Thanks to PCBWay for providing PCB Manufacturing services at no cost for this project!

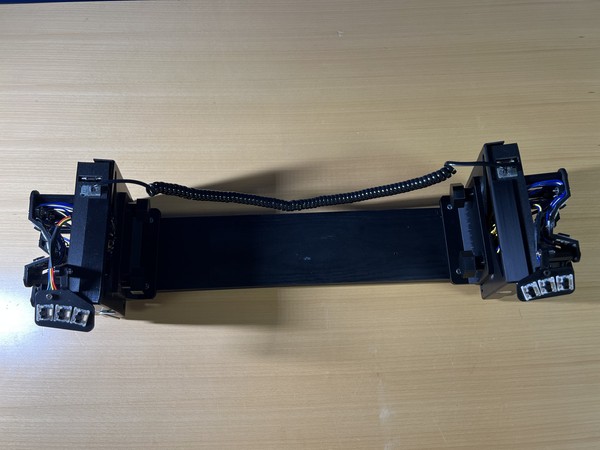

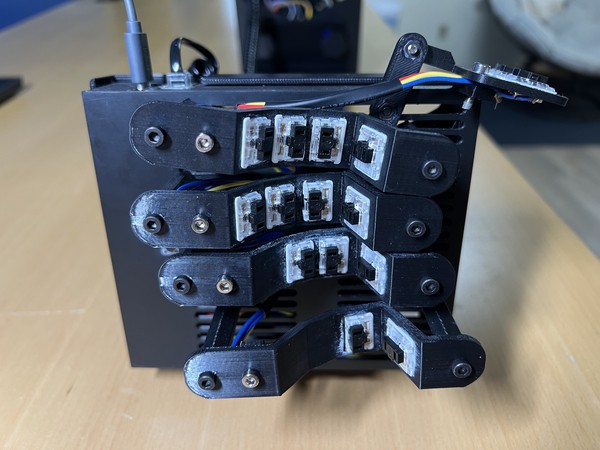

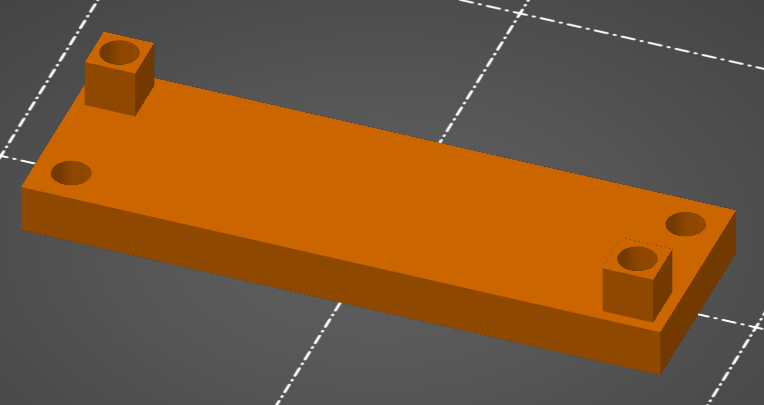

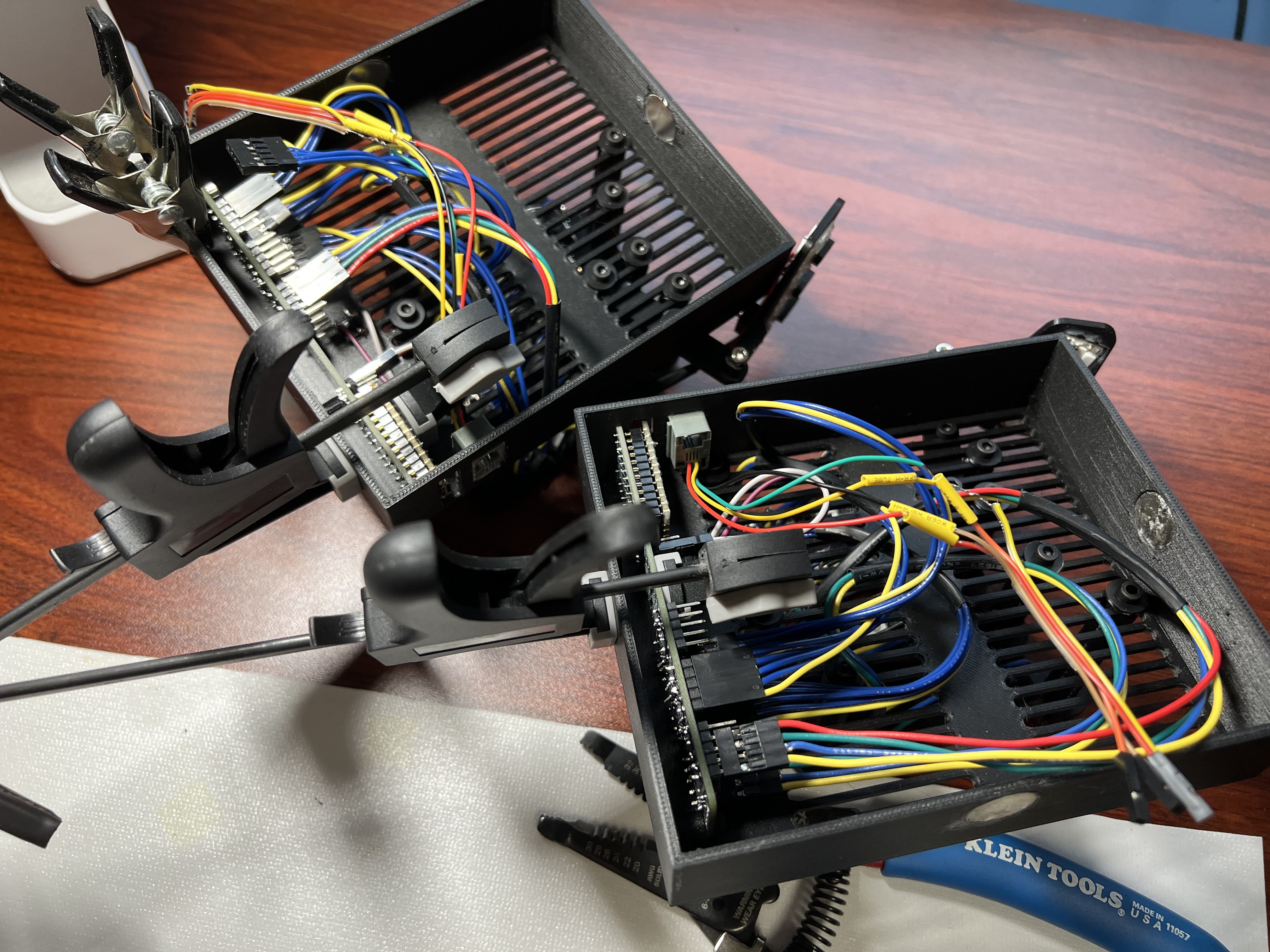

