Noted with the sigmoid table that the nozzle zigzags a lot when taking the large steps, but what really matters is getting the maximum precision in pitch, not whether some steps are too small or whether it zigzags when moving.

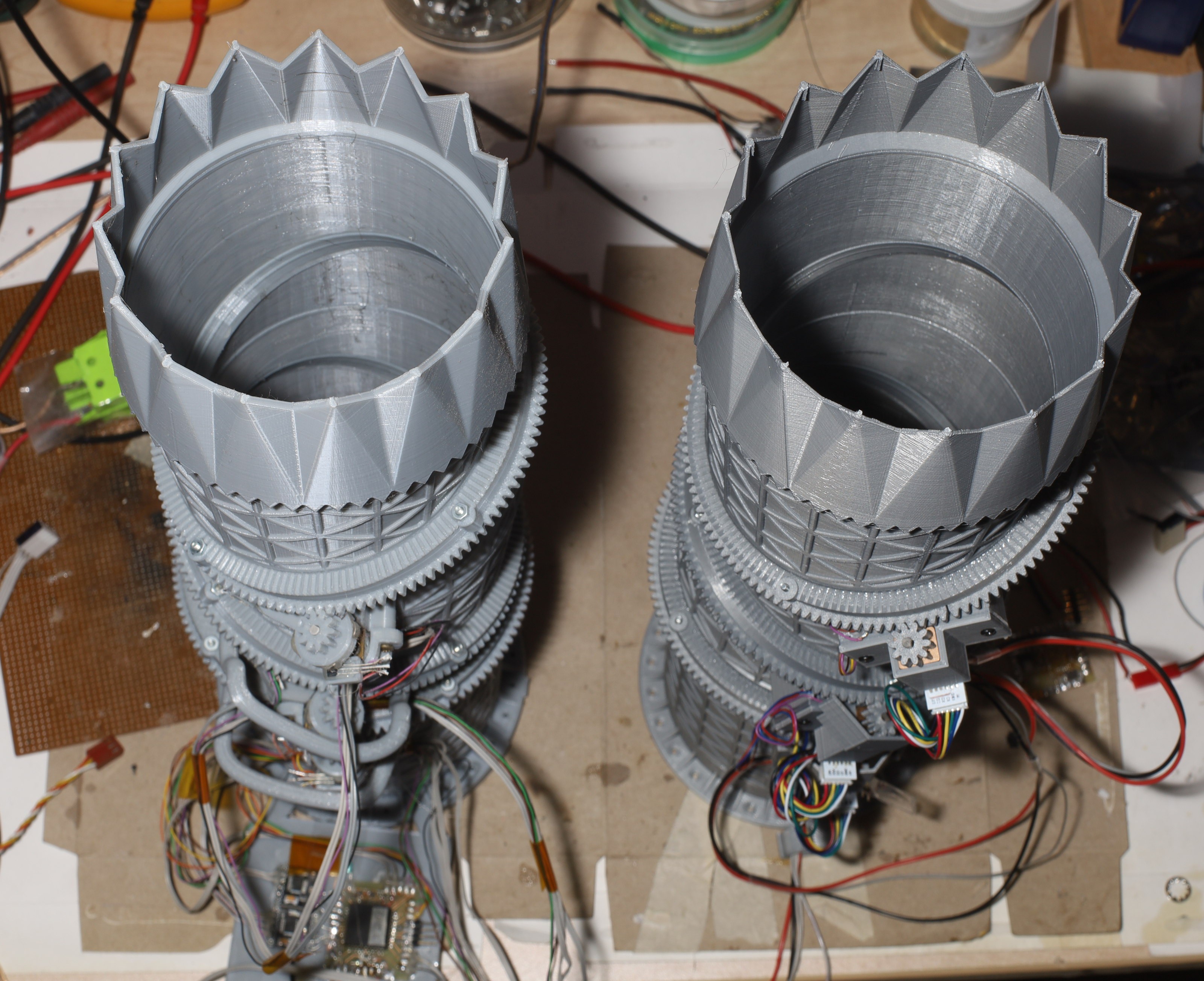

The decision was made to desolder the programming headers from the 2 pitch motors & install it on the blower. The pitch firmware never had any problems so it won't be receiving a bootloader. 1 final check of the boundary sensors showed a lot more sensor margin with the 2 pitch motors than the yaw motor & the yaw sensor is only used in the position where it gives the strongest signal so that covered any new motor mounts.

Of course, the brain board's programming header breaks all the time. There's kind of a need for either a bootloader or a more robust programming header.

