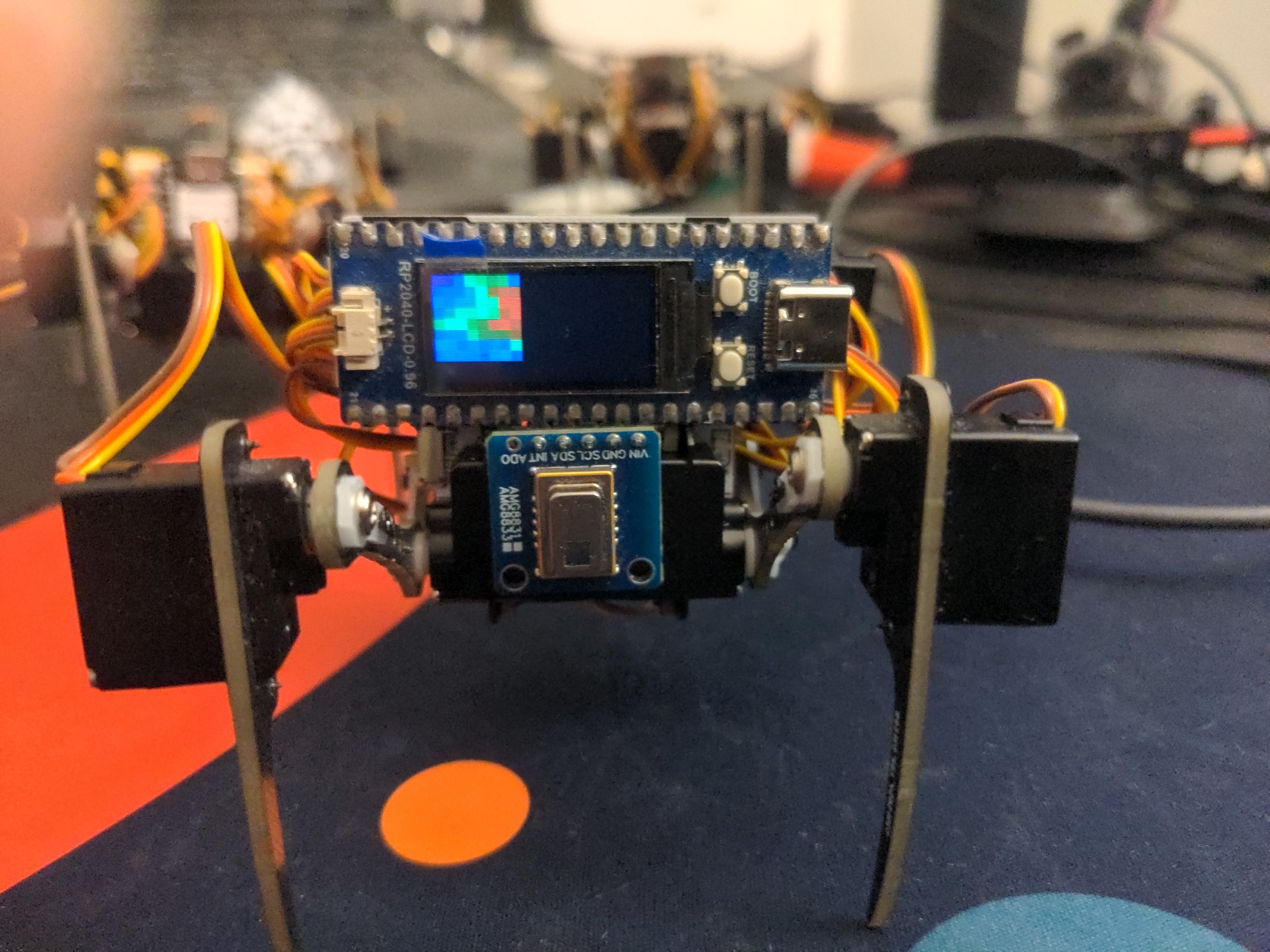

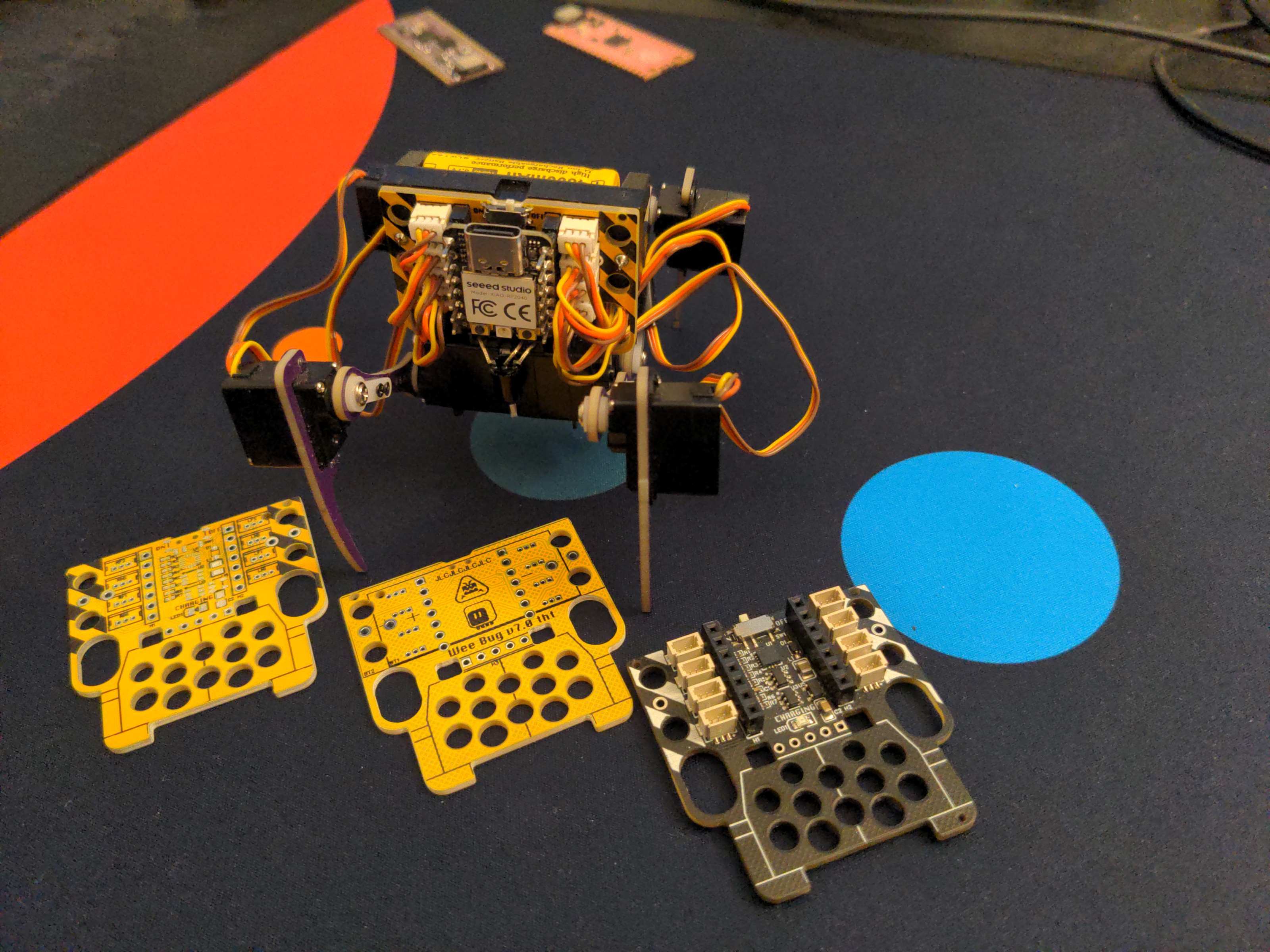

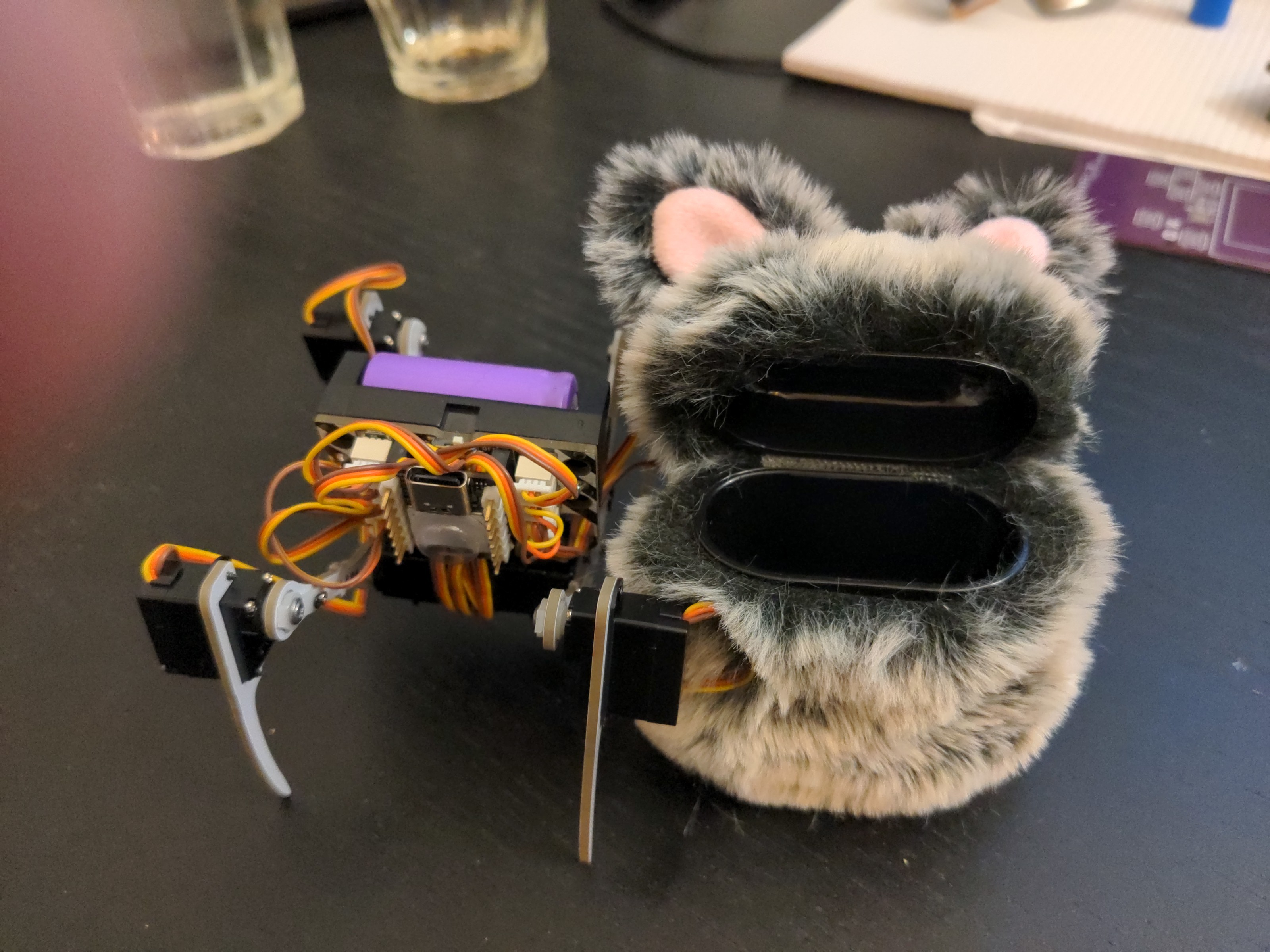

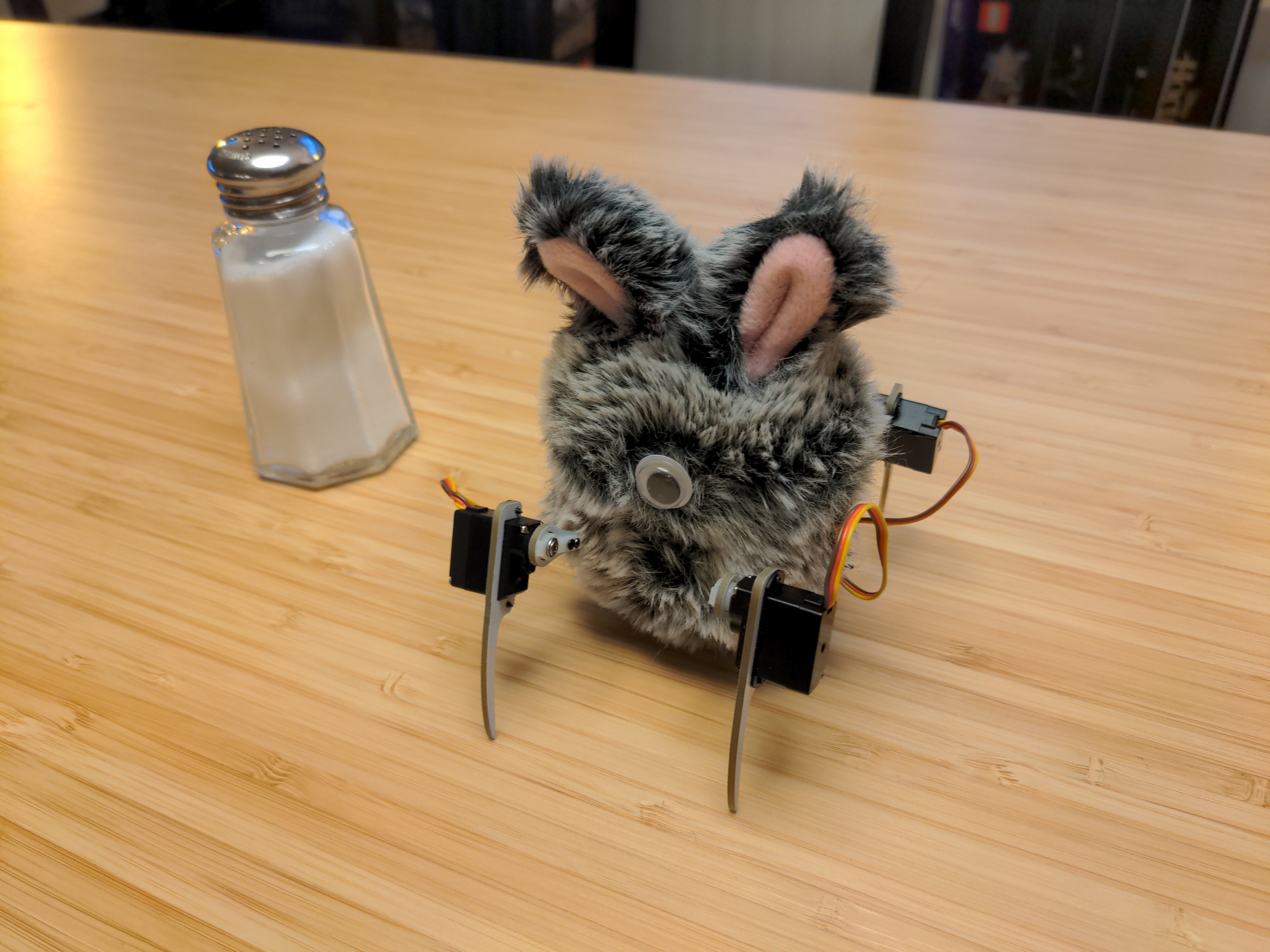

