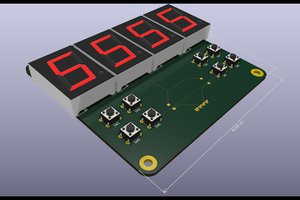

The build process for this project consists of the following components:

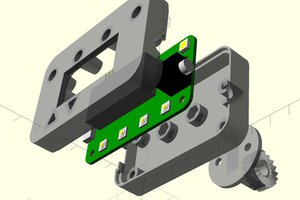

- Create a 3D printable individual 7 segment display

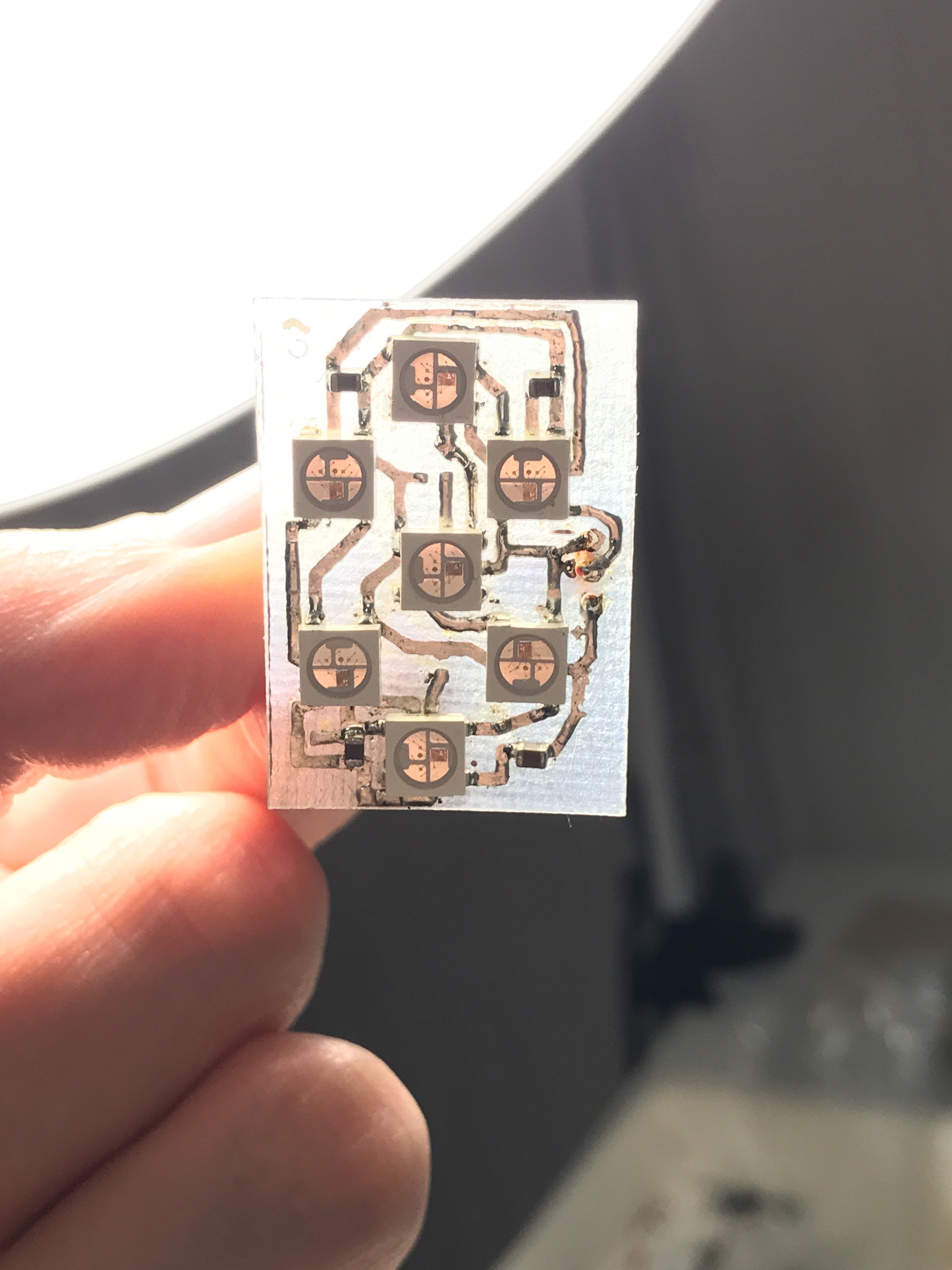

