Features:

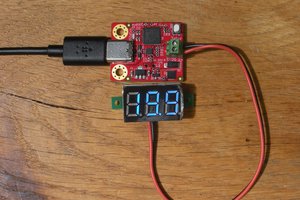

- very compact - will fit into handle

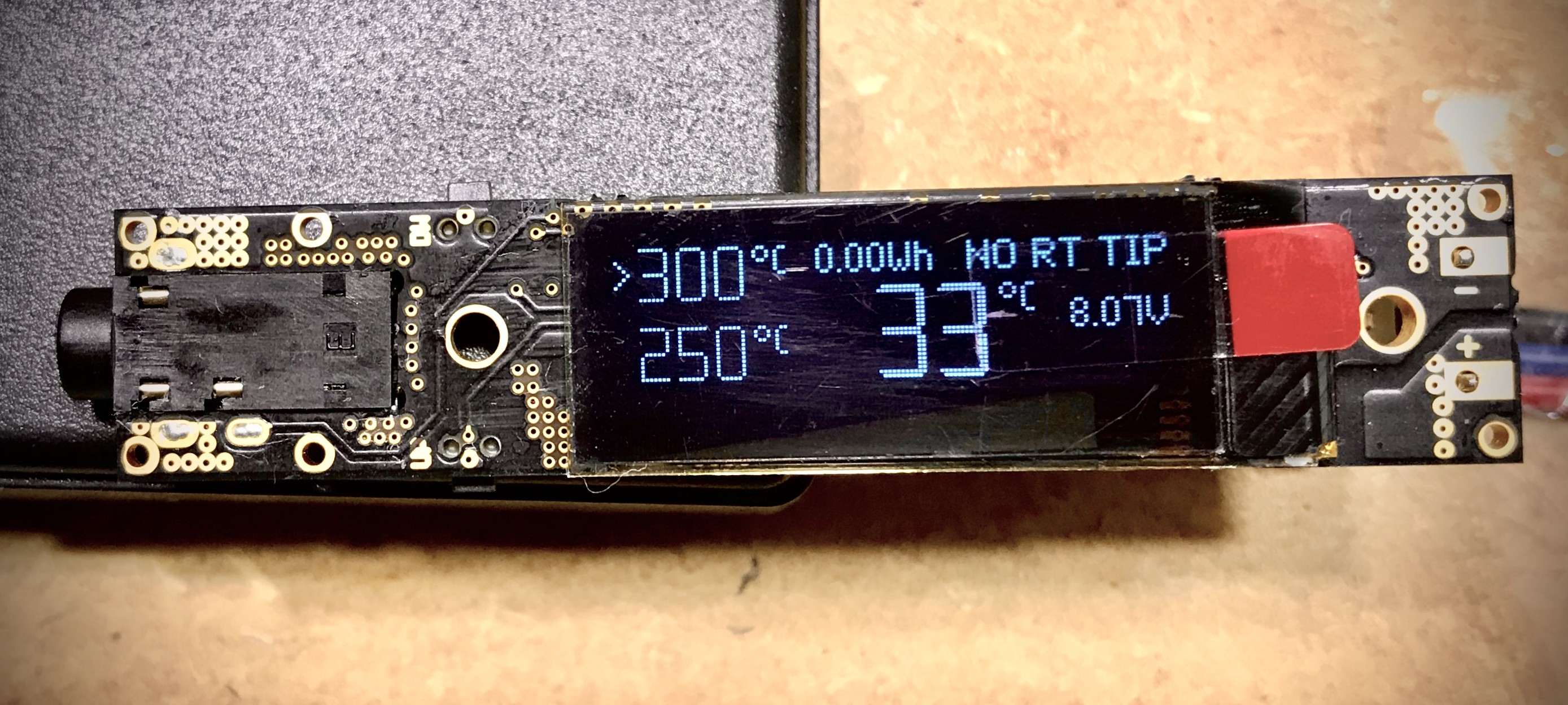

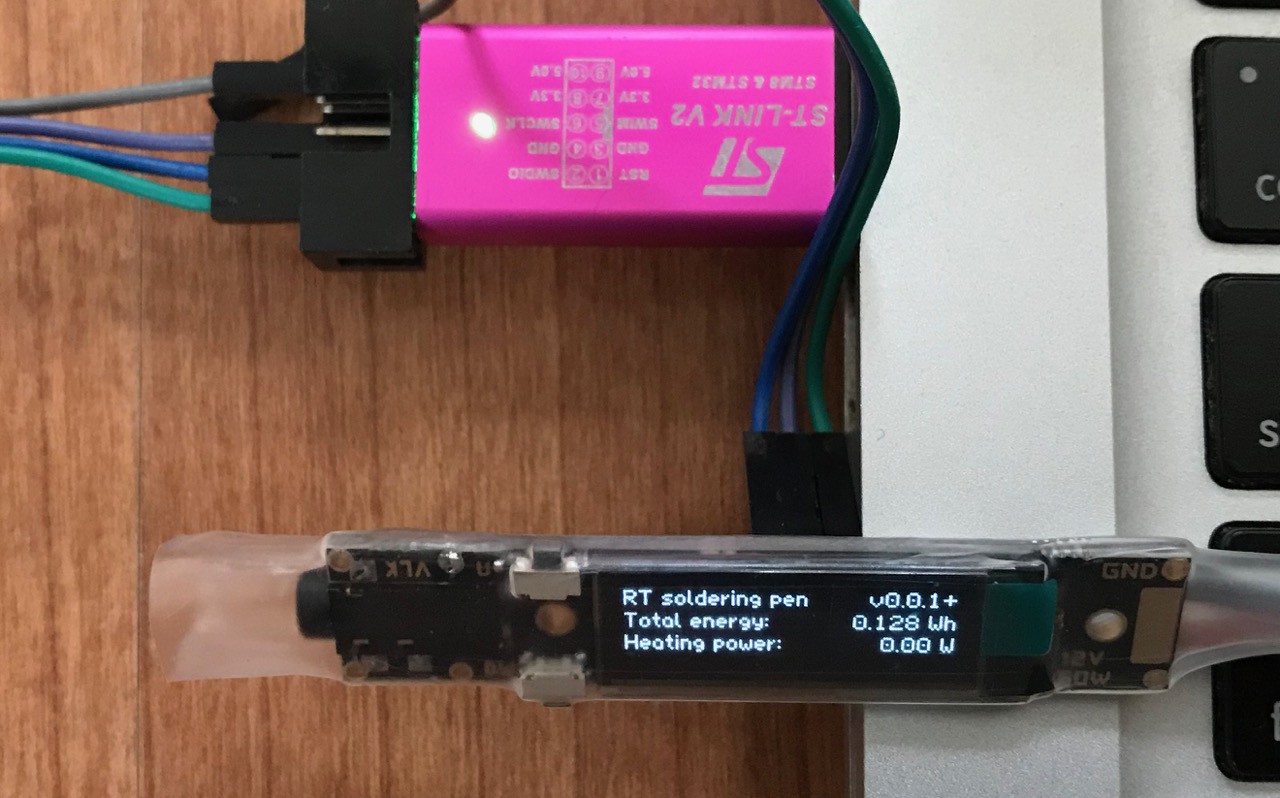

- display show status, preset and tip temperature, power, supply voltage, drop, ...

- two buttons

- automatic standby

- sensing supply voltage and tip current

- precise regulation with PID (PSD controller with some modifications)

- supply voltage is from 5V to 18V (best is 10-13V)

- designed to supply from LIPO battery 2S (7.4V max is about 18W) or 3S (11.1V max is more than 40W)

- calculating consumed Wh

- heat-up in 5sec from 25 to 400°C (with 40W limit)

- Idle current about 8mA

What is planed:

- case

- battery monitor (warn when battery need charge)

- configuration editor for some constants from PSD controller, power limit, ....