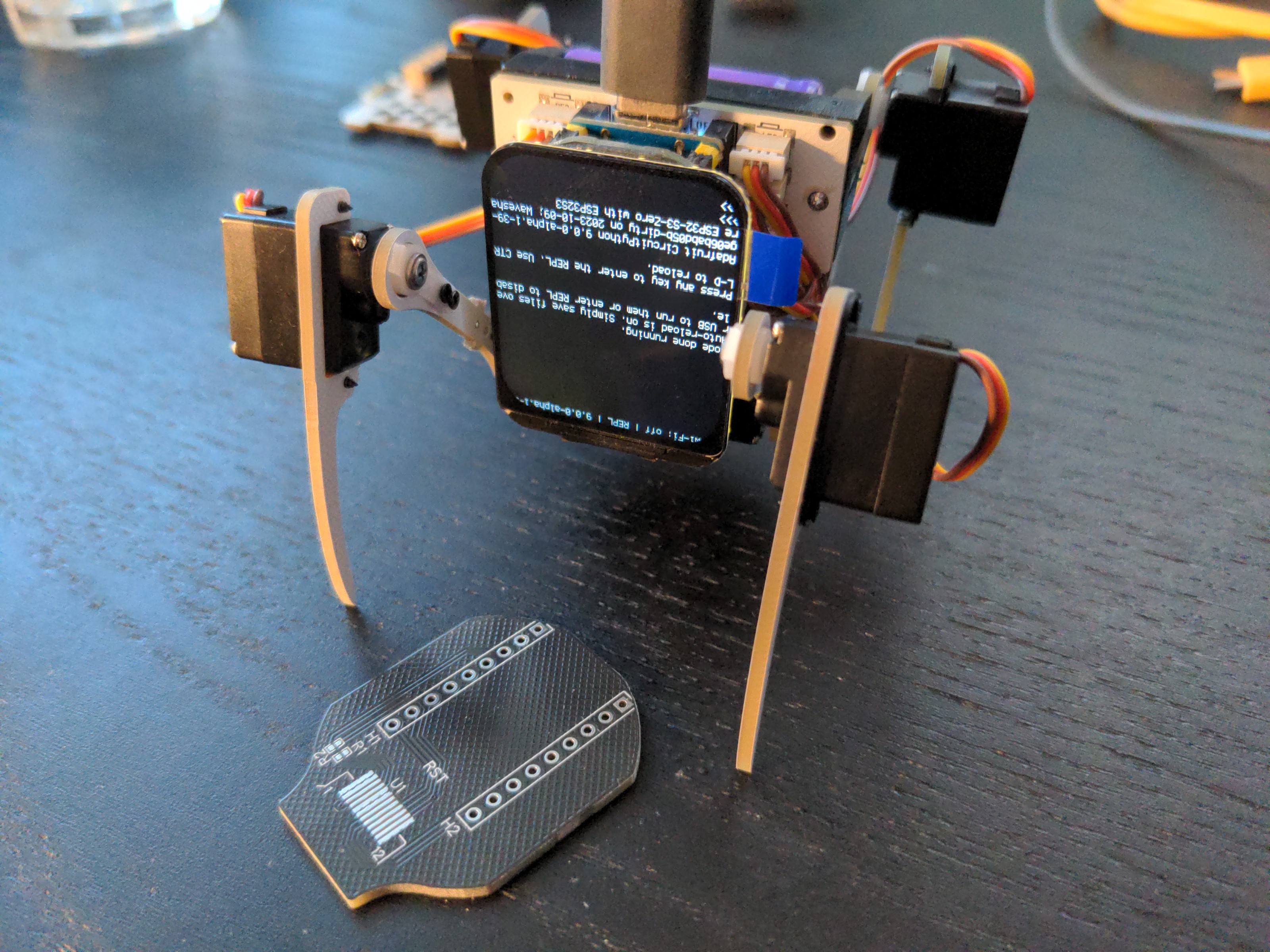

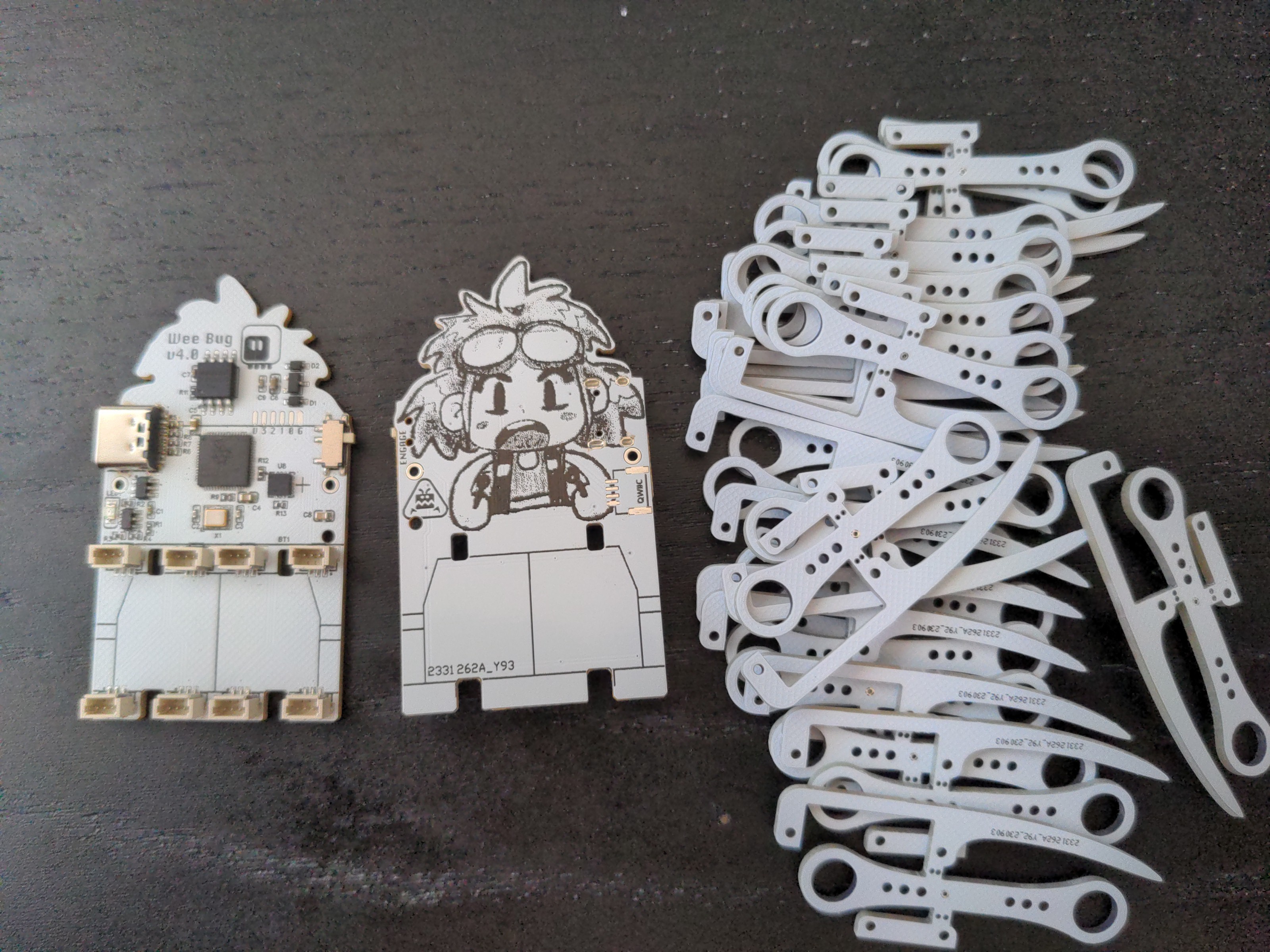

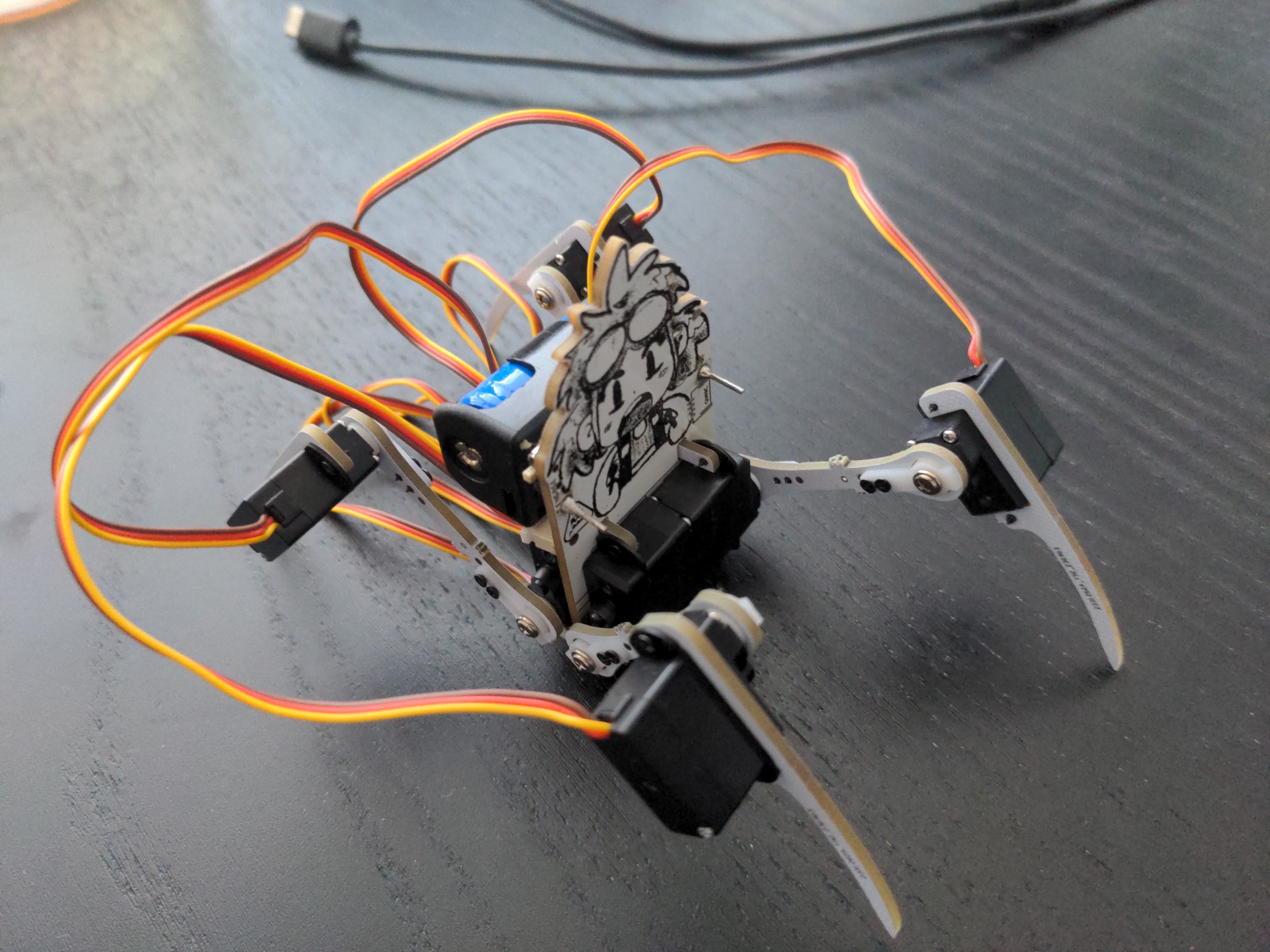