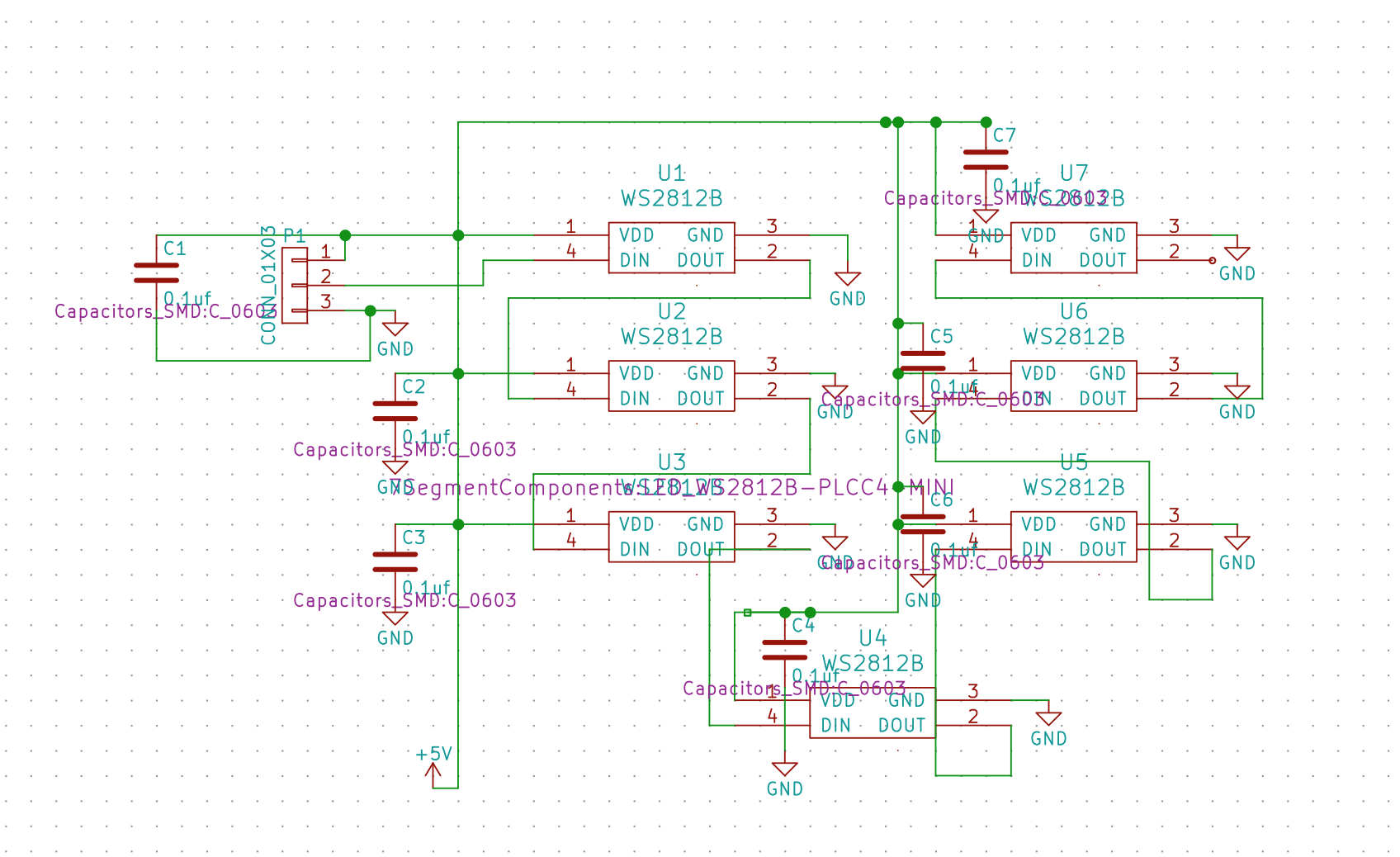

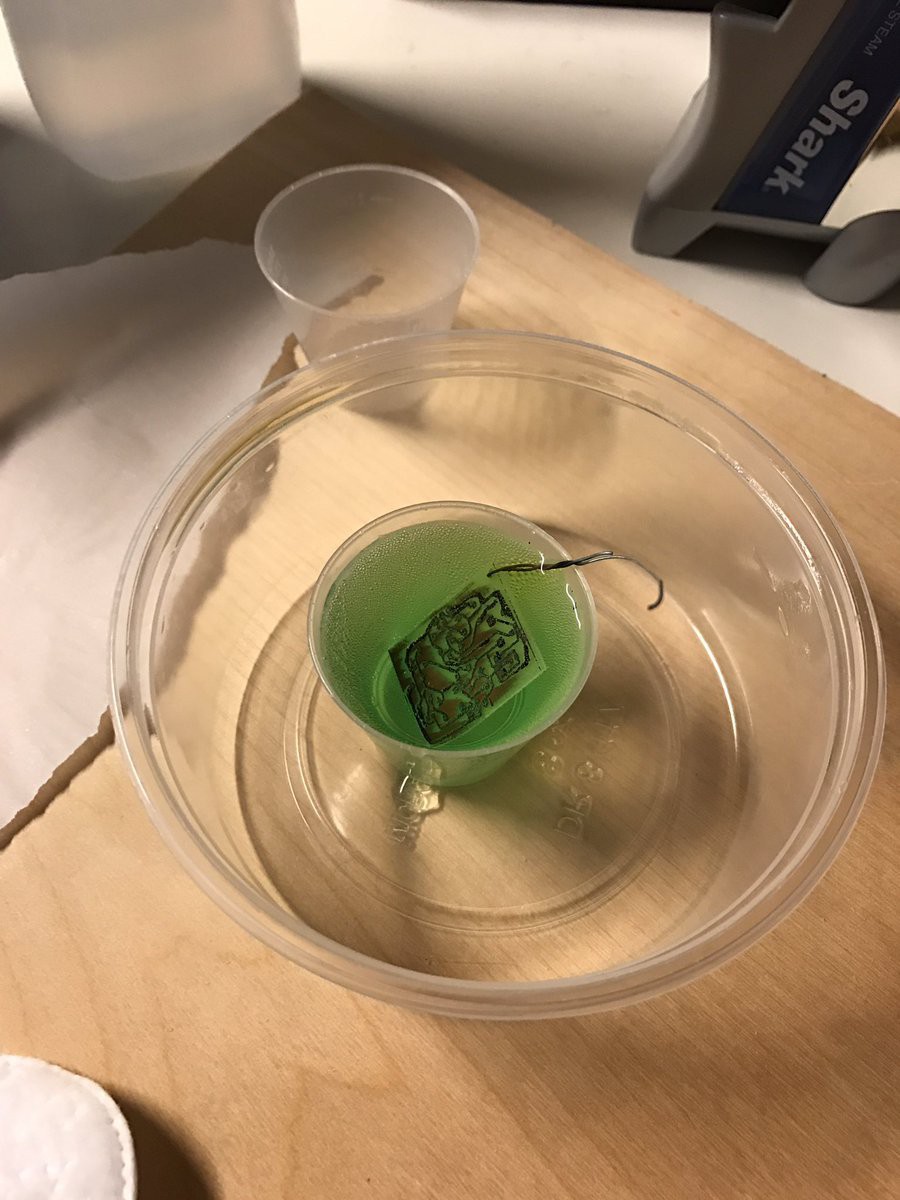

- Create schematics and PCB for individual display

- Create Arduino Library to drive some number of 7 segment displays

Here's the latest update for this project:

Maksim Surguy

Maksim Surguy

SUF

SUF

Stephen Holdaway

Stephen Holdaway

Ken Yap

Ken Yap

Hey, nice work! Have you seen my library? https://github.com/h-c-c/Seven_Segment_Pixel You can pull it in through the library manager in the Arduino IDE.