BIG GOAL !

What if us, makers could access a true tool to electrify the world ? For Automation, mobility, power, energy storage and much more ?

What if we could gather as a whole to stand for a more sustainable electric based future built with a generic open source framework ?

We’ve seen the emergence of fast prototyping solutions for coding, we lived the booming of 3D printed, we will build the era of DIY power together !

Wait what ? Is that even possible ? Well, lets try and see what happens !

We all know the cheap power blocks we can buy for cheap from overseas, and we also know that they often do not suffice. We also know the myriad of offers of highly specialized IC’s available out there to build up a power supply from scratch with a whole bunch of knowledge involved.

But what if we could use a micro-controller to do it instead ? This way we could do software defined switched mode power supplies !

That's easier said than done because the power stage is a heck of a nightmare to design, while most readily available dev’ kits are not really good for generating super fast PWMs and sensing super fast signals while keeping their head above the water with the time critical fast calculation and the communication with the outer world.

It gets even more complicated when the power demand increases. Making beefy converters is even harder!

Going Modular !

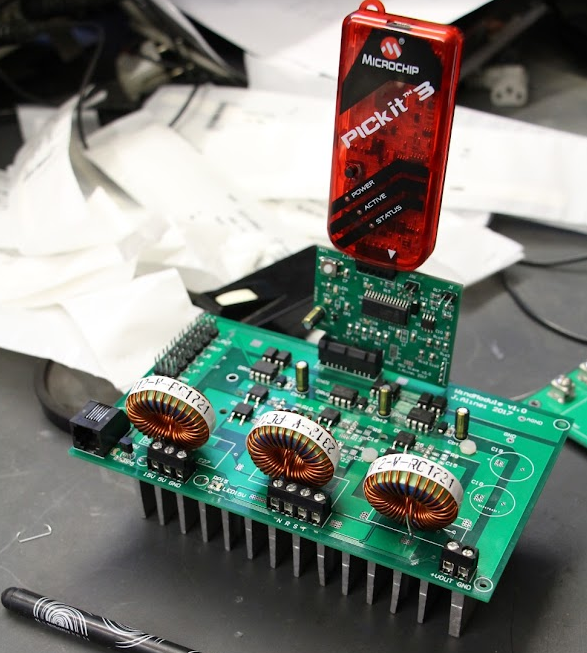

So why not assembling a bunch of smaller (and easier to make) converters together to deliver a higher power?

Going Versatile !

