Components to develop

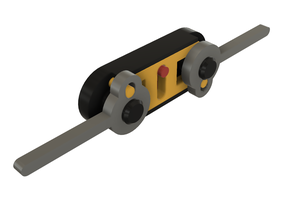

Fixtures compatible with a standard kitchen digital scale as the force measurement instrument

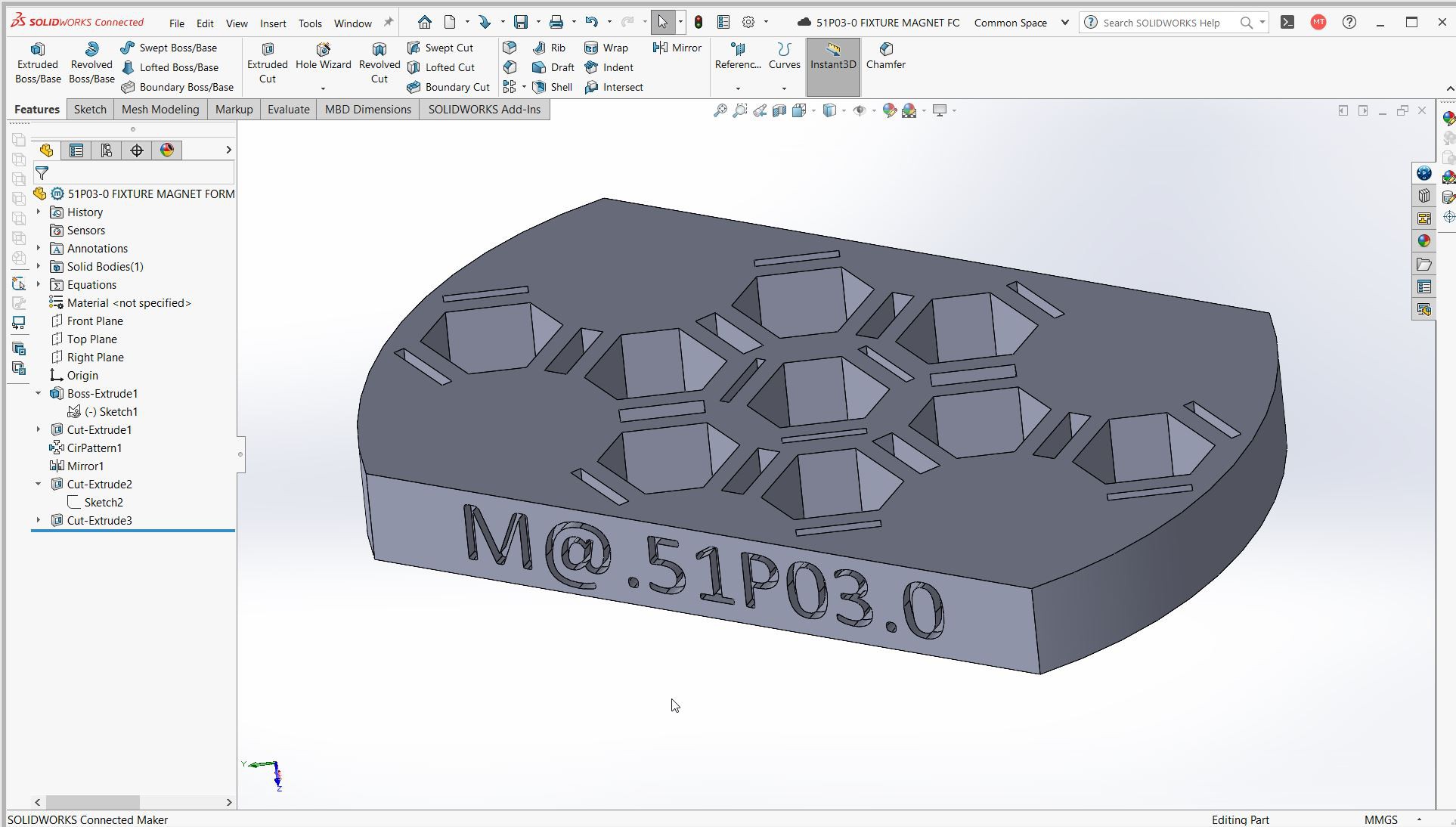

Test fixture to measure tensile force to separate magnets and magnet+steel target

Test fixture to measure shear force to separate magnets and magnet+steel target

Test fixture to measure peel force to separate magnets and magnet+steel target

Test method for each force measurement - tensile, shear and peel

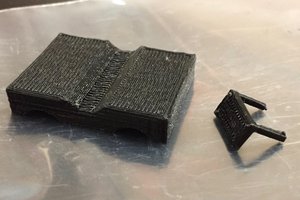

Spacing shims in increments of typical 3D printing layer thicknesses

Requirements

Test fixtures shall be operable using one hand (to allow for picture or note-taking).

Shall measure force up to 5kgf.

Shall accommodate up to 7 magnets or targets per side.

Shall allow for testing any number of magnets or targets up to the maximum of 7.

Shall control the face-to-face gap between mating magnets.

Shall identify the tolerance of magnet position for a given set of fixtures.

Shall accommodate magnets in any orientation (all N up, alternating N and S up)

Desirements

Could accommodate more than one size magnet or target in a single printed fixture. Only a single size would be tested simultaneously.

Matt

Matt

Patrick

Patrick

Andrea Piccinno

Andrea Piccinno

Greg Zumwalt

Greg Zumwalt