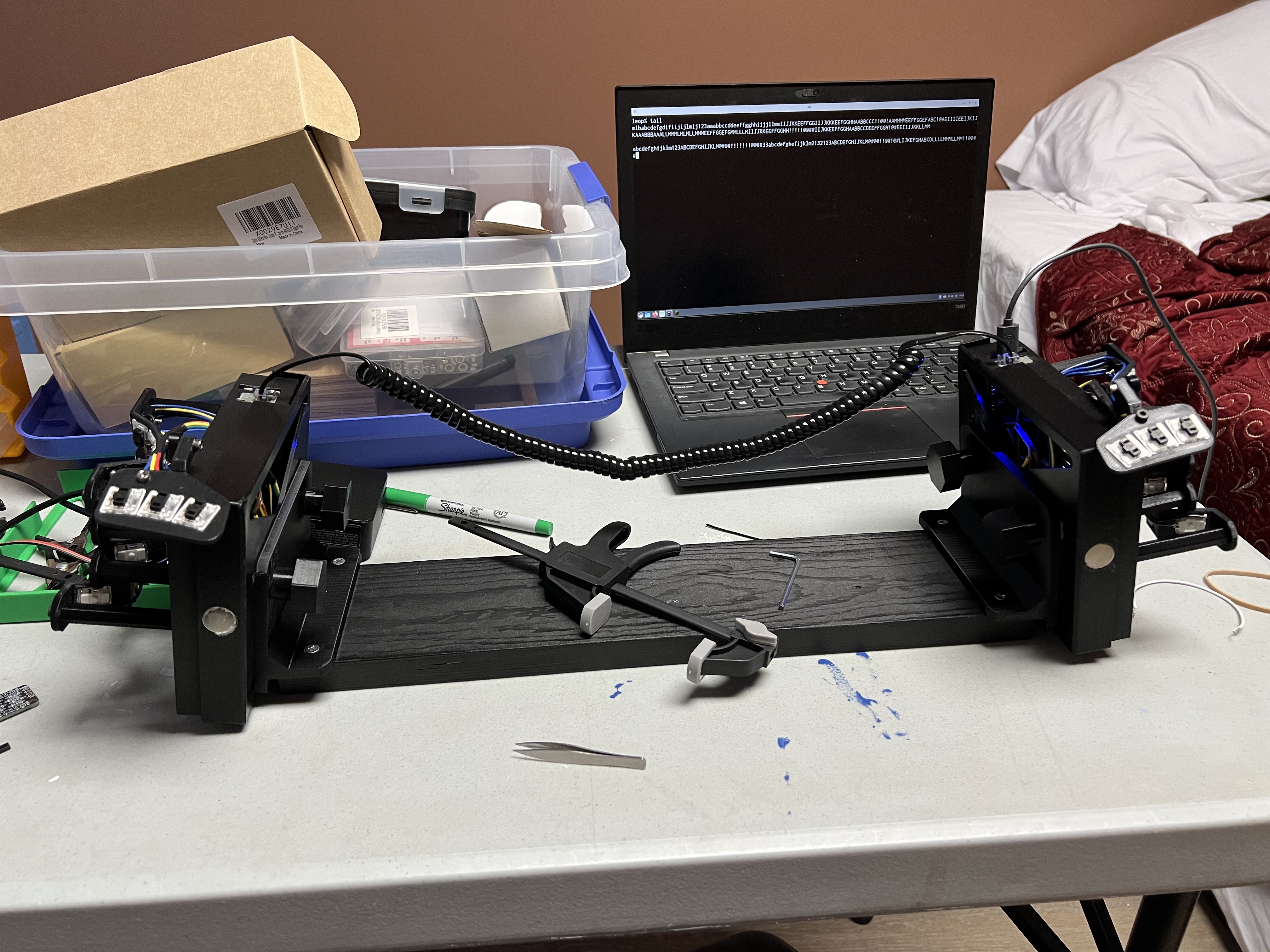

Squeezebox Keyboard v2209

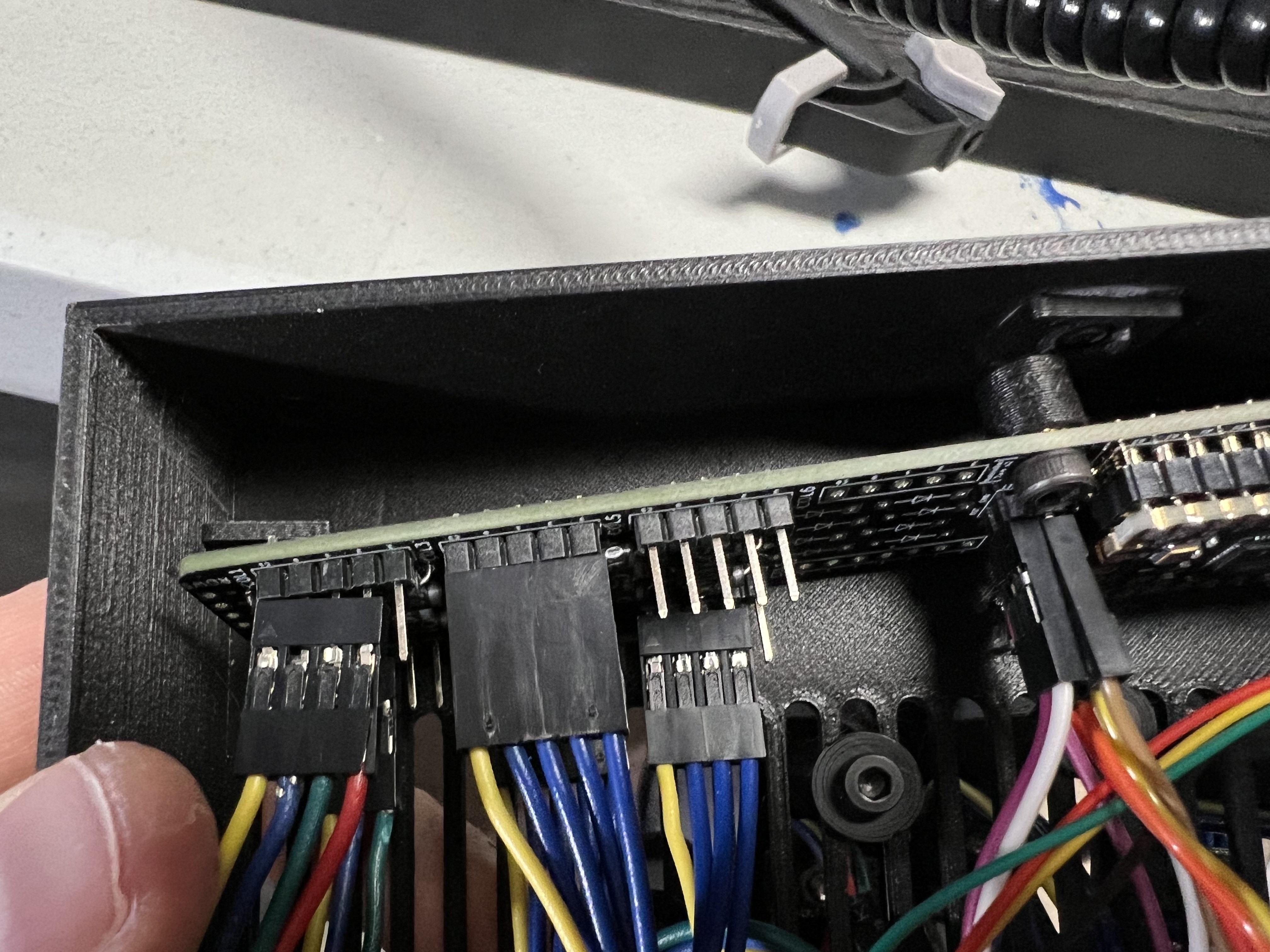