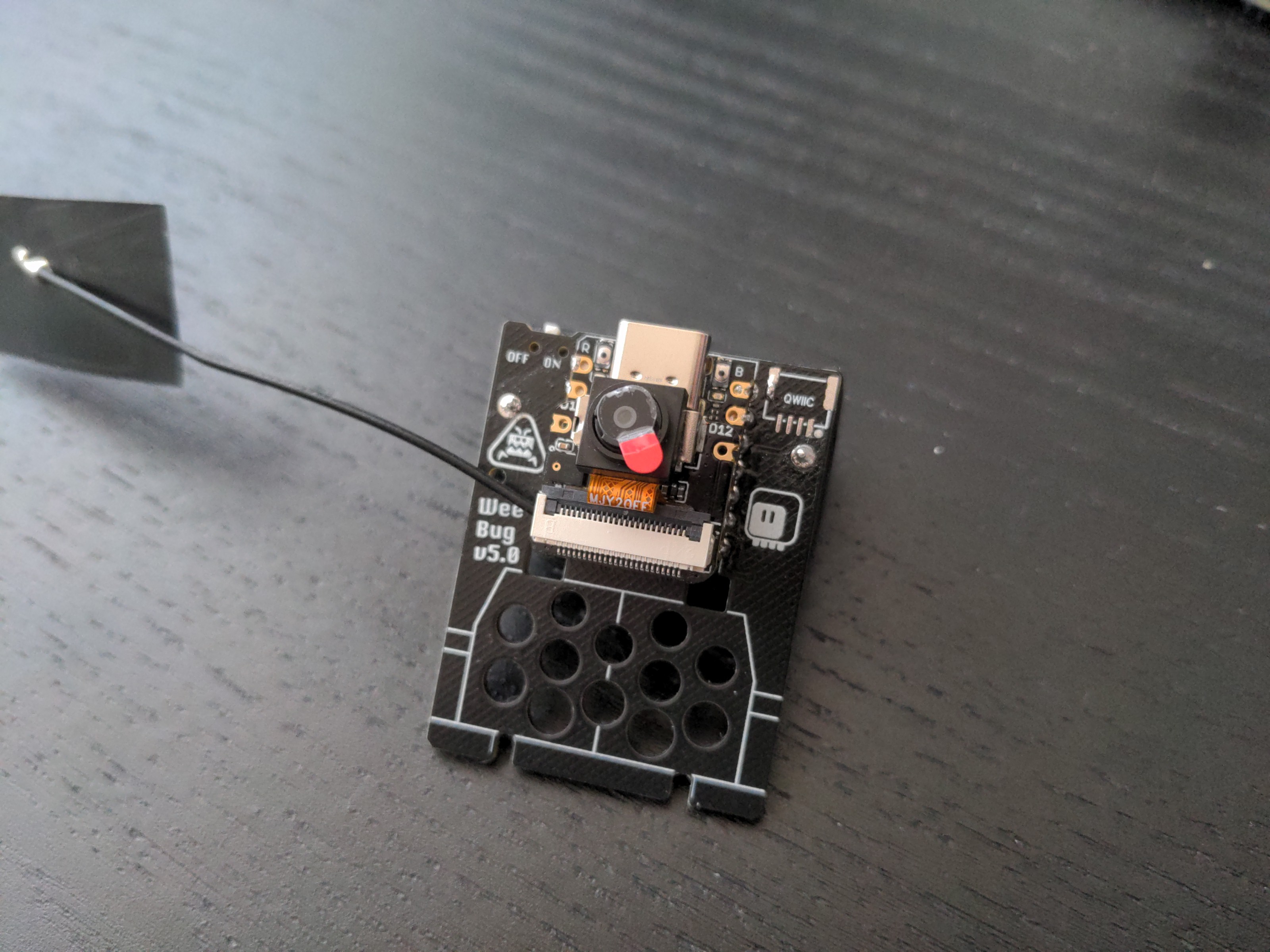

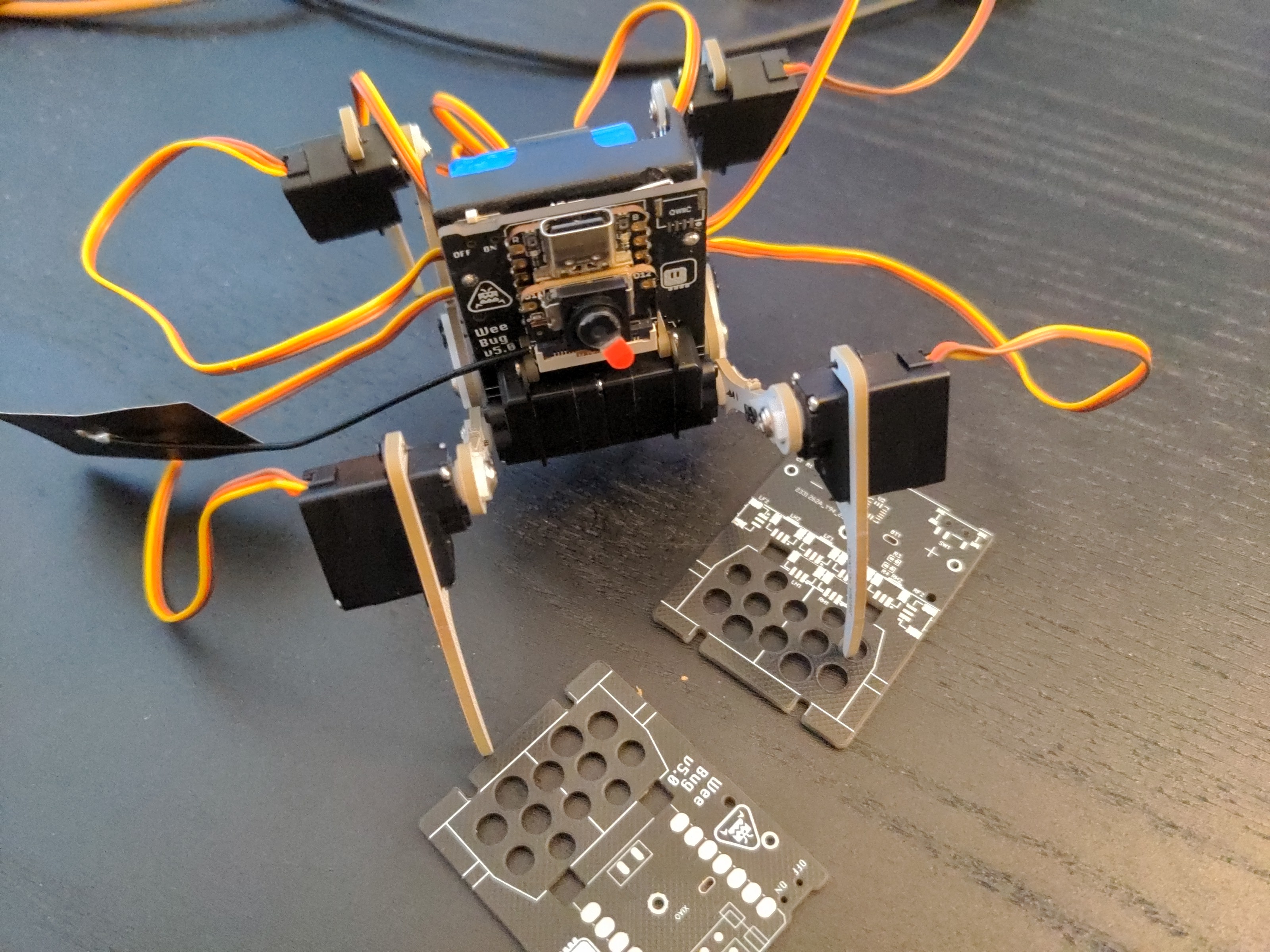

While digging through my drawers, I stumbled upon a bag of sub-micro servos I bought a few