It's been an incredibly slow process, on account of the atmega328 tools & the complex 3 board design.

It seems no-one either uses arduinoISP outside a classroom & no-one hacks their arduinoISP to use a higher baud rate, since setting the baud rate to 115200 has been part of the failures. The arduino library might be too slow to handle anything over prehistoric baud rates.

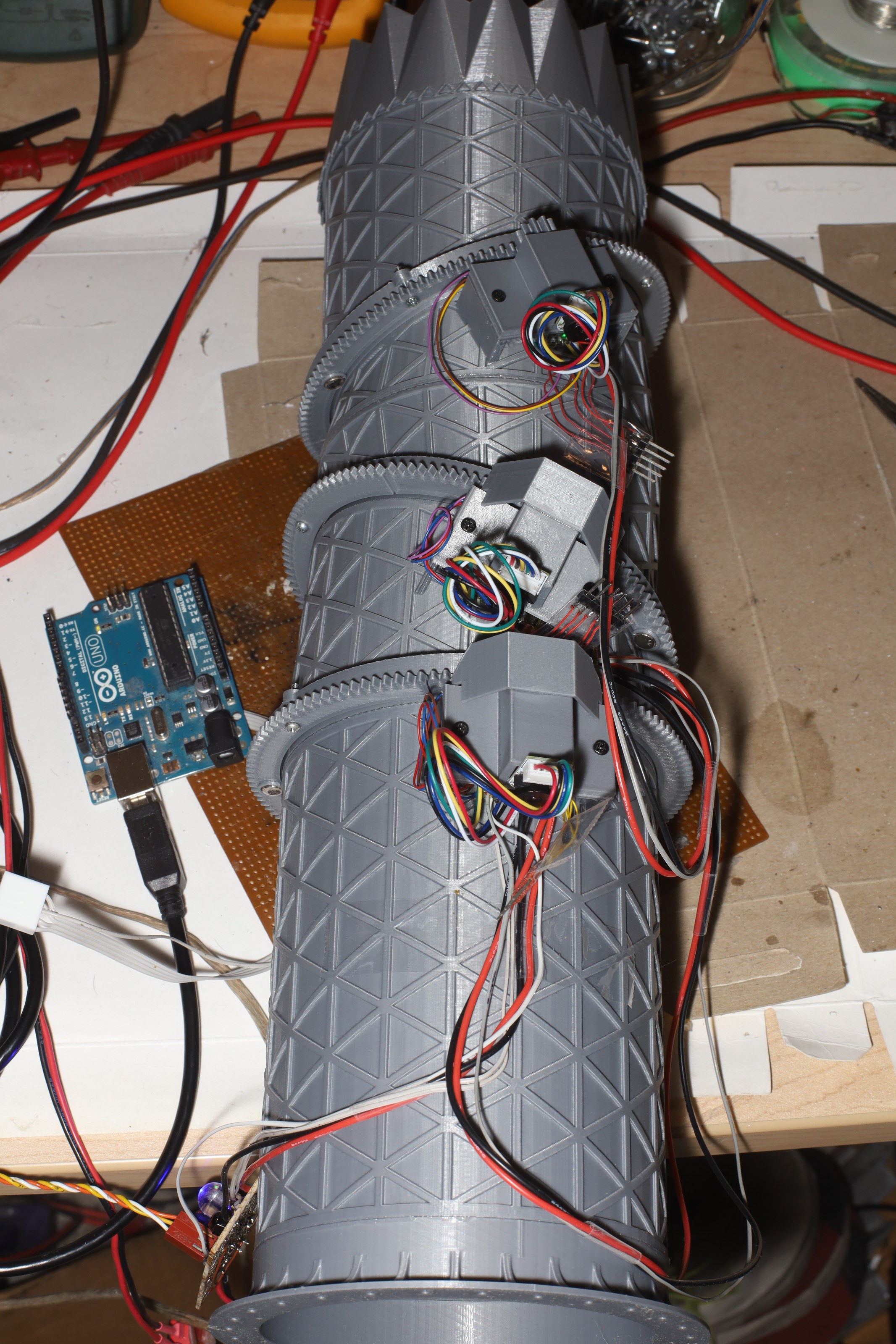

The boundary magnets had to be rearranged again into alternating sides of the motors.

In going from straight to a right angle, the exit tube goes clockwise. The middle tube goes counterclockwise. To reset without manual intervention, the magnets have to be positioned so the middle tube goes clockwise to hit the boundary & the exit tube goes counterclockwise to hit the boundary.

Then since these motors are much slower, there have to be different rules governing motion when a button is tapped & when a button is repeating. When roll is repeating, it needs to keep the roll motor on instead of waiting for the next repeat event. When pitch is repeating, it needs to wait for tracking to finish & set new target positions from the table without waiting for the next repeat event. It also has to make sure the next pitch step doesn't make any motors back up because the encoders lag the motor movement.

This results in some crosstalk when adjusting roll. The pitch motors sometimes backtrack when adjusting roll because they overshot. The 1:298 motors overshoot a lot because they're being moved in smaller steps. The number of pitch steps was increased from 24 to 64. Despite the overshoot, they're getting just enough precision. Anything below 1:298 probably wouldn't have been precise enough, despite the slowness.

During pitch movement when all 3 motors are firing, current goes to 500mA. Quiescent current is 100mA. There's no easy way to measure the starting current.

Noted in the video that the step size varies from virtually no movement when it's near the endpoints to very large movements when it's 45 deg, hence why the lion is stepping it back & forth. Instead of a higher number of steps, it probably needs a nonlinear step size. It still needs the 1:298 gear ratio & encoders.

The 1mm of play in the bearings causes the hall effect sensors to give wildly varying boundary signals. The motor mounts might need a tweek along with the cable shrouds. The cables snare more often because they're silicone instead of ribbon & the new cable shrouds are junk overall.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.