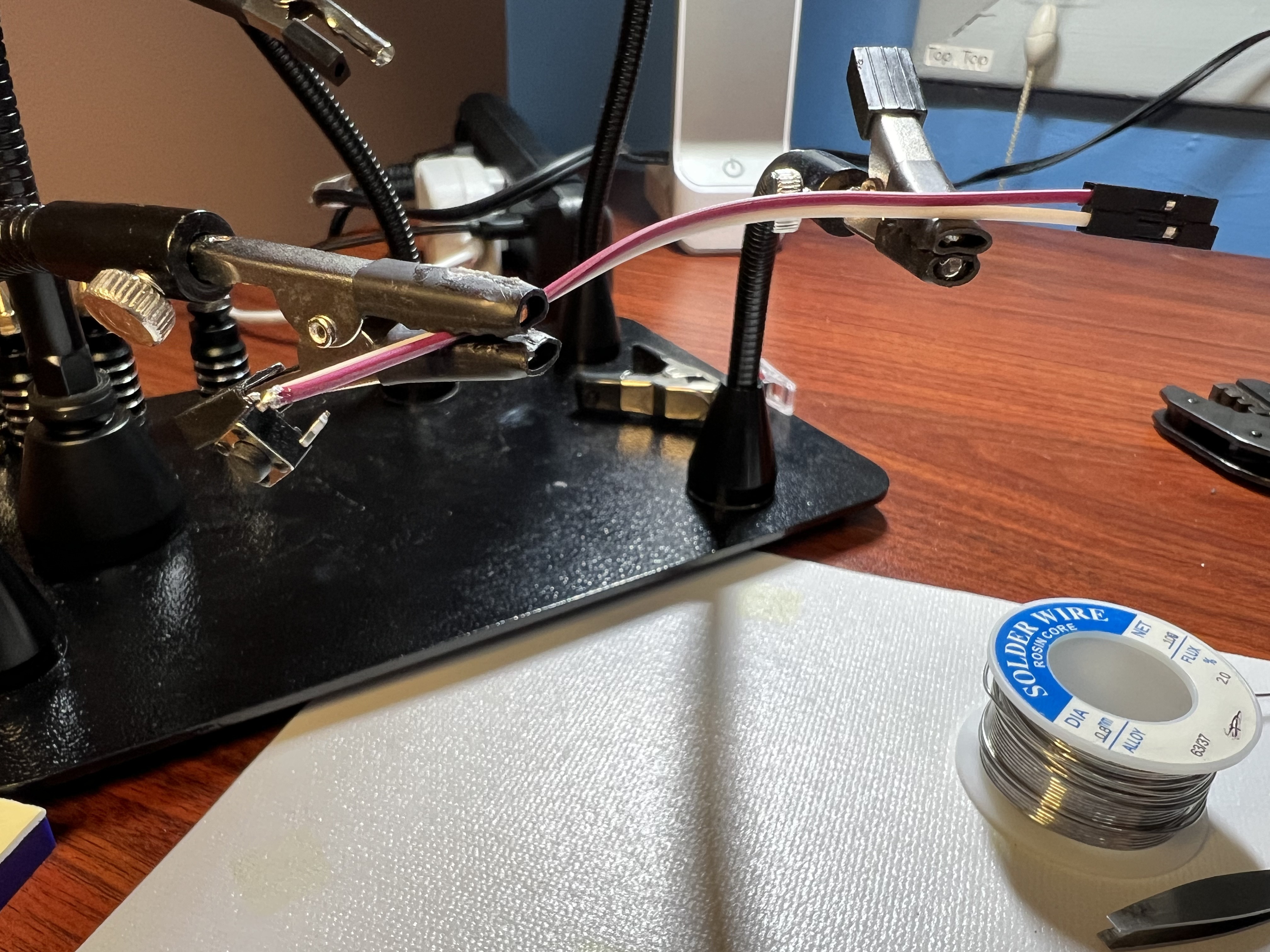

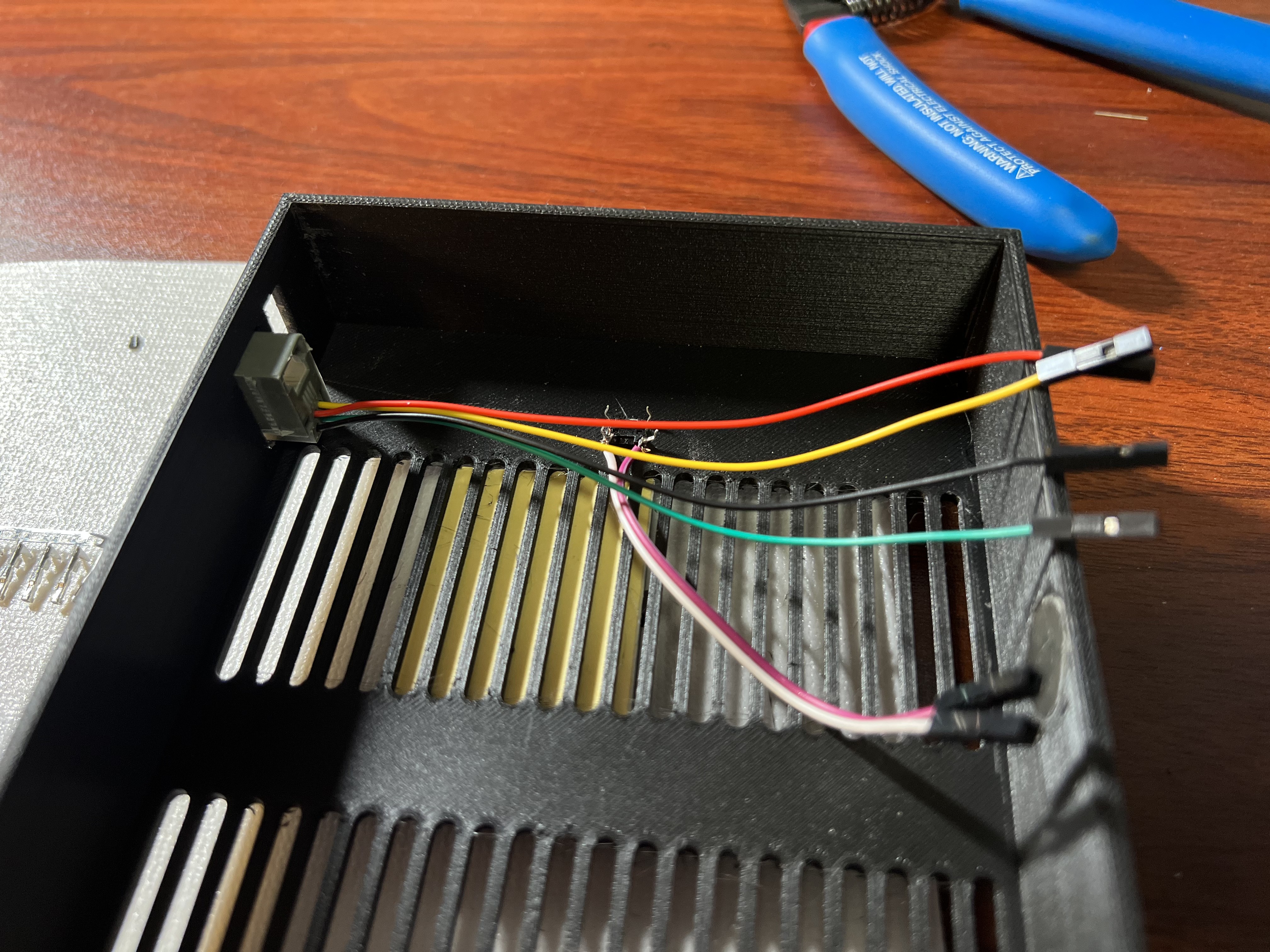

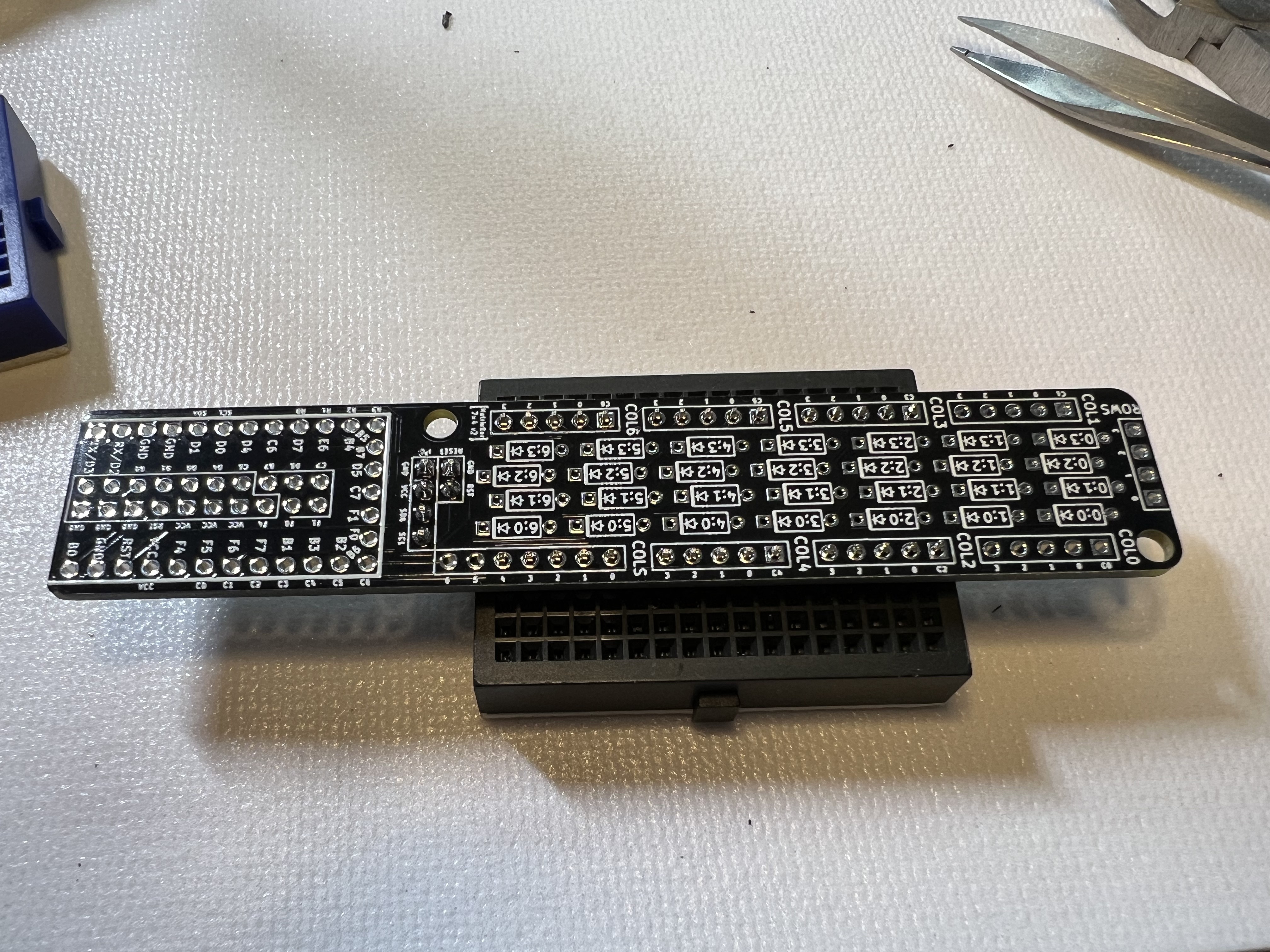