The mane bugs are simultaneous homing of the motors fails when it's horizontal. Boundary sensor 1 glitches when all 3 motors are going, maybe because of the current draw. The homing has to be 1 motor at a time. The glitch is a single analog report in the 140's or the 90's.

The 1st preset after homing goes to a fully deflected pitch before going back to straight & then going to the requested preset. The later presets work.

The segments aren't aligned when pitch is fully deflected. It might need new values for ENCODER_MAX.

Communication needs to be hardened so when it gets a packet intended for another board it waits for the entire packet to finish before waiting for a start code.

These were rare enough use cases to be ignored.

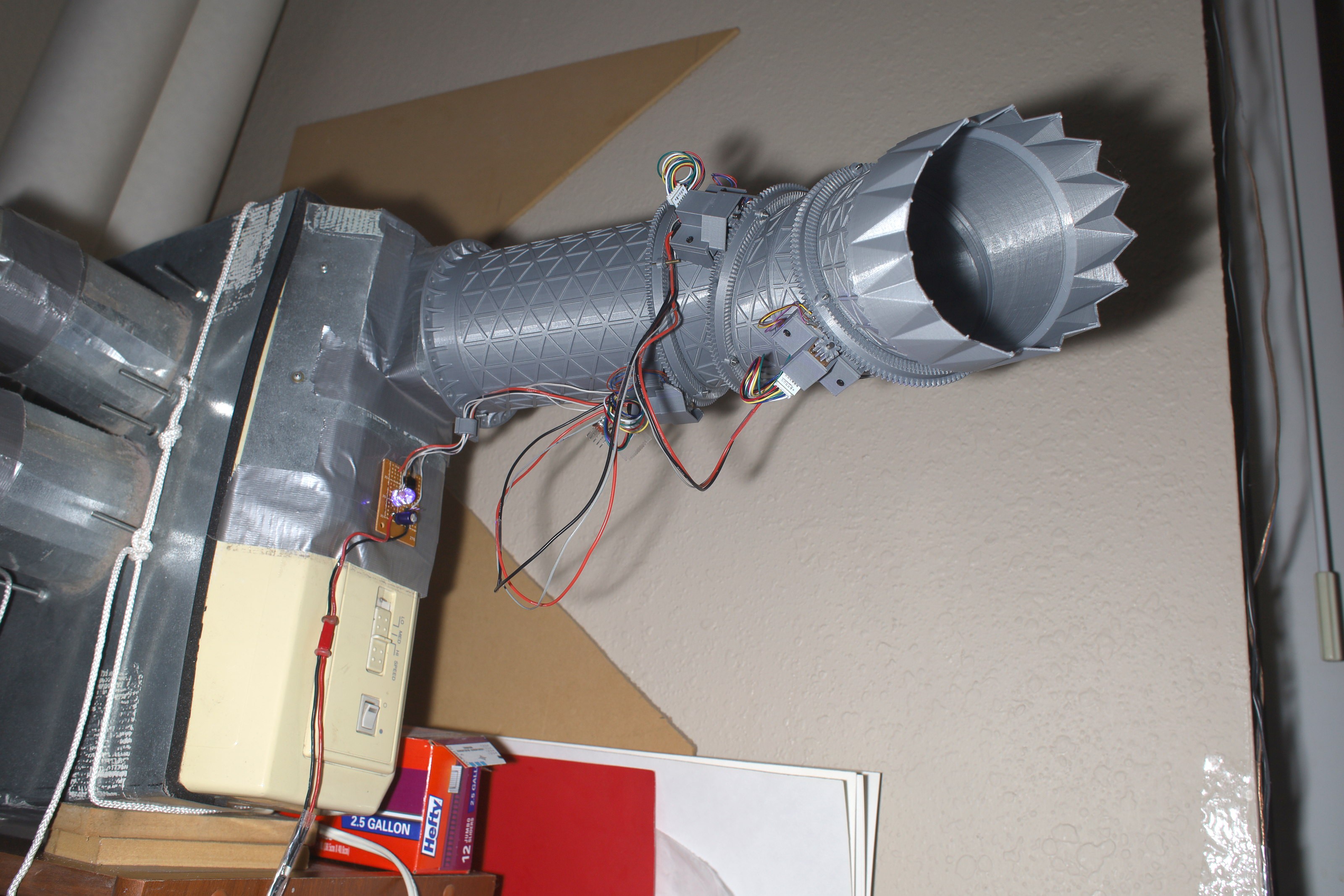

A final view of nozzle 1 before it's sent to landfill.

Horizontal mount was resurrected for testing. Any condition not tested on the bench is a failure mode.

Final installation.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.