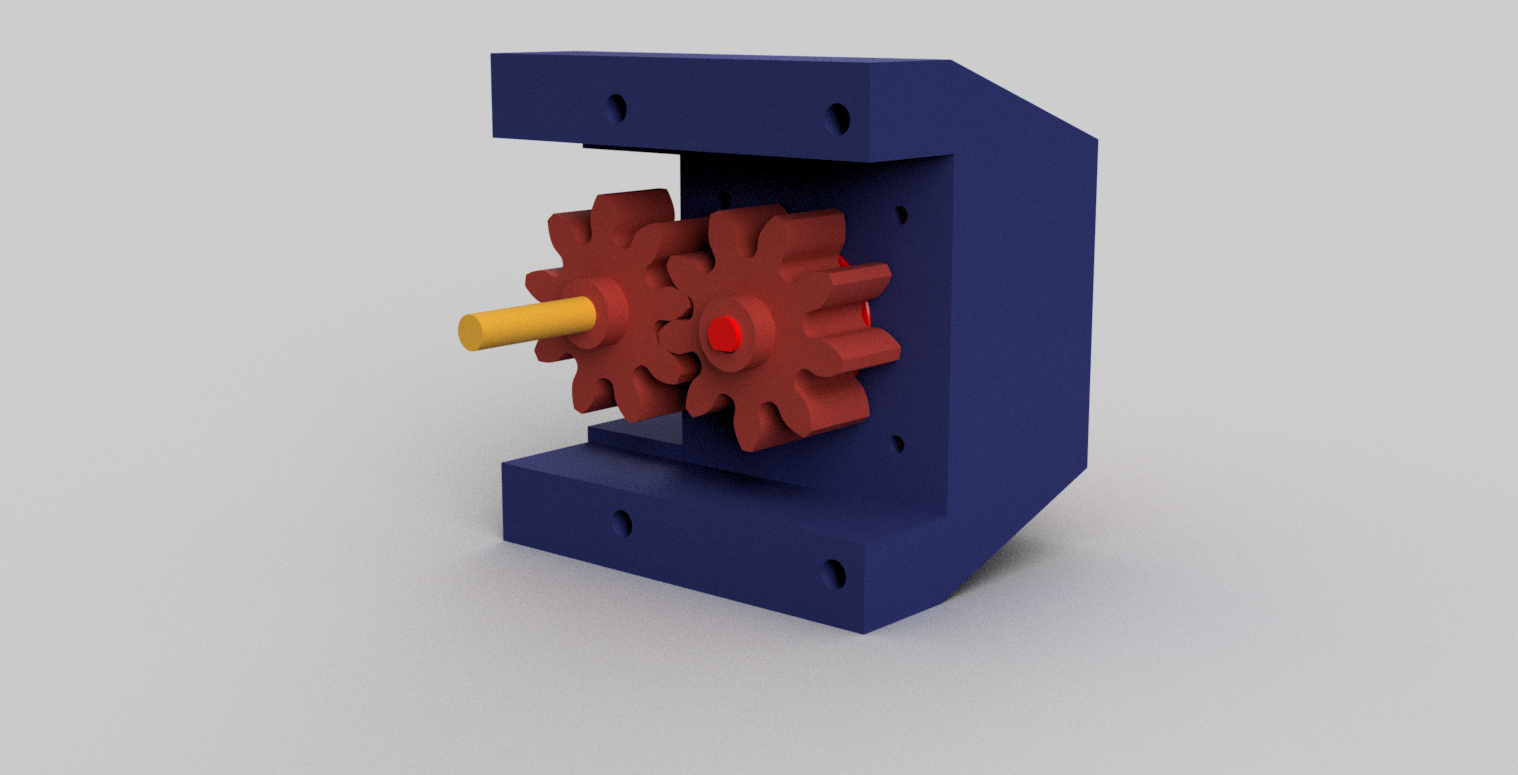

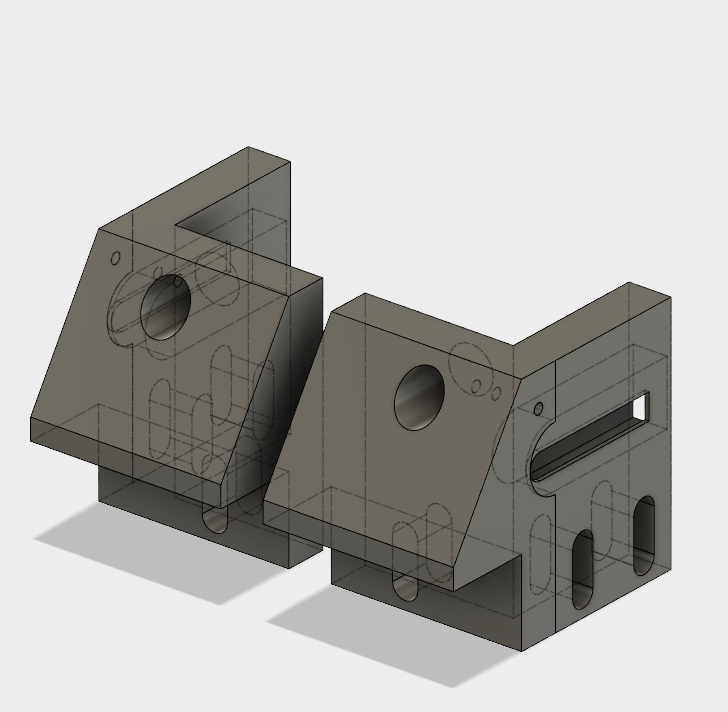

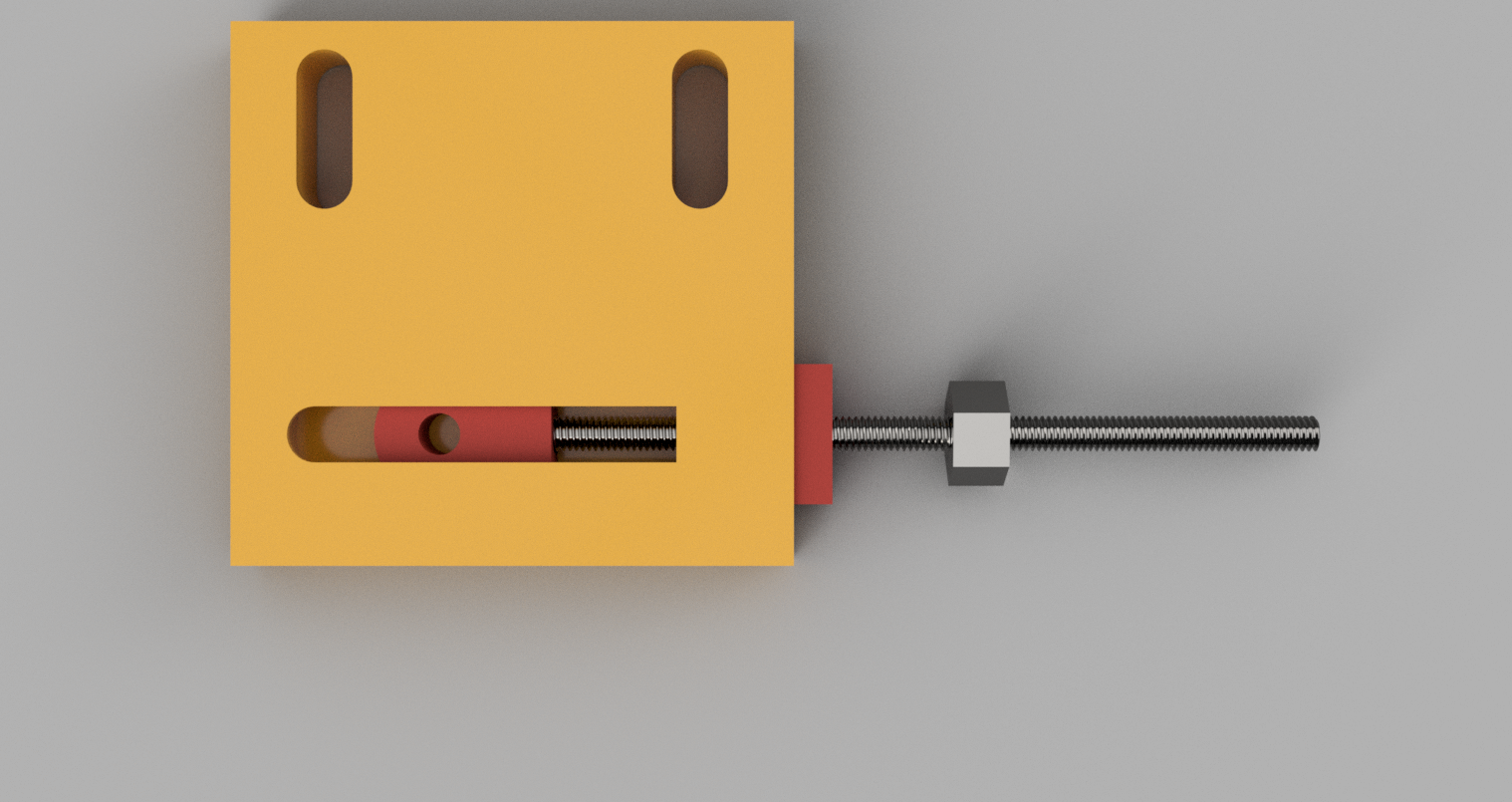

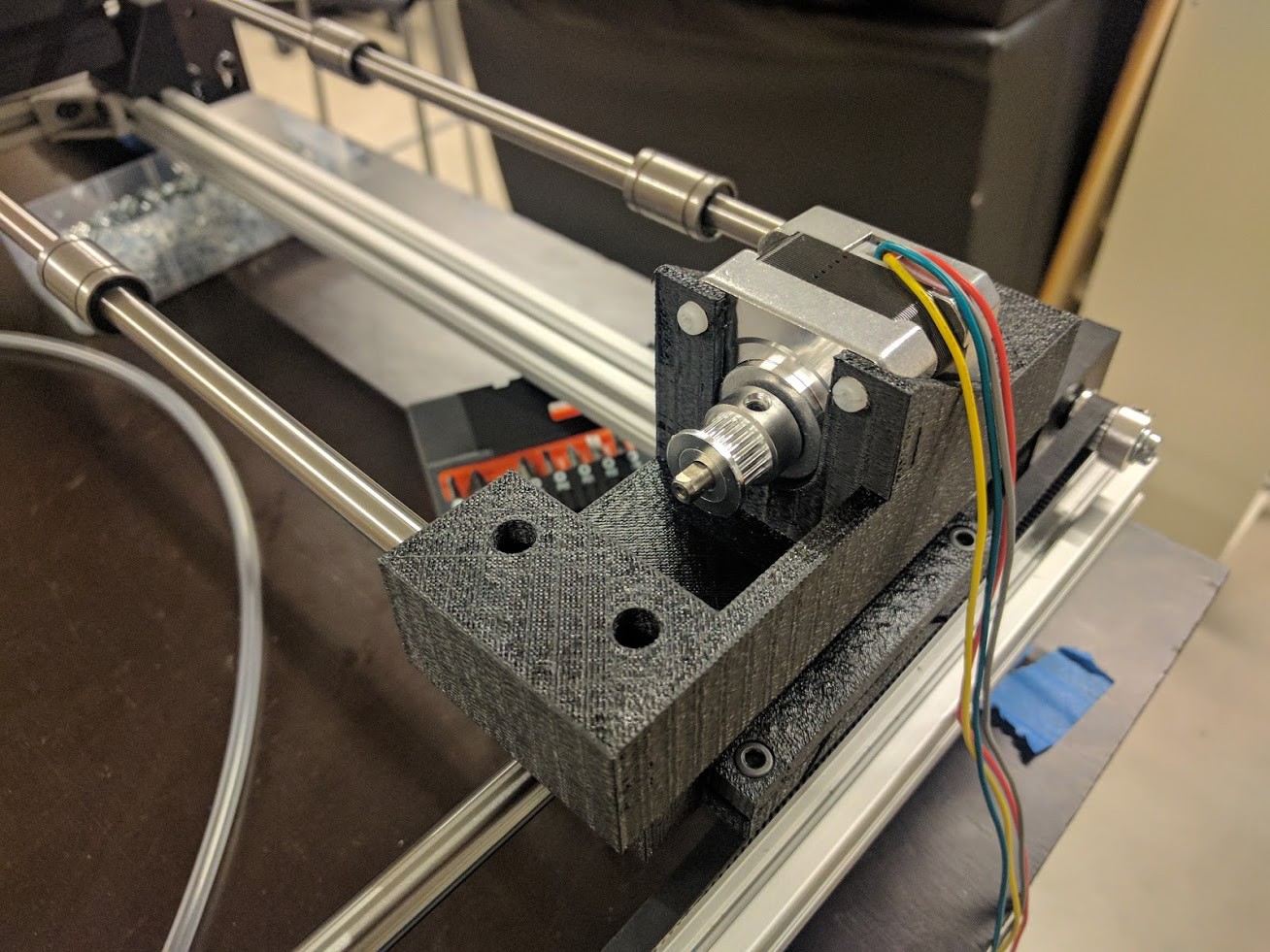

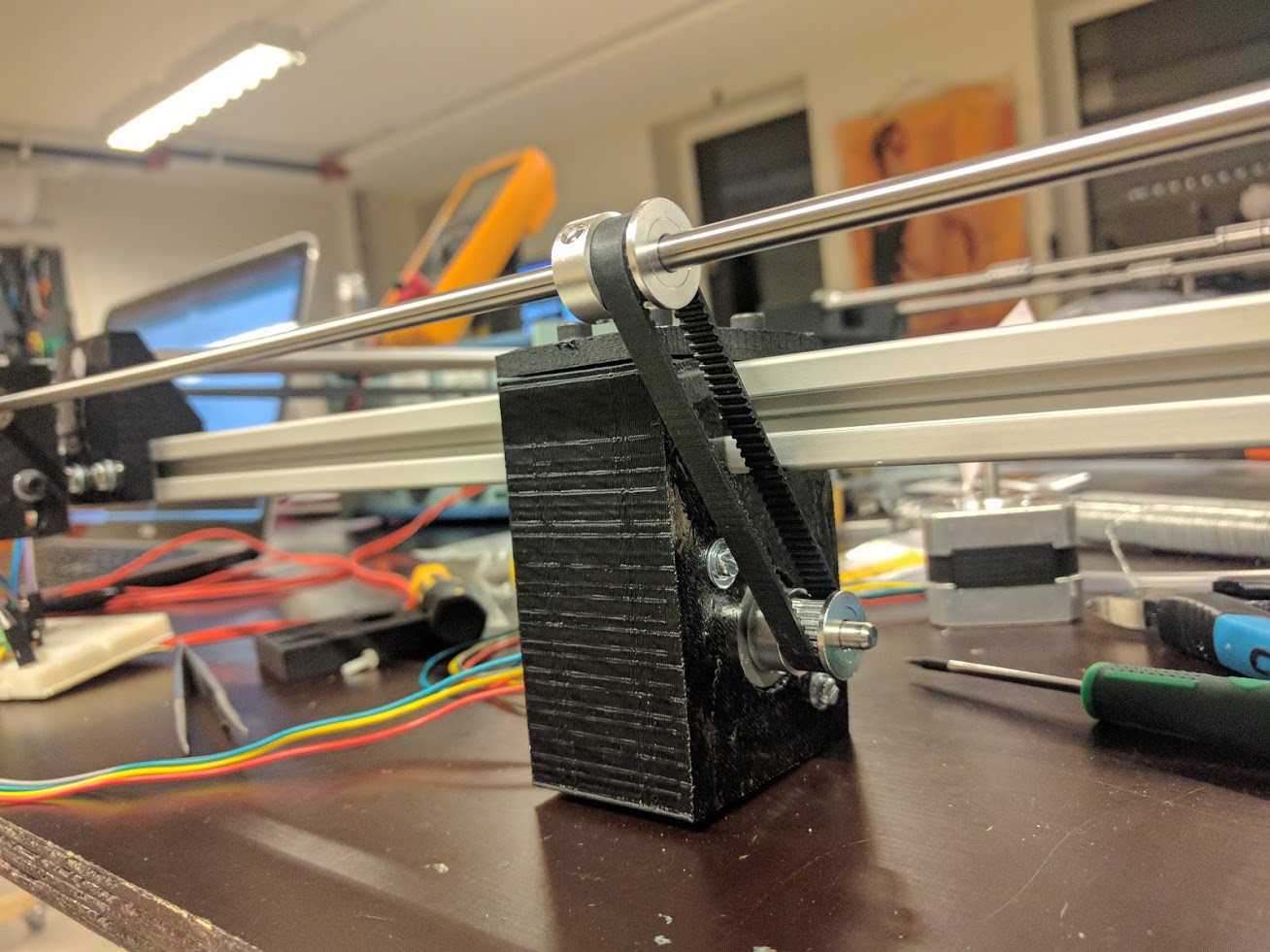

The main body itself will be built of 20mm aluminium profiles and I intend to design 3d print as many components as possible for the rest of the stuff, I've used Autodesk Fusion360 a fair bit the last year so this is good training when it comes to 3d modeling if nothing else.

I will start with the mechanical aspects of the project and once I have that sorted I'll start looking into the electronics and whether I'll use a premade PCB or design my own.

I tend to dive into projects letting them unfold as I work on them so no fancy pants plans of what I'll do ahead of time.

Nikolai Ovesen

Nikolai Ovesen

Oscar S.

Oscar S.

Alex Gontmakher

Alex Gontmakher

Sebastian Lenartowicz

Sebastian Lenartowicz

Myles Eftos

Myles Eftos