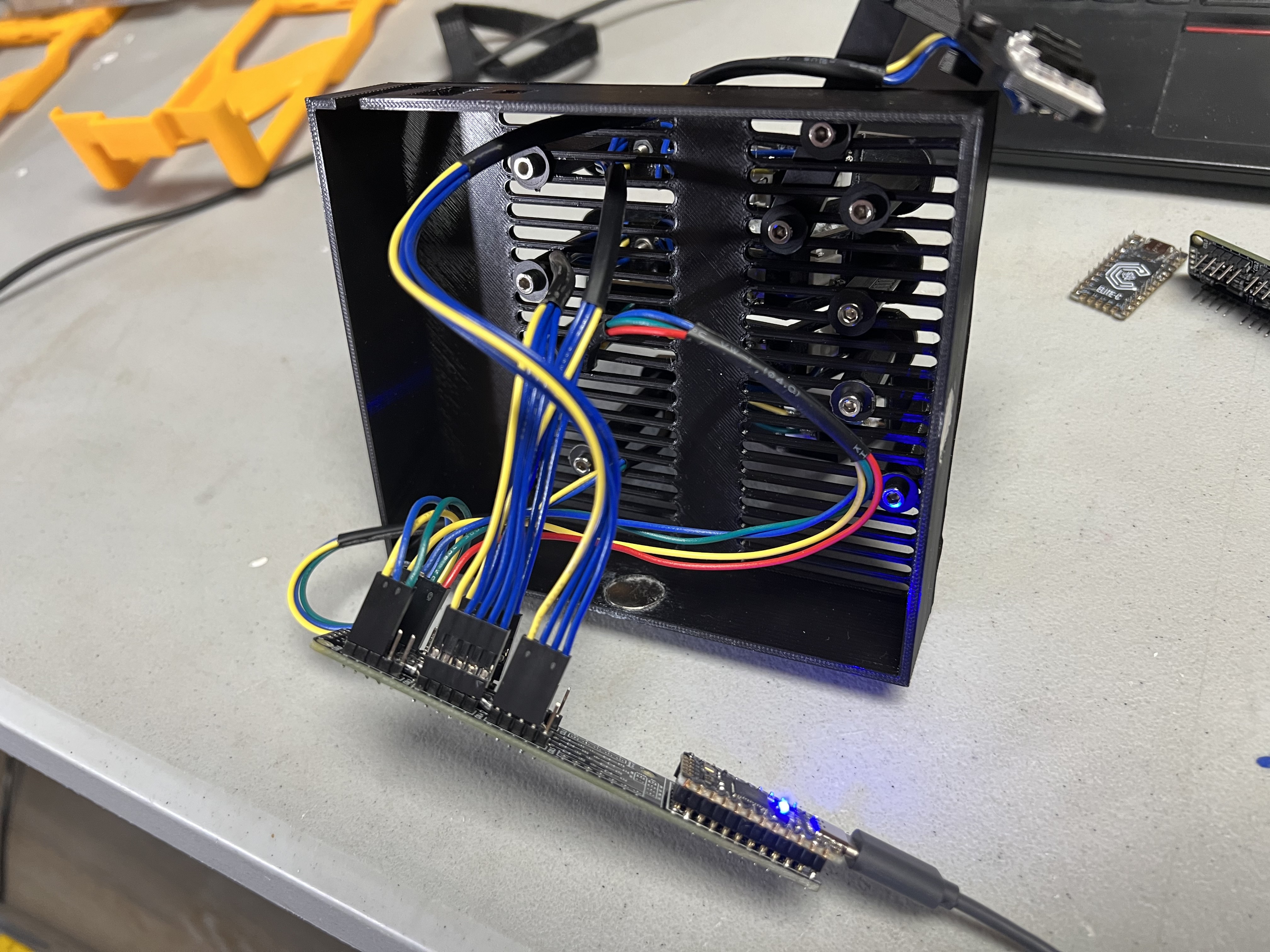

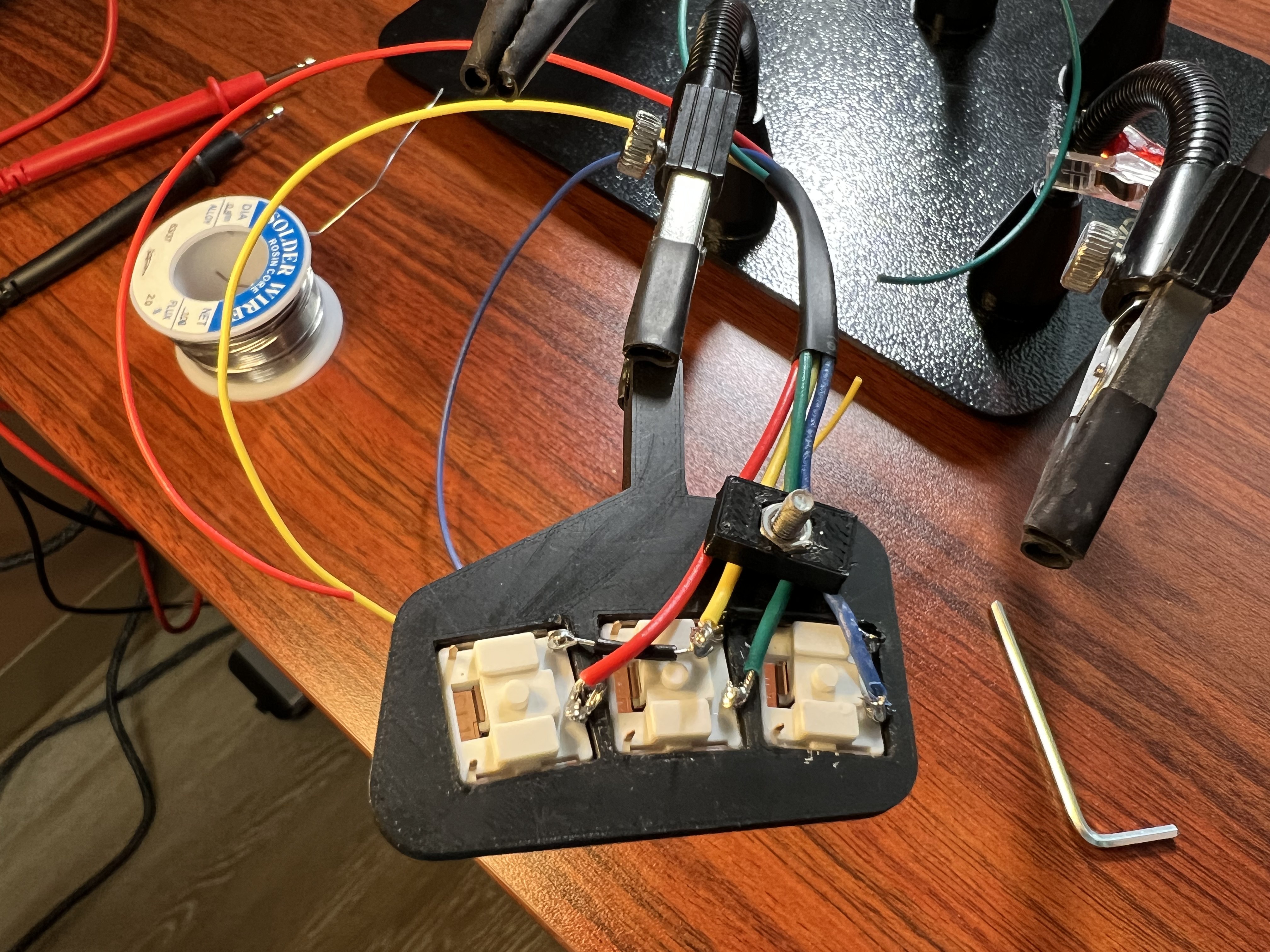