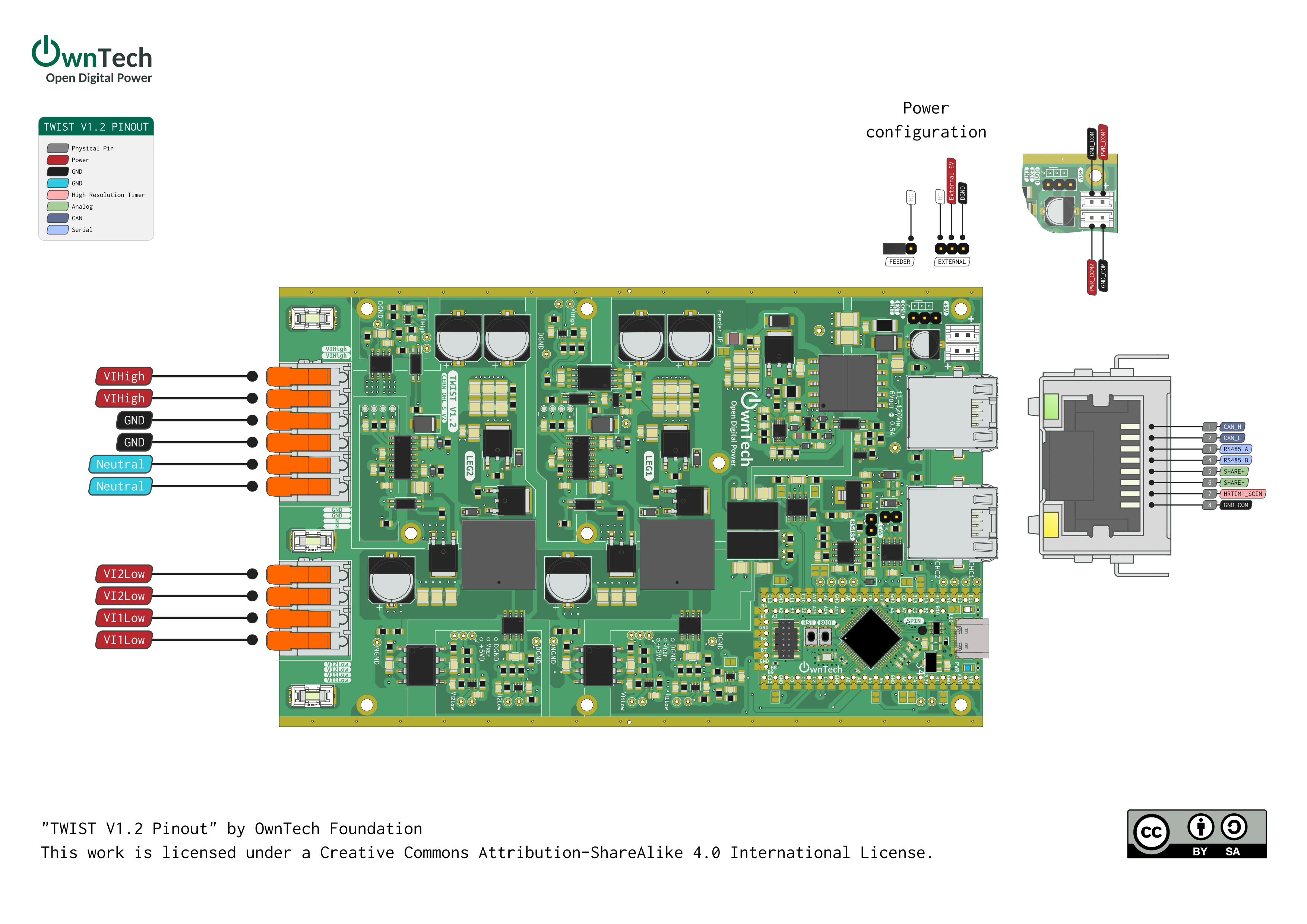

Last, most power blocks cover a specific case, which makes it less attractive as a community project. We dreamed of a generic power stage that could address most use cases out there, to make it less prone to get dumped in the dusty corner of the workshop when it is not relevant any more and also to be able to foster a community of users and makers around it.