years ago from HobbyKing for the #Pony Bot, but never used in the end, because they had wrong connectors. Turns out there are HK-282A servos with 1.25mm-pitch JST connectors and HK-282AS, with 1mm-pitch unidentified connectors. In any case, the Pony Bot is on hold indefinitely for now, until I can find the energy to actually program a gait for it, so I thought that maybe I can use those tiny servos for something else: make a tiny version of the #Fluffbug robot. That would also have the advantage of not needing to write a new gait code, since the one already written for Fluffbug should work.

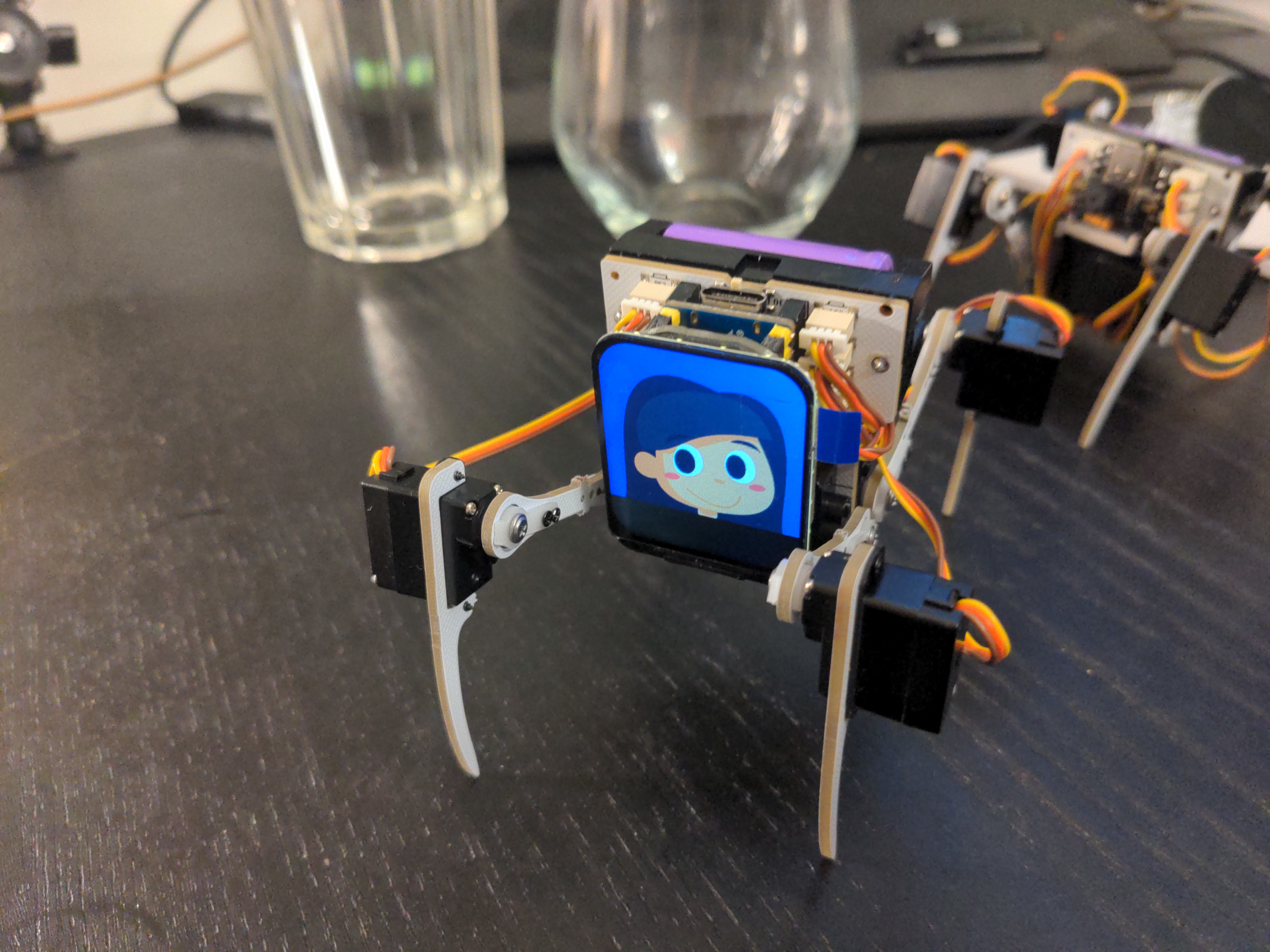