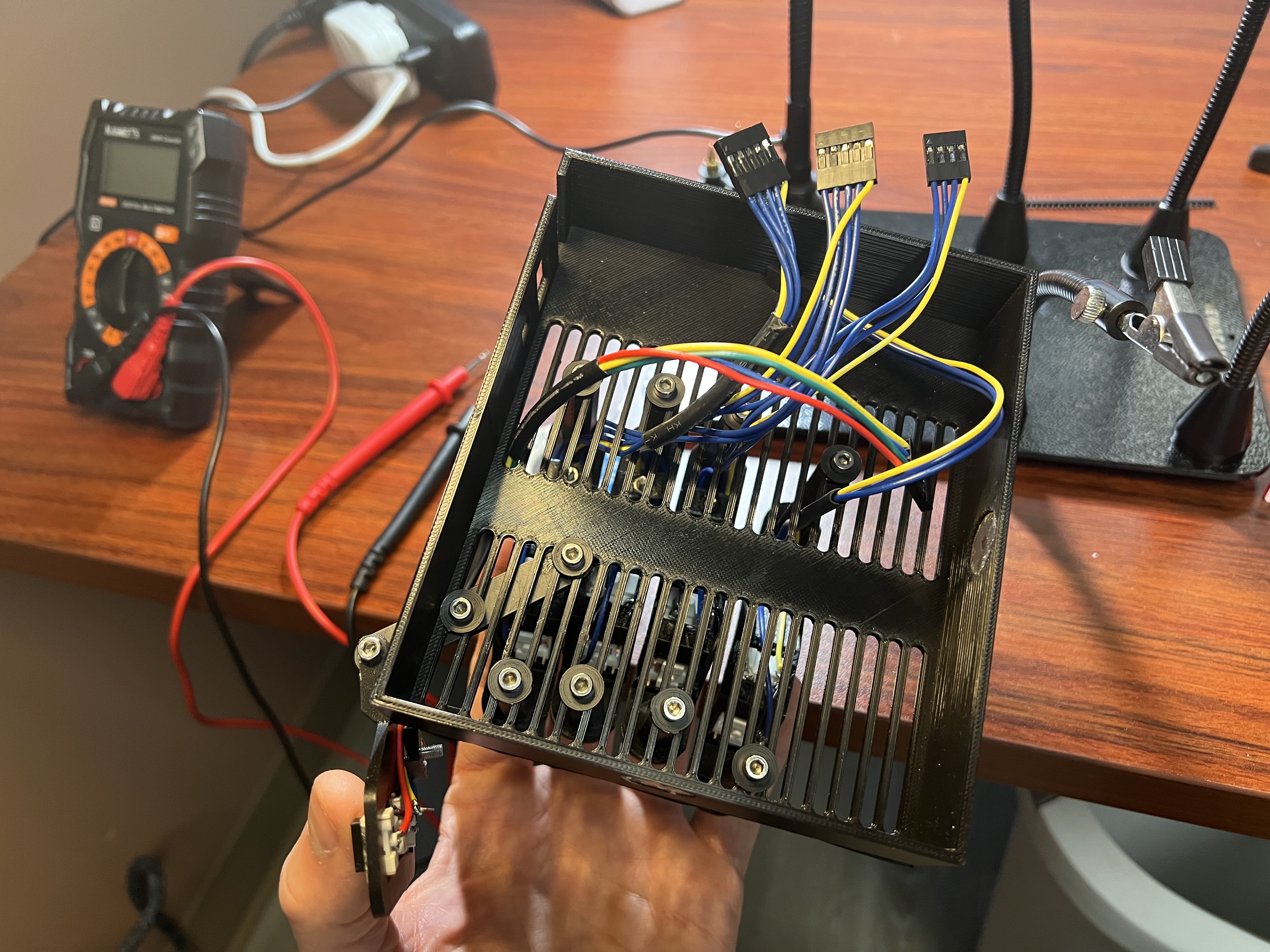

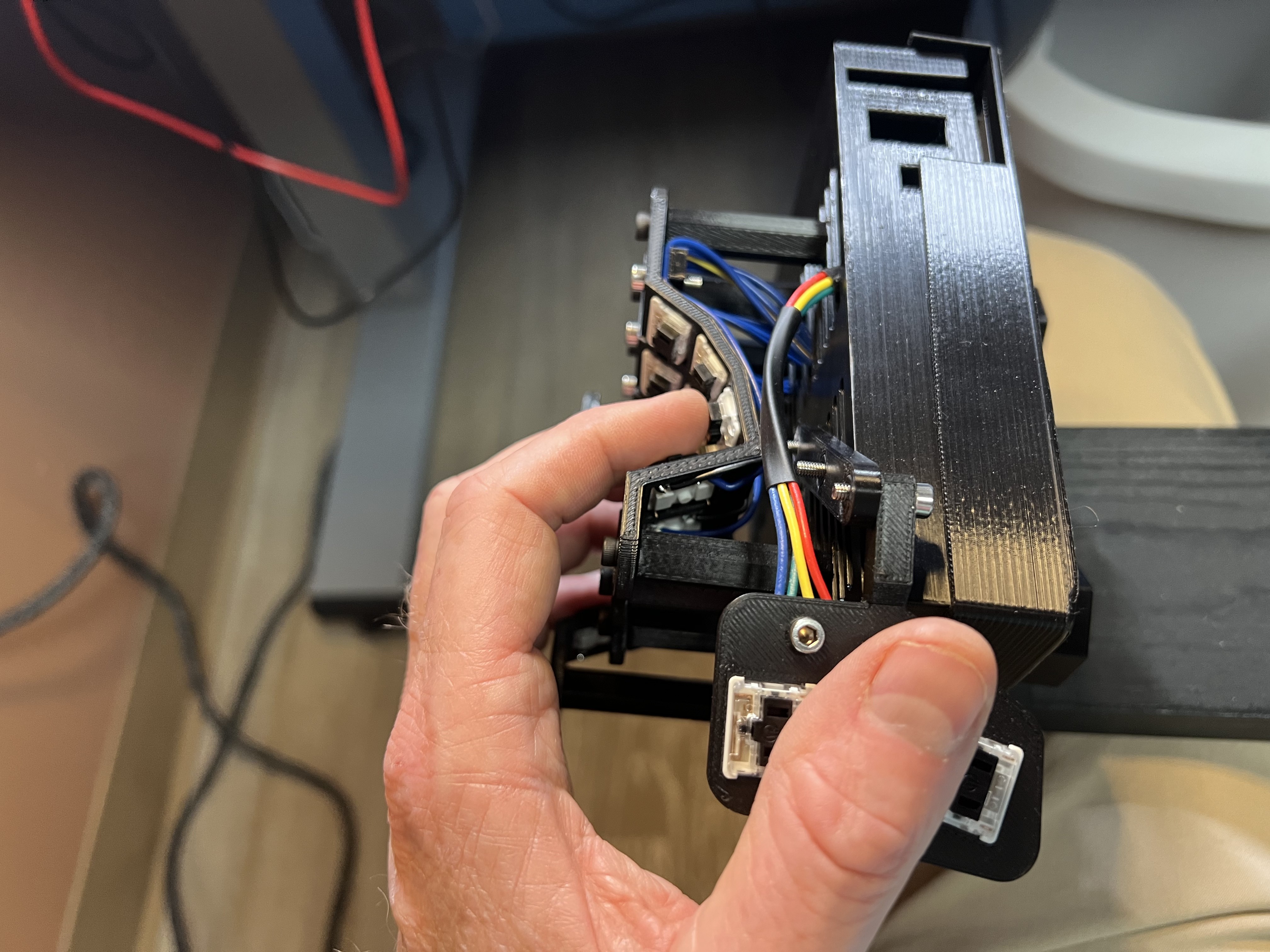

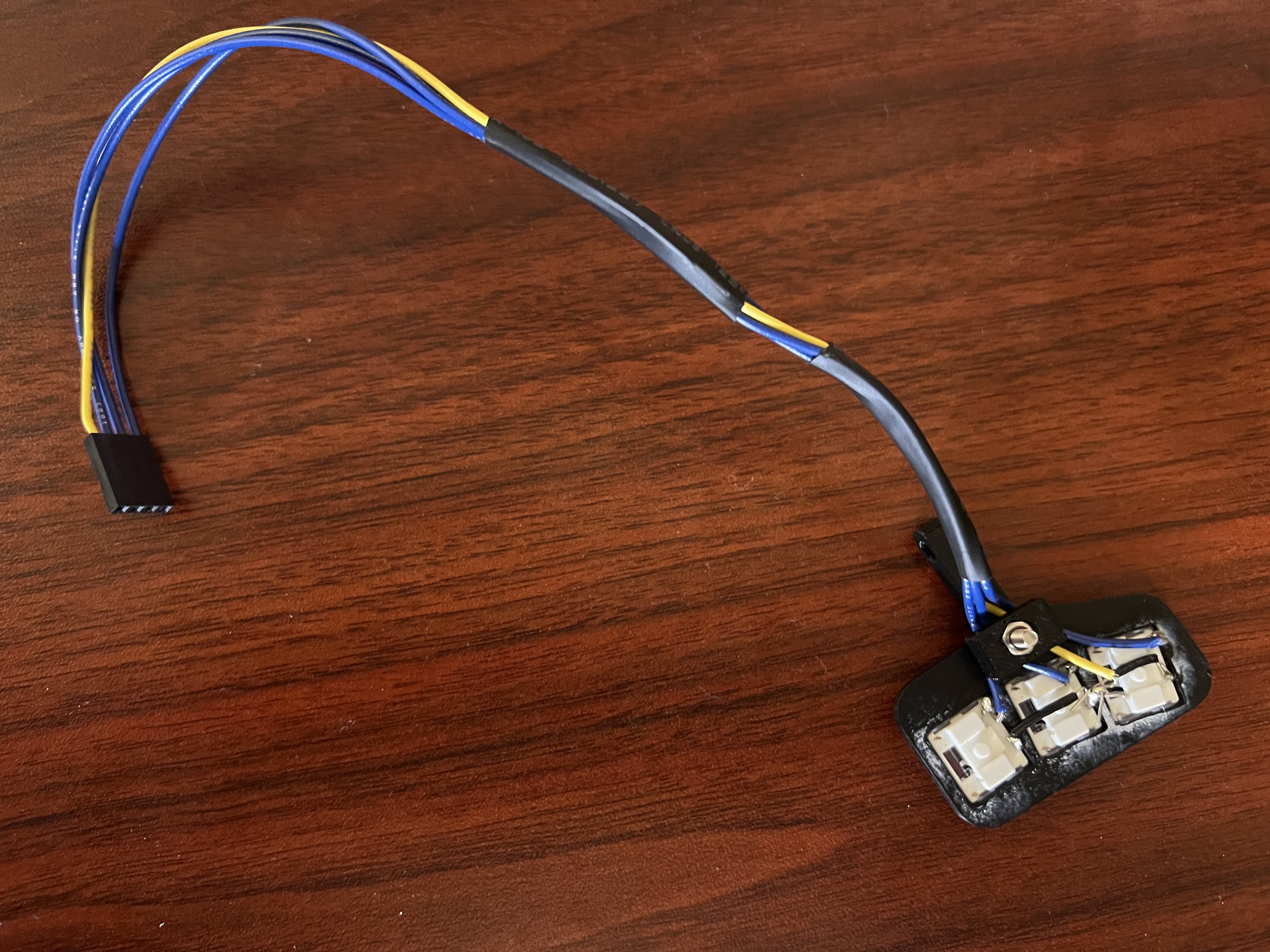

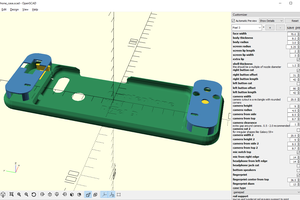

Iterating on the Squeezebox scooped split ergonomic keyboard. This version features a PCB instead of full hand wiring and choc mini switches

Peter Lyons

Peter Lyons

Jarrett

Jarrett

NFM

NFM

Maave

Maave