So I managed to finish sorting through all my stuff and packing it away into boxes of related items. That allowed me to get my car back into the garage, although it does not leave me with lots of space to work. Still it is good to have things cleaned back up and now I can get my hands on anything with much less effort.

I have been thinking about my new workshop carts for a while now, but I'm fairly overwhelmed by the process. I have not made anything this complex before and with the price of sheet goods I really only want to do this once and get it right the first time.

To help things along I purchased plans from alch.shop for there miter saw stand, assortment cabinet, and assortment box with inserts. There carts are similar but not identical to what I want to build and I thought I could get some good ideas from there plans. The dimensions are surprisingly close, that gives me some confidence that I'm not heading off the rails.

One thing I really like that he came up with are these small 3D printed storage boxes that are roughly 2"x2" wide and 3" tall. They have boxes that are multiples of that base dimension that can be used to store larger items. And being even multiples makes it easy to pack may different sized boxes together. I have not tried to print any of there boxes out yet, but my hope is to incorporate something like that into my design.

I have 10 of these large fishing tackle boxes that I have picked up over the years. They are 14"x9"x2" and they work out great for holding smaller items. However I have always just stored them on a shelf in stacks and that makes then fussy to work with since your always needing the box at the bottom of the last stack.

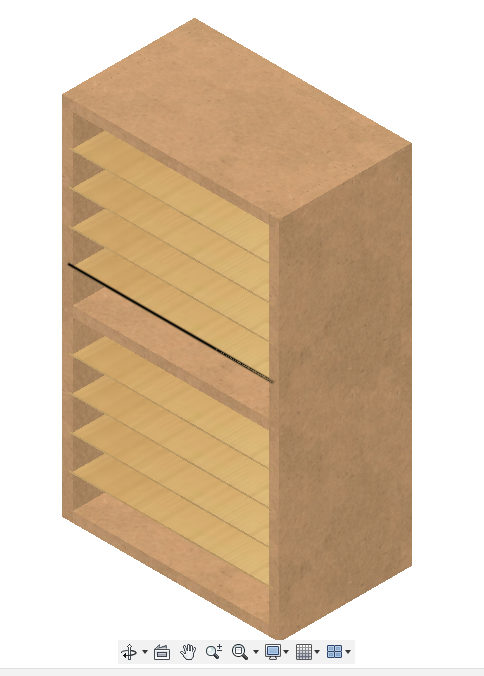

So as a first step I decided to make a small wall cabinet that can store these organizers so I can reach each of them in one move rather than unstacking them. This will use roughly 1/4 of a sheet of 3/4" MDF and 1/4 of a sheet of 1/8" plywood. That is relatively risk free, I will have lots of material left to cut from if I make a mistake.

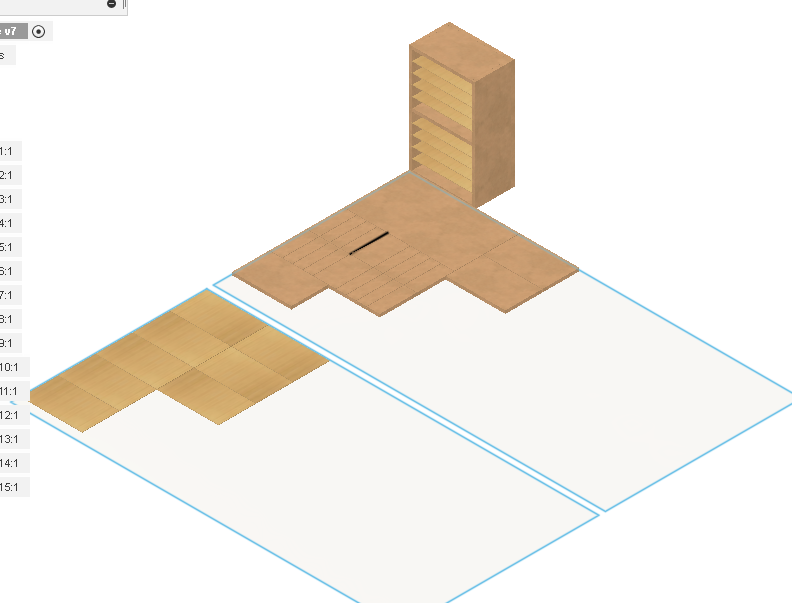

To help things along I have ordered a WEN biscuit joiner and a box of #20 biscuits. While I wait for that to come in I'm trying to refine my design. Part of my process was working out how to best layout the parts on a 4x8 sheet of material. I experimented with doing the layout myself in fusion but that is frustrating and it really feels like there must be a better way. I came across the Map Boards Pro plugin and it seems to do a reasonable job of pulling your model apart and doing a layout. I don't think it is optimal, but it gives you a good starting point with a single click of a button.

I have a problem, the largest vehicle I have could fit a 2'x8' sheet in it, and possibly a 4'x4' sheet but there is no way to fit a 4'x8' sheet in the vehicle. After playing around with map board pro it became fairly obvious that cutting the sheets down at the store is going to make it difficult to optimally use the material without a lot of hard work. So I need to come up with a way to bring full sheets home from the store.

I looked into delivery but that adds $70 or more to the price, that only makes sense if I'm buying 10 or more sheets at a time. I could try to rent a trailer, however that is $30 or more and unlikely to work out better than the delivery. My vehicle has mounting holes for a roof rack but no rack. I could pick up a rack, but I don't have any other use for it. So I decided to go ahead and build my own temporary rack out of 2x3's and a 3D printed spacer. The whole bunch will be bolted down to the roof and should comfortably support a sheet or two of wood, allowing me to pick up small runs of material. The best part is it can all be broken back down into its original parts and stored on my wood rack when not in use.

I spent most of yesterday working out the spacer bracket and it seems to work well. I will run a 100 mm M8 bolt through the wood, through the spacer and into the roof of the vehicle. That arrangement should be quite secure, even if the spacer failed it would not come loose from the vehicle (but may mar the roof, so we don't want that). It will take a few days to finish printing these out, so again were waiting.

David Tucker

David Tucker

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.