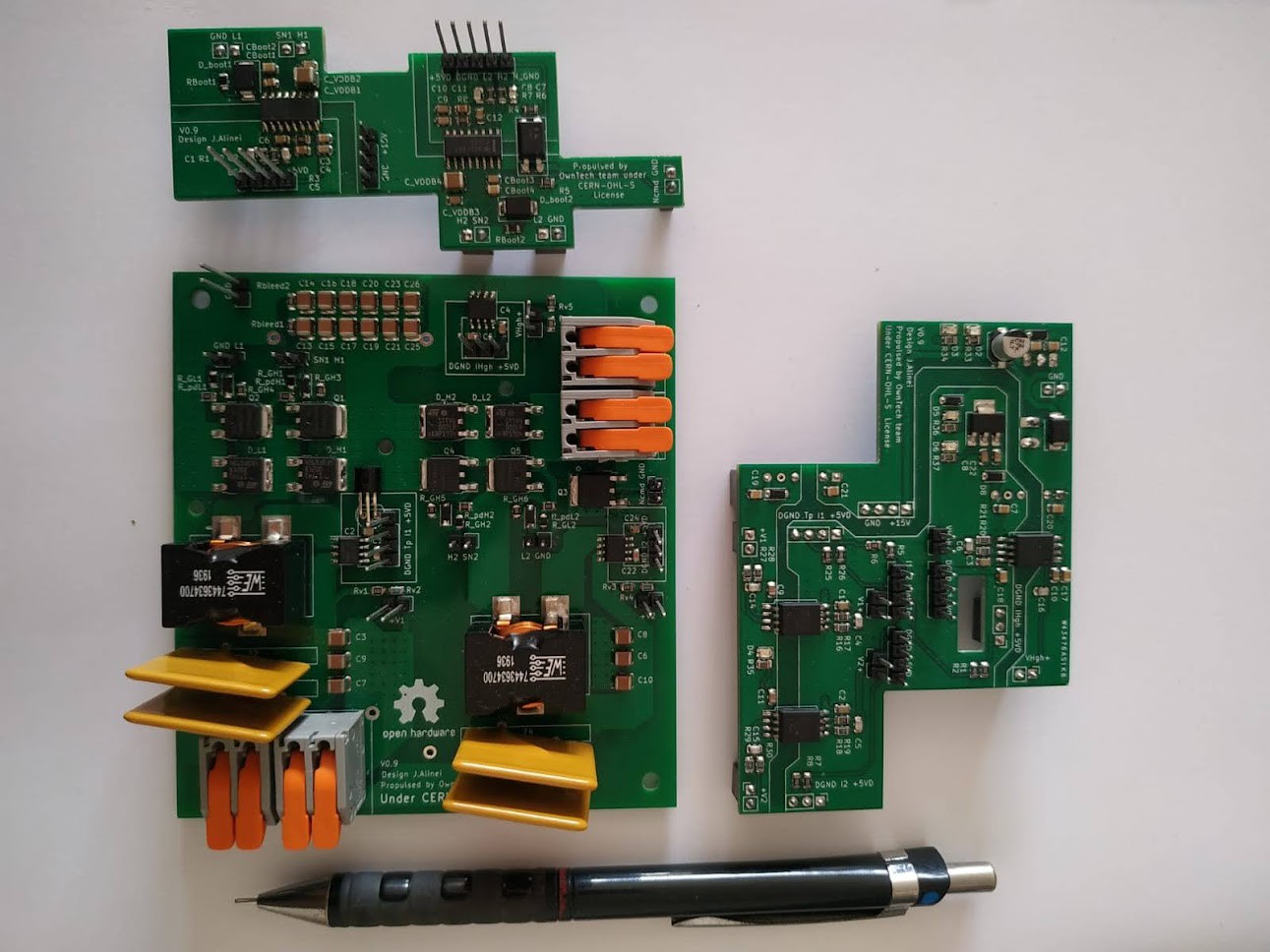

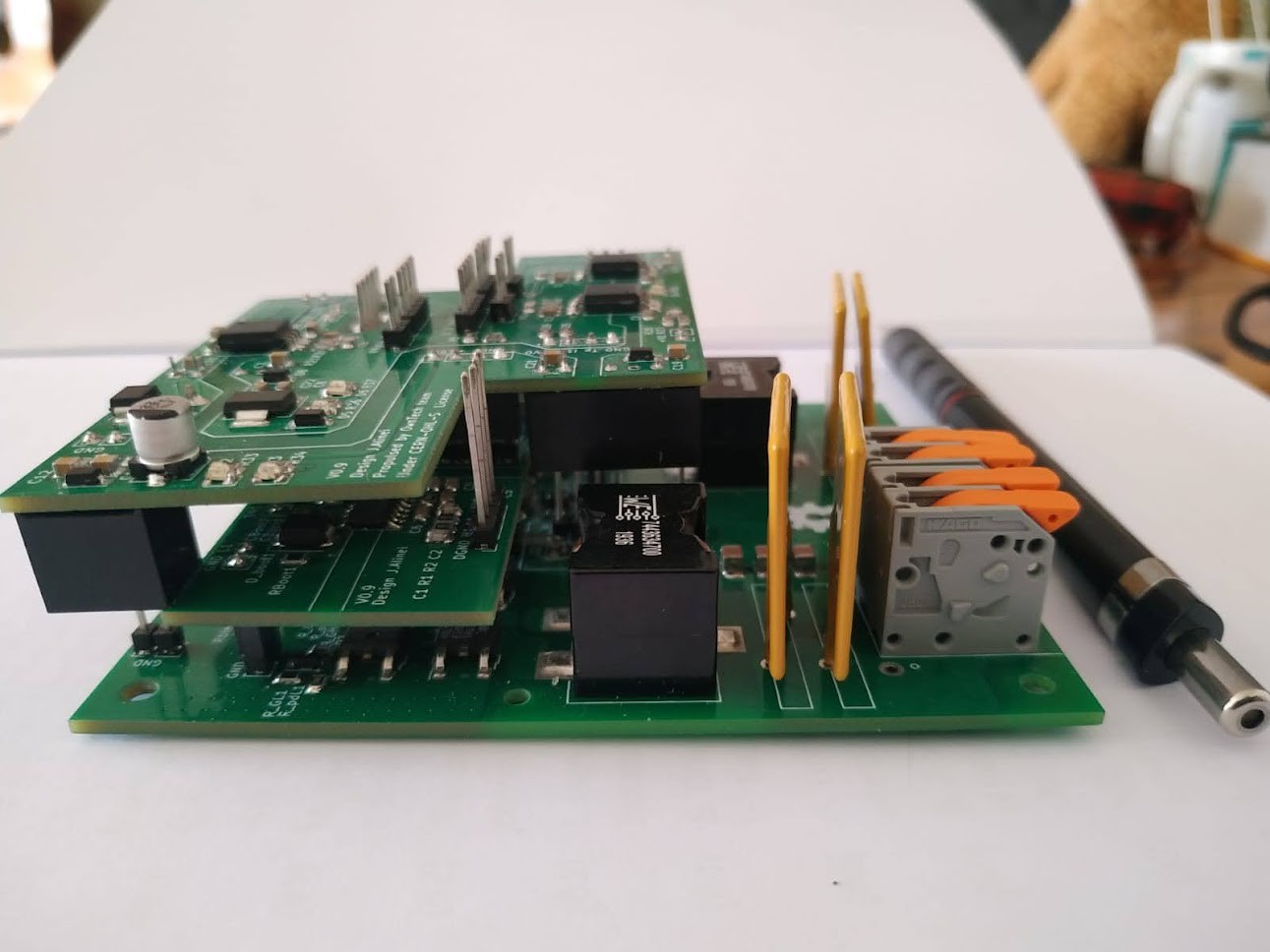

With this BIG GOAL in mind, we decided that we were eager to give this wild card challenge a shot. We’ve came with a dual solution:

