Even though there are various nutrition and management factors affecting egg production and quality, the feeding schedule proportional to cage density affects egg production considerably since hens can stop laying eggs intrinsically when they notice a sporadic feeding schedule or paltry feed. Hence, applying a regular and nutritional feeding regimen helps hens lay eggs abundantly.

Furthermore, as the hen’s age increases, the weight of the produced egg usually increases, and the weekly produced egg number decreases. Although each hen has an inveterate laying time, the weekly produced egg number denotes the overall health condition of the hens in the coop. Therefore, tracking unhatched eggs and logging the daily produced egg number assist farmers in determining a potential contagious poultry disease or malnutrition.

However, these processes can be compelling and arduous for small businesses in the poultry industry or people raising domesticated birds in their houses or backyards to produce eggs for profit. Since I am also raising quails as pets on my balcony, I am well aware of the struggles with tracking the poultry feeder status and the produced egg number daily. Hence, I decided to create this budget-friendly and accessible device to track the poultry feeder status and the produced egg number automatically with object detection.

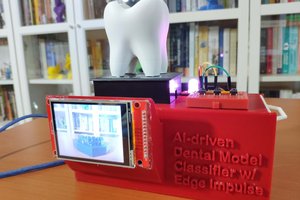

To recognize eggs in the coop (cage) and track the poultry feeder status accurately, I needed to collect data from the coop in order to train my object detection model with notable validity. Since OpenMV Cam H7 is a considerably small high-performance microcontroller board designed for machine vision applications in the real world, I decided to utilize OpenMV Cam H7 in this project. Also, I could easily capture images of my coop and store them on an SD card since OpenMV Cam H7 has a built-in MicroSD card module. Then, I employed a color TFT screen (ST7735) to display a real-time video stream and the prediction (detection) results.

After completing my data set by taking pictures of the produced eggs and the poultry feeder in my quail coop, I built my object detection model with Edge Impulse to recognize (count) the produced eggs and track the poultry feeder status: OK or EMPTY. I utilized Edge Impulse FOMO (Faster Objects, More Objects) algorithm to train my model, which is a novel machine learning algorithm that brings object detection to highly constrained devices. Since Edge Impulse is nearly compatible with all microcontrollers and development boards, I had not encountered any issues while uploading and running my model on OpenMV Cam H7. As labels, I appended two main classes to the file names while capturing and storing pictures:

- Egg

- Feeder

After training and testing my object detection (FOMO) model, I deployed and uploaded the model on OpenMV Cam H7 as an OpenMV firmware. Therefore, the device is capable of counting the produced eggs and tracking the poultry feeder status by running the model independently without any additional procedures.

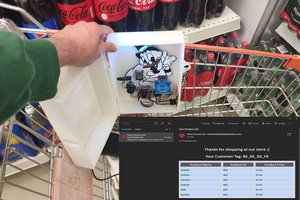

Since I decided to log the detection results on a MySQL database and inform the user of the detection results over WhatsApp, I set an Apache HTTP Server on LattePanda 3 Delta 864 and developed a PHP web application from scratch. To be able to send WhatsApp messages to a verified phone number, I utilized Twilio's API for WhatsApp.

Since OpenMV Cam H7 does not provide Wi-Fi or BLE connectivity, I employed WizFi360-EVB-Pico to communicate with OpenMV Cam H7 and transfer the detection results to the web application. WizFi360-EVB-Pico is a budget-friendly development board based on Raspberry Pi RP2040 and enables Wi-Fi connectivity with the integrated WizFi360 Wi-Fi module. Also, I connected a DHT22 temperature and humidity sensor to WizFi360-EVB-Pico to log and get informed of the current weather condition of my coop (cage) in addition to the detection results.

Lastly, to make the device as robust, sturdy, and compact as possible while experimenting...

Read more » kutluhan_aktar

kutluhan_aktar