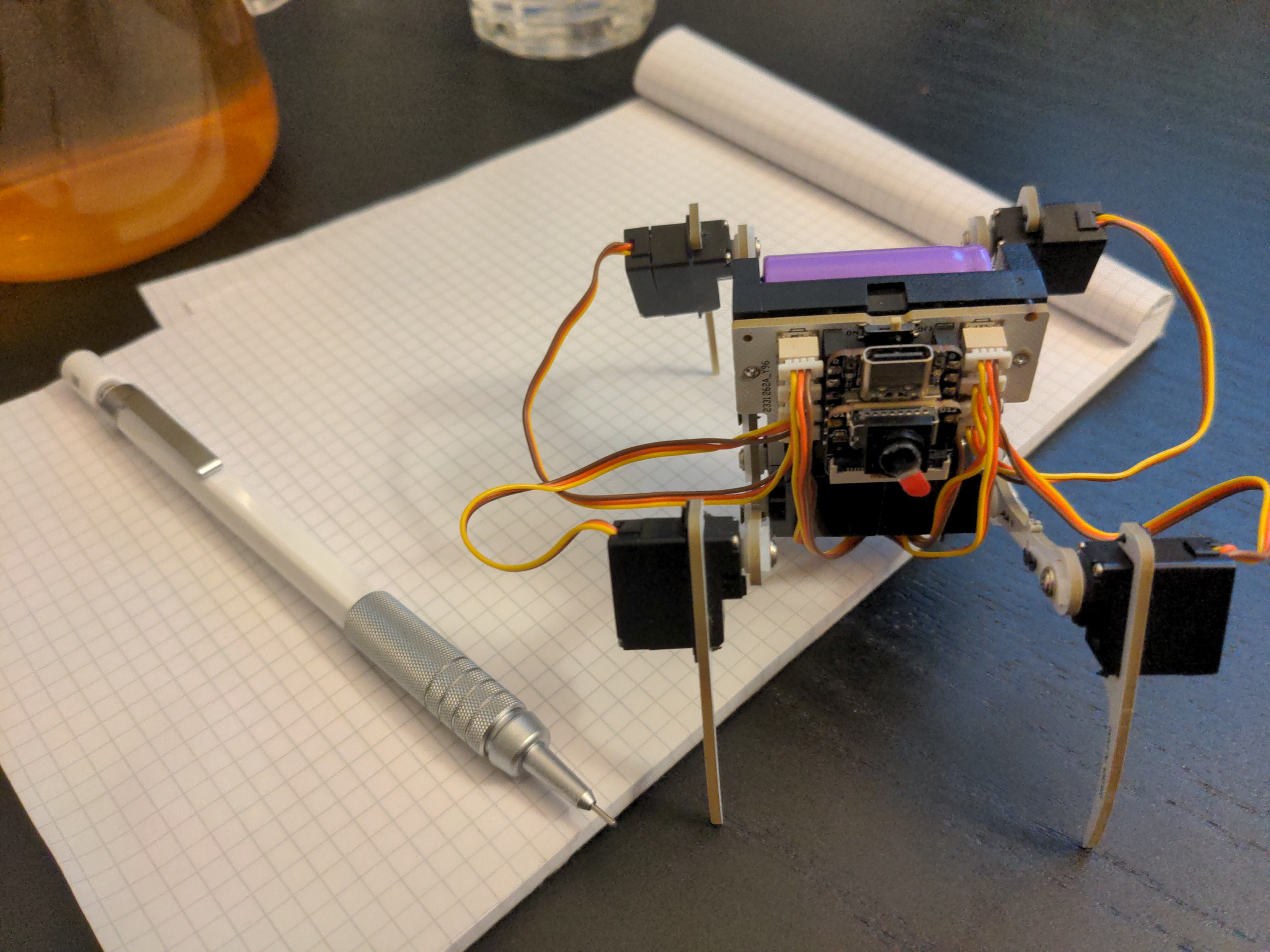

So I went ahead and started to design a Fluffbug, but with everything smaller.

deʃhipu

deʃhipu