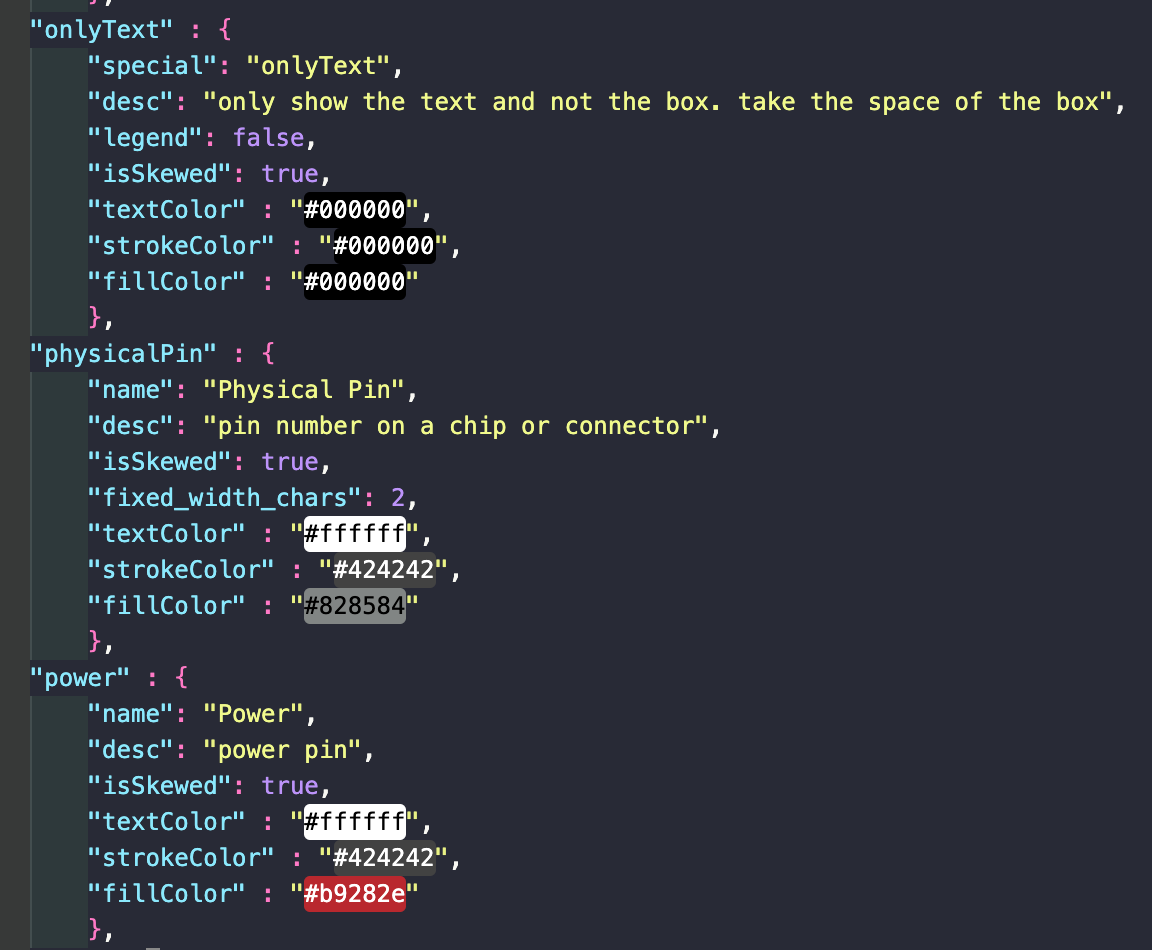

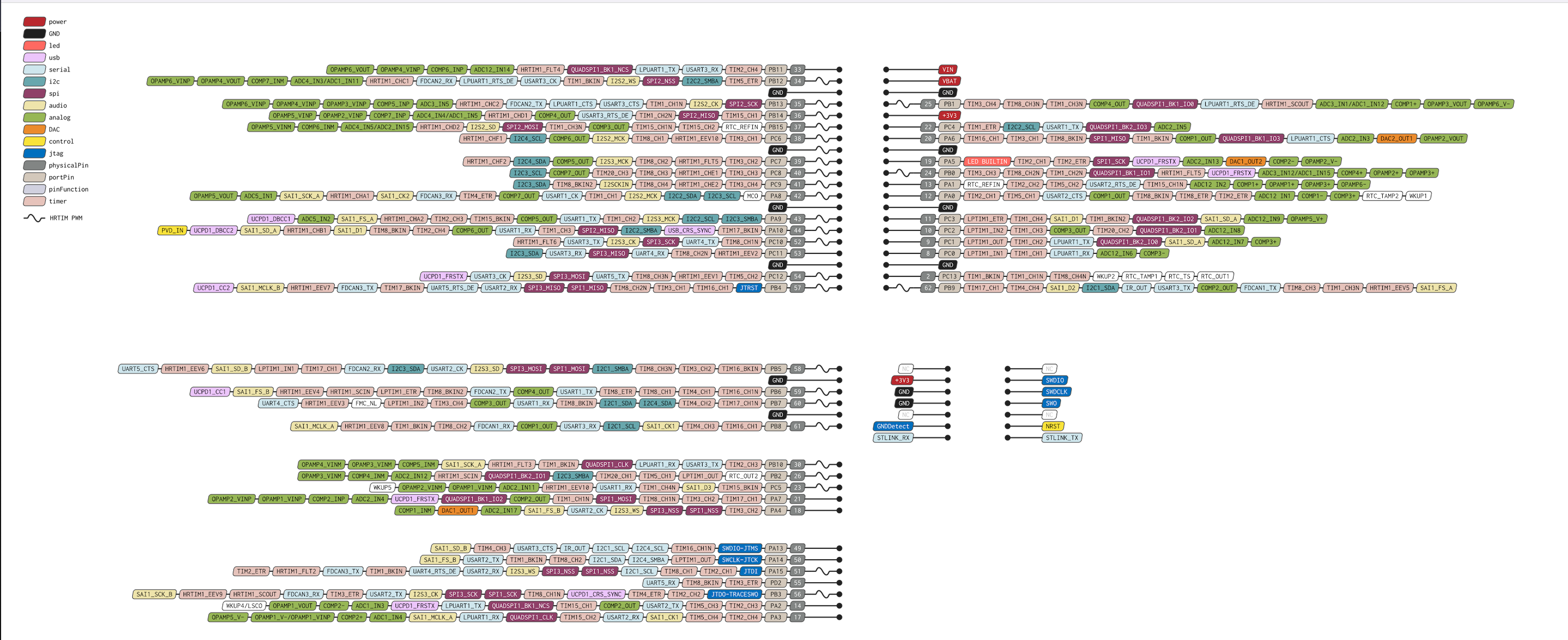

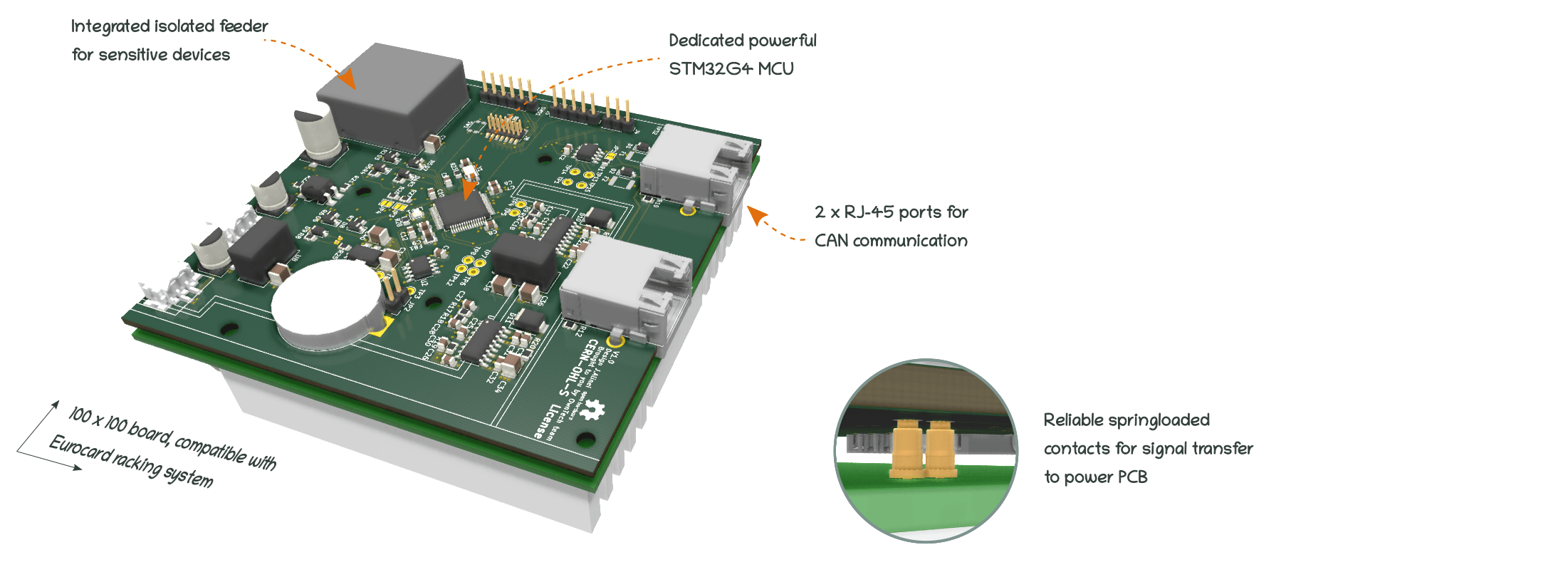