- open-source everything

Videos:

vlk

vlk

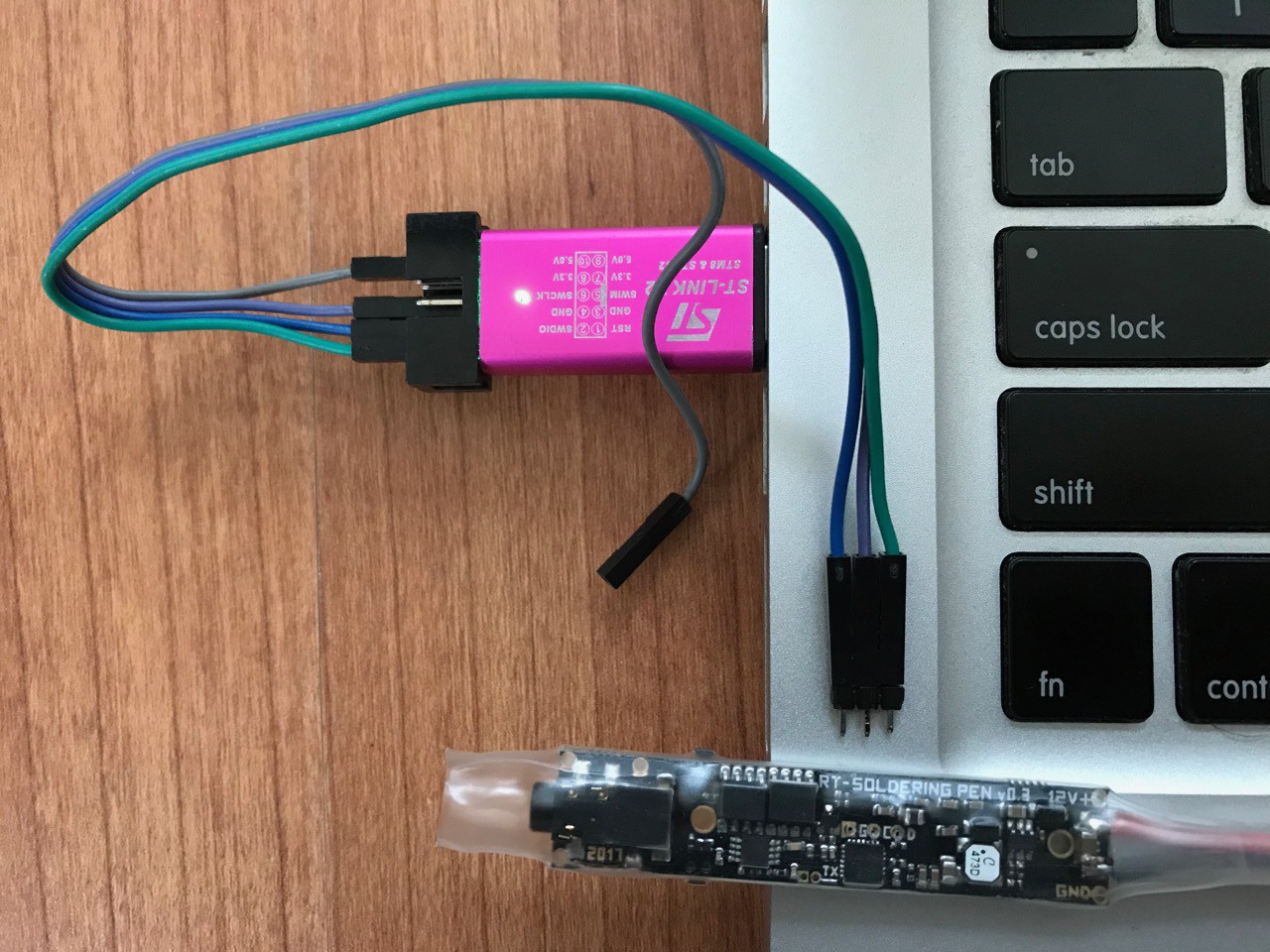

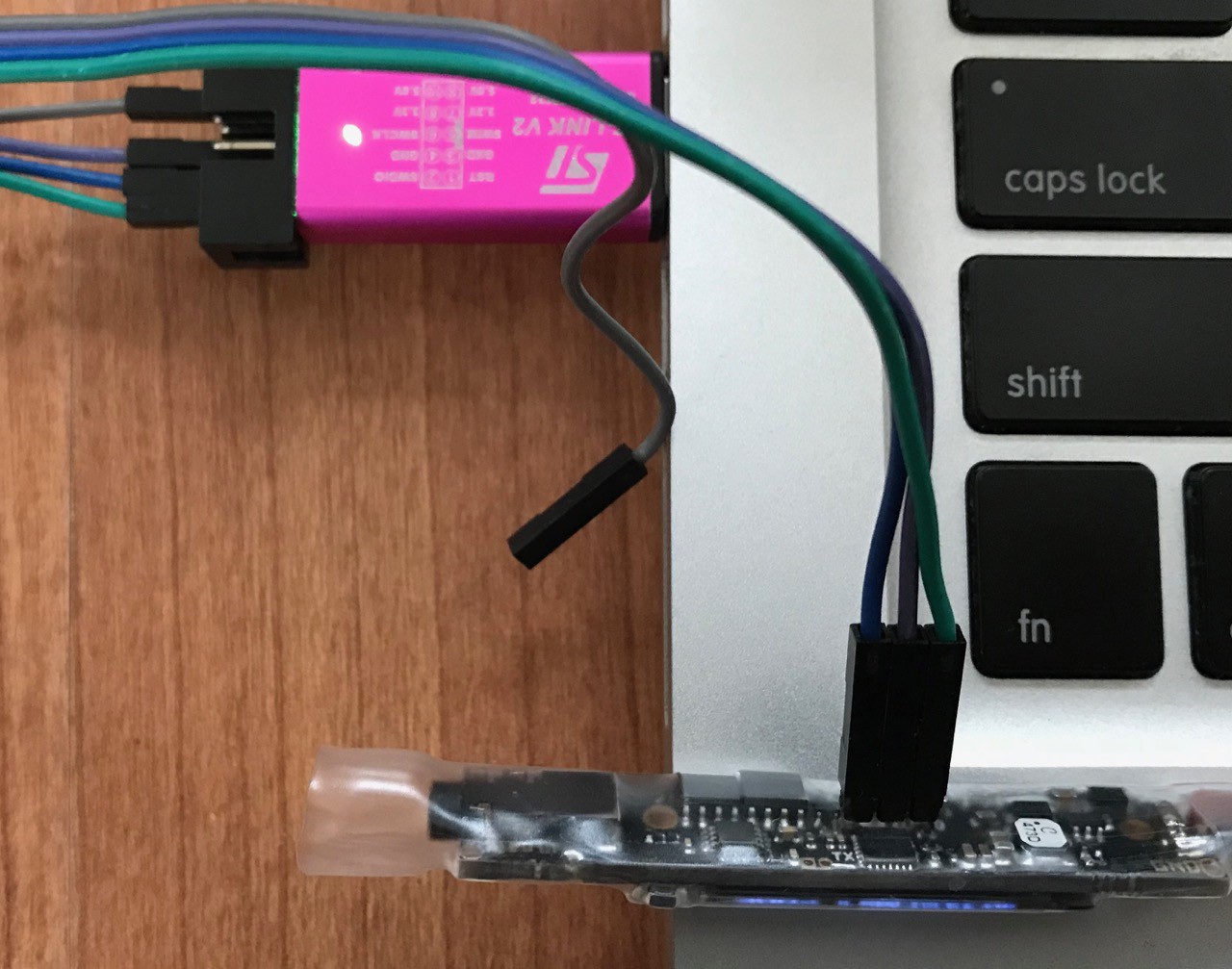

To program, use ST-Link utility from ST, or any other SW for Flashing STM32 micro-controllers (openocd, texane/stlink, pystlink, ...)

To program, use ST-Link utility from ST, or any other SW for Flashing STM32 micro-controllers (openocd, texane/stlink, pystlink, ...)

Nathaniel VerLee

Nathaniel VerLee

Clara Hobbs

Clara Hobbs

Denis

Denis

Markus Loeffler

Markus Loeffler

Does anybody know if something happened to VLK? It's like he is disappeared..