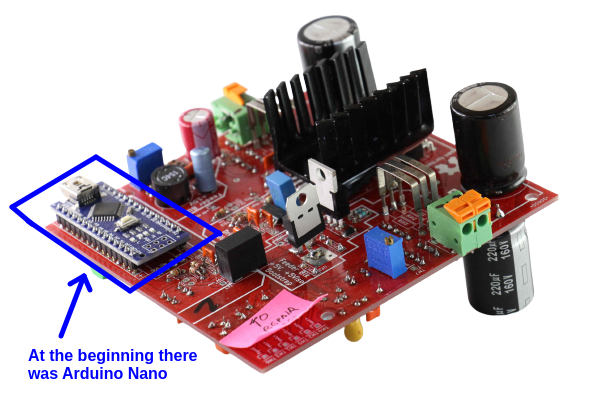

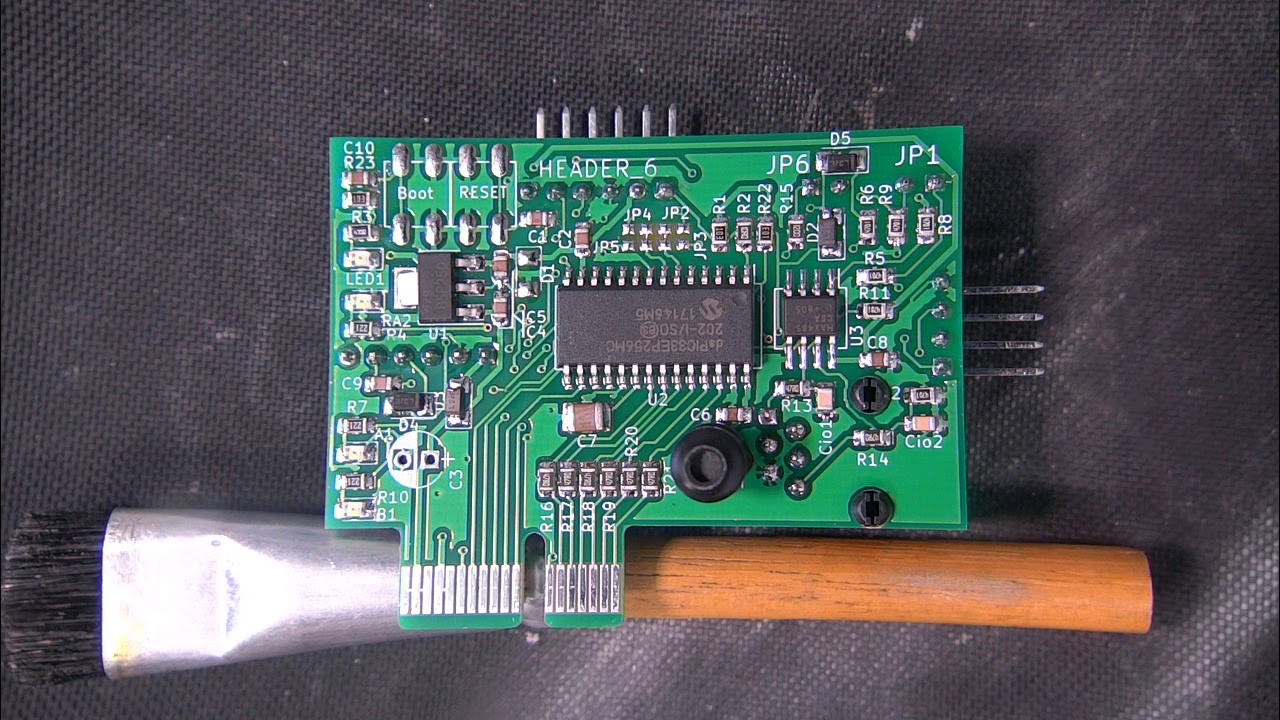

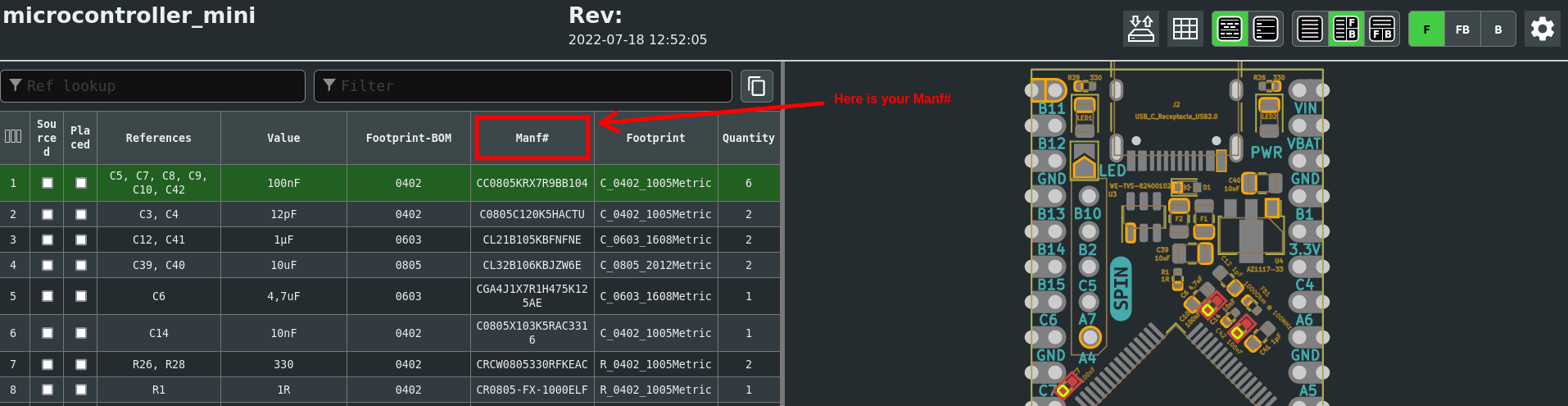

- On one hand we’ve developed a “small brain”, a specialized microcontroller dev' board with a special embedded software framework for power applications

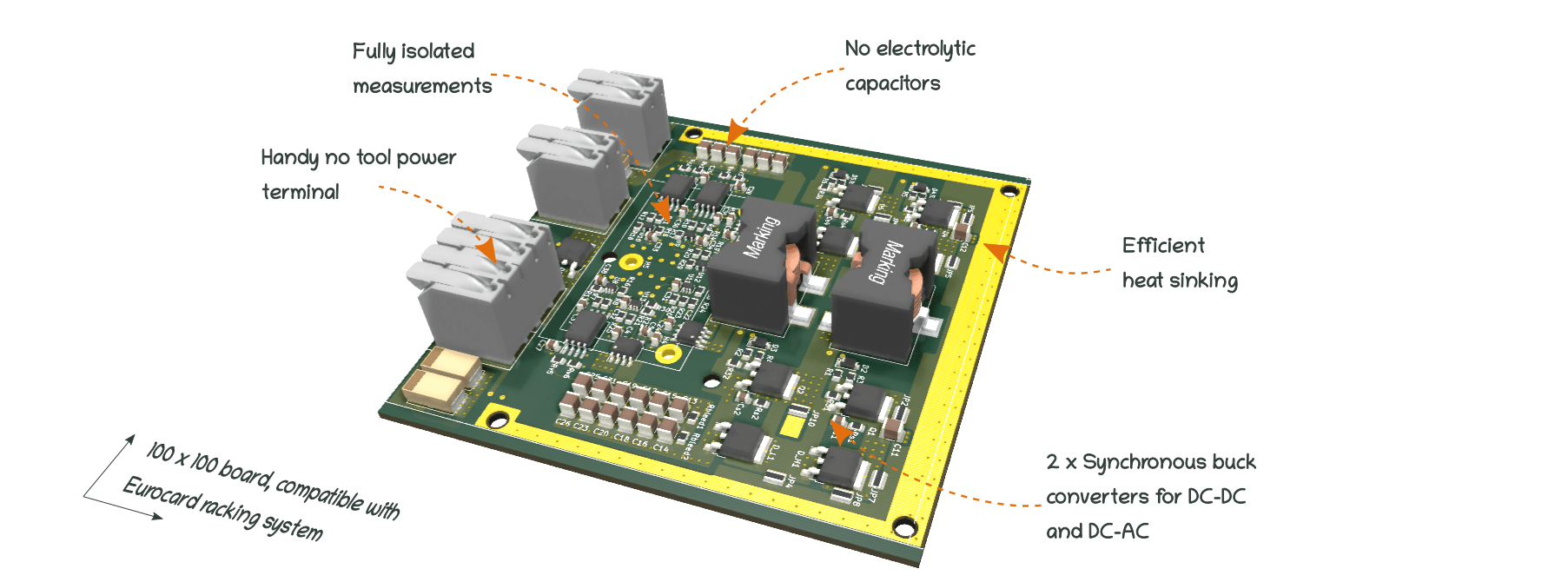

- On the second hand, we’ve developed a “muscle board” that is a generic power stage that can cover plenty of use cases.

And we are about to unveil it ***epic drum sound***

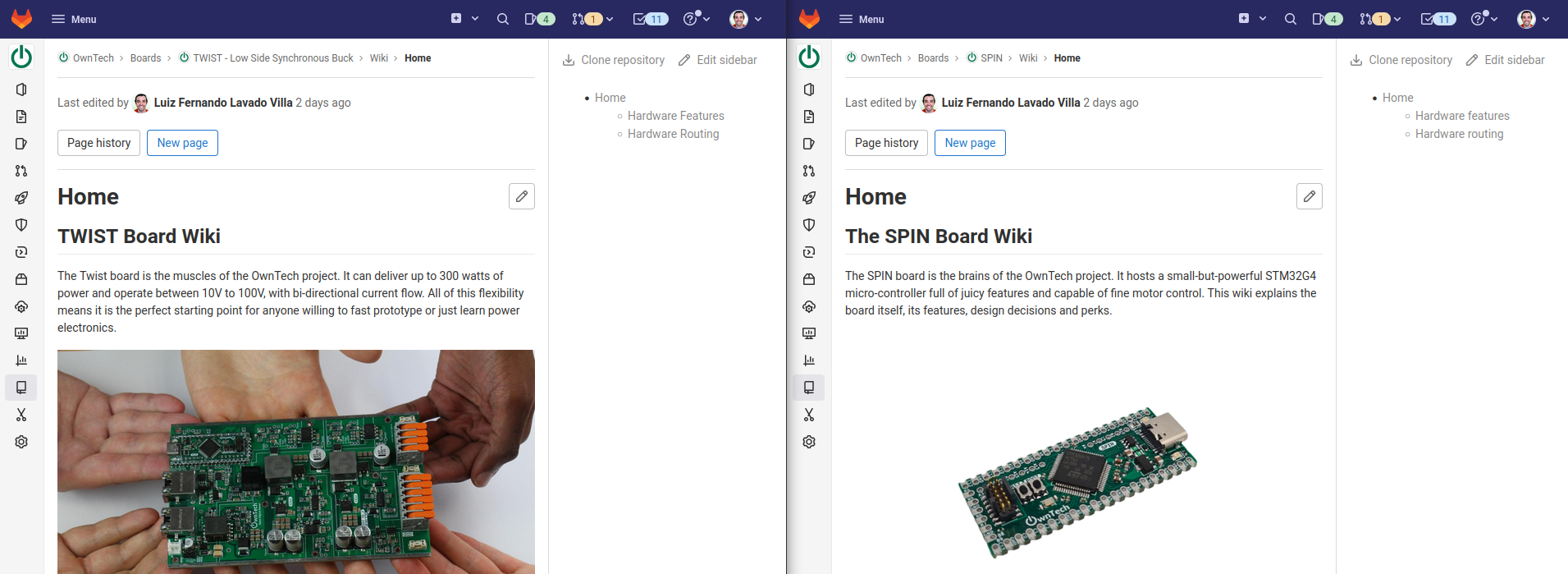

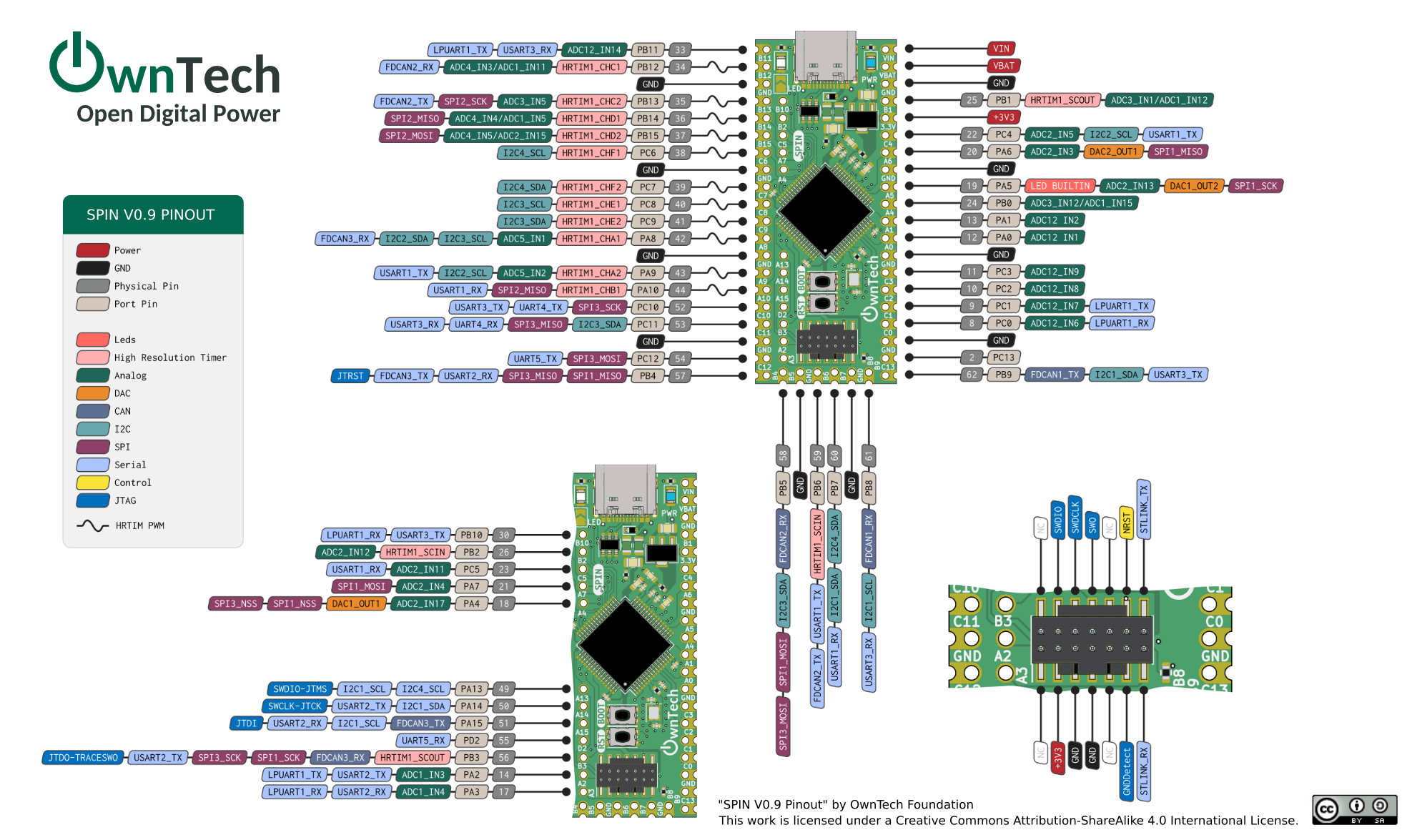

SPIN

Let me introduce you SPIN, the first dev’ board specialized for handling power applications.

Spin do you want to say a word about yourself ?

Hello World !

Brilliant! It even speaks !

And here are its perks :

- It is thought to be the power brain of your future project

- It has a small form factor and you can solder it onboard of your very own power stage

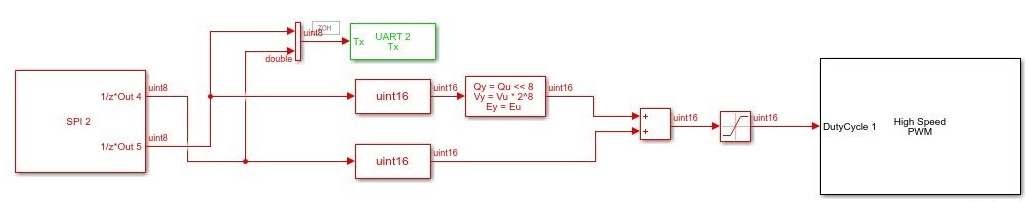

- It has a super special framework that we’ve developed to get on track super fast and deploy super precise PWMs, super fast measurements all of that with simple ergonomics

From the software perspective, we have written the OwnTech Power API code. Based on the ZephyrOS, an open-source RTOS driven by the Linux Foundation, our code is a driver to low-level peripherals that are essential to the control of power hardware. By using this approach, our code is vendor agnostic, which opens the door to supporting more vendors and aggregating a larger community on the long term. In practice, this means improved software resilience. Our code is fully compatible with PlatformIO and can be easily downloaded, compiled and flashed using VSCode.

To be able to talk and monitor SPIN, we have written a data-monitoring tool called OwnPlot. This serial based data acquisition system allows the users to monitor any data being sent via any serial port to a target computer. This platform-agnostic application allows data logging and will, on the longer term, provide a GUI...

Read more » Jean Alinei

Jean Alinei

andriy.malyshenko

andriy.malyshenko

Markus Loeffler

Markus Loeffler

oneohm

oneohm

